Crystal Clear Resilience: Unveiling the Properties and Versatile Applications of Polystyrene (PS) Film

2025-10-30 17:01 In the fast-paced arena of modern packaging, where every glance at a shelf can sway a purchase and every layer must safeguard against unseen threats, polystyrene (PS) film steps forward as a beacon of clarity and strength. This versatile thermoplastic, born from the polymerization of styrene monomers, isn't merely a wrapper—it's a silent architect that cradles products with unyielding precision while inviting the eye to explore. Envision the satisfying snap of peeling back a blister pack of fresh pastries, revealing golden croissants bathed in soft morning light through an impeccably clear film, or the reassuring visibility of neatly arrayed tablets in a medicine blister, their forms unmistakable amid the film's pristine surface. Transparent PS film embodies this duality: a rigid shield that whispers elegance, transforming everyday essentials into displays of temptation and trust.

In the fast-paced arena of modern packaging, where every glance at a shelf can sway a purchase and every layer must safeguard against unseen threats, polystyrene (PS) film steps forward as a beacon of clarity and strength. This versatile thermoplastic, born from the polymerization of styrene monomers, isn't merely a wrapper—it's a silent architect that cradles products with unyielding precision while inviting the eye to explore. Envision the satisfying snap of peeling back a blister pack of fresh pastries, revealing golden croissants bathed in soft morning light through an impeccably clear film, or the reassuring visibility of neatly arrayed tablets in a medicine blister, their forms unmistakable amid the film's pristine surface. Transparent PS film embodies this duality: a rigid shield that whispers elegance, transforming everyday essentials into displays of temptation and trust.Polystyrene film's journey traces back to the 1930s, when its lightweight rigidity first caught the eye of innovators seeking alternatives to glass and metal. Today, in its film form—typically extruded to thicknesses of 0.2 to 1.0 mm—it owes its prowess to a molecular backbone of repeating phenyl-ethylene units, yielding a material that's 88-92% transparent to visible light. This optical excellence isn't accidental; it's engineered through controlled polymerization, minimizing haze to under 3% and ensuring distortion-free views. Yet, transparency is merely the invitation; the film's true symphony plays out in its constellation of properties, each note harmonizing to meet the demands of rigorous applications.

Thermoformability is another virtuoso performance, enabled by a glass transition temperature of 100-105°C. Sheets heat rapidly to 140-160°C, draping over molds with the grace of molten silk before cooling into intricate contours in seconds. This low-energy process—requiring 20-30% less heat than alternatives—slashes production times, allowing lines to churn out 500-1,000 units per minute. The film's low shrinkage (under 0.5%) ensures dimensional stability, so a molded cavity for a fork remains exact, avoiding misfits that plague softer materials.

Thermoformability is another virtuoso performance, enabled by a glass transition temperature of 100-105°C. Sheets heat rapidly to 140-160°C, draping over molds with the grace of molten silk before cooling into intricate contours in seconds. This low-energy process—requiring 20-30% less heat than alternatives—slashes production times, allowing lines to churn out 500-1,000 units per minute. The film's low shrinkage (under 0.5%) ensures dimensional stability, so a molded cavity for a fork remains exact, avoiding misfits that plague softer materials.Barrier properties, while not impenetrable, offer targeted defense. With a water vapor transmission rate (WVTR) of 50-100 g/m²/day and oxygen transmission rate (OTR) around 1,500-2,000 cm³/m²/day, PS film excels in short-shelf-life scenarios, insulating against humidity and oxidation to preserve flavors and textures. Its chemical inertness shines here: resistant to dilute acids, bases, and aqueous solutions, it repels spills from sauces or sodas without leaching flavors. Density at 1.04-1.06 g/cm³ keeps it featherlight, reducing shipping weights by up to 40% versus glass, while thermal insulation—conductivity as low as 0.03 W/m·K in foamed variants—maintains chill in cold chains, extending dairy freshness by 15-20%.

Venturing into the charged frontier of anti-static packaging, PS film emerges as the invisible force field, taming the wild sparks that threaten delicate tech. Electronics—from silicon wafers to assembled drones—crave sanctuary from electrostatic discharge (ESD), a silent killer zapping circuits with voltages up to 15kV. Enter anti-static PS: infused with migratory additives like ethoxylated amines or carbon fillers, it dials surface resistivity to 10^9-10^11 ohms/sq, bleeding charges in under 2 seconds per ESD standards. Envision a humming cleanroom: fragile sensors nested in PS blisters, their golden leads visible for inspection, yet cocooned against the static whisper of gloved hands.This film's transparency is no afterthought; haze below 4% allows non-destructive verification, trimming QA times by 35%. Extruded with pink tints for quick ID, it's slit into sheets or bags, thermoformed into trays that interlock like Lego for dense storage. In practice, a circuit board fabricator might shield 1,000 units per run, the film's uniform dissipation—stable across 10-90% humidity—foiling static surges from dry winters. For consumer packs, like blister-wrapped earbuds, it adds peace of mind: shoppers spy the prize, knowing ESD-safe transport preserved performance. HIPS variants amp toughness for rough rides, enduring 10J impacts without fracturing, while lightweight design (saving 20% on freight) keeps costs grounded. In explosive-risk zones, like battery assembly, its non-conductive core prevents ignition, a quiet hero in the electric age.

Venturing into the charged frontier of anti-static packaging, PS film emerges as the invisible force field, taming the wild sparks that threaten delicate tech. Electronics—from silicon wafers to assembled drones—crave sanctuary from electrostatic discharge (ESD), a silent killer zapping circuits with voltages up to 15kV. Enter anti-static PS: infused with migratory additives like ethoxylated amines or carbon fillers, it dials surface resistivity to 10^9-10^11 ohms/sq, bleeding charges in under 2 seconds per ESD standards. Envision a humming cleanroom: fragile sensors nested in PS blisters, their golden leads visible for inspection, yet cocooned against the static whisper of gloved hands.This film's transparency is no afterthought; haze below 4% allows non-destructive verification, trimming QA times by 35%. Extruded with pink tints for quick ID, it's slit into sheets or bags, thermoformed into trays that interlock like Lego for dense storage. In practice, a circuit board fabricator might shield 1,000 units per run, the film's uniform dissipation—stable across 10-90% humidity—foiling static surges from dry winters. For consumer packs, like blister-wrapped earbuds, it adds peace of mind: shoppers spy the prize, knowing ESD-safe transport preserved performance. HIPS variants amp toughness for rough rides, enduring 10J impacts without fracturing, while lightweight design (saving 20% on freight) keeps costs grounded. In explosive-risk zones, like battery assembly, its non-conductive core prevents ignition, a quiet hero in the electric age.  Thermoforming precision is paramount—PS's low melt viscosity fills micro-details flawlessly, achieving tolerances under 0.1 mm for child-resistant pushes. Though its standalone WVTR suits dry powders (extending stability by 6-12 months), lamination with EVOH drops it to 1 g/m²/day, fortifying against humidity in tropical climes. Regulatory nods affirm its purity: extractables under 5 mg/L in simulant tests, inert to drug actives like aspirin or antibiotics. In hospitals, where traceability saves lives, the film's gloss aids barcode scanning at 99% accuracy, cutting errors. A compelling instance: during flu seasons, PS trays for test kits stack 50 high without warp, their impact resistance surviving autoclave-like sterilization proxies. For OTC lines, compact designs fit pill organizers, empowering patients with at-a-glance assurance.PS film's tapestry weaves beyond these pillars, threading into horticulture with seedling trays that nurture growth under its UV-filtered gaze, or retail with cosmetic clamshells that seduce with sparkle. Challenges like solvent sensitivity spur coatings, and brittleness inspires bio-composites, yet its affordability—20-30% cheaper than PET—cements dominance. Looking ahead, smart PS with embedded RFID promises real-time tracking in supply chains, while recycled-content variants hit 50% PCR without clarity loss.

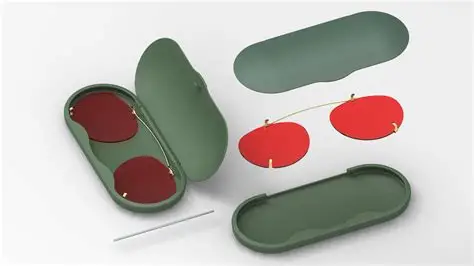

Thermoforming precision is paramount—PS's low melt viscosity fills micro-details flawlessly, achieving tolerances under 0.1 mm for child-resistant pushes. Though its standalone WVTR suits dry powders (extending stability by 6-12 months), lamination with EVOH drops it to 1 g/m²/day, fortifying against humidity in tropical climes. Regulatory nods affirm its purity: extractables under 5 mg/L in simulant tests, inert to drug actives like aspirin or antibiotics. In hospitals, where traceability saves lives, the film's gloss aids barcode scanning at 99% accuracy, cutting errors. A compelling instance: during flu seasons, PS trays for test kits stack 50 high without warp, their impact resistance surviving autoclave-like sterilization proxies. For OTC lines, compact designs fit pill organizers, empowering patients with at-a-glance assurance.PS film's tapestry weaves beyond these pillars, threading into horticulture with seedling trays that nurture growth under its UV-filtered gaze, or retail with cosmetic clamshells that seduce with sparkle. Challenges like solvent sensitivity spur coatings, and brittleness inspires bio-composites, yet its affordability—20-30% cheaper than PET—cements dominance. Looking ahead, smart PS with embedded RFID promises real-time tracking in supply chains, while recycled-content variants hit 50% PCR without clarity loss. In essence, polystyrene film isn't just material; it's the clear thread binding protection to presentation, a resilient partner in humanity's daily rituals. From the crunch of a fresh apple slice to the pop of a vital dose, it illuminates the invisible labor of safeguarding what matters—one transparent embrace at a time.

In essence, polystyrene film isn't just material; it's the clear thread binding protection to presentation, a resilient partner in humanity's daily rituals. From the crunch of a fresh apple slice to the pop of a vital dose, it illuminates the invisible labor of safeguarding what matters—one transparent embrace at a time.