Characteristics and Applications of PE Self-Adhesive Protective Film for Thermal Break Aluminum and Laser-Engraved Steel Plates

2025-06-20 14:13Characteristics and Applications of PE Self-Adhesive Protective Film for Thermal Break Aluminum and Laser-Engraved Steel Plates

In modern manufacturing and construction, protecting high-value surfaces during processing, transportation, and installation is critical to ensuring product quality and customer satisfaction. Polyethylene (PE) self-adhesive protective films have emerged as a versatile and reliable solution for safeguarding materials like thermal break aluminum and laser-engraved steel plates. These films, made from polyethylene with advanced adhesive technologies, offer a combination of flexibility, durability, and residue-free removal that makes them indispensable across industries. This article explores the characteristics of PE self-adhesive protective films and their specific applications in protecting thermal break aluminum and laser-engraved steel plates, providing a comprehensive understanding of their role in enhancing manufacturing efficiency and product integrity.

These films, made from polyethylene with advanced adhesive technologies, offer a combination of flexibility, durability, and residue-free removal that makes them indispensable across industries. This article explores the characteristics of PE self-adhesive protective films and their specific applications in protecting thermal break aluminum and laser-engraved steel plates, providing a comprehensive understanding of their role in enhancing manufacturing efficiency and product integrity.

Characteristics of PE Self-Adhesive Protective Film

PE self-adhesive protective film is a specialized packaging material designed to shield surfaces from scratches, contamination, and environmental damage. Its unique properties make it a preferred choice for protecting delicate and high-value materials. Below are the key characteristics that define its effectiveness:

Environmental Friendliness and Non-Toxicity

PE protective film is crafted from low-density polyethylene (LDPE), a non-toxic, recyclable material that aligns with modern sustainability goals. Unlike traditional adhesive-coated films, self-adhesive PE films rely on co-extrusion processes that eliminate the need for solvent-based glues, reducing volatile organic compound (VOC) emissions. This eco-friendly composition ensures safety for both users and the environment, making it suitable for applications in sensitive industries like electronics and food-related equipment manufacturing.

Residue-Free Adhesion

One of the standout features of PE self-adhesive film is its ability to adhere securely to surfaces without leaving sticky residues upon removal. This is achieved through a co-extrusion process where adhesive properties are integrated into the film itself, rather than applied as a separate layer. The film’s adhesion is stable, with peel strengths typically ranging from 5 to 610 g/50 mm, depending on the surface and application requirements. This ensures that surfaces remain pristine after the film is removed, which is particularly crucial for aesthetic finishes like those on laser-engraved steel plates.

Flexibility and Conformability

PE protective film is highly flexible and can conform to complex shapes and contours, making it ideal for protecting irregularly shaped components such as thermal break aluminum profiles. Its elongation properties, often exceeding 400%, allow it to withstand stretching and deformation during processes like bending, cutting, or deep drawing without tearing or losing adhesion.

Weather and UV Resistance

For applications involving outdoor storage or transportation, PE protective film offers excellent weather resistance. Some formulations include UV stabilizers that prevent degradation for up to six months of outdoor exposure, ensuring that protected surfaces remain unaffected by sunlight, moisture, or temperature fluctuations. This is particularly beneficial for thermal break aluminum used in construction, where profiles may be exposed to the elements before installation.

Customizable Adhesion Levels

PE self-adhesive films are available in low, medium, and high viscosity variants, allowing manufacturers to select the appropriate adhesive strength for specific surfaces. For instance, low-viscosity films are ideal for smooth surfaces like polished aluminum, while high-viscosity films are better suited for rougher textures, such as powder-coated aluminum or engraved steel. This customization ensures optimal performance across diverse applications.

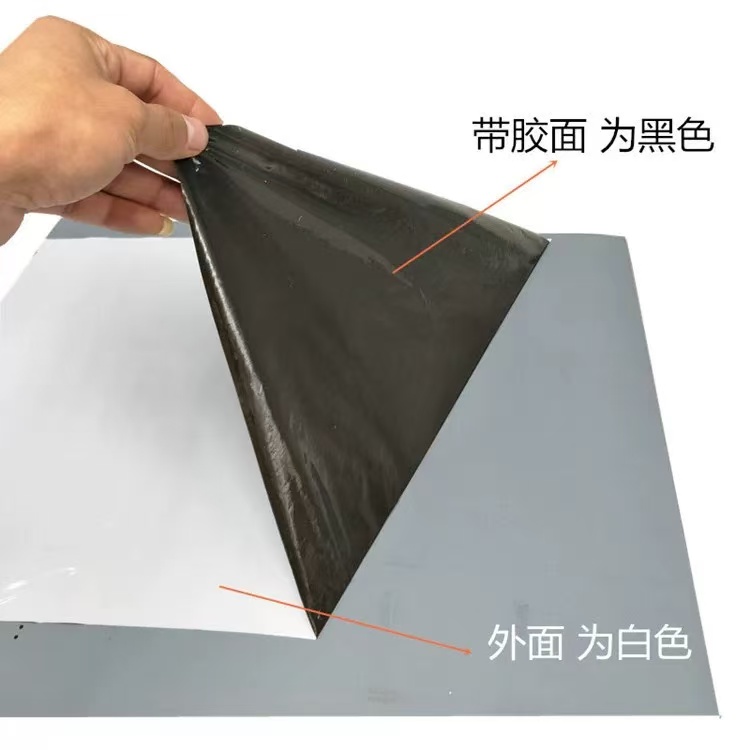

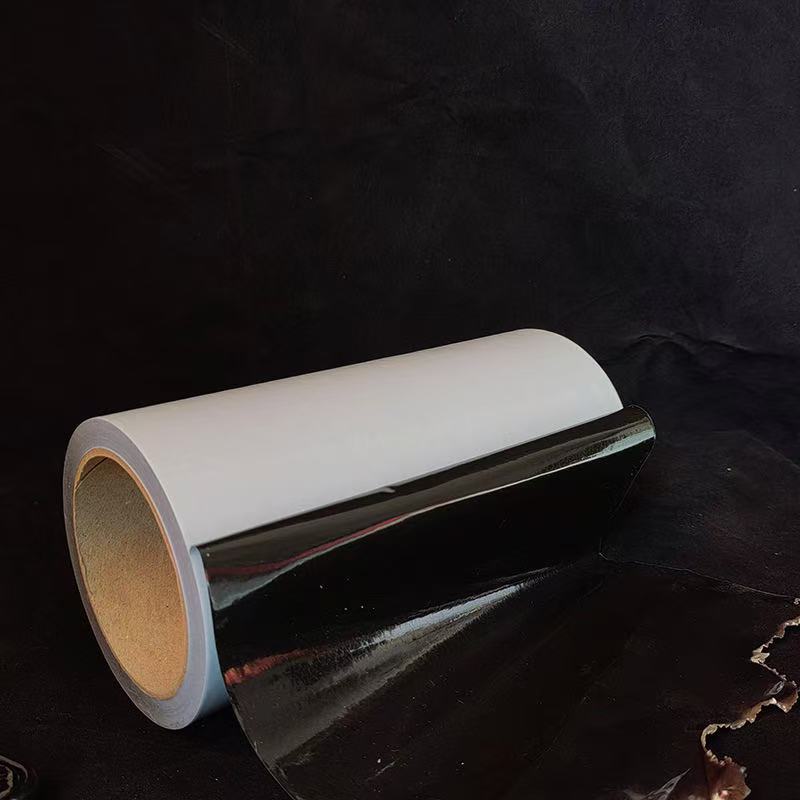

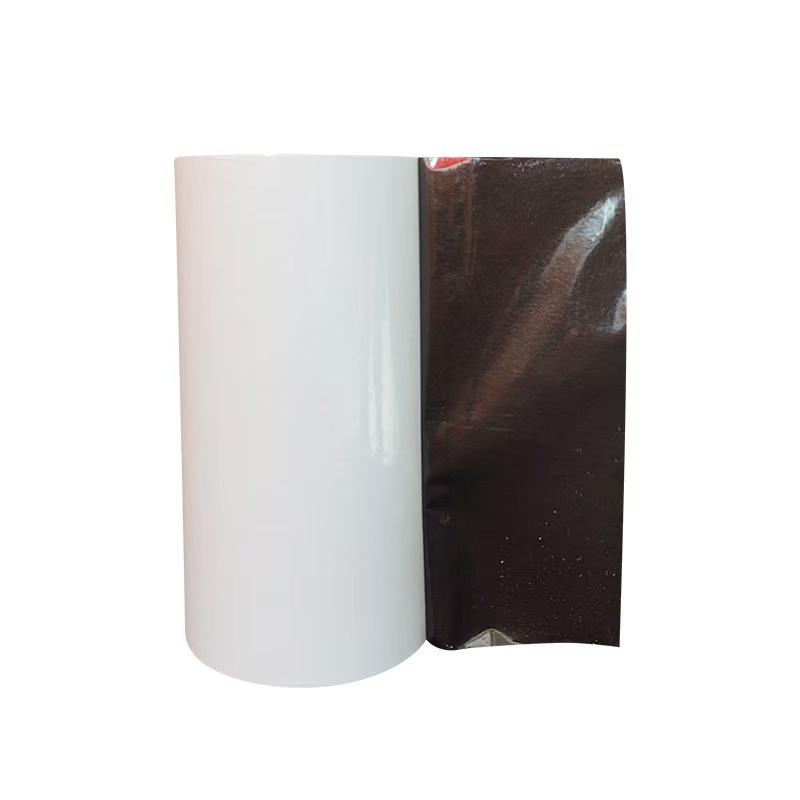

High Transparency and Aesthetic Options

PE protective films come in various colors, including transparent, blue, milky white, and black/white combinations, allowing for both functional and aesthetic applications. Transparent films are often used when visual inspection of the surface is required during processing, while colored films can enhance brand visibility or indicate specific handling instructions.

Applications in Thermal Break Aluminum

Thermal break aluminum, widely used in window frames, curtain walls, and other architectural applications, features a polyamide strip that interrupts thermal conductivity, enhancing energy efficiency. However, its surfaces—often anodized, powder-coated, or fluorocarbon-sprayed—are susceptible to scratches, abrasions, and contamination during fabrication, transportation, and installation. PE self-adhesive protective film addresses these challenges effectively, ensuring that thermal break aluminum maintains its aesthetic and functional integrity.

Protection During Fabrication

The manufacturing of thermal break aluminum involves processes like cutting, drilling, bending, and assembly, which expose surfaces to potential damage. PE protective film, with its excellent tensile strength and puncture resistance, acts as a robust barrier against scratches caused by tools or machinery. For instance, films with medium to high adhesion levels (80–100 g/cm peel strength) are ideal for anodized or powder-coated aluminum, as they adhere securely to textured surfaces without peeling off during processing.

Safeguarding During Transportation and Storage

Thermal break aluminum profiles are often transported over long distances or stored for extended periods before installation. During these stages, surfaces can be exposed to dust, moisture, or physical impacts. PE protective film, particularly those with UV-resistant properties, prevents corrosion and surface degradation. For example, a 50μ low-density PE film can protect aluminum profiles stored outdoors for up to a year without adhesive transfer or film breakdown.

Ease of Application and Removal

The self-adhesive nature of PE protective film allows for easy application by hand or machine, reducing labor costs and time. Its residue-free removal ensures that aluminum surfaces remain clean and ready for installation, eliminating the need for additional cleaning processes. This is particularly valuable in construction projects, where time efficiency is critical.

Case Example: Architectural Applications

Consider a high-rise building project where thermal break aluminum profiles are used for window frames. During fabrication, a medium-viscosity PE protective film is applied to the anodized aluminum surfaces to protect them from scratches during cutting and assembly. The profiles are then transported to the construction site, where they are exposed to outdoor conditions for several weeks. The UV-resistant film ensures that the surfaces remain pristine, and upon installation, the film is easily peeled off, revealing flawless aluminum frames that enhance the building’s aesthetic appeal.

Applications in Laser-Engraved Steel Plates

Laser-engraved steel plates, used in industries like architecture, automotive, and product design, feature intricate patterns or designs that require meticulous surface protection. The laser engraving process itself, along with subsequent handling and transportation, poses risks of scratches, burn marks, or contamination. PE self-adhesive protective film is specifically engineered to meet these challenges, ensuring that the engraved surfaces remain flawless.

Protection During Laser Cutting and Engraving

Laser cutting and engraving involve high-powered laser beams that can generate heat and debris, potentially damaging the steel surface. Specialized PE laser protective films, often coated with rubber or acrylic adhesives, are designed to withstand the thermal stresses of CO2 or fiber laser cutting. These films prevent burn marks and ensure clean cuts with minimal burrs, enhancing the precision of the engraving process. For optimal results, films are applied to the non-cutting side of the steel plate, or oxygen-assisted cutting is used when cutting from the protected side.

Durability During Fabrication and Handling

Post-engraving processes, such as bending, stamping, or polishing, can expose laser-engraved steel plates to mechanical damage. PE protective film with high tensile strength and elongation properties (e.g., >400% elongation) can endure these processes without tearing or losing adhesion. For instance, a 2.5-mil thick PE film with medium-tack adhesion is ideal for protecting No. 3 or No. 4 brushed stainless steel finishes, commonly used in commercial applications.

Preventing Adhesive Residue

One of the critical requirements for laser-engraved steel plates is maintaining a residue-free surface after film removal. PE self-adhesive films, with their co-extruded adhesive layers, ensure clean removal even after prolonged application (up to 45 days in some cases). This is particularly important for high-gloss or mirror-finished steel plates, where any residue could compromise the aesthetic quality.

Case Example: Automotive Design

In the automotive industry, laser-engraved steel plates are used for decorative trim or branding elements. During production, a PE laser protective film is applied to the steel surface before engraving to prevent burn marks and scratches. The film remains in place during subsequent stamping and assembly processes, protecting the intricate designs from damage. Upon final assembly, the film is removed, revealing a flawless engraved surface that enhances the vehicle’s premium appeal.

Comparative Advantages Over Other Protective Films

While other materials like PVC or PP films are also used for surface protection, PE self-adhesive protective film offers distinct advantages:

Cost-Effectiveness: PE films are generally cheaper than PVC or PP films due to the widespread availability of polyethylene and simpler manufacturing processes.

Environmental Impact: PE films are recyclable and produce fewer VOCs compared to solvent-based adhesive films.

Versatility: PE films can be tailored to a wide range of surfaces and adhesion levels, unlike PP films, which are better suited for high-heat applications, or PVC films, which are more elastic but less environmentally friendly.

Challenges and Considerations

Despite their advantages, PE self-adhesive protective films require careful selection to ensure optimal performance. For instance, choosing the wrong adhesion level (e.g., high viscosity for a smooth surface) can result in adhesive residue or difficulty in removal. Additionally, prolonged exposure to sunlight beyond the film’s UV resistance period can cause adhesive breakdown, particularly for transparent films. Manufacturers must also ensure that films are applied at recommended temperatures (typically 15–40°C) to avoid adhesion issues.

To mitigate these challenges, suppliers like NB Technology and Pregis offer customized solutions and free samples to help customers select the right film for their specific needs. Testing the film’s performance under actual processing conditions is crucial to achieving the desired protection without compromising efficiency.

Conclusion

PE self-adhesive protective film is a cornerstone of modern surface protection, offering a blend of environmental friendliness, flexibility, and residue-free performance that makes it ideal for safeguarding thermal break aluminum and laser-engraved steel plates. Its ability to protect surfaces during fabrication, transportation, and installation ensures that high-value materials maintain their quality and aesthetic appeal. By selecting the appropriate adhesion level and film type, manufacturers can enhance productivity, reduce waste, and deliver flawless products to their customers. As industries continue to prioritize sustainability and precision, PE protective film will remain an essential tool in the quest for manufacturing excellence.