The Versatile World of PVC/PE Composite Film: Performance Advantages and Wide-Ranging Real-Life Applications

2025-11-28 14:43 The Versatile World of PVC/PE Composite Film: Performance Advantages and Wide-Ranging Real-Life Applications  PVC/PE composite film, commonly known as PVC/PE laminated or co-extruded film, is produced by combining rigid polyvinyl chloride (PVC) with flexible polyethylene (PE) through calendering, extrusion lamination or co-extrusion technology. This combination perfectly balances the excellent transparency and rigidity from PVC with outstanding toughness, heat-sealing performance and low-temperature resistance from PE. The resulting composite film exhibits superior comprehensive properties that single-layer PVC or PE film cannot match, making it one of the most widely used flexible packaging materials in pharmaceutical, food, electronics, daily consumer goods and industrial fields.

PVC/PE composite film, commonly known as PVC/PE laminated or co-extruded film, is produced by combining rigid polyvinyl chloride (PVC) with flexible polyethylene (PE) through calendering, extrusion lamination or co-extrusion technology. This combination perfectly balances the excellent transparency and rigidity from PVC with outstanding toughness, heat-sealing performance and low-temperature resistance from PE. The resulting composite film exhibits superior comprehensive properties that single-layer PVC or PE film cannot match, making it one of the most widely used flexible packaging materials in pharmaceutical, food, electronics, daily consumer goods and industrial fields. 1. Core Physical and Chemical Properties That Determine Its SuccessOutstanding transparency and gloss

1. Core Physical and Chemical Properties That Determine Its SuccessOutstanding transparency and gloss

Medical-grade PVC/PE film can achieve light transmittance above 90%, rivaling glass. This crystal-clear appearance allows consumers to directly see the color, shape and quantity of contents, significantly enhancing product display effect and consumer trust—especially critical in pharmaceutical and food packaging.Excellent barrier performance

Although PVC itself has moderate oxygen and water vapor barrier properties, after compounding with high-barrier PE or adding EVOH intermediate layers, the composite film’s oxygen transmission rate (OTR) can be reduced to below 1 cm³/m²·24h·0.1MPa, and water vapor transmission rate (WVTR) below 2 g/m²·24h. This effectively extends the shelf life of moisture- and oxygen-sensitive drugs and foods. Wide heat-sealing temperature window and strong seal strength

Wide heat-sealing temperature window and strong seal strength

The PE layer serves as the heat-sealing layer, with heat-sealing initiation temperature as low as 105–120 °C, and peel strength after sealing easily exceeding 8–12 N/15mm (far higher than ordinary PVC blister sealing with aluminum foil). This ensures the package remains intact even under severe transportation vibration or drop conditions.Superior cold resistance and impact resistance

Pure PVC becomes brittle below 0 °C, but after compounding with PE, the film maintains good flexibility even at –40 °C, with dart impact strength greater than 800 g. This characteristic makes it particularly suitable for refrigerated and frozen food packaging and low-temperature transport of pharmaceuticals.**Tunable rigidity and softness

By adjusting the thickness ratio of PVC layer (usually 150–300 μm) to PE layer (30–100 μm), manufacturers can precisely control the film’s stiffness. For pharmaceutical blister packaging requiring high rigidity, a thicker PVC layer is used; for soft bags or shrink film, a thicker PE layer is increased. Antistatic and dust-proof performance

Antistatic and dust-proof performance

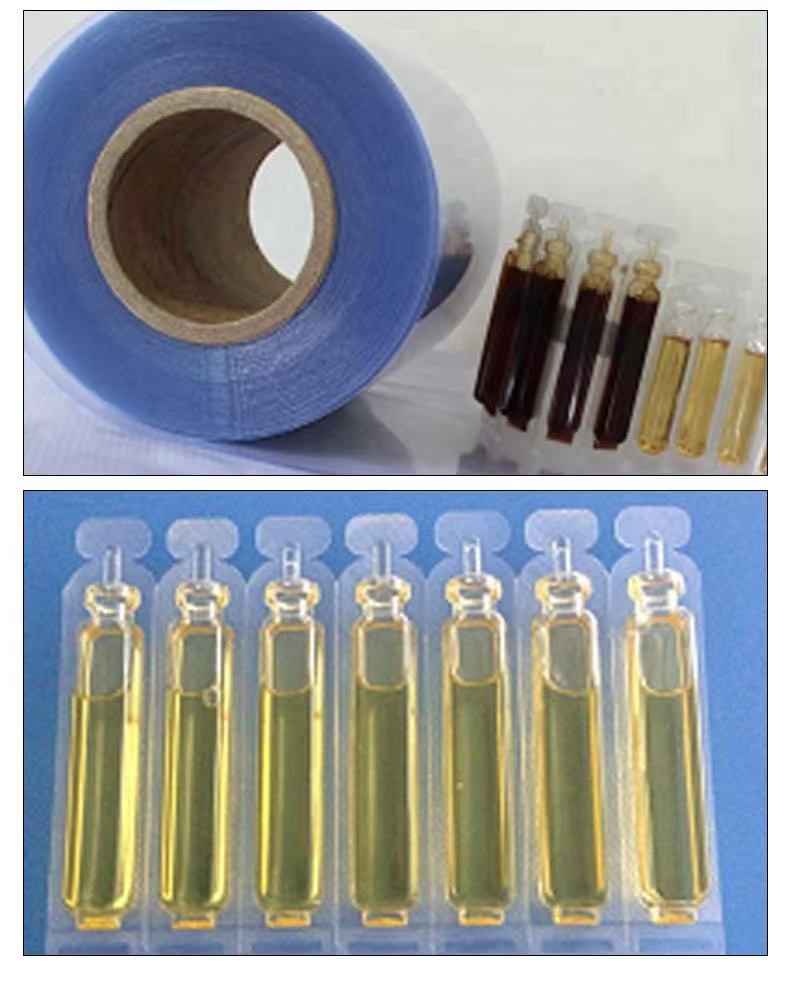

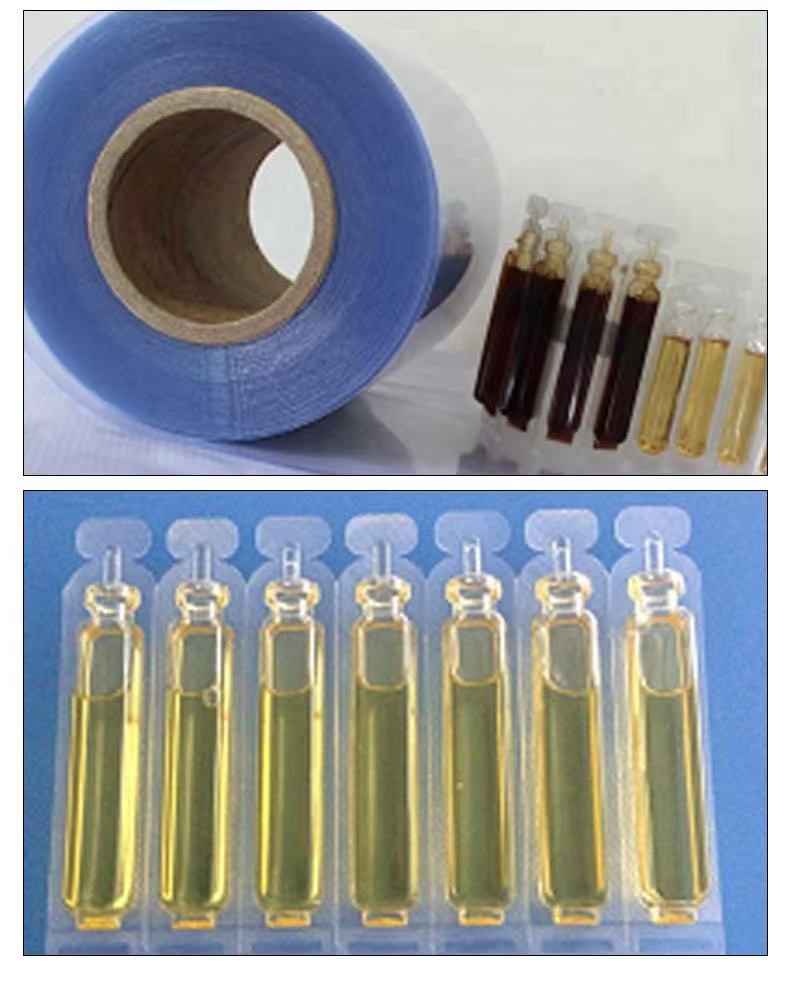

Through adding permanent antistatic agents in the PE layer or surface coating treatment, surface resistivity can be controlled at 10⁸–10¹¹ Ω, effectively preventing dust adsorption and static discharge damage to electronic components.2. Pharmaceutical Blister Packaging for Pharmaceuticals – The Largest Application AreaMore than 65% of global solid oral drugs (tablets, capsules) use PVC/PE composite film as the base material for thermoformed blister packaging, the core reasons being safety, convenience and cost performance.Perfect match with aluminum foil cold forming

PVC/PE film has excellent thermoforming performance. Under 120–140 °C and 0.4–0.6 MPa, it can form clear, uniform cavities of 20 mm depth without thinning or breakage at corners. After filling the drug, it is heat-sealed with pharmaceutical-grade PTP aluminum foil to form a single-dose independent sealed unit that achieves “one dose, one blister,” greatly reducing cross-contamination and misuse risks.Excellent moisture and oxygen barrier protection

For moisture-sensitive drugs such as effervescent tablets, probiotics and certain antibiotics, ordinary 250 μm PVC monolayer film has a water vapor transmission rate of approximately 6–8 g/m²·24h, which cannot meet long-term storage requirements. After compounding 60 μm PE, the transmission rate drops to below 1.5 g/m²·24h, and shelf life can be extended from 12 months to 36 months or more. Child-resistant and senior-friendly design

Child-resistant and senior-friendly design

The composite film can easily adjust rigidity. When paired with peelable or push-through aluminum foil, it can achieve both child-resistant (CR) and senior-friendly (SF) functions, meeting strict EU F=1 level and US CPSC 16 CFR §1700.20 standards.Visual tamper-evident and anti-counterfeiting features

The high transparency allows printing anti-counterfeiting patterns, QR codes, or color-changing inks on the PVC surface, while the PE layer ensures printing ink does not directly contact the drug, ensuring safety. 3. Disposable Tableware and Food Contact PackagingIn recent years, with the explosive growth of takeout and instant foods, PVC/PE film has gained new application space in disposable plastic tableware sealing and fresh food packaging.Lidding film for PP/PS trays

3. Disposable Tableware and Food Contact PackagingIn recent years, with the explosive growth of takeout and instant foods, PVC/PE film has gained new application space in disposable plastic tableware sealing and fresh food packaging.Lidding film for PP/PS trays

Disposable lunch boxes, airline meal trays, and fruit trays mostly use PP or PS as the tray body. PVC/PE composite film (typically 80–120 μm) serves as easy-peel or lock-tight lidding film. The PE layer provides reliable heat sealing with PP at 140–160 °C, with peel strength controllable between 2–15 N/15mm, satisfying both easy opening and leak-proof requirements during transport. High-speed automatic packaging compatibility

High-speed automatic packaging compatibility

The film has a friction coefficient as low as 0.2–0.3 and excellent antistatic properties, perfectly adapting to high-speed horizontal form-fill-seal (HFFS) and vertical form-fill-seal (VFFS) equipment, with packaging speeds reaching 300–600 packs/min, significantly improving production efficiency for large catering enterprises.Microwave and refrigeration dual-use

Special food-grade PVC/PE film can withstand –30 °C freezing to +100 °C microwave heating (limited to low-power defrosting and heating), meeting modern consumers’ demands for “freezer-to-microwave convenience.4. Antistatic Packaging for Electronic and Precision InstrumentsStatic electricity is the invisible killer of integrated circuits, LCD screens, and precision mechanical parts. PVC/PE antistatic film has become the preferred material for inner linings, trays, and carrier tapes in the electronics industry.Permanent antistatic mechanism

By adding polymer-type antistatic agents (such as polyether amide block copolymers) to the PE layer, even after multiple frictions or long-term storage, surface resistivity remains stable at 10⁹–10¹¹ Ω, far superior to small-molecule antistatic agents that migrate and fail.Cleanroom compatibility

High-cleanliness PVC/PE film can reach Class 1000 or even Class 100 cleanroom standards, with particle release <30 particles/ft³ (>0.5 μm) and extremely low ion precipitation (Na⁺, Cl⁻, etc. <1 ppb), fully meeting semiconductor and hard drive manufacturing requirements.Vacuum-formed trays and carrier tapes

The film can be accurately thermoformed into complex anti-static trays with positioning posts, buckling positions, and ventilation holes. Paired with PSD (pressure-sensitive adhesive) cover tape, it forms a complete IC chip carrier tape packaging that meets EIA-481 international standards.5. Other Emerging and Potential Applications

PVC/PE composite film, commonly known as PVC/PE laminated or co-extruded film, is produced by combining rigid polyvinyl chloride (PVC) with flexible polyethylene (PE) through calendering, extrusion lamination or co-extrusion technology. This combination perfectly balances the excellent transparency and rigidity from PVC with outstanding toughness, heat-sealing performance and low-temperature resistance from PE. The resulting composite film exhibits superior comprehensive properties that single-layer PVC or PE film cannot match, making it one of the most widely used flexible packaging materials in pharmaceutical, food, electronics, daily consumer goods and industrial fields.

PVC/PE composite film, commonly known as PVC/PE laminated or co-extruded film, is produced by combining rigid polyvinyl chloride (PVC) with flexible polyethylene (PE) through calendering, extrusion lamination or co-extrusion technology. This combination perfectly balances the excellent transparency and rigidity from PVC with outstanding toughness, heat-sealing performance and low-temperature resistance from PE. The resulting composite film exhibits superior comprehensive properties that single-layer PVC or PE film cannot match, making it one of the most widely used flexible packaging materials in pharmaceutical, food, electronics, daily consumer goods and industrial fields. 1. Core Physical and Chemical Properties That Determine Its SuccessOutstanding transparency and gloss

1. Core Physical and Chemical Properties That Determine Its SuccessOutstanding transparency and glossMedical-grade PVC/PE film can achieve light transmittance above 90%, rivaling glass. This crystal-clear appearance allows consumers to directly see the color, shape and quantity of contents, significantly enhancing product display effect and consumer trust—especially critical in pharmaceutical and food packaging.Excellent barrier performance

Although PVC itself has moderate oxygen and water vapor barrier properties, after compounding with high-barrier PE or adding EVOH intermediate layers, the composite film’s oxygen transmission rate (OTR) can be reduced to below 1 cm³/m²·24h·0.1MPa, and water vapor transmission rate (WVTR) below 2 g/m²·24h. This effectively extends the shelf life of moisture- and oxygen-sensitive drugs and foods.

Wide heat-sealing temperature window and strong seal strength

Wide heat-sealing temperature window and strong seal strengthThe PE layer serves as the heat-sealing layer, with heat-sealing initiation temperature as low as 105–120 °C, and peel strength after sealing easily exceeding 8–12 N/15mm (far higher than ordinary PVC blister sealing with aluminum foil). This ensures the package remains intact even under severe transportation vibration or drop conditions.Superior cold resistance and impact resistance

Pure PVC becomes brittle below 0 °C, but after compounding with PE, the film maintains good flexibility even at –40 °C, with dart impact strength greater than 800 g. This characteristic makes it particularly suitable for refrigerated and frozen food packaging and low-temperature transport of pharmaceuticals.**Tunable rigidity and softness

By adjusting the thickness ratio of PVC layer (usually 150–300 μm) to PE layer (30–100 μm), manufacturers can precisely control the film’s stiffness. For pharmaceutical blister packaging requiring high rigidity, a thicker PVC layer is used; for soft bags or shrink film, a thicker PE layer is increased.

Antistatic and dust-proof performance

Antistatic and dust-proof performanceThrough adding permanent antistatic agents in the PE layer or surface coating treatment, surface resistivity can be controlled at 10⁸–10¹¹ Ω, effectively preventing dust adsorption and static discharge damage to electronic components.2. Pharmaceutical Blister Packaging for Pharmaceuticals – The Largest Application AreaMore than 65% of global solid oral drugs (tablets, capsules) use PVC/PE composite film as the base material for thermoformed blister packaging, the core reasons being safety, convenience and cost performance.Perfect match with aluminum foil cold forming

PVC/PE film has excellent thermoforming performance. Under 120–140 °C and 0.4–0.6 MPa, it can form clear, uniform cavities of 20 mm depth without thinning or breakage at corners. After filling the drug, it is heat-sealed with pharmaceutical-grade PTP aluminum foil to form a single-dose independent sealed unit that achieves “one dose, one blister,” greatly reducing cross-contamination and misuse risks.Excellent moisture and oxygen barrier protection

For moisture-sensitive drugs such as effervescent tablets, probiotics and certain antibiotics, ordinary 250 μm PVC monolayer film has a water vapor transmission rate of approximately 6–8 g/m²·24h, which cannot meet long-term storage requirements. After compounding 60 μm PE, the transmission rate drops to below 1.5 g/m²·24h, and shelf life can be extended from 12 months to 36 months or more.

Child-resistant and senior-friendly design

Child-resistant and senior-friendly designThe composite film can easily adjust rigidity. When paired with peelable or push-through aluminum foil, it can achieve both child-resistant (CR) and senior-friendly (SF) functions, meeting strict EU F=1 level and US CPSC 16 CFR §1700.20 standards.Visual tamper-evident and anti-counterfeiting features

The high transparency allows printing anti-counterfeiting patterns, QR codes, or color-changing inks on the PVC surface, while the PE layer ensures printing ink does not directly contact the drug, ensuring safety.

3. Disposable Tableware and Food Contact PackagingIn recent years, with the explosive growth of takeout and instant foods, PVC/PE film has gained new application space in disposable plastic tableware sealing and fresh food packaging.Lidding film for PP/PS trays

3. Disposable Tableware and Food Contact PackagingIn recent years, with the explosive growth of takeout and instant foods, PVC/PE film has gained new application space in disposable plastic tableware sealing and fresh food packaging.Lidding film for PP/PS traysDisposable lunch boxes, airline meal trays, and fruit trays mostly use PP or PS as the tray body. PVC/PE composite film (typically 80–120 μm) serves as easy-peel or lock-tight lidding film. The PE layer provides reliable heat sealing with PP at 140–160 °C, with peel strength controllable between 2–15 N/15mm, satisfying both easy opening and leak-proof requirements during transport.

High-speed automatic packaging compatibility

High-speed automatic packaging compatibilityThe film has a friction coefficient as low as 0.2–0.3 and excellent antistatic properties, perfectly adapting to high-speed horizontal form-fill-seal (HFFS) and vertical form-fill-seal (VFFS) equipment, with packaging speeds reaching 300–600 packs/min, significantly improving production efficiency for large catering enterprises.Microwave and refrigeration dual-use

Special food-grade PVC/PE film can withstand –30 °C freezing to +100 °C microwave heating (limited to low-power defrosting and heating), meeting modern consumers’ demands for “freezer-to-microwave convenience.4. Antistatic Packaging for Electronic and Precision InstrumentsStatic electricity is the invisible killer of integrated circuits, LCD screens, and precision mechanical parts. PVC/PE antistatic film has become the preferred material for inner linings, trays, and carrier tapes in the electronics industry.Permanent antistatic mechanism

By adding polymer-type antistatic agents (such as polyether amide block copolymers) to the PE layer, even after multiple frictions or long-term storage, surface resistivity remains stable at 10⁹–10¹¹ Ω, far superior to small-molecule antistatic agents that migrate and fail.Cleanroom compatibility

High-cleanliness PVC/PE film can reach Class 1000 or even Class 100 cleanroom standards, with particle release <30 particles/ft³ (>0.5 μm) and extremely low ion precipitation (Na⁺, Cl⁻, etc. <1 ppb), fully meeting semiconductor and hard drive manufacturing requirements.Vacuum-formed trays and carrier tapes

The film can be accurately thermoformed into complex anti-static trays with positioning posts, buckling positions, and ventilation holes. Paired with PSD (pressure-sensitive adhesive) cover tape, it forms a complete IC chip carrier tape packaging that meets EIA-481 international standards.5. Other Emerging and Potential Applications

Medical infusion soft bags: PVC/PE multilayer co-extruded film replaces traditional PVC soft bags, eliminating plasticizer DEHP migration risks.

Agricultural seedling trays and mulch films: Excellent UV resistance to aging and puncture enables long-term outdoor use.

Battery separator base film: Certain modified PVC/PE films are used as lithium battery aluminum-plastic film substrates, providing higher puncture strength.

Building interior decorative films: Combined with printing and embossing technology, they serve as waterproof and easy-to-clean wall panels.

Get the latest price? We'll respond as soon as possible(within 12 hours)