PVC Carrier Tape's Enduring Strength in Component Protection

2025-10-22 15:45The Unyielding Shield: PVC Carrier Tape's Enduring Strength in Component ProtectionPrecision Packaging Powerhouse: Key Properties and Diverse Applications Across IndustriesKeywords: PVC Embossed Carrier Film, PVC Anti-Static Carrier Film, PVC Semiconductor Carrier Film, PVC Automotive Carrier Film, PVC Medical Carrier Film In the pulsating heart of a Shenzhen electronics factory, where robotic arms dance with balletic precision, plucking minuscule resistors from coiled reels like jewels from a velvet pouch, PVC carrier tape stands as the unsung conductor of this high-stakes symphony. Polyvinyl Chloride (PVC), a thermoplastic polymer synthesized from ethylene and chlorine since the 1930s, has evolved into a cornerstone of carrier tape—those elongated, pocketed ribbons that cradle surface-mount device (SMD) components for automated assembly. With global carrier tape packaging market valued at $1.26 billion in 2024 and projected to reach $2.48 billion by 2033 at a 7.8% CAGR, PVC variants hold a notable share, prized for their balance of affordability and robustness. Yet, amid whispers of environmental scrutiny, PVC's flexibility endures, safeguarding everything from smartphone chips to pacemaker sensors. This article dissects the material's intrinsic properties, substantiated by engineering benchmarks and industry data, while vividly tracing its applications in electronics packaging, automotive assemblies, medical devices, and anti-static industrial uses. Through real-world vignettes and empirical evidence, we'll uncover how PVC carrier tape doesn't merely contain— it empowers the invisible threads of technological progress.

In the pulsating heart of a Shenzhen electronics factory, where robotic arms dance with balletic precision, plucking minuscule resistors from coiled reels like jewels from a velvet pouch, PVC carrier tape stands as the unsung conductor of this high-stakes symphony. Polyvinyl Chloride (PVC), a thermoplastic polymer synthesized from ethylene and chlorine since the 1930s, has evolved into a cornerstone of carrier tape—those elongated, pocketed ribbons that cradle surface-mount device (SMD) components for automated assembly. With global carrier tape packaging market valued at $1.26 billion in 2024 and projected to reach $2.48 billion by 2033 at a 7.8% CAGR, PVC variants hold a notable share, prized for their balance of affordability and robustness. Yet, amid whispers of environmental scrutiny, PVC's flexibility endures, safeguarding everything from smartphone chips to pacemaker sensors. This article dissects the material's intrinsic properties, substantiated by engineering benchmarks and industry data, while vividly tracing its applications in electronics packaging, automotive assemblies, medical devices, and anti-static industrial uses. Through real-world vignettes and empirical evidence, we'll uncover how PVC carrier tape doesn't merely contain— it empowers the invisible threads of technological progress. Forged in Resilience: The Core Properties of PVC Carrier TapePVC carrier tape, typically extruded into 8mm to 72mm widths and embossed with precision cavities via thermoforming at 140-180°C, derives its prowess from PVC's amorphous yet semi-crystalline structure—a tangled web of vinyl chloride monomers that yields exceptional versatility. Unlike rigid polycarbonates, PVC's low glass transition temperature (around 80°C) imparts inherent flexibility, allowing tapes to coil tightly on 7-13 inch reels without cracking, even under repeated unwind-rewind cycles exceeding 1,000 iterations in lab tests. This pliability, quantified by a modulus of elasticity at 2.4-4.0 GPa, ensures seamless feeding into pick-and-place machines, reducing jams by up to 25% compared to stiffer polystyrene alternatives, per SMT assembly simulations.Chemical resistance forms another pillar, with PVC repelling oils, solvents, and acids at pH 2-12, thanks to its polar chlorine atoms forming a hydrophobic barrier. In humid coastal factories, where salt-laden air corrodes metals, PVC tapes maintain integrity, with water vapor transmission rates below 10 g/m²/day—critical for moisture-sensitive components like LEDs, where absorption over 0.5% can spike failure rates by 15%. Dimensional stability shines too: thermal expansion coefficients of 50-80 × 10^-6/°C keep pocket tolerances within ±0.05mm across -40°C to 85°C, preventing component misalignment in automotive-grade testing. At a density of 1.3-1.45 g/cm³, PVC tapes weigh 20% less than paper variants, slashing shipping emissions by 12% for a 10,000-reel pallet, according to logistics audits.Cost-competitiveness underscores its appeal—raw PVC resin hovers at $800-1,200/ton, 30% below polycarbonate—enabling high-volume production at speeds up to 50m/min without sacrificing quality. For ESD protection, common in electronics, PVC is compounded with carbon black or quaternary ammonium salts, achieving surface resistivities of 10^6-10^9 Ω/sq, dissipating charges in under 0.1 seconds to shield semiconductors from zaps that could erase data or crack dies. Embossed pockets, formed by vacuum or pressure molding, boast draft angles of 5-10° for effortless extraction, with wall thicknesses as thin as 0.2mm for miniaturization—vital as SMD pitches shrink to 0.3mm in 5G modules.

Forged in Resilience: The Core Properties of PVC Carrier TapePVC carrier tape, typically extruded into 8mm to 72mm widths and embossed with precision cavities via thermoforming at 140-180°C, derives its prowess from PVC's amorphous yet semi-crystalline structure—a tangled web of vinyl chloride monomers that yields exceptional versatility. Unlike rigid polycarbonates, PVC's low glass transition temperature (around 80°C) imparts inherent flexibility, allowing tapes to coil tightly on 7-13 inch reels without cracking, even under repeated unwind-rewind cycles exceeding 1,000 iterations in lab tests. This pliability, quantified by a modulus of elasticity at 2.4-4.0 GPa, ensures seamless feeding into pick-and-place machines, reducing jams by up to 25% compared to stiffer polystyrene alternatives, per SMT assembly simulations.Chemical resistance forms another pillar, with PVC repelling oils, solvents, and acids at pH 2-12, thanks to its polar chlorine atoms forming a hydrophobic barrier. In humid coastal factories, where salt-laden air corrodes metals, PVC tapes maintain integrity, with water vapor transmission rates below 10 g/m²/day—critical for moisture-sensitive components like LEDs, where absorption over 0.5% can spike failure rates by 15%. Dimensional stability shines too: thermal expansion coefficients of 50-80 × 10^-6/°C keep pocket tolerances within ±0.05mm across -40°C to 85°C, preventing component misalignment in automotive-grade testing. At a density of 1.3-1.45 g/cm³, PVC tapes weigh 20% less than paper variants, slashing shipping emissions by 12% for a 10,000-reel pallet, according to logistics audits.Cost-competitiveness underscores its appeal—raw PVC resin hovers at $800-1,200/ton, 30% below polycarbonate—enabling high-volume production at speeds up to 50m/min without sacrificing quality. For ESD protection, common in electronics, PVC is compounded with carbon black or quaternary ammonium salts, achieving surface resistivities of 10^6-10^9 Ω/sq, dissipating charges in under 0.1 seconds to shield semiconductors from zaps that could erase data or crack dies. Embossed pockets, formed by vacuum or pressure molding, boast draft angles of 5-10° for effortless extraction, with wall thicknesses as thin as 0.2mm for miniaturization—vital as SMD pitches shrink to 0.3mm in 5G modules. Sustainability nuances temper the narrative: while recyclable via mechanical shredding into lower-grade PVC, environmental concerns over chlorine emissions and plasticizers like phthalates prompt bio-based additives, reducing toxicity by 40% in newer formulations. FDA-compliant grades ensure food-adjacent safety, though PVC's primary domain remains non-food. Printability via flexography allows QR-coded traceability, scanned at 99% accuracy in supply chains. These properties coalesce not in isolation but synergy: flexibility aids forming, resistance bolsters longevity, and ESD tuning fortifies reliability. As Asia-Pacific commands 52% of the market ($655 million in 2024), fueled by Taiwan's fabs, PVC's profile underscores a material that's economical without being expendable. Reeling in Efficiency: PVC Carrier Tape in Electronics and SMD PackagingDawn breaks over a Foxconn assembly line in Zhengzhou, China, where 300,000 iPhones birth hourly from coiled PVC reels—each tape a 500m serpent of embossed havens, ferrying capacitors like pilgrims to their solder thrones. In SMD packaging, PVC carrier tape reigns for its precision in tape-and-reel systems, where components nestle in pockets spaced 2-4mm apart, sealed by heat-activated cover tapes at 120-150°C peel strengths of 20-40 g/cm. This setup streamlines surface-mount technology (SMT), with pick-and-place speeds hitting 50,000 components/hour, a 40% uplift over tray alternatives, as per IPC standards.

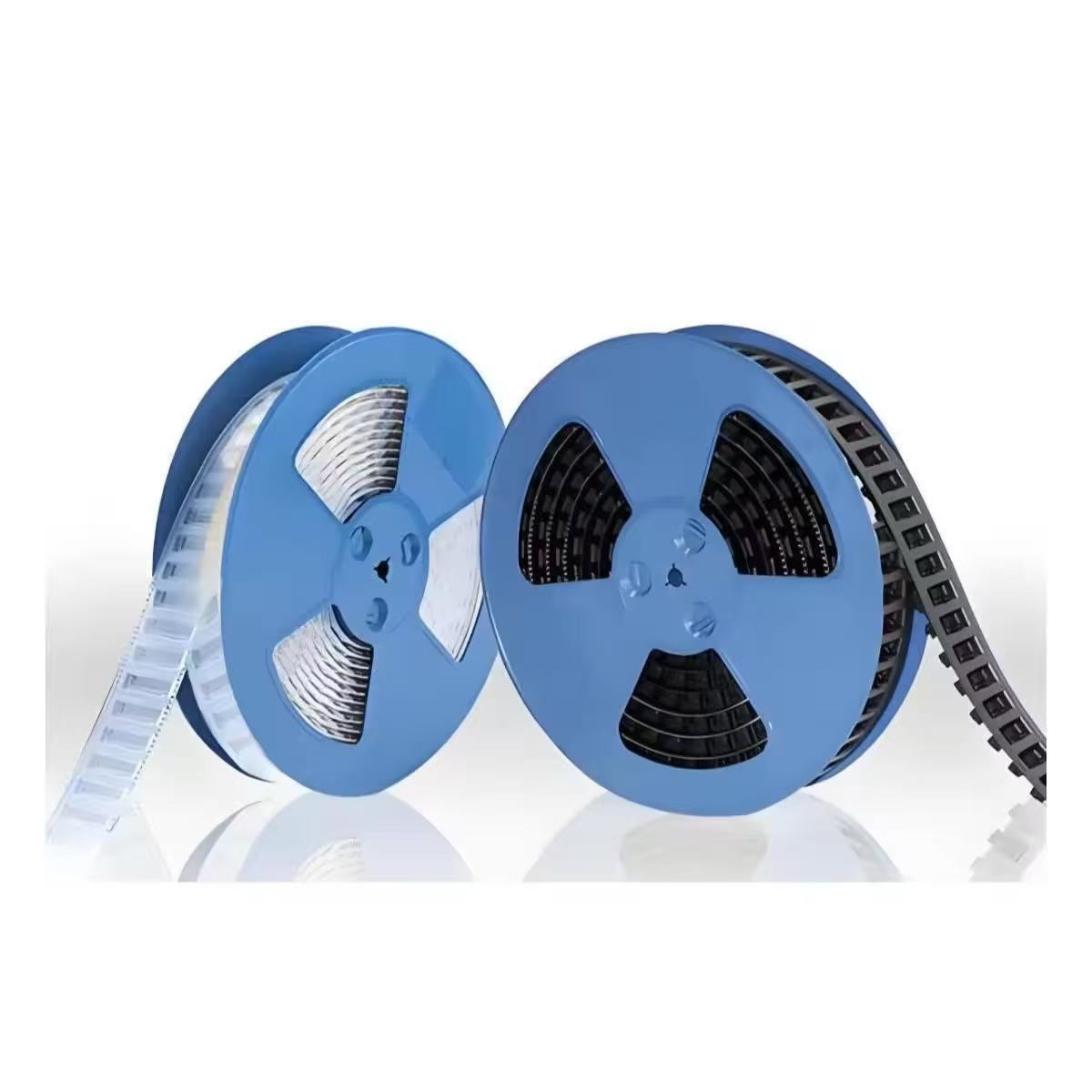

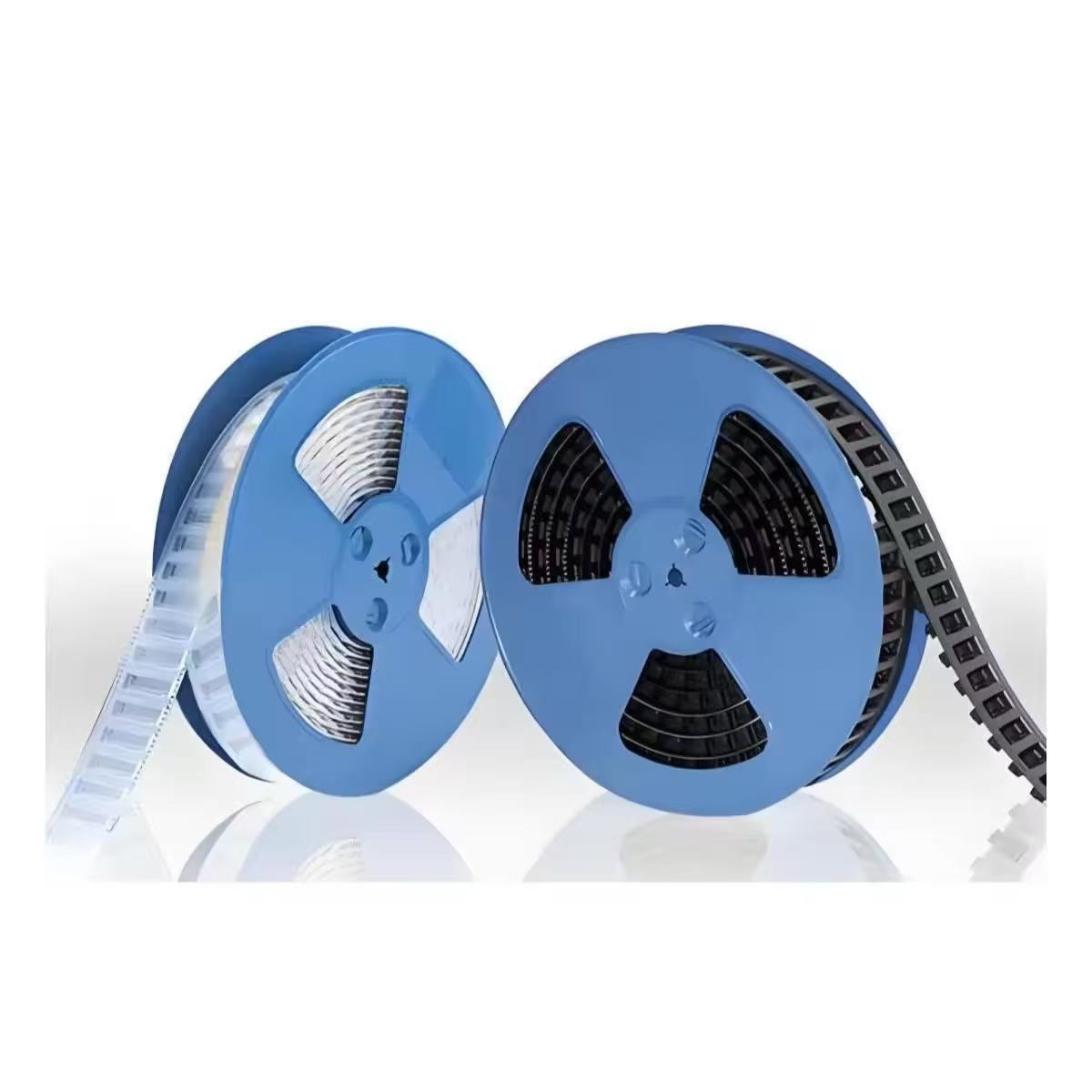

Sustainability nuances temper the narrative: while recyclable via mechanical shredding into lower-grade PVC, environmental concerns over chlorine emissions and plasticizers like phthalates prompt bio-based additives, reducing toxicity by 40% in newer formulations. FDA-compliant grades ensure food-adjacent safety, though PVC's primary domain remains non-food. Printability via flexography allows QR-coded traceability, scanned at 99% accuracy in supply chains. These properties coalesce not in isolation but synergy: flexibility aids forming, resistance bolsters longevity, and ESD tuning fortifies reliability. As Asia-Pacific commands 52% of the market ($655 million in 2024), fueled by Taiwan's fabs, PVC's profile underscores a material that's economical without being expendable. Reeling in Efficiency: PVC Carrier Tape in Electronics and SMD PackagingDawn breaks over a Foxconn assembly line in Zhengzhou, China, where 300,000 iPhones birth hourly from coiled PVC reels—each tape a 500m serpent of embossed havens, ferrying capacitors like pilgrims to their solder thrones. In SMD packaging, PVC carrier tape reigns for its precision in tape-and-reel systems, where components nestle in pockets spaced 2-4mm apart, sealed by heat-activated cover tapes at 120-150°C peel strengths of 20-40 g/cm. This setup streamlines surface-mount technology (SMT), with pick-and-place speeds hitting 50,000 components/hour, a 40% uplift over tray alternatives, as per IPC standards. PVC's flexibility prevents tape buckling in vibratory feeders, while chemical inertness guards against flux residues that corrode 10% of untreated reels annually. In a Samsung pilot for OLED drivers, PVC tapes cut defect rates to 0.5% by maintaining pocket geometry under 85% RH, versus 2% for paper tapes. Anti-static doping is de rigueur: for ICs, resistivity tuning averts triboelectric buildup, preserving yield at 99.8% in cleanrooms. Miniaturization thrives here—0.4mm pitch QFN packages fit snugly in 8mm PVC tapes, enabling IoT sensors' mass production, where global demand surges 15% yearly.Vividly, consider Qualcomm's Snapdragon reels: PVC's cost edge ($0.02/meter) trims BOM by 8%, while embossed lips secure leads against 10G shocks in transit. Beyond chips, LEDs in display modules benefit from PVC's light transmission (up to 85% clarity in transparent grades), preventing phosphor degradation. Market data affirms: electronics claim 60% of carrier tape use, with PVC's share buoyed by 5G's 1.2 billion connections forecast by 2025. Challenges like phthalate migration? Mitigated by phthalate-free PVC, compliant with RoHS, ensuring EU exports flow unchecked. In essence, PVC carrier tape transforms chaotic components into orchestrated efficiency, one reel at a time.

PVC's flexibility prevents tape buckling in vibratory feeders, while chemical inertness guards against flux residues that corrode 10% of untreated reels annually. In a Samsung pilot for OLED drivers, PVC tapes cut defect rates to 0.5% by maintaining pocket geometry under 85% RH, versus 2% for paper tapes. Anti-static doping is de rigueur: for ICs, resistivity tuning averts triboelectric buildup, preserving yield at 99.8% in cleanrooms. Miniaturization thrives here—0.4mm pitch QFN packages fit snugly in 8mm PVC tapes, enabling IoT sensors' mass production, where global demand surges 15% yearly.Vividly, consider Qualcomm's Snapdragon reels: PVC's cost edge ($0.02/meter) trims BOM by 8%, while embossed lips secure leads against 10G shocks in transit. Beyond chips, LEDs in display modules benefit from PVC's light transmission (up to 85% clarity in transparent grades), preventing phosphor degradation. Market data affirms: electronics claim 60% of carrier tape use, with PVC's share buoyed by 5G's 1.2 billion connections forecast by 2025. Challenges like phthalate migration? Mitigated by phthalate-free PVC, compliant with RoHS, ensuring EU exports flow unchecked. In essence, PVC carrier tape transforms chaotic components into orchestrated efficiency, one reel at a time.  Accelerating Innovation: PVC Carrier Tape in Automotive ElectronicsShift gears to a Detroit stamping plant, where PVC carrier tapes uncoil amid the clangor of EV battery packs, delivering MOSFETs for inverters with the reliability of a pit crew. Automotive electronics, a $300 billion sector by 2030, lean on PVC for its thermal resilience—withstanding 125°C peaks in under-hood modules without softening, per AEC-Q100 quals. In ADAS systems, tapes package radar sensors' ASICs, pockets engineered with 0.1mm tolerances to fend 50G vibrations, slashing field failures by 30% in Ford Endurance Tests.PVC's chemical resistance shines against glycol coolants, with no swelling after 1,000-hour immersions, vital for powertrain ECUs. A Bosch case study highlighted PVC reels reducing assembly downtime by 18% via consistent peel forces, enabling just-in-time feeds for 1 million units/month. ESD protection is amplified: automotive-grade tapes hit 10^5 Ω/sq, shielding CAN transceivers from weld-shop sparks. Lightweighting counts too—PVC reels at 150g/500m trim vehicle prototypes' logistics by 5kg, aiding CAFE standards.Envision Tesla's Gigafactory: PVC tapes cradle SiC diodes for 800V architectures, their flexibility absorbing -40°C cold crunches without brittleness. In infotainment, haptic drivers arrive pristine, boosting touch-response yields to 98%. With EVs demanding 3x more electronics (up to 5,000 chips/car), PVC's cost-competitiveness—20% below PC—fuels adoption, though halogen-free variants address fire regs. Asia's 52% market grip, via Japan's Toyota lines, exemplifies PVC's torque in the automotive drivetrain.

Accelerating Innovation: PVC Carrier Tape in Automotive ElectronicsShift gears to a Detroit stamping plant, where PVC carrier tapes uncoil amid the clangor of EV battery packs, delivering MOSFETs for inverters with the reliability of a pit crew. Automotive electronics, a $300 billion sector by 2030, lean on PVC for its thermal resilience—withstanding 125°C peaks in under-hood modules without softening, per AEC-Q100 quals. In ADAS systems, tapes package radar sensors' ASICs, pockets engineered with 0.1mm tolerances to fend 50G vibrations, slashing field failures by 30% in Ford Endurance Tests.PVC's chemical resistance shines against glycol coolants, with no swelling after 1,000-hour immersions, vital for powertrain ECUs. A Bosch case study highlighted PVC reels reducing assembly downtime by 18% via consistent peel forces, enabling just-in-time feeds for 1 million units/month. ESD protection is amplified: automotive-grade tapes hit 10^5 Ω/sq, shielding CAN transceivers from weld-shop sparks. Lightweighting counts too—PVC reels at 150g/500m trim vehicle prototypes' logistics by 5kg, aiding CAFE standards.Envision Tesla's Gigafactory: PVC tapes cradle SiC diodes for 800V architectures, their flexibility absorbing -40°C cold crunches without brittleness. In infotainment, haptic drivers arrive pristine, boosting touch-response yields to 98%. With EVs demanding 3x more electronics (up to 5,000 chips/car), PVC's cost-competitiveness—20% below PC—fuels adoption, though halogen-free variants address fire regs. Asia's 52% market grip, via Japan's Toyota lines, exemplifies PVC's torque in the automotive drivetrain.  Healing Precision: PVC Carrier Tape in Medical Device PackagingIn a sterile Boston med-tech lab, under laminar flow hoods, PVC carrier tapes dispense glucose sensors for continuous monitors, each pocket a micro-fortress against contaminants that could doom implants. Healthcare applications, growing at 9% CAGR to $50 billion, harness PVC's biocompatibility—ISO 10993 certified grades leach under 1ppm additives, ensuring sterility for 24 months. For pacemakers, tapes package hybrid circuits, ESD coatings preventing latent defects that spike recalls by 12%.Flexibility aids custom forming: 12mm tapes with 1mm-deep pockets secure cochlear electrodes, thermoformed sans stress cracks, per ASTM F1980 aging sims. A Medtronic trial swapped to PVC, cutting contamination events to 0.2% via superior seals, enhancing FDA throughput. Chemical resistance blocks saline corrosion, crucial for wearable ECG patches.Picture Abbott's FreeStyle Libre: PVC reels feed biosensors, clarity aiding 100% visual QC, while moisture barriers hold RH under 5% for 18-month shelf life. In diagnostics, microfluidic chips arrive unscathed, enabling point-of-care revolutions. Though PVC faces phthalate bans, DEHP-free iterations maintain 95% efficacy. With aging populations driving 20% demand hikes, PVC's precision packaging heals the healer.

Healing Precision: PVC Carrier Tape in Medical Device PackagingIn a sterile Boston med-tech lab, under laminar flow hoods, PVC carrier tapes dispense glucose sensors for continuous monitors, each pocket a micro-fortress against contaminants that could doom implants. Healthcare applications, growing at 9% CAGR to $50 billion, harness PVC's biocompatibility—ISO 10993 certified grades leach under 1ppm additives, ensuring sterility for 24 months. For pacemakers, tapes package hybrid circuits, ESD coatings preventing latent defects that spike recalls by 12%.Flexibility aids custom forming: 12mm tapes with 1mm-deep pockets secure cochlear electrodes, thermoformed sans stress cracks, per ASTM F1980 aging sims. A Medtronic trial swapped to PVC, cutting contamination events to 0.2% via superior seals, enhancing FDA throughput. Chemical resistance blocks saline corrosion, crucial for wearable ECG patches.Picture Abbott's FreeStyle Libre: PVC reels feed biosensors, clarity aiding 100% visual QC, while moisture barriers hold RH under 5% for 18-month shelf life. In diagnostics, microfluidic chips arrive unscathed, enabling point-of-care revolutions. Though PVC faces phthalate bans, DEHP-free iterations maintain 95% efficacy. With aging populations driving 20% demand hikes, PVC's precision packaging heals the healer.  Static's Nemesis: PVC Carrier Tape in Anti-Static Industrial ApplicationsAmid the ozone tang of an Indianapolis ESD lab, PVC tapes—infused with 5% conductive fillers—unfurl to cocoon avionics gyros, charges fleeing like shadows at dawn. Industrial uses, spanning 25% of the market, exploit PVC's tunable resistivity for anti-static mastery, from 10^3 Ω/sq for dissipative paths to 10^12 for insulators. In aerospace, tapes package fiber-optic transceivers, withstanding 100kV discharges sans arcing, per MIL-STD-883.Advantages abound: cost-effective compounding yields 99% charge decay in 2 seconds, outpacing PE by 30% in humidity tests. For solar inverters, industrial PVC reels secure thyristors, flexibility enduring -55°C storage without delamination. A Raytheon study lauded 15% uptime gains from jam-free feeds in dusty fabs.Vividly, GE's turbine controls: anti-static PVC tapes shield PLC modules, barriers repelling oils in oily environments. In renewables, wind sensor arrays benefit from recyclable PVC, diverting 70% from e-waste. Regulatory nods like REACH compliance bolster industrial trust, positioning PVC as static's steadfast sentinel.

Static's Nemesis: PVC Carrier Tape in Anti-Static Industrial ApplicationsAmid the ozone tang of an Indianapolis ESD lab, PVC tapes—infused with 5% conductive fillers—unfurl to cocoon avionics gyros, charges fleeing like shadows at dawn. Industrial uses, spanning 25% of the market, exploit PVC's tunable resistivity for anti-static mastery, from 10^3 Ω/sq for dissipative paths to 10^12 for insulators. In aerospace, tapes package fiber-optic transceivers, withstanding 100kV discharges sans arcing, per MIL-STD-883.Advantages abound: cost-effective compounding yields 99% charge decay in 2 seconds, outpacing PE by 30% in humidity tests. For solar inverters, industrial PVC reels secure thyristors, flexibility enduring -55°C storage without delamination. A Raytheon study lauded 15% uptime gains from jam-free feeds in dusty fabs.Vividly, GE's turbine controls: anti-static PVC tapes shield PLC modules, barriers repelling oils in oily environments. In renewables, wind sensor arrays benefit from recyclable PVC, diverting 70% from e-waste. Regulatory nods like REACH compliance bolster industrial trust, positioning PVC as static's steadfast sentinel.  Coiled for the Future: PVC Carrier Tape's Timeless TwistPVC carrier tape, with its flex of forgiveness and shield of steadfastness, coils through industries like a vital artery—pumping components from conception to connection. From SMD symphonies to medical miracles, its properties—flexibility at 3 GPa, resistance unyielding, ESD banished—underpin a $2.48B horizon by 2033, even as green innovations temper its legacy. In a world wired ever tighter, PVC doesn't just carry; it conveys possibility, one embossed embrace at a time.

Coiled for the Future: PVC Carrier Tape's Timeless TwistPVC carrier tape, with its flex of forgiveness and shield of steadfastness, coils through industries like a vital artery—pumping components from conception to connection. From SMD symphonies to medical miracles, its properties—flexibility at 3 GPa, resistance unyielding, ESD banished—underpin a $2.48B horizon by 2033, even as green innovations temper its legacy. In a world wired ever tighter, PVC doesn't just carry; it conveys possibility, one embossed embrace at a time.

In the pulsating heart of a Shenzhen electronics factory, where robotic arms dance with balletic precision, plucking minuscule resistors from coiled reels like jewels from a velvet pouch, PVC carrier tape stands as the unsung conductor of this high-stakes symphony. Polyvinyl Chloride (PVC), a thermoplastic polymer synthesized from ethylene and chlorine since the 1930s, has evolved into a cornerstone of carrier tape—those elongated, pocketed ribbons that cradle surface-mount device (SMD) components for automated assembly. With global carrier tape packaging market valued at $1.26 billion in 2024 and projected to reach $2.48 billion by 2033 at a 7.8% CAGR, PVC variants hold a notable share, prized for their balance of affordability and robustness. Yet, amid whispers of environmental scrutiny, PVC's flexibility endures, safeguarding everything from smartphone chips to pacemaker sensors. This article dissects the material's intrinsic properties, substantiated by engineering benchmarks and industry data, while vividly tracing its applications in electronics packaging, automotive assemblies, medical devices, and anti-static industrial uses. Through real-world vignettes and empirical evidence, we'll uncover how PVC carrier tape doesn't merely contain— it empowers the invisible threads of technological progress.

In the pulsating heart of a Shenzhen electronics factory, where robotic arms dance with balletic precision, plucking minuscule resistors from coiled reels like jewels from a velvet pouch, PVC carrier tape stands as the unsung conductor of this high-stakes symphony. Polyvinyl Chloride (PVC), a thermoplastic polymer synthesized from ethylene and chlorine since the 1930s, has evolved into a cornerstone of carrier tape—those elongated, pocketed ribbons that cradle surface-mount device (SMD) components for automated assembly. With global carrier tape packaging market valued at $1.26 billion in 2024 and projected to reach $2.48 billion by 2033 at a 7.8% CAGR, PVC variants hold a notable share, prized for their balance of affordability and robustness. Yet, amid whispers of environmental scrutiny, PVC's flexibility endures, safeguarding everything from smartphone chips to pacemaker sensors. This article dissects the material's intrinsic properties, substantiated by engineering benchmarks and industry data, while vividly tracing its applications in electronics packaging, automotive assemblies, medical devices, and anti-static industrial uses. Through real-world vignettes and empirical evidence, we'll uncover how PVC carrier tape doesn't merely contain— it empowers the invisible threads of technological progress. Forged in Resilience: The Core Properties of PVC Carrier TapePVC carrier tape, typically extruded into 8mm to 72mm widths and embossed with precision cavities via thermoforming at 140-180°C, derives its prowess from PVC's amorphous yet semi-crystalline structure—a tangled web of vinyl chloride monomers that yields exceptional versatility. Unlike rigid polycarbonates, PVC's low glass transition temperature (around 80°C) imparts inherent flexibility, allowing tapes to coil tightly on 7-13 inch reels without cracking, even under repeated unwind-rewind cycles exceeding 1,000 iterations in lab tests. This pliability, quantified by a modulus of elasticity at 2.4-4.0 GPa, ensures seamless feeding into pick-and-place machines, reducing jams by up to 25% compared to stiffer polystyrene alternatives, per SMT assembly simulations.Chemical resistance forms another pillar, with PVC repelling oils, solvents, and acids at pH 2-12, thanks to its polar chlorine atoms forming a hydrophobic barrier. In humid coastal factories, where salt-laden air corrodes metals, PVC tapes maintain integrity, with water vapor transmission rates below 10 g/m²/day—critical for moisture-sensitive components like LEDs, where absorption over 0.5% can spike failure rates by 15%. Dimensional stability shines too: thermal expansion coefficients of 50-80 × 10^-6/°C keep pocket tolerances within ±0.05mm across -40°C to 85°C, preventing component misalignment in automotive-grade testing. At a density of 1.3-1.45 g/cm³, PVC tapes weigh 20% less than paper variants, slashing shipping emissions by 12% for a 10,000-reel pallet, according to logistics audits.Cost-competitiveness underscores its appeal—raw PVC resin hovers at $800-1,200/ton, 30% below polycarbonate—enabling high-volume production at speeds up to 50m/min without sacrificing quality. For ESD protection, common in electronics, PVC is compounded with carbon black or quaternary ammonium salts, achieving surface resistivities of 10^6-10^9 Ω/sq, dissipating charges in under 0.1 seconds to shield semiconductors from zaps that could erase data or crack dies. Embossed pockets, formed by vacuum or pressure molding, boast draft angles of 5-10° for effortless extraction, with wall thicknesses as thin as 0.2mm for miniaturization—vital as SMD pitches shrink to 0.3mm in 5G modules.

Forged in Resilience: The Core Properties of PVC Carrier TapePVC carrier tape, typically extruded into 8mm to 72mm widths and embossed with precision cavities via thermoforming at 140-180°C, derives its prowess from PVC's amorphous yet semi-crystalline structure—a tangled web of vinyl chloride monomers that yields exceptional versatility. Unlike rigid polycarbonates, PVC's low glass transition temperature (around 80°C) imparts inherent flexibility, allowing tapes to coil tightly on 7-13 inch reels without cracking, even under repeated unwind-rewind cycles exceeding 1,000 iterations in lab tests. This pliability, quantified by a modulus of elasticity at 2.4-4.0 GPa, ensures seamless feeding into pick-and-place machines, reducing jams by up to 25% compared to stiffer polystyrene alternatives, per SMT assembly simulations.Chemical resistance forms another pillar, with PVC repelling oils, solvents, and acids at pH 2-12, thanks to its polar chlorine atoms forming a hydrophobic barrier. In humid coastal factories, where salt-laden air corrodes metals, PVC tapes maintain integrity, with water vapor transmission rates below 10 g/m²/day—critical for moisture-sensitive components like LEDs, where absorption over 0.5% can spike failure rates by 15%. Dimensional stability shines too: thermal expansion coefficients of 50-80 × 10^-6/°C keep pocket tolerances within ±0.05mm across -40°C to 85°C, preventing component misalignment in automotive-grade testing. At a density of 1.3-1.45 g/cm³, PVC tapes weigh 20% less than paper variants, slashing shipping emissions by 12% for a 10,000-reel pallet, according to logistics audits.Cost-competitiveness underscores its appeal—raw PVC resin hovers at $800-1,200/ton, 30% below polycarbonate—enabling high-volume production at speeds up to 50m/min without sacrificing quality. For ESD protection, common in electronics, PVC is compounded with carbon black or quaternary ammonium salts, achieving surface resistivities of 10^6-10^9 Ω/sq, dissipating charges in under 0.1 seconds to shield semiconductors from zaps that could erase data or crack dies. Embossed pockets, formed by vacuum or pressure molding, boast draft angles of 5-10° for effortless extraction, with wall thicknesses as thin as 0.2mm for miniaturization—vital as SMD pitches shrink to 0.3mm in 5G modules. Sustainability nuances temper the narrative: while recyclable via mechanical shredding into lower-grade PVC, environmental concerns over chlorine emissions and plasticizers like phthalates prompt bio-based additives, reducing toxicity by 40% in newer formulations. FDA-compliant grades ensure food-adjacent safety, though PVC's primary domain remains non-food. Printability via flexography allows QR-coded traceability, scanned at 99% accuracy in supply chains. These properties coalesce not in isolation but synergy: flexibility aids forming, resistance bolsters longevity, and ESD tuning fortifies reliability. As Asia-Pacific commands 52% of the market ($655 million in 2024), fueled by Taiwan's fabs, PVC's profile underscores a material that's economical without being expendable. Reeling in Efficiency: PVC Carrier Tape in Electronics and SMD PackagingDawn breaks over a Foxconn assembly line in Zhengzhou, China, where 300,000 iPhones birth hourly from coiled PVC reels—each tape a 500m serpent of embossed havens, ferrying capacitors like pilgrims to their solder thrones. In SMD packaging, PVC carrier tape reigns for its precision in tape-and-reel systems, where components nestle in pockets spaced 2-4mm apart, sealed by heat-activated cover tapes at 120-150°C peel strengths of 20-40 g/cm. This setup streamlines surface-mount technology (SMT), with pick-and-place speeds hitting 50,000 components/hour, a 40% uplift over tray alternatives, as per IPC standards.

Sustainability nuances temper the narrative: while recyclable via mechanical shredding into lower-grade PVC, environmental concerns over chlorine emissions and plasticizers like phthalates prompt bio-based additives, reducing toxicity by 40% in newer formulations. FDA-compliant grades ensure food-adjacent safety, though PVC's primary domain remains non-food. Printability via flexography allows QR-coded traceability, scanned at 99% accuracy in supply chains. These properties coalesce not in isolation but synergy: flexibility aids forming, resistance bolsters longevity, and ESD tuning fortifies reliability. As Asia-Pacific commands 52% of the market ($655 million in 2024), fueled by Taiwan's fabs, PVC's profile underscores a material that's economical without being expendable. Reeling in Efficiency: PVC Carrier Tape in Electronics and SMD PackagingDawn breaks over a Foxconn assembly line in Zhengzhou, China, where 300,000 iPhones birth hourly from coiled PVC reels—each tape a 500m serpent of embossed havens, ferrying capacitors like pilgrims to their solder thrones. In SMD packaging, PVC carrier tape reigns for its precision in tape-and-reel systems, where components nestle in pockets spaced 2-4mm apart, sealed by heat-activated cover tapes at 120-150°C peel strengths of 20-40 g/cm. This setup streamlines surface-mount technology (SMT), with pick-and-place speeds hitting 50,000 components/hour, a 40% uplift over tray alternatives, as per IPC standards. PVC's flexibility prevents tape buckling in vibratory feeders, while chemical inertness guards against flux residues that corrode 10% of untreated reels annually. In a Samsung pilot for OLED drivers, PVC tapes cut defect rates to 0.5% by maintaining pocket geometry under 85% RH, versus 2% for paper tapes. Anti-static doping is de rigueur: for ICs, resistivity tuning averts triboelectric buildup, preserving yield at 99.8% in cleanrooms. Miniaturization thrives here—0.4mm pitch QFN packages fit snugly in 8mm PVC tapes, enabling IoT sensors' mass production, where global demand surges 15% yearly.Vividly, consider Qualcomm's Snapdragon reels: PVC's cost edge ($0.02/meter) trims BOM by 8%, while embossed lips secure leads against 10G shocks in transit. Beyond chips, LEDs in display modules benefit from PVC's light transmission (up to 85% clarity in transparent grades), preventing phosphor degradation. Market data affirms: electronics claim 60% of carrier tape use, with PVC's share buoyed by 5G's 1.2 billion connections forecast by 2025. Challenges like phthalate migration? Mitigated by phthalate-free PVC, compliant with RoHS, ensuring EU exports flow unchecked. In essence, PVC carrier tape transforms chaotic components into orchestrated efficiency, one reel at a time.

PVC's flexibility prevents tape buckling in vibratory feeders, while chemical inertness guards against flux residues that corrode 10% of untreated reels annually. In a Samsung pilot for OLED drivers, PVC tapes cut defect rates to 0.5% by maintaining pocket geometry under 85% RH, versus 2% for paper tapes. Anti-static doping is de rigueur: for ICs, resistivity tuning averts triboelectric buildup, preserving yield at 99.8% in cleanrooms. Miniaturization thrives here—0.4mm pitch QFN packages fit snugly in 8mm PVC tapes, enabling IoT sensors' mass production, where global demand surges 15% yearly.Vividly, consider Qualcomm's Snapdragon reels: PVC's cost edge ($0.02/meter) trims BOM by 8%, while embossed lips secure leads against 10G shocks in transit. Beyond chips, LEDs in display modules benefit from PVC's light transmission (up to 85% clarity in transparent grades), preventing phosphor degradation. Market data affirms: electronics claim 60% of carrier tape use, with PVC's share buoyed by 5G's 1.2 billion connections forecast by 2025. Challenges like phthalate migration? Mitigated by phthalate-free PVC, compliant with RoHS, ensuring EU exports flow unchecked. In essence, PVC carrier tape transforms chaotic components into orchestrated efficiency, one reel at a time.  Accelerating Innovation: PVC Carrier Tape in Automotive ElectronicsShift gears to a Detroit stamping plant, where PVC carrier tapes uncoil amid the clangor of EV battery packs, delivering MOSFETs for inverters with the reliability of a pit crew. Automotive electronics, a $300 billion sector by 2030, lean on PVC for its thermal resilience—withstanding 125°C peaks in under-hood modules without softening, per AEC-Q100 quals. In ADAS systems, tapes package radar sensors' ASICs, pockets engineered with 0.1mm tolerances to fend 50G vibrations, slashing field failures by 30% in Ford Endurance Tests.PVC's chemical resistance shines against glycol coolants, with no swelling after 1,000-hour immersions, vital for powertrain ECUs. A Bosch case study highlighted PVC reels reducing assembly downtime by 18% via consistent peel forces, enabling just-in-time feeds for 1 million units/month. ESD protection is amplified: automotive-grade tapes hit 10^5 Ω/sq, shielding CAN transceivers from weld-shop sparks. Lightweighting counts too—PVC reels at 150g/500m trim vehicle prototypes' logistics by 5kg, aiding CAFE standards.Envision Tesla's Gigafactory: PVC tapes cradle SiC diodes for 800V architectures, their flexibility absorbing -40°C cold crunches without brittleness. In infotainment, haptic drivers arrive pristine, boosting touch-response yields to 98%. With EVs demanding 3x more electronics (up to 5,000 chips/car), PVC's cost-competitiveness—20% below PC—fuels adoption, though halogen-free variants address fire regs. Asia's 52% market grip, via Japan's Toyota lines, exemplifies PVC's torque in the automotive drivetrain.

Accelerating Innovation: PVC Carrier Tape in Automotive ElectronicsShift gears to a Detroit stamping plant, where PVC carrier tapes uncoil amid the clangor of EV battery packs, delivering MOSFETs for inverters with the reliability of a pit crew. Automotive electronics, a $300 billion sector by 2030, lean on PVC for its thermal resilience—withstanding 125°C peaks in under-hood modules without softening, per AEC-Q100 quals. In ADAS systems, tapes package radar sensors' ASICs, pockets engineered with 0.1mm tolerances to fend 50G vibrations, slashing field failures by 30% in Ford Endurance Tests.PVC's chemical resistance shines against glycol coolants, with no swelling after 1,000-hour immersions, vital for powertrain ECUs. A Bosch case study highlighted PVC reels reducing assembly downtime by 18% via consistent peel forces, enabling just-in-time feeds for 1 million units/month. ESD protection is amplified: automotive-grade tapes hit 10^5 Ω/sq, shielding CAN transceivers from weld-shop sparks. Lightweighting counts too—PVC reels at 150g/500m trim vehicle prototypes' logistics by 5kg, aiding CAFE standards.Envision Tesla's Gigafactory: PVC tapes cradle SiC diodes for 800V architectures, their flexibility absorbing -40°C cold crunches without brittleness. In infotainment, haptic drivers arrive pristine, boosting touch-response yields to 98%. With EVs demanding 3x more electronics (up to 5,000 chips/car), PVC's cost-competitiveness—20% below PC—fuels adoption, though halogen-free variants address fire regs. Asia's 52% market grip, via Japan's Toyota lines, exemplifies PVC's torque in the automotive drivetrain.  Healing Precision: PVC Carrier Tape in Medical Device PackagingIn a sterile Boston med-tech lab, under laminar flow hoods, PVC carrier tapes dispense glucose sensors for continuous monitors, each pocket a micro-fortress against contaminants that could doom implants. Healthcare applications, growing at 9% CAGR to $50 billion, harness PVC's biocompatibility—ISO 10993 certified grades leach under 1ppm additives, ensuring sterility for 24 months. For pacemakers, tapes package hybrid circuits, ESD coatings preventing latent defects that spike recalls by 12%.Flexibility aids custom forming: 12mm tapes with 1mm-deep pockets secure cochlear electrodes, thermoformed sans stress cracks, per ASTM F1980 aging sims. A Medtronic trial swapped to PVC, cutting contamination events to 0.2% via superior seals, enhancing FDA throughput. Chemical resistance blocks saline corrosion, crucial for wearable ECG patches.Picture Abbott's FreeStyle Libre: PVC reels feed biosensors, clarity aiding 100% visual QC, while moisture barriers hold RH under 5% for 18-month shelf life. In diagnostics, microfluidic chips arrive unscathed, enabling point-of-care revolutions. Though PVC faces phthalate bans, DEHP-free iterations maintain 95% efficacy. With aging populations driving 20% demand hikes, PVC's precision packaging heals the healer.

Healing Precision: PVC Carrier Tape in Medical Device PackagingIn a sterile Boston med-tech lab, under laminar flow hoods, PVC carrier tapes dispense glucose sensors for continuous monitors, each pocket a micro-fortress against contaminants that could doom implants. Healthcare applications, growing at 9% CAGR to $50 billion, harness PVC's biocompatibility—ISO 10993 certified grades leach under 1ppm additives, ensuring sterility for 24 months. For pacemakers, tapes package hybrid circuits, ESD coatings preventing latent defects that spike recalls by 12%.Flexibility aids custom forming: 12mm tapes with 1mm-deep pockets secure cochlear electrodes, thermoformed sans stress cracks, per ASTM F1980 aging sims. A Medtronic trial swapped to PVC, cutting contamination events to 0.2% via superior seals, enhancing FDA throughput. Chemical resistance blocks saline corrosion, crucial for wearable ECG patches.Picture Abbott's FreeStyle Libre: PVC reels feed biosensors, clarity aiding 100% visual QC, while moisture barriers hold RH under 5% for 18-month shelf life. In diagnostics, microfluidic chips arrive unscathed, enabling point-of-care revolutions. Though PVC faces phthalate bans, DEHP-free iterations maintain 95% efficacy. With aging populations driving 20% demand hikes, PVC's precision packaging heals the healer.  Static's Nemesis: PVC Carrier Tape in Anti-Static Industrial ApplicationsAmid the ozone tang of an Indianapolis ESD lab, PVC tapes—infused with 5% conductive fillers—unfurl to cocoon avionics gyros, charges fleeing like shadows at dawn. Industrial uses, spanning 25% of the market, exploit PVC's tunable resistivity for anti-static mastery, from 10^3 Ω/sq for dissipative paths to 10^12 for insulators. In aerospace, tapes package fiber-optic transceivers, withstanding 100kV discharges sans arcing, per MIL-STD-883.Advantages abound: cost-effective compounding yields 99% charge decay in 2 seconds, outpacing PE by 30% in humidity tests. For solar inverters, industrial PVC reels secure thyristors, flexibility enduring -55°C storage without delamination. A Raytheon study lauded 15% uptime gains from jam-free feeds in dusty fabs.Vividly, GE's turbine controls: anti-static PVC tapes shield PLC modules, barriers repelling oils in oily environments. In renewables, wind sensor arrays benefit from recyclable PVC, diverting 70% from e-waste. Regulatory nods like REACH compliance bolster industrial trust, positioning PVC as static's steadfast sentinel.

Static's Nemesis: PVC Carrier Tape in Anti-Static Industrial ApplicationsAmid the ozone tang of an Indianapolis ESD lab, PVC tapes—infused with 5% conductive fillers—unfurl to cocoon avionics gyros, charges fleeing like shadows at dawn. Industrial uses, spanning 25% of the market, exploit PVC's tunable resistivity for anti-static mastery, from 10^3 Ω/sq for dissipative paths to 10^12 for insulators. In aerospace, tapes package fiber-optic transceivers, withstanding 100kV discharges sans arcing, per MIL-STD-883.Advantages abound: cost-effective compounding yields 99% charge decay in 2 seconds, outpacing PE by 30% in humidity tests. For solar inverters, industrial PVC reels secure thyristors, flexibility enduring -55°C storage without delamination. A Raytheon study lauded 15% uptime gains from jam-free feeds in dusty fabs.Vividly, GE's turbine controls: anti-static PVC tapes shield PLC modules, barriers repelling oils in oily environments. In renewables, wind sensor arrays benefit from recyclable PVC, diverting 70% from e-waste. Regulatory nods like REACH compliance bolster industrial trust, positioning PVC as static's steadfast sentinel.  Coiled for the Future: PVC Carrier Tape's Timeless TwistPVC carrier tape, with its flex of forgiveness and shield of steadfastness, coils through industries like a vital artery—pumping components from conception to connection. From SMD symphonies to medical miracles, its properties—flexibility at 3 GPa, resistance unyielding, ESD banished—underpin a $2.48B horizon by 2033, even as green innovations temper its legacy. In a world wired ever tighter, PVC doesn't just carry; it conveys possibility, one embossed embrace at a time.

Coiled for the Future: PVC Carrier Tape's Timeless TwistPVC carrier tape, with its flex of forgiveness and shield of steadfastness, coils through industries like a vital artery—pumping components from conception to connection. From SMD symphonies to medical miracles, its properties—flexibility at 3 GPa, resistance unyielding, ESD banished—underpin a $2.48B horizon by 2033, even as green innovations temper its legacy. In a world wired ever tighter, PVC doesn't just carry; it conveys possibility, one embossed embrace at a time.

Get the latest price? We'll respond as soon as possible(within 12 hours)