In the modern food packaging industry, there has been a growing demand for sustainable and environmentally friendly materials. Transparent PLA (polylactic acid) film has emerged as a remarkable solution, especially in the production of thermoformed lunch boxes, food plates, and cold - drink cups. This article will explore the various aspects of using transparent PLA film in these applications, including its material properties, the thermoforming process, advantages, and its impact on food packaging and the environment.

PLA is a biodegradable and bio - based polymer made from renewable resources such as corn starch or sugarcane. The chemical structure of PLA consists of repeating units of lactic acid monomers. These monomers can be polymerized through different processes to form either amorphous or semi - crystalline PLA. The transparency of the film is related to its molecular structure and the absence of impurities. The ordered arrangement of the polymer chains in the film contributes to its clear appearance, allowing consumers to easily see the contents inside the packaging.

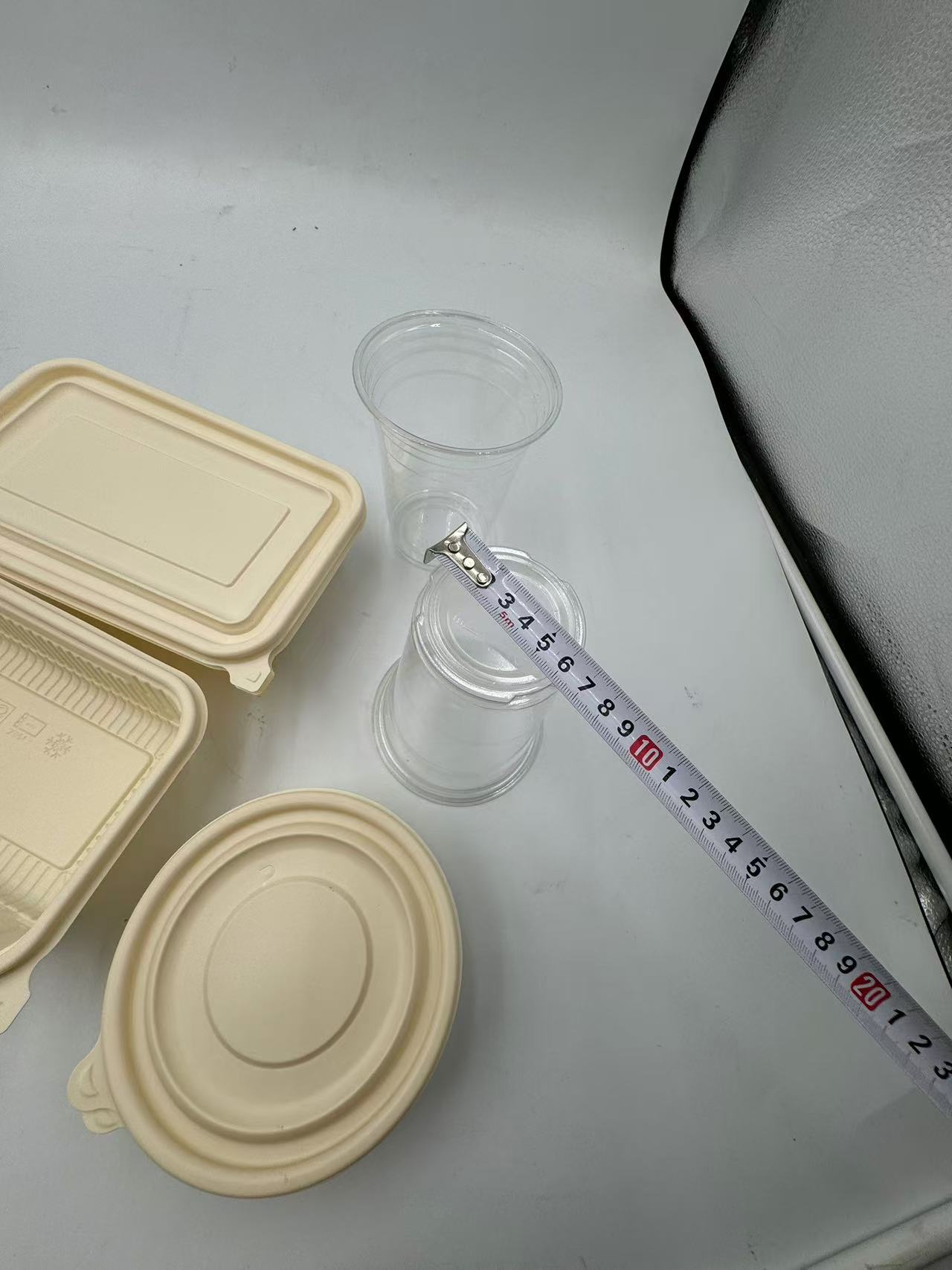

The transparency of PLA film is one of its most appealing features for food packaging. It provides a clear view of the food, which is not only aesthetically pleasing but also allows consumers to assess the quality and appearance of the food. This high - level transparency is comparable to traditional plastic films used in packaging. The clarity of the film remains stable under normal storage conditions, making it an ideal choice for presenting food items attractively.

PLA film has sufficient mechanical strength for use in thermoformed food packaging. It has a certain tensile strength that enables it to withstand the forces during the thermoforming process, such as stretching and shaping. During handling and use, the film can resist puncture and tearing to some extent, protecting the food from external damage. The flexibility of the film also allows it to be easily formed into different shapes, conforming to the requirements of lunch boxes, plates, and cups. However, compared to some petroleum - based plastics, PLA film may have slightly different mechanical properties, and its performance can be optimized through proper processing techniques.

In food packaging, barrier properties are crucial. Transparent PLA film offers a certain level of protection against moisture, gases, and odors. It can help maintain the freshness of the food by reducing the exchange of water vapor and oxygen between the food and the surrounding environment. For example, in the case of a lunch box containing a sandwich, the PLA film can prevent the bread from drying out too quickly. The barrier properties also play a role in preventing the absorption of unwanted odors from the external environment, ensuring that the flavor of the food remains intact.

PLA film has unique thermal properties relevant to thermoforming. It has a relatively low melting point compared to some traditional plastics, which allows it to be easily melted and formed during the thermoforming process. However, this also means that it may have limitations in high - temperature applications. For cold - drink cups, the thermal properties of PLA are well - suited as it can withstand the cold temperatures of beverages without becoming brittle. In the case of hot food packaging, special formulations or additional coatings may be required to improve its heat resistance.

One of the most significant advantages of PLA film is its biodegradability. In the natural environment, PLA can break down into carbon dioxide and water under the action of microorganisms. This property makes it an environmentally friendly alternative to traditional non - biodegradable plastics. When used in food packaging, it reduces the environmental impact of packaging waste, especially in landfills or composting facilities. The biodegradation process of PLA can be influenced by factors such as temperature, humidity, and the presence of specific microorganisms.

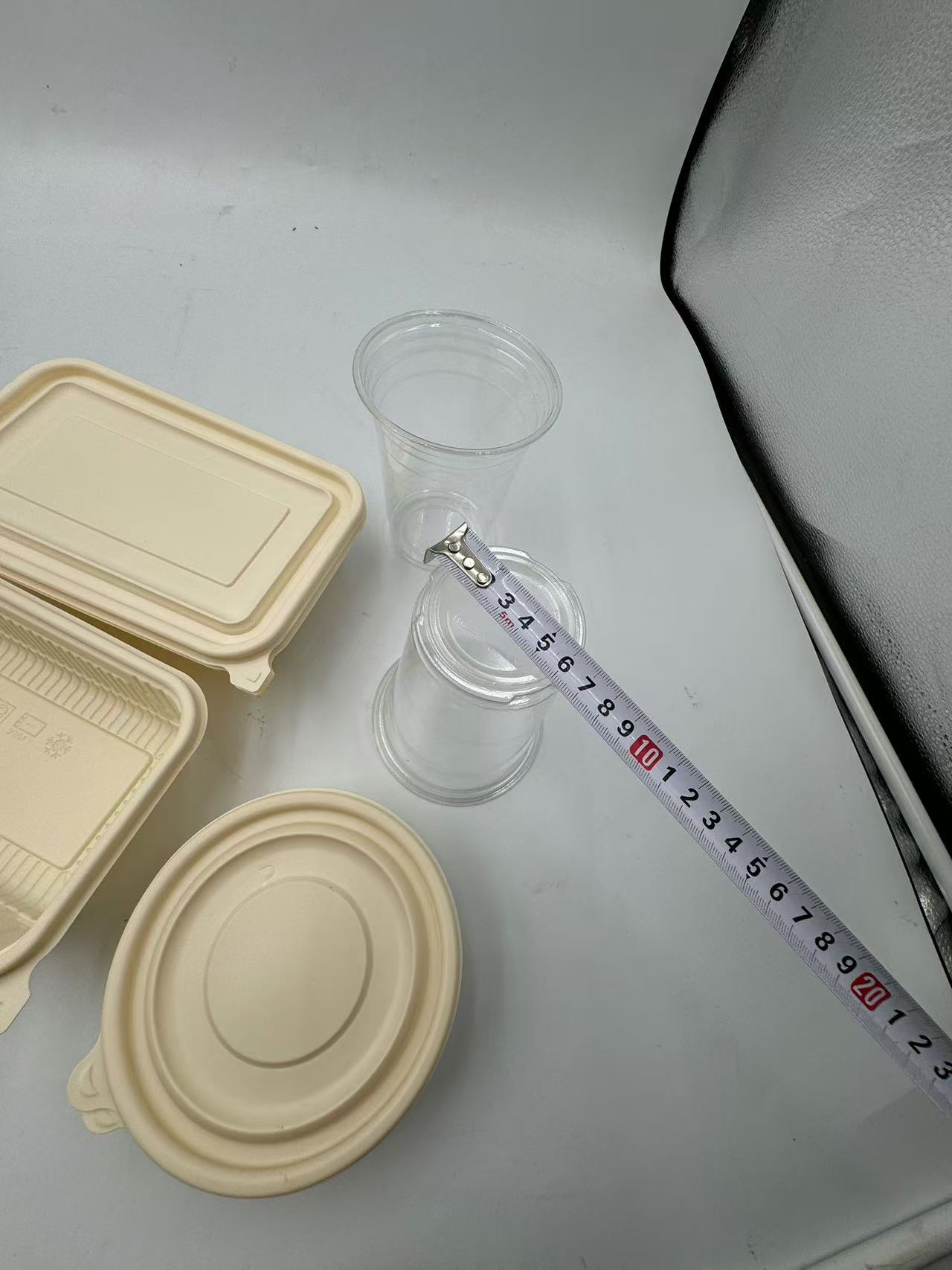

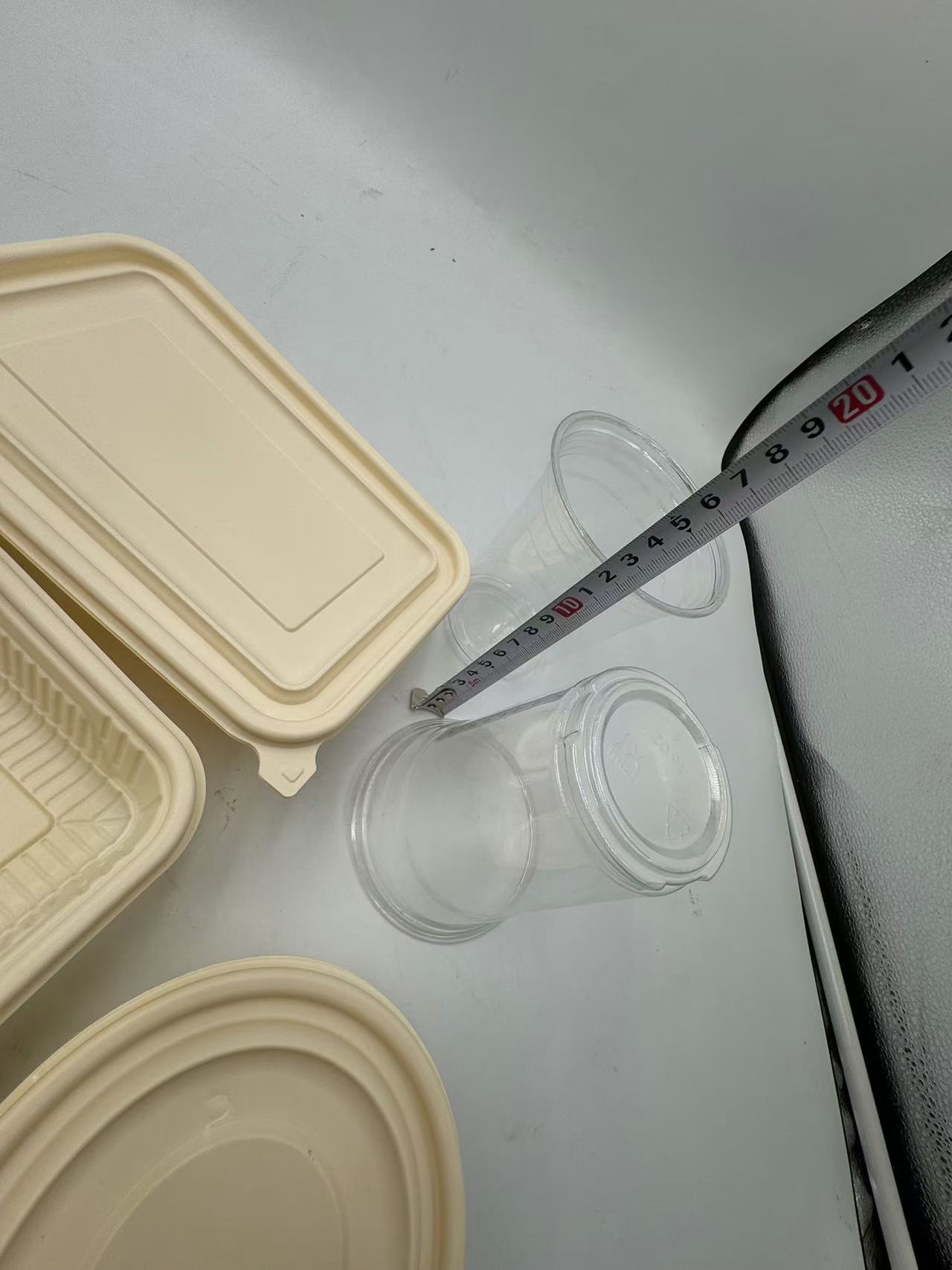

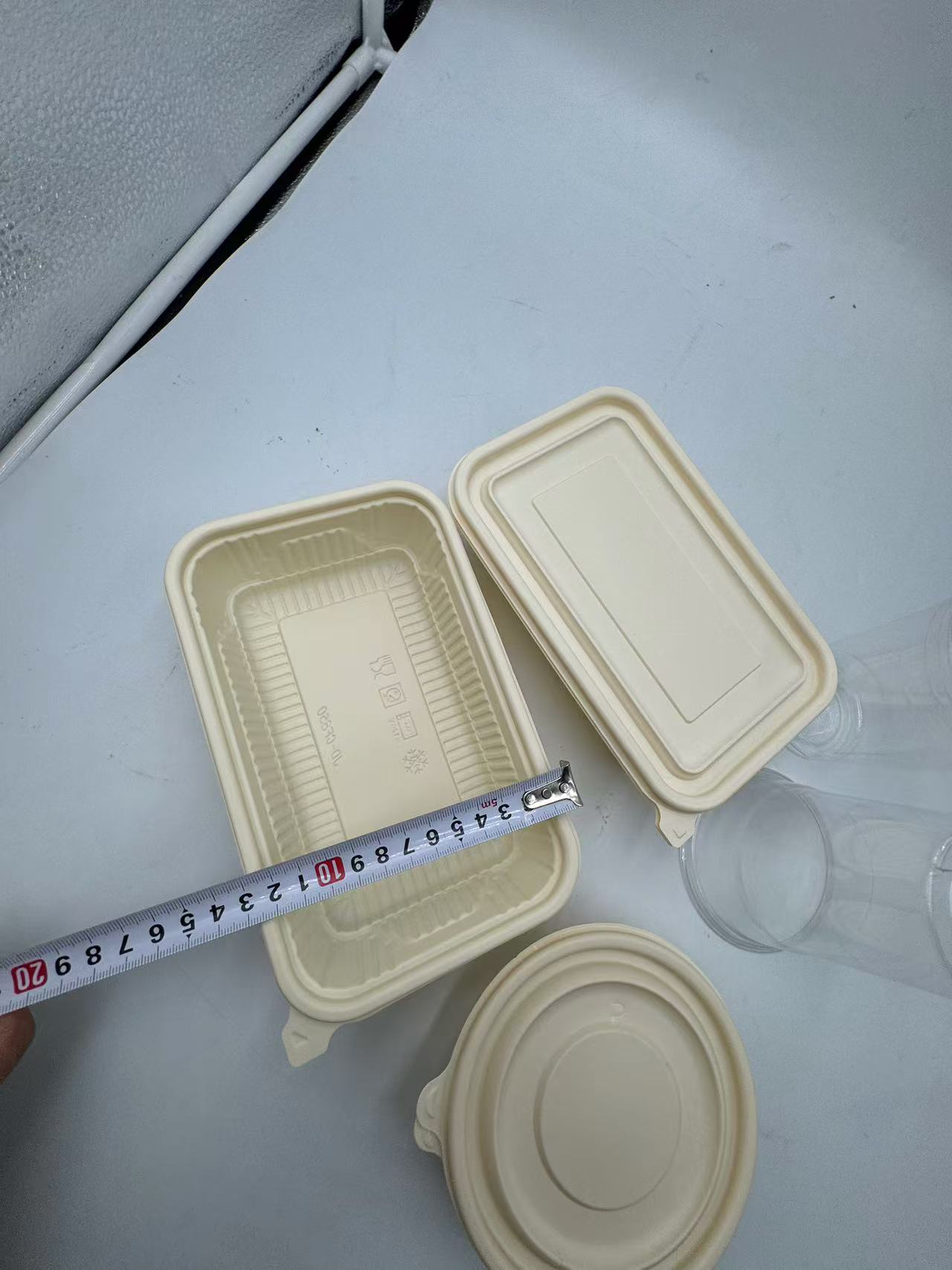

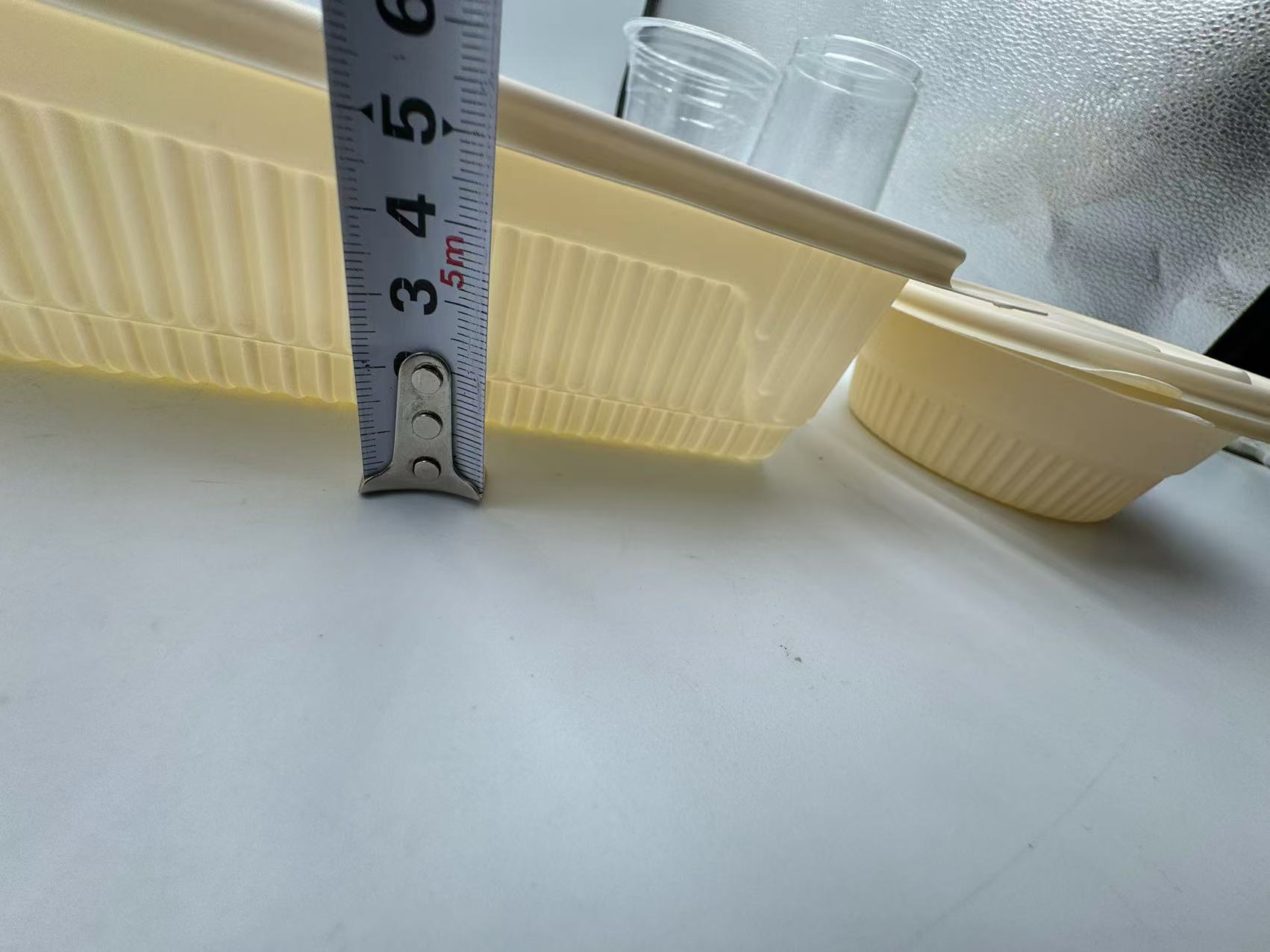

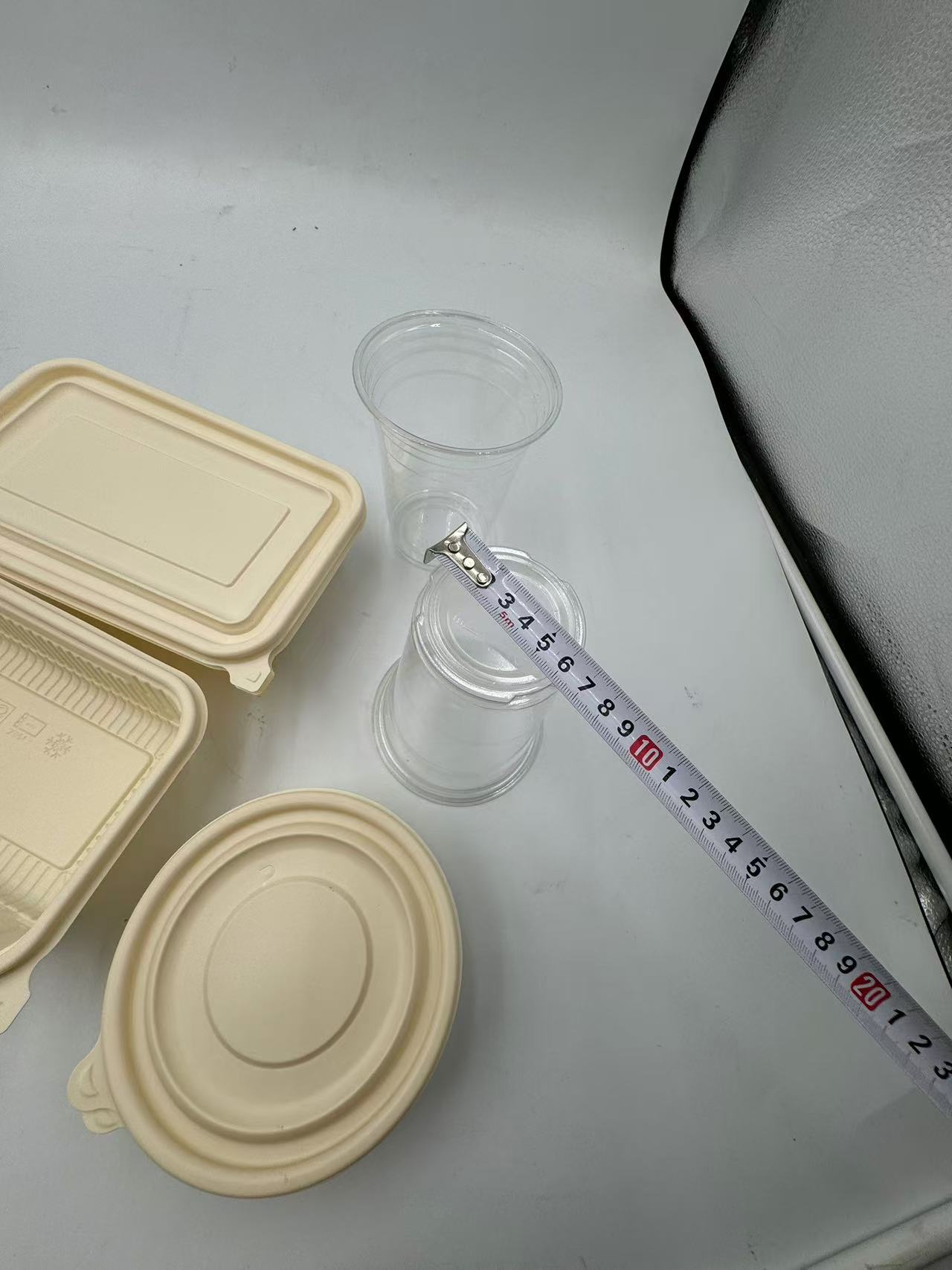

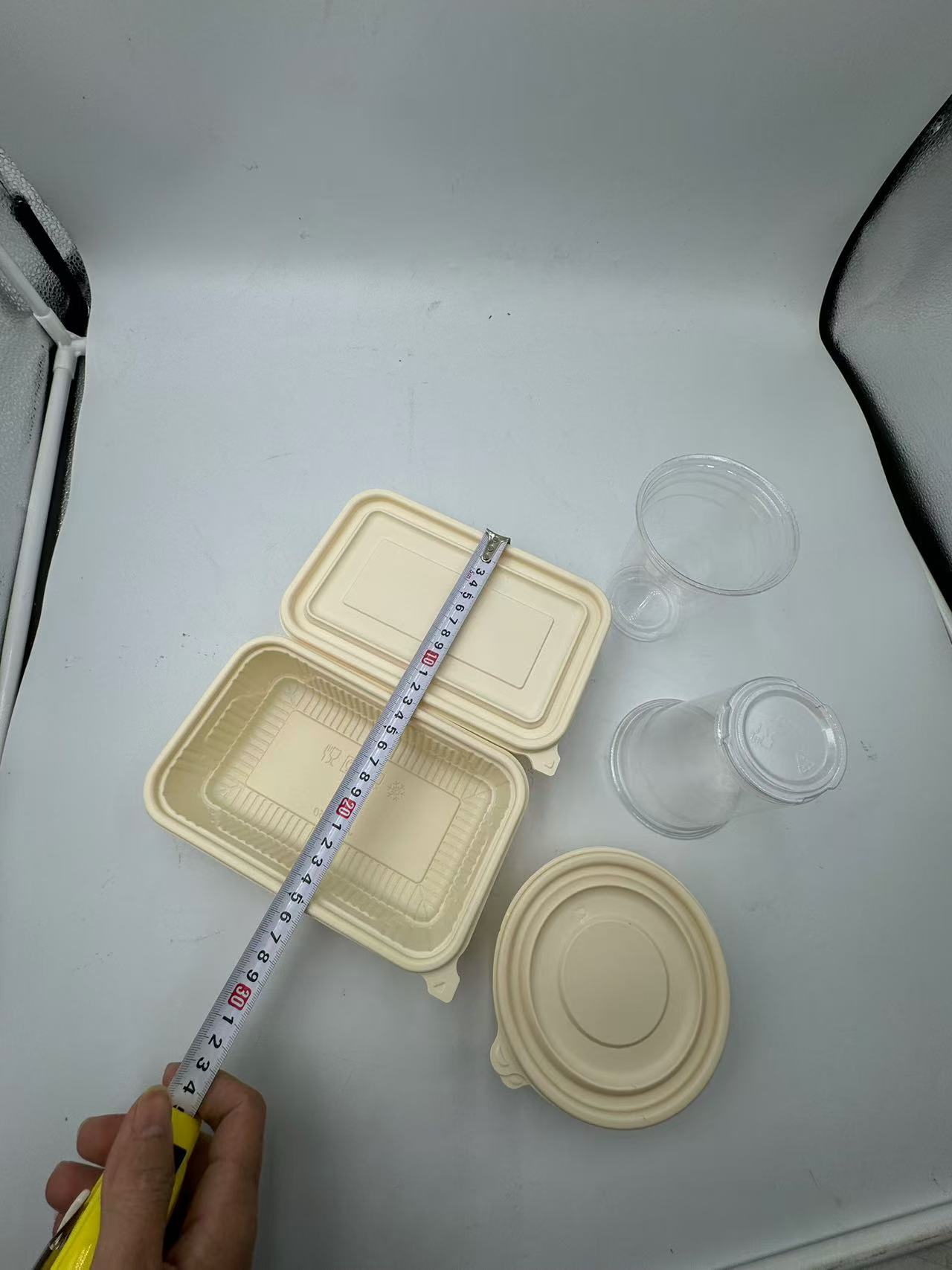

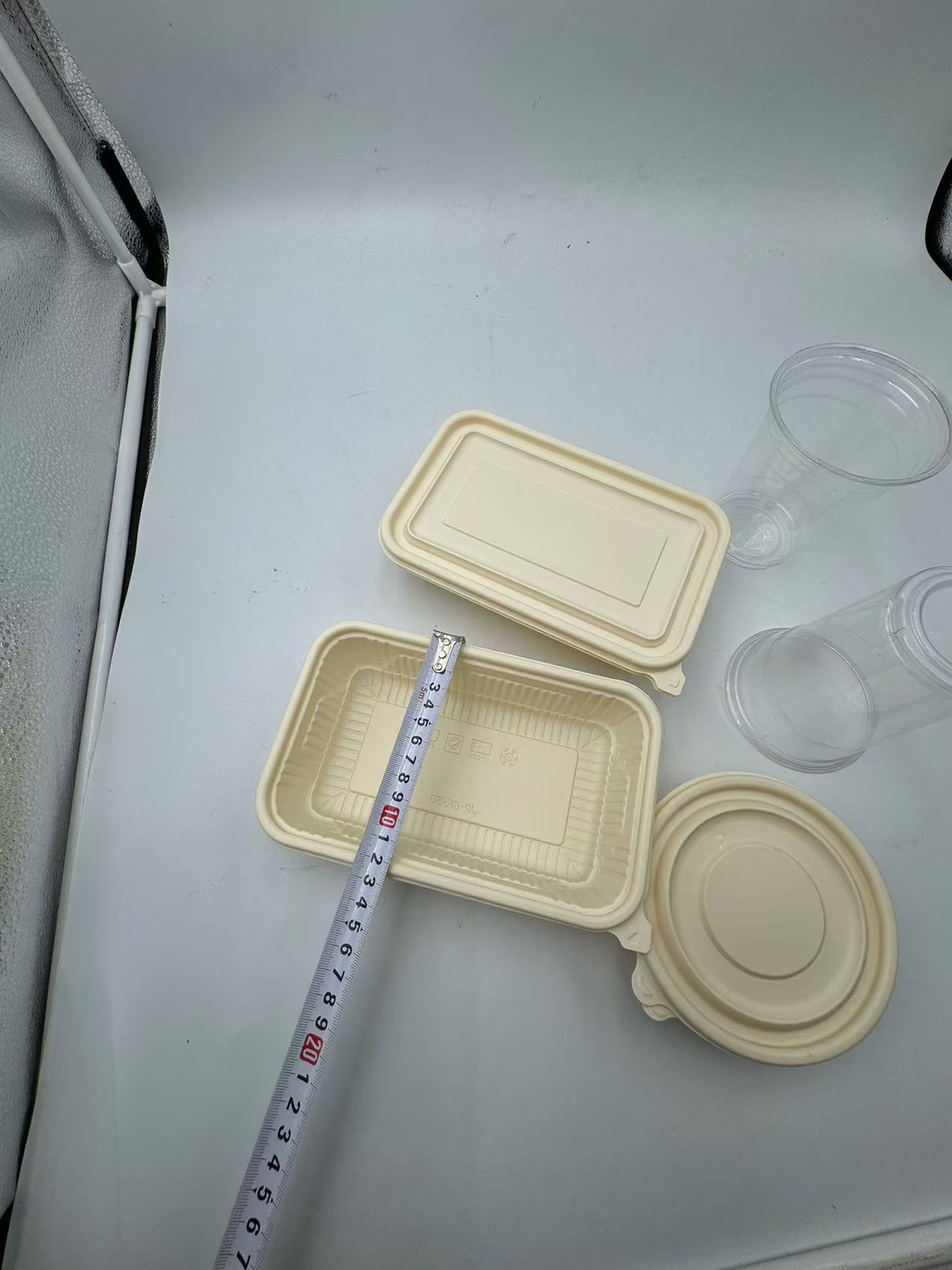

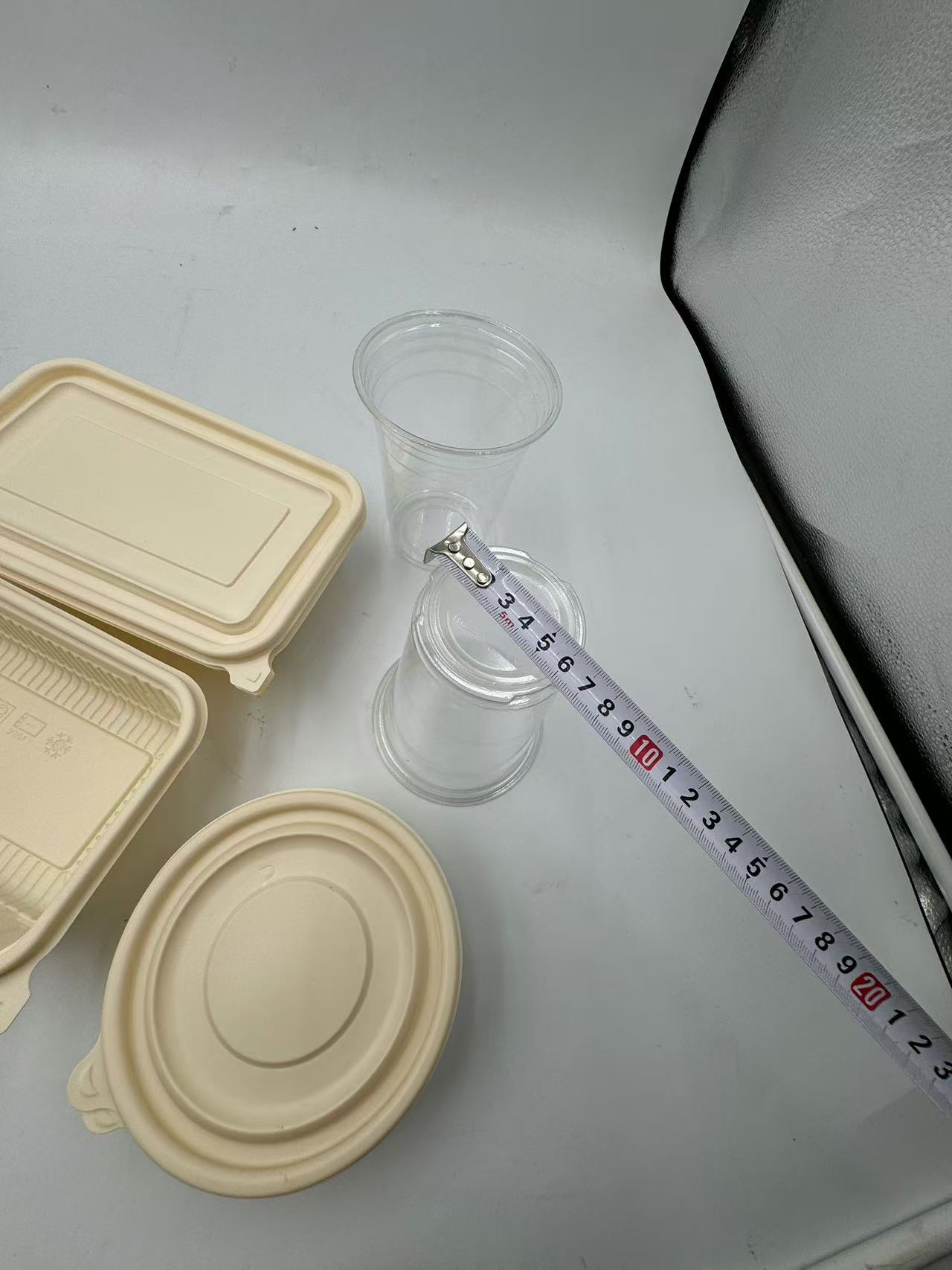

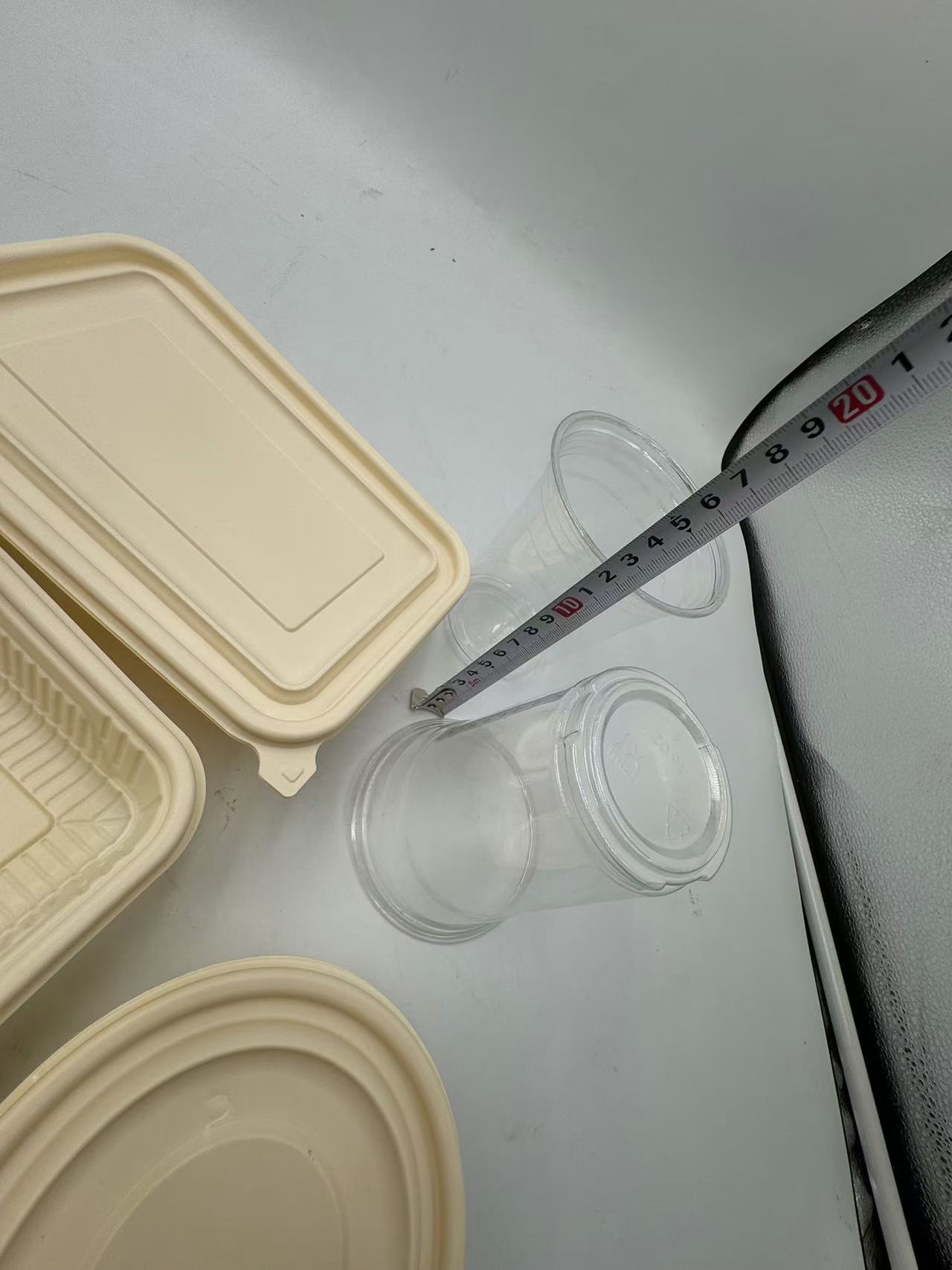

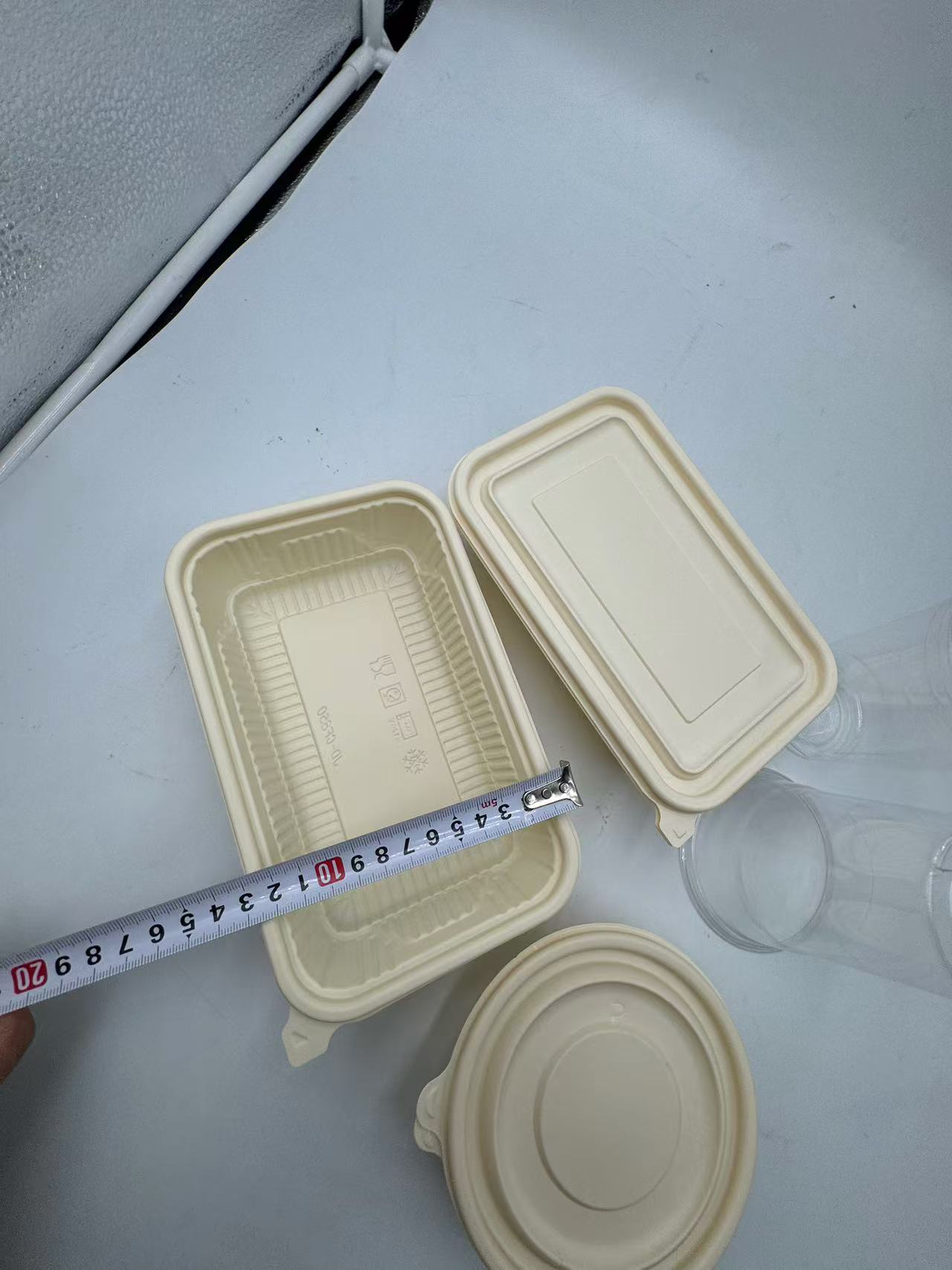

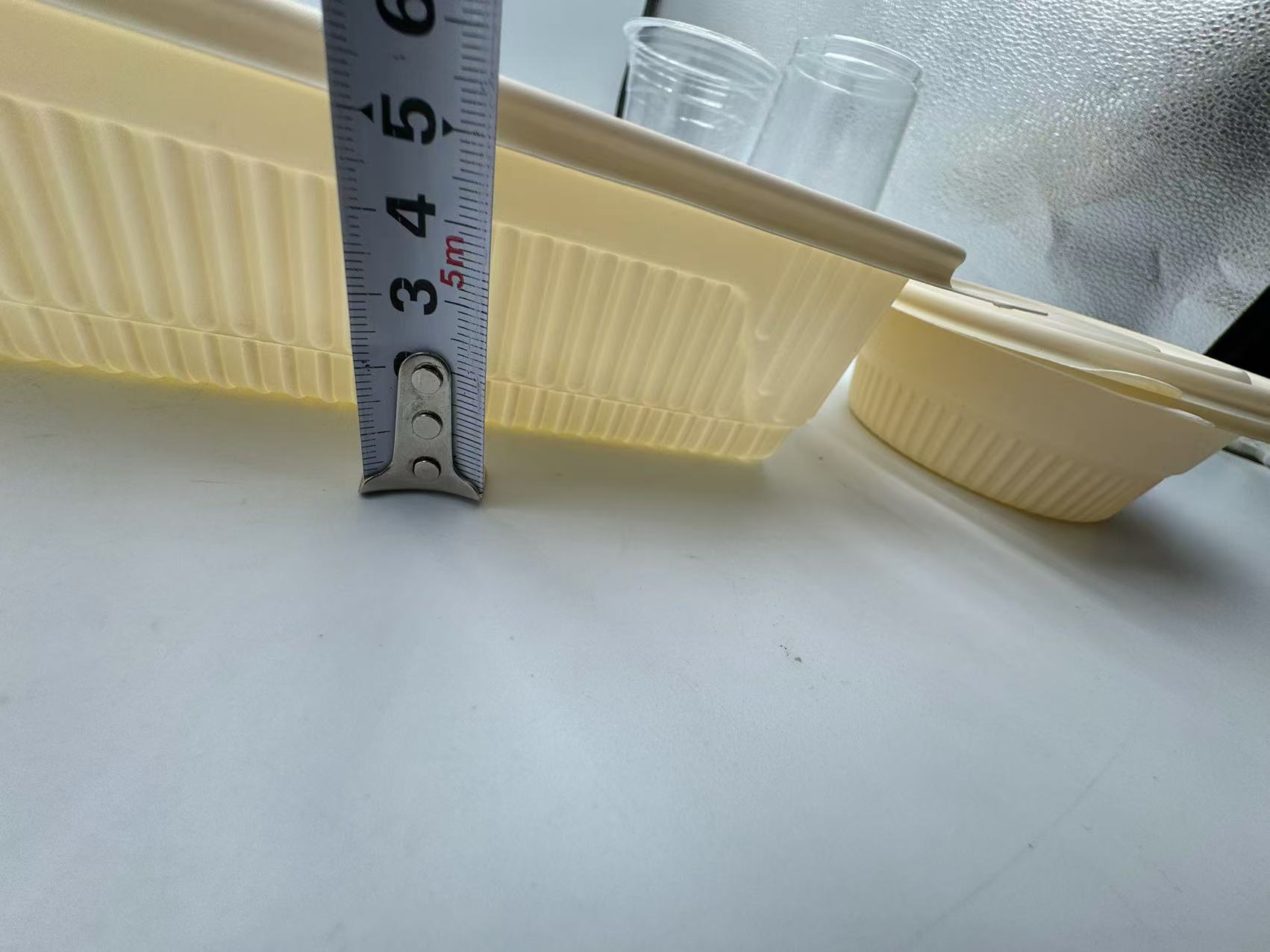

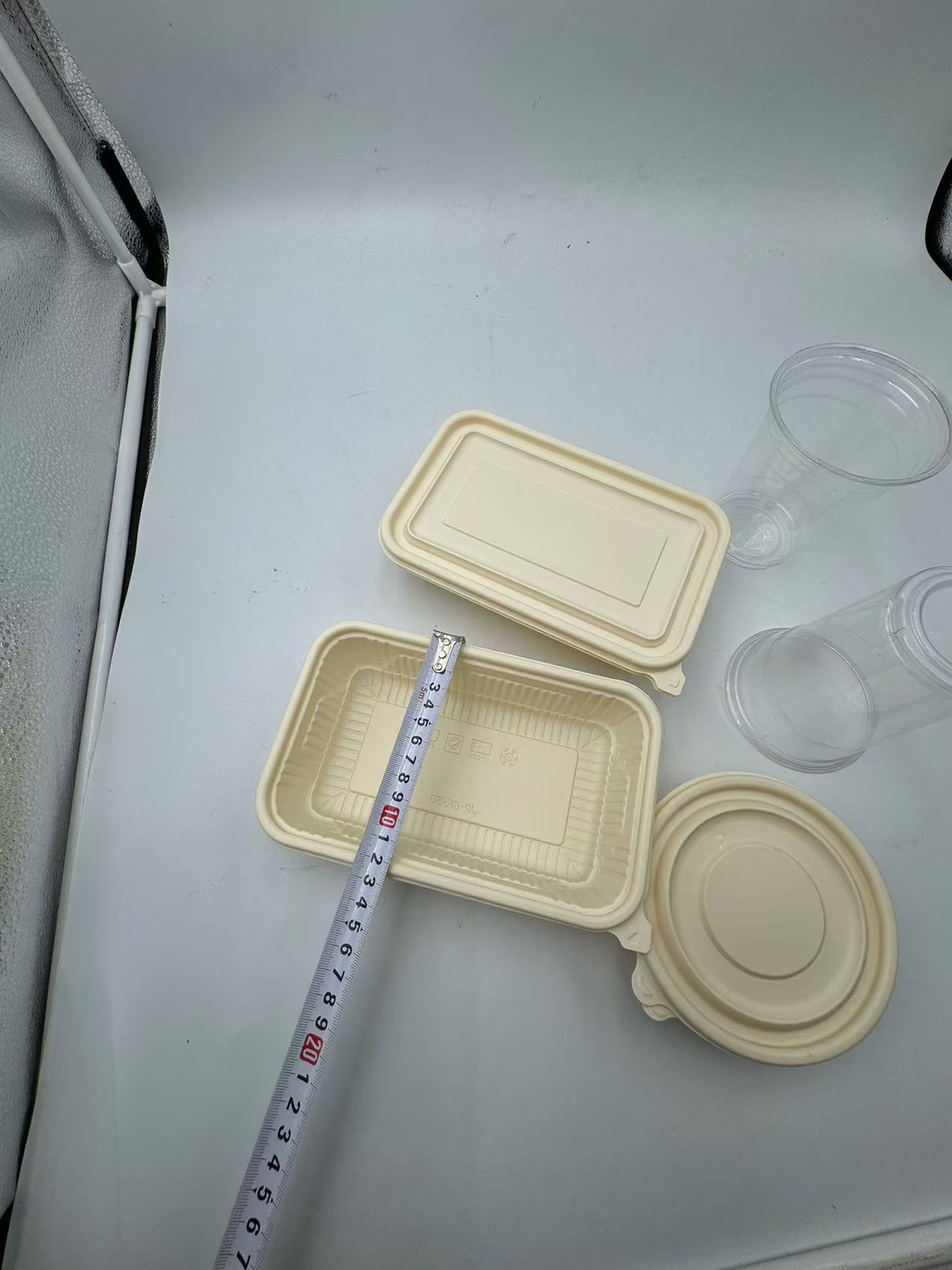

Before thermoforming, the transparent PLA film needs to be properly prepared. The film is usually supplied in rolls and may undergo pre - treatment processes. This can include drying to remove any moisture that could affect the thermoforming process. The quality of the film, including its thickness and uniformity, is carefully controlled. The thickness of the PLA film for lunch boxes, food plates, and cups can range from a few hundred micrometers to a millimeter, depending on the specific requirements of the packaging.

The thermoforming process begins with heating the PLA film. Specialized heating elements are used to raise the temperature of the film to its softening point. The heating temperature and time are precisely controlled to ensure that the film is evenly heated. This is crucial as uneven heating can lead to defects in the formed products, such as thin spots or wrinkles. The heating system may be designed to heat the film from one or both sides, depending on the equipment and the desired quality of the final product.

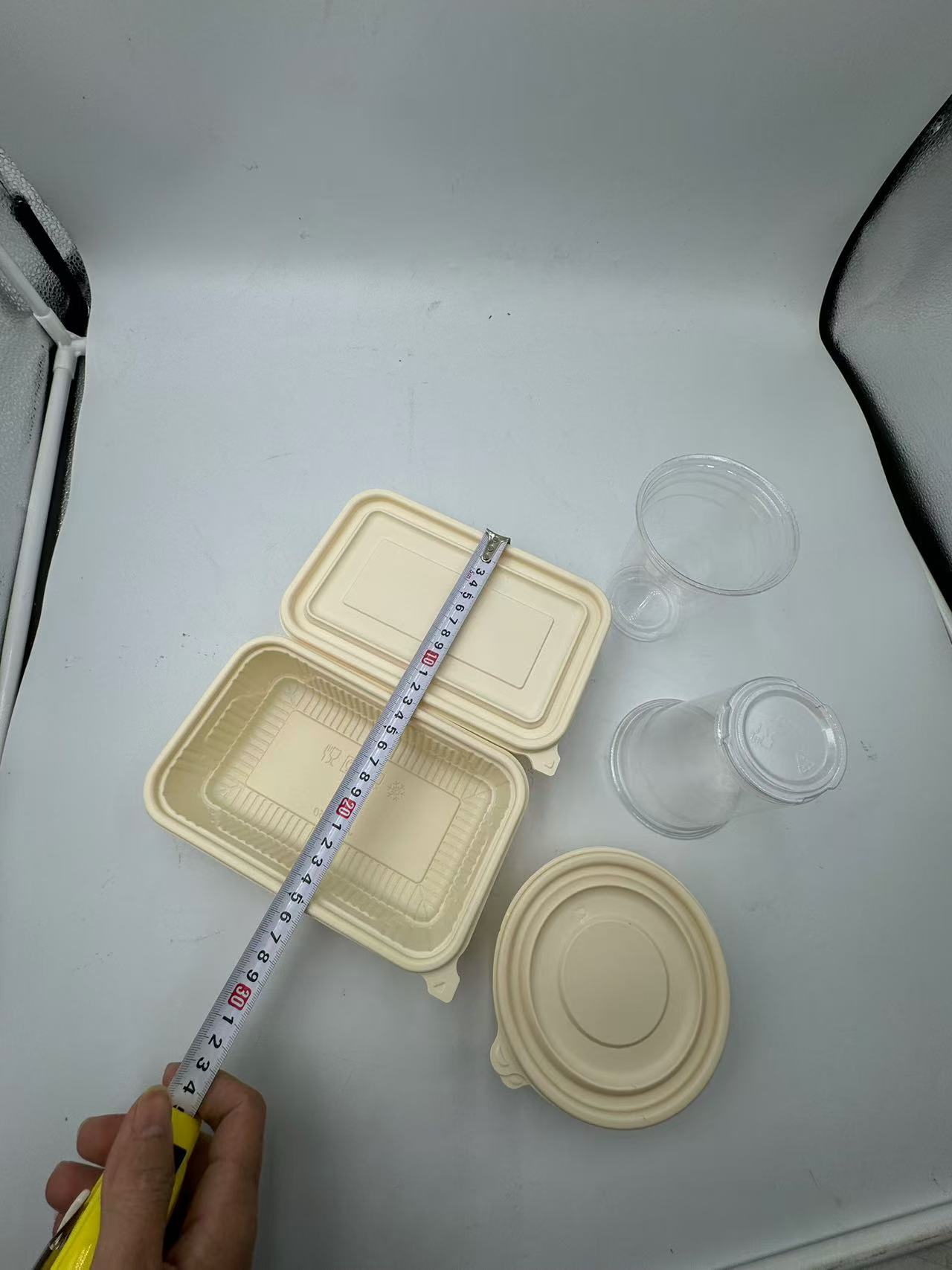

Once the film is heated to the appropriate temperature, it is then formed into the desired shape. For lunch boxes, the film is typically placed over a male or female mold. Vacuum or pressure techniques are employed to shape the film. In vacuum thermoforming, a vacuum is created beneath the heated film, causing it to be drawn into the mold cavity. In pressure thermoforming, compressed air is used to force the film onto the mold. The same principles are applied for forming food plates and cold - drink cups. The design of the mold determines the shape, size, and details of the final product. For example, a lunch box mold may have compartments and edges designed to hold different food items.

After the film is formed into the desired shape, it is cooled to solidify the PLA. Cooling can be achieved through the use of cooling channels within the mold or by exposing the formed product to a cooling medium. Once cooled, the excess film around the edges of the formed product is trimmed off. Trimming is done using cutting tools that are designed to provide clean and accurate edges. The trimmed edges of the lunch box, plate, or cup are smooth to ensure the safety of the users.

Transparent PLA film - based lunch boxes are designed to meet the needs of consumers for convenient and eco - friendly food storage. The transparency of the film allows users to see the different food items inside the box at a glance. The lunch boxes can have multiple compartments to separate different types of food, such as fruits, sandwiches, and snacks. The compartments are designed to keep the food in place during transport and prevent mixing. The mechanical strength of the PLA film ensures that the lunch box can withstand the rigors of being carried in a bag or backpack without breaking.

PLA film used in lunch boxes is food - grade, ensuring the safety of the food. The barrier properties of the film help maintain the freshness of the food. For example, if a lunch box contains a salad with dressing, the PLA film can prevent the dressing from leaking and keep the salad crisp by reducing moisture loss. The ability to keep the food fresh also makes it possible for consumers to prepare their lunches in advance and enjoy them later without sacrificing quality.

In cafeterias, restaurants, and food service settings, transparent PLA food plates are used for serving food. The clear film allows the presentation of the food to be visually appealing. Chefs can arrange the food on the plate in an artistic manner, and the transparency of the PLA film enhances the visual impact. The plates can be used for both hot and cold dishes, although for hot dishes, additional considerations may be needed to ensure heat resistance. The smooth surface of the PLA film - based plates also makes them easy to clean and reuse in some cases.

Food plates made from transparent PLA film can be easily customized. Restaurants and food service providers can print their logos or designs on the film. This not only adds a touch of branding but also makes the plates more unique. The ability to customize the plates can also be used for special events or occasions, such as birthday parties or corporate functions, where customized plates can enhance the overall atmosphere.

Cold - drink cups made from transparent PLA film are designed to hold cold beverages. The film has good insulation properties for cold temperatures, keeping the drink cold for a longer period. Additionally, the cup design may incorporate features to control condensation. The inner layer of the PLA film can be designed to minimize the formation of water droplets on the outside of the cup, providing a better user experience. The transparency of the cup allows consumers to see the contents, which is especially important for drinks with added ingredients like fruit slices or ice cubes.

PLA - based cold - drink cups are lightweight and easy to carry. They are often used in take - out and fast - food settings. The cups can be designed with lids to prevent spills during transportation. The flexibility of the PLA film allows for the design of cups with different shapes and sizes, catering to various beverage volumes. The biodegradability of the cups also makes them an environmentally friendly choice for consumers who are conscious of the environmental impact of disposable packaging.

The use of transparent PLA film in lunch boxes, food plates, and cold - drink cups significantly reduces the environmental impact of packaging waste. As a biodegradable material, PLA breaks down naturally, reducing the amount of plastic waste that accumulates in landfills or the environment. This is in contrast to traditional petroleum - based plastics, which can take hundreds of years to decompose. The use of renewable resources in the production of PLA also makes it a more sustainable option, contributing to the reduction of reliance on fossil fuels.

Consumers are increasingly aware of environmental issues and are more likely to choose products packaged in eco - friendly materials. Transparent PLA film - based packaging has a positive appeal to consumers. The transparency allows them to see the food, which is an important factor in food purchasing decisions. Additionally, the knowledge that the packaging is biodegradable can enhance the brand image of the food product and the food service provider. This can lead to increased customer satisfaction and loyalty.

The barrier and mechanical properties of transparent PLA film ensure that the food is well - protected. The film helps maintain the freshness, flavor, and texture of the food by preventing moisture loss, gas exchange, and physical damage. This is crucial for maintaining the quality of the food during storage and transportation. The food - grade nature of PLA film also ensures that there is no risk of harmful chemicals leaching into the food, ensuring food safety.

PLA film offers great versatility in the design of lunch boxes, food plates, and cold - drink cups. It can be easily formed into different shapes and sizes to meet the specific requirements of various food products and food service settings. The ability to print on the film allows for customization and branding, making the packaging more attractive and unique. The flexibility of the film also enables the incorporation of additional features such as compartments in lunch boxes or condensation - control mechanisms in cups.

Although the initial cost of PLA film may be slightly higher than some traditional plastic films, in the long run, it can be cost - effective. The reduced environmental impact can lead to savings in waste management costs. Additionally, as the demand for sustainable packaging increases, the production volume of PLA film is likely to grow, which may lead to cost reductions through economies of scale. The ability to reuse and recycle PLA - based packaging in some cases can also contribute to cost savings.

A local school district implemented the use of transparent PLA - based lunch boxes in its lunch program. The transparency of the boxes allowed students to see their food, which increased their interest in the school lunches. The lunch boxes were durable enough to withstand daily use by the students. The biodegradability of the PLA film was also a significant advantage as it aligned with the school's environmental education goals. The school district noticed a reduction in the amount of plastic waste generated from lunch packaging, and the parents were also supportive of the eco - friendly initiative.

A popular restaurant chain started using transparent PLA food plates for serving their dishes. The plates enhanced the presentation of the food, making it more visually appealing to the customers. The ability to print the restaurant's logo on the plates added a touch of branding. The plates were easy to clean and reuse, reducing the restaurant's need for disposable plates. The use of PLA plates also improved the restaurant's environmental image, attracting more customers who were concerned about sustainability.

A take - out coffee shop switched to using transparent PLA - based cold - drink cups. The cups were well - received by the customers due to their transparency and the fact that they were biodegradable. The insulation properties of the cups kept the cold drinks cold for a longer time, and the design to control condensation was effective. The coffee shop saw an increase in customer satisfaction, and the use of PLA cups also helped in reducing their environmental footprint.

One of the main challenges in using PLA film for food packaging, especially for hot food, is its limited heat resistance. PLA can soften or deform at relatively low temperatures compared to some traditional plastics. To address this issue, special formulations of PLA with higher heat - resistant properties can be developed. Additionally, coatings or laminates can be applied to the PLA film to improve its heat resistance. For example, a thin layer of a heat - stable polymer can be added to the inner surface of a lunch box made from PLA film to allow it to hold hot food without deforming.

While PLA film has some barrier properties, there may be a need to further improve them for certain food products. For example, some highly perishable foods may require better oxygen and moisture barrier protection. This can be achieved through the use of multilayer films. A layer of a high - barrier material can be combined with the PLA film to enhance its overall barrier performance. Another approach is to modify the PLA film itself through the addition of nanomaterials or other additives to improve its barrier properties.

Although PLA is biodegradable, the proper disposal and recycling of PLA - based packaging require appropriate infrastructure. In many areas, there may be a lack of facilities for composting or recycling PLA. To overcome this, efforts should be made to develop and expand the recycling and composting infrastructure. This can include setting up collection points for PLA waste, educating the public about the proper disposal of PLA - based packaging, and establishing partnerships between food service providers, packaging manufacturers, and waste management companies.

The production cost of PLA film can be relatively high compared to traditional plastics, which can be a barrier to its widespread use. To reduce the cost, research and development efforts should focus on improving the production efficiency of PLA. This can involve optimizing the polymerization process, reducing the use of expensive additives, and finding more cost - effective sources of raw materials. Additionally, the thermoforming process for PLA film may require specialized equipment or adjustments compared to traditional plastic films. Manufacturers should invest in training and equipment upgrades to ensure efficient production of high - quality PLA - based food packaging.

Transparent PLA film has shown great potential in the thermoforming of lunch boxes, food plates, and cold - drink cups for food packaging applications. Its unique combination of properties, including transparency, mechanical strength, barrier protection, thermal properties, and biodegradability, makes it an attractive alternative to traditional plastics. Despite the challenges related to heat resistance, barrier performance, recycling infrastructure, and cost, there are various solutions available to address these issues. With continued research and development, the use of transparent PLA film in food packaging is expected to grow, contributing to a more sustainable and environmentally friendly food packaging industry. The application of this eco - friendly material not only benefits the environment but also meets the needs of consumers and food service providers in terms of food protection, presentation, and cost - effectiveness. As the world becomes more conscious of the environmental impact of packaging waste, transparent PLA film is set to play an increasingly important role in shaping the future of food packaging.