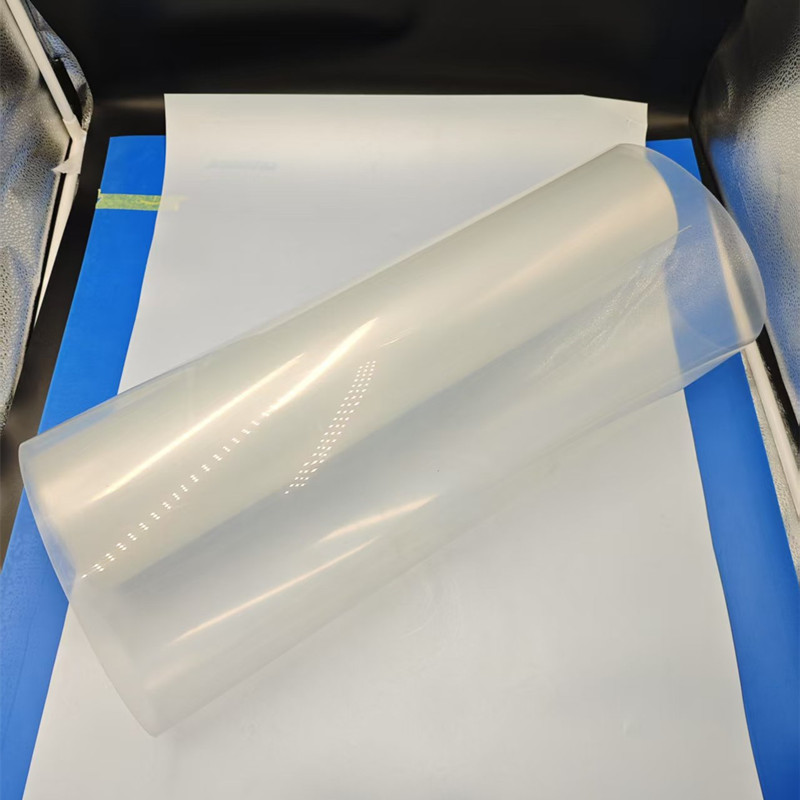

PP Sheet For Thermoforming Packaging

2025-11-07 15:33Core Advantages

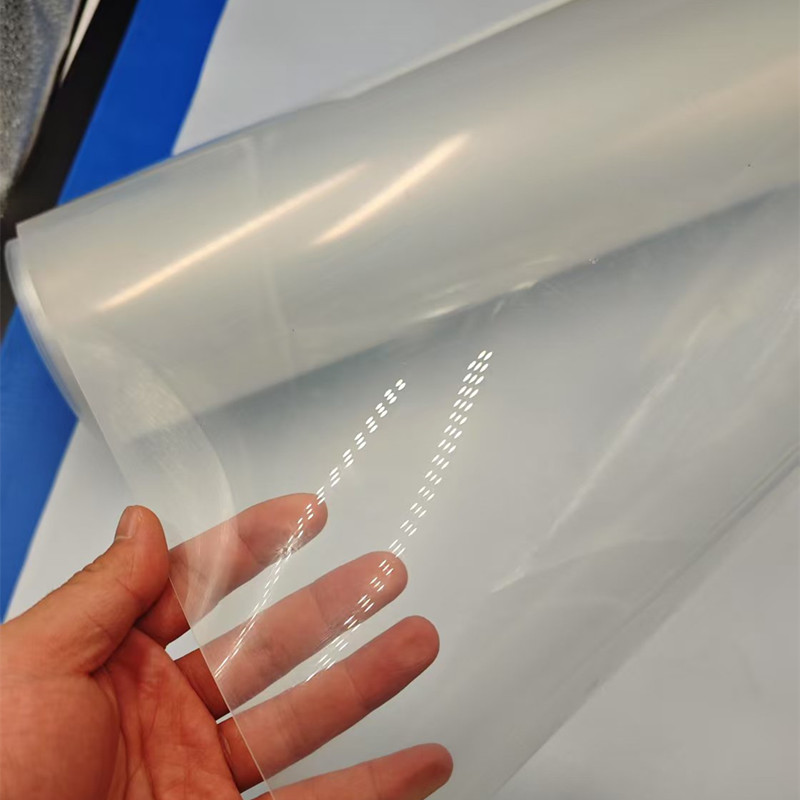

Persistent Anti-fog Performance: The built-in anti-fog formula is uniformly integrated into the PP matrix during production, rather than being a surface coating. This ensures long-lasting anti-fogging effect—even in high-humidity environments (such as refrigeration or after food heating) and during long-term storage, it effectively prevents water vapor condensation on the sheet surface, keeping the packaging transparent and clear. Consumers can directly see the fresh state of the food without wiping the packaging.

Food-grade Safety Assurance: Made of 100% food-grade polypropylene (PP) raw materials, the sheet complies with international food safety standards such as FDA and EU 10/2011. It is non-toxic, odorless, and free of harmful substances like bisphenol A (BPA) and phthalates. It can directly contact various foods, including fresh fruits and vegetables, meat, seafood, baked goods, and ready-to-eat meals, without affecting food taste or safety.

Excellent Thermoformability: The sheet features stable physical properties and good thermal processing performance. It can be easily formed into various shapes of food packaging containers (such as trays, boxes, and clamshell packages) through thermoforming processes. During forming, it maintains uniform thickness and stable anti-fog performance, with no cracks or performance degradation, adapting to large-scale industrial production needs.

Superior Protective Properties: It has good mechanical strength, impact resistance, and puncture resistance, which can effectively protect food from external pressure, collision, and contamination during transportation and storage. Meanwhile, it has good barrier properties against dust and microorganisms, helping to extend the shelf life of food.