Unveiling the Crystal Clarity: Transparent BOPP Film and Its Versatile World of Applications

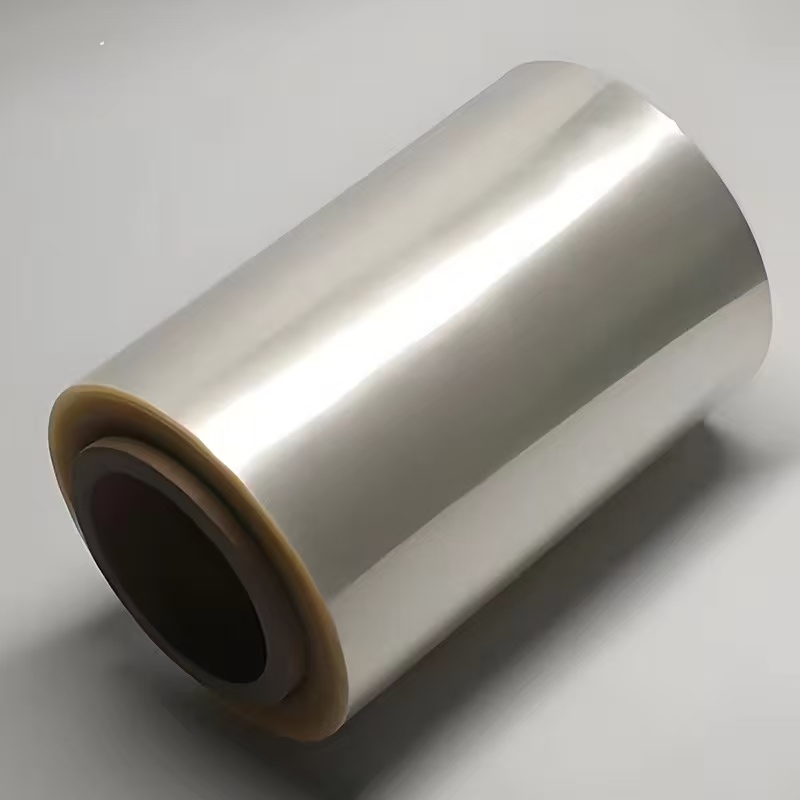

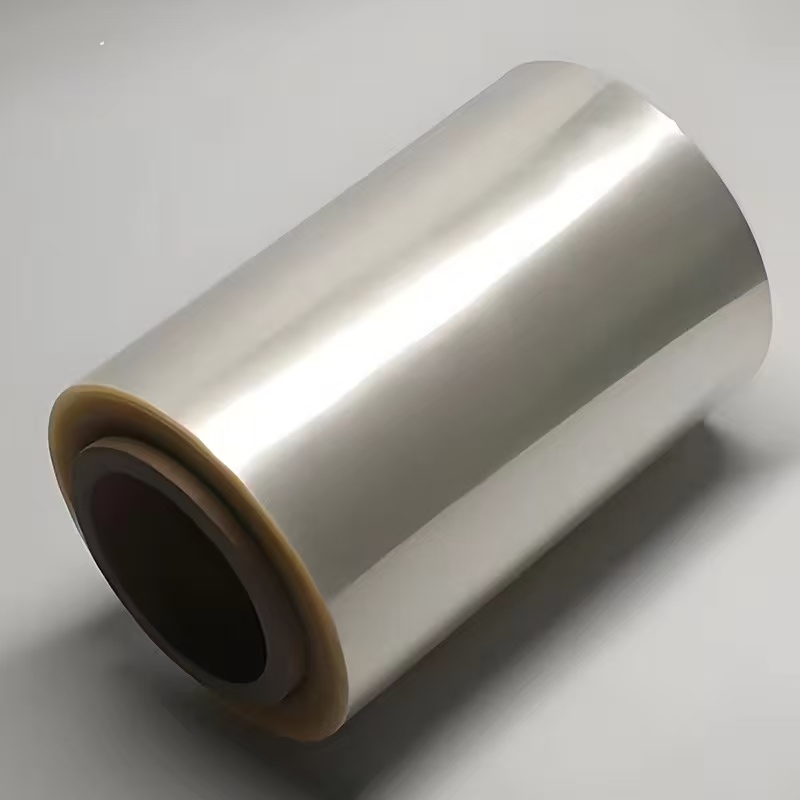

2025-11-04 17:41Introduction: The Sheer Power of TransparencyImagine unwrapping a crisp apple from the grocery store, its vibrant red skin gleaming through a flawless layer of film that hugs it like a second skin—unblemished, inviting, and utterly protective. This isn't just any wrapper; it's the work of transparent Biaxially Oriented Polypropylene (BOPP) film, a marvel of modern materials science that combines optical elegance with unyielding functionality. Born from the ingenious process of stretching polypropylene sheets in two perpendicular directions, BOPP film achieves a level of clarity and strength that rivals glass while remaining lightweight and flexible.  Transparent BOPP film, often simply called clear BOPP film, has revolutionized packaging since its widespread adoption in the late 20th century. Its journey from industrial innovation to everyday staple underscores a simple truth: in a world obsessed with visibility and efficiency, what you see is often what protects. This article delves into the intrinsic properties that make transparent BOPP film indispensable, then explores its starring roles in food packaging, disposable tableware wrapping, and antistatic enclosures. Through vivid examples and grounded explanations, we'll uncover why this film isn't just a barrier—it's a silent guardian that enhances safety, extends shelf life, and elevates consumer experience.At its core, transparent BOPP film's appeal lies in its molecular architecture. Polypropylene, a thermoplastic polymer derived from petroleum, is extruded into a thin sheet and then oriented biaxially—stretched longitudinally and transversely under controlled heat and tension. This dual stretching aligns the polymer chains, boosting tensile strength by up to 300% compared to unoriented films, while thinning the material to as little as 10 microns without sacrificing durability. The result? A film that's 90-95% transparent, with a haze level under 2%, allowing light to pass through almost unimpeded. Picture holding a sheet to the sun: the transmitted rays dance through it like sunlight on a mountain stream, revealing every detail beneath.But transparency alone doesn't crown it king of packaging. Mechanical robustness is key. With a tensile strength exceeding 150 MPa in the machine direction, it resists tears and punctures better than many alternatives like polyethylene. This isn't abstract engineering; consider a bustling supermarket where a bag of frozen vegetables tumbles from a shelf. The BOPP film encasing it flexes but doesn't fracture, preserving the contents' integrity. Add to that its low moisture vapor transmission rate (MVTR) of around 1-2 g/m²/day, which acts as a shield against humidity, and you've got a material that breathes just enough to prevent condensation while blocking excess water vapor. Thermal stability rounds out the profile: it withstands temperatures from -20°C to 120°C, making it ideal for everything from chilled displays to microwave-safe wraps.Surface properties further elevate its prowess. The film's smooth, glossy finish—achievable through corona treatment that increases surface energy to 38-42 dynes/cm—ensures excellent printability. Inks and labels adhere vibrantly, turning a simple wrapper into a marketing canvas. And for sealing, its heat-sealability shines: at 120-150°C, edges fuse seamlessly under pressure, creating airtight bonds that can hold up to 5-10 N/cm of peel force. These traits aren't just specs on a datasheet; they're the reasons transparent BOPP film dominates over 40% of the global flexible packaging market, saving industries billions in waste reduction and spoilage prevention.The Hallmark Properties: A Symphony of Strength and Sheen

Transparent BOPP film, often simply called clear BOPP film, has revolutionized packaging since its widespread adoption in the late 20th century. Its journey from industrial innovation to everyday staple underscores a simple truth: in a world obsessed with visibility and efficiency, what you see is often what protects. This article delves into the intrinsic properties that make transparent BOPP film indispensable, then explores its starring roles in food packaging, disposable tableware wrapping, and antistatic enclosures. Through vivid examples and grounded explanations, we'll uncover why this film isn't just a barrier—it's a silent guardian that enhances safety, extends shelf life, and elevates consumer experience.At its core, transparent BOPP film's appeal lies in its molecular architecture. Polypropylene, a thermoplastic polymer derived from petroleum, is extruded into a thin sheet and then oriented biaxially—stretched longitudinally and transversely under controlled heat and tension. This dual stretching aligns the polymer chains, boosting tensile strength by up to 300% compared to unoriented films, while thinning the material to as little as 10 microns without sacrificing durability. The result? A film that's 90-95% transparent, with a haze level under 2%, allowing light to pass through almost unimpeded. Picture holding a sheet to the sun: the transmitted rays dance through it like sunlight on a mountain stream, revealing every detail beneath.But transparency alone doesn't crown it king of packaging. Mechanical robustness is key. With a tensile strength exceeding 150 MPa in the machine direction, it resists tears and punctures better than many alternatives like polyethylene. This isn't abstract engineering; consider a bustling supermarket where a bag of frozen vegetables tumbles from a shelf. The BOPP film encasing it flexes but doesn't fracture, preserving the contents' integrity. Add to that its low moisture vapor transmission rate (MVTR) of around 1-2 g/m²/day, which acts as a shield against humidity, and you've got a material that breathes just enough to prevent condensation while blocking excess water vapor. Thermal stability rounds out the profile: it withstands temperatures from -20°C to 120°C, making it ideal for everything from chilled displays to microwave-safe wraps.Surface properties further elevate its prowess. The film's smooth, glossy finish—achievable through corona treatment that increases surface energy to 38-42 dynes/cm—ensures excellent printability. Inks and labels adhere vibrantly, turning a simple wrapper into a marketing canvas. And for sealing, its heat-sealability shines: at 120-150°C, edges fuse seamlessly under pressure, creating airtight bonds that can hold up to 5-10 N/cm of peel force. These traits aren't just specs on a datasheet; they're the reasons transparent BOPP film dominates over 40% of the global flexible packaging market, saving industries billions in waste reduction and spoilage prevention.The Hallmark Properties: A Symphony of Strength and Sheen To truly appreciate transparent BOPP film's versatility, let's dissect its properties with the precision of a materials engineer and the flair of a storyteller. Start with optical clarity, the film's signature trait. Measured by ASTM D1003 standards, its transmittance often hits 92%, far surpassing PVC films at 85%. This isn't mere aesthetics; in retail, where first impressions sell, clarity boosts impulse buys by 20-30%, as shoppers can inspect products without peeling back layers. Envision a fruit vendor at a morning market: strawberries nestled in a BOPP pouch, their juicy facets sparkling like rubies, drawing crowds before the dew even dries.Mechanical fortitude follows suit. The biaxial orientation creates a balanced isotropy—strength in both directions prevents warping under stress. In lab tests, a 20-micron BOPP film endures over 200% elongation before breaking, a resilience that echoes in real-world chaos: think of a courier's van swerving on a rainy highway, packages jostling like sailors in a storm, yet arriving intact. Barrier performance is equally compelling. Its oxygen transmission rate (OTRR) hovers at 1500-2000 cm³/m²/day, sufficient to curb oxidation in perishables without the full impermeability of metallized films, which can trap gases and accelerate spoilage. For moisture, the low WVTR means a loaf of bread wrapped in BOPP stays soft for days longer than in paper, reducing food waste that plagues households worldwide..Food Packaging: Preserving the Palette of PlentyNowhere does transparent BOPP film flex its muscles more than in food packaging, where it safeguards nutrition while seducing the senses. In an era of farm-to-table transparency—pun intended—this film turns groceries into gallery pieces. Take fresh produce: bagged salads in supermarkets owe their week-long crispness to BOPP's barrier magic. A single layer, often laminated with a sealant like polyethylene for added moisture lock, extends shelf life by 50% versus loose storage. Visualize a head of iceberg lettuce, its leaves unfurling like green sails through the film's veil, moisture beads harmlessly repelled, flavors locked in.For snacks, the story amplifies. Crisps and nuts in stand-up pouches gleam with printed graphics—bold reds and golds that pop against the film's gloss, boosting brand recall by 25%. The film's print receptivity allows flexographic inks to render intricate designs, from nutritional facts to playful mascots, all while its strength handles the crunch of automated filling lines. Heat-sealing ensures tamper-evidence: a firm tug reveals if meddlers have pried. In bakery aisles, BOPP sleeves around baguettes prevent staleness; the film's breathability vents ethylene gas, delaying ripening without sogginess. One vivid case: a European bakery chain reported 15% less waste after switching to BOPP over foil, as the clarity let bakers spot overproofing early.Disposable Tableware Packaging: Hygiene in a HurryShift to the fast-paced world of disposables, where transparent BOPP film wraps utensils in a hygienic embrace, ready for the grab-and-go life. In catering halls or airline galleys, plastic forks and knives arrive sheathed in BOPP sleeves, their sterility visible at a glance. This transparency isn't vanity; it's verification. A quick peek confirms no dust or dents, instilling confidence in users from picnickers to pilots. The film's slim profile—often 15 microns—allows nesting of dozens per pack without bulk, yet its tear resistance ensures single servings dispense cleanly, no wrestling required.Picture a wedding reception: hundreds of BOPP-wrapped sets laid out like silver soldiers, gleaming under chandeliers. As guests snag one, the film's low-friction glide prevents static cling, utensils emerging pristine. Heat-sealability here creates mini-fortresses; seals withstand 80°C dishwater splashes, protecting against contamination. For eco-conscious twists, biodegradable additives in BOPP variants degrade 40% faster in compost, easing landfill burdens without compromising clarity. In schools, where lunch lines buzz with energy, BOPP packs of spoons keep counts accurate—transparent counts prevent over-dispensing, saving pennies that add up.Durability shines in transit: stacked pallets of tableware rumble across oceans in BOPP overwraps, arriving unbent. One logistics firm noted zero breakage over 10,000 shipments, crediting the film's impact strength. And for customization, printed warnings like "Single Use Only" adhere sharply, promoting responsible disposal. In essence, for disposable tableware, BOPP film isn't just packaging—it's a promise of purity, turning everyday essentials into reliable allies in the rush of modern meals.

To truly appreciate transparent BOPP film's versatility, let's dissect its properties with the precision of a materials engineer and the flair of a storyteller. Start with optical clarity, the film's signature trait. Measured by ASTM D1003 standards, its transmittance often hits 92%, far surpassing PVC films at 85%. This isn't mere aesthetics; in retail, where first impressions sell, clarity boosts impulse buys by 20-30%, as shoppers can inspect products without peeling back layers. Envision a fruit vendor at a morning market: strawberries nestled in a BOPP pouch, their juicy facets sparkling like rubies, drawing crowds before the dew even dries.Mechanical fortitude follows suit. The biaxial orientation creates a balanced isotropy—strength in both directions prevents warping under stress. In lab tests, a 20-micron BOPP film endures over 200% elongation before breaking, a resilience that echoes in real-world chaos: think of a courier's van swerving on a rainy highway, packages jostling like sailors in a storm, yet arriving intact. Barrier performance is equally compelling. Its oxygen transmission rate (OTRR) hovers at 1500-2000 cm³/m²/day, sufficient to curb oxidation in perishables without the full impermeability of metallized films, which can trap gases and accelerate spoilage. For moisture, the low WVTR means a loaf of bread wrapped in BOPP stays soft for days longer than in paper, reducing food waste that plagues households worldwide..Food Packaging: Preserving the Palette of PlentyNowhere does transparent BOPP film flex its muscles more than in food packaging, where it safeguards nutrition while seducing the senses. In an era of farm-to-table transparency—pun intended—this film turns groceries into gallery pieces. Take fresh produce: bagged salads in supermarkets owe their week-long crispness to BOPP's barrier magic. A single layer, often laminated with a sealant like polyethylene for added moisture lock, extends shelf life by 50% versus loose storage. Visualize a head of iceberg lettuce, its leaves unfurling like green sails through the film's veil, moisture beads harmlessly repelled, flavors locked in.For snacks, the story amplifies. Crisps and nuts in stand-up pouches gleam with printed graphics—bold reds and golds that pop against the film's gloss, boosting brand recall by 25%. The film's print receptivity allows flexographic inks to render intricate designs, from nutritional facts to playful mascots, all while its strength handles the crunch of automated filling lines. Heat-sealing ensures tamper-evidence: a firm tug reveals if meddlers have pried. In bakery aisles, BOPP sleeves around baguettes prevent staleness; the film's breathability vents ethylene gas, delaying ripening without sogginess. One vivid case: a European bakery chain reported 15% less waste after switching to BOPP over foil, as the clarity let bakers spot overproofing early.Disposable Tableware Packaging: Hygiene in a HurryShift to the fast-paced world of disposables, where transparent BOPP film wraps utensils in a hygienic embrace, ready for the grab-and-go life. In catering halls or airline galleys, plastic forks and knives arrive sheathed in BOPP sleeves, their sterility visible at a glance. This transparency isn't vanity; it's verification. A quick peek confirms no dust or dents, instilling confidence in users from picnickers to pilots. The film's slim profile—often 15 microns—allows nesting of dozens per pack without bulk, yet its tear resistance ensures single servings dispense cleanly, no wrestling required.Picture a wedding reception: hundreds of BOPP-wrapped sets laid out like silver soldiers, gleaming under chandeliers. As guests snag one, the film's low-friction glide prevents static cling, utensils emerging pristine. Heat-sealability here creates mini-fortresses; seals withstand 80°C dishwater splashes, protecting against contamination. For eco-conscious twists, biodegradable additives in BOPP variants degrade 40% faster in compost, easing landfill burdens without compromising clarity. In schools, where lunch lines buzz with energy, BOPP packs of spoons keep counts accurate—transparent counts prevent over-dispensing, saving pennies that add up.Durability shines in transit: stacked pallets of tableware rumble across oceans in BOPP overwraps, arriving unbent. One logistics firm noted zero breakage over 10,000 shipments, crediting the film's impact strength. And for customization, printed warnings like "Single Use Only" adhere sharply, promoting responsible disposal. In essence, for disposable tableware, BOPP film isn't just packaging—it's a promise of purity, turning everyday essentials into reliable allies in the rush of modern meals. Conclusion: A Clear Future UnwrappedTransparent BOPP film stands as a testament to ingenuity's quiet triumphs: a material that reveals as it protects, strengthens without shadowing. From the verdant crunch of packaged greens to the sterile snap of a fork wrapper, and the silent shield over silicon souls, its properties—clarity, resilience, barrier brilliance—interweave with applications that touch billions daily. As sustainability pressures mount, innovations like recycled-content blends promise an even greener horizon, without dimming its shine.In a world veiled by uncertainties, transparent BOPP film offers unclouded assurance. It's the unsung hero in your shopping cart, the guardian in your gadget drawer, the enabler of effortless eats. Next time you tear open a pack, pause: beneath that fleeting rip lies a legacy of science serving society, clear as day.

Conclusion: A Clear Future UnwrappedTransparent BOPP film stands as a testament to ingenuity's quiet triumphs: a material that reveals as it protects, strengthens without shadowing. From the verdant crunch of packaged greens to the sterile snap of a fork wrapper, and the silent shield over silicon souls, its properties—clarity, resilience, barrier brilliance—interweave with applications that touch billions daily. As sustainability pressures mount, innovations like recycled-content blends promise an even greener horizon, without dimming its shine.In a world veiled by uncertainties, transparent BOPP film offers unclouded assurance. It's the unsung hero in your shopping cart, the guardian in your gadget drawer, the enabler of effortless eats. Next time you tear open a pack, pause: beneath that fleeting rip lies a legacy of science serving society, clear as day.

Transparent BOPP film, often simply called clear BOPP film, has revolutionized packaging since its widespread adoption in the late 20th century. Its journey from industrial innovation to everyday staple underscores a simple truth: in a world obsessed with visibility and efficiency, what you see is often what protects. This article delves into the intrinsic properties that make transparent BOPP film indispensable, then explores its starring roles in food packaging, disposable tableware wrapping, and antistatic enclosures. Through vivid examples and grounded explanations, we'll uncover why this film isn't just a barrier—it's a silent guardian that enhances safety, extends shelf life, and elevates consumer experience.At its core, transparent BOPP film's appeal lies in its molecular architecture. Polypropylene, a thermoplastic polymer derived from petroleum, is extruded into a thin sheet and then oriented biaxially—stretched longitudinally and transversely under controlled heat and tension. This dual stretching aligns the polymer chains, boosting tensile strength by up to 300% compared to unoriented films, while thinning the material to as little as 10 microns without sacrificing durability. The result? A film that's 90-95% transparent, with a haze level under 2%, allowing light to pass through almost unimpeded. Picture holding a sheet to the sun: the transmitted rays dance through it like sunlight on a mountain stream, revealing every detail beneath.But transparency alone doesn't crown it king of packaging. Mechanical robustness is key. With a tensile strength exceeding 150 MPa in the machine direction, it resists tears and punctures better than many alternatives like polyethylene. This isn't abstract engineering; consider a bustling supermarket where a bag of frozen vegetables tumbles from a shelf. The BOPP film encasing it flexes but doesn't fracture, preserving the contents' integrity. Add to that its low moisture vapor transmission rate (MVTR) of around 1-2 g/m²/day, which acts as a shield against humidity, and you've got a material that breathes just enough to prevent condensation while blocking excess water vapor. Thermal stability rounds out the profile: it withstands temperatures from -20°C to 120°C, making it ideal for everything from chilled displays to microwave-safe wraps.Surface properties further elevate its prowess. The film's smooth, glossy finish—achievable through corona treatment that increases surface energy to 38-42 dynes/cm—ensures excellent printability. Inks and labels adhere vibrantly, turning a simple wrapper into a marketing canvas. And for sealing, its heat-sealability shines: at 120-150°C, edges fuse seamlessly under pressure, creating airtight bonds that can hold up to 5-10 N/cm of peel force. These traits aren't just specs on a datasheet; they're the reasons transparent BOPP film dominates over 40% of the global flexible packaging market, saving industries billions in waste reduction and spoilage prevention.The Hallmark Properties: A Symphony of Strength and Sheen

Transparent BOPP film, often simply called clear BOPP film, has revolutionized packaging since its widespread adoption in the late 20th century. Its journey from industrial innovation to everyday staple underscores a simple truth: in a world obsessed with visibility and efficiency, what you see is often what protects. This article delves into the intrinsic properties that make transparent BOPP film indispensable, then explores its starring roles in food packaging, disposable tableware wrapping, and antistatic enclosures. Through vivid examples and grounded explanations, we'll uncover why this film isn't just a barrier—it's a silent guardian that enhances safety, extends shelf life, and elevates consumer experience.At its core, transparent BOPP film's appeal lies in its molecular architecture. Polypropylene, a thermoplastic polymer derived from petroleum, is extruded into a thin sheet and then oriented biaxially—stretched longitudinally and transversely under controlled heat and tension. This dual stretching aligns the polymer chains, boosting tensile strength by up to 300% compared to unoriented films, while thinning the material to as little as 10 microns without sacrificing durability. The result? A film that's 90-95% transparent, with a haze level under 2%, allowing light to pass through almost unimpeded. Picture holding a sheet to the sun: the transmitted rays dance through it like sunlight on a mountain stream, revealing every detail beneath.But transparency alone doesn't crown it king of packaging. Mechanical robustness is key. With a tensile strength exceeding 150 MPa in the machine direction, it resists tears and punctures better than many alternatives like polyethylene. This isn't abstract engineering; consider a bustling supermarket where a bag of frozen vegetables tumbles from a shelf. The BOPP film encasing it flexes but doesn't fracture, preserving the contents' integrity. Add to that its low moisture vapor transmission rate (MVTR) of around 1-2 g/m²/day, which acts as a shield against humidity, and you've got a material that breathes just enough to prevent condensation while blocking excess water vapor. Thermal stability rounds out the profile: it withstands temperatures from -20°C to 120°C, making it ideal for everything from chilled displays to microwave-safe wraps.Surface properties further elevate its prowess. The film's smooth, glossy finish—achievable through corona treatment that increases surface energy to 38-42 dynes/cm—ensures excellent printability. Inks and labels adhere vibrantly, turning a simple wrapper into a marketing canvas. And for sealing, its heat-sealability shines: at 120-150°C, edges fuse seamlessly under pressure, creating airtight bonds that can hold up to 5-10 N/cm of peel force. These traits aren't just specs on a datasheet; they're the reasons transparent BOPP film dominates over 40% of the global flexible packaging market, saving industries billions in waste reduction and spoilage prevention.The Hallmark Properties: A Symphony of Strength and Sheen To truly appreciate transparent BOPP film's versatility, let's dissect its properties with the precision of a materials engineer and the flair of a storyteller. Start with optical clarity, the film's signature trait. Measured by ASTM D1003 standards, its transmittance often hits 92%, far surpassing PVC films at 85%. This isn't mere aesthetics; in retail, where first impressions sell, clarity boosts impulse buys by 20-30%, as shoppers can inspect products without peeling back layers. Envision a fruit vendor at a morning market: strawberries nestled in a BOPP pouch, their juicy facets sparkling like rubies, drawing crowds before the dew even dries.Mechanical fortitude follows suit. The biaxial orientation creates a balanced isotropy—strength in both directions prevents warping under stress. In lab tests, a 20-micron BOPP film endures over 200% elongation before breaking, a resilience that echoes in real-world chaos: think of a courier's van swerving on a rainy highway, packages jostling like sailors in a storm, yet arriving intact. Barrier performance is equally compelling. Its oxygen transmission rate (OTRR) hovers at 1500-2000 cm³/m²/day, sufficient to curb oxidation in perishables without the full impermeability of metallized films, which can trap gases and accelerate spoilage. For moisture, the low WVTR means a loaf of bread wrapped in BOPP stays soft for days longer than in paper, reducing food waste that plagues households worldwide..Food Packaging: Preserving the Palette of PlentyNowhere does transparent BOPP film flex its muscles more than in food packaging, where it safeguards nutrition while seducing the senses. In an era of farm-to-table transparency—pun intended—this film turns groceries into gallery pieces. Take fresh produce: bagged salads in supermarkets owe their week-long crispness to BOPP's barrier magic. A single layer, often laminated with a sealant like polyethylene for added moisture lock, extends shelf life by 50% versus loose storage. Visualize a head of iceberg lettuce, its leaves unfurling like green sails through the film's veil, moisture beads harmlessly repelled, flavors locked in.For snacks, the story amplifies. Crisps and nuts in stand-up pouches gleam with printed graphics—bold reds and golds that pop against the film's gloss, boosting brand recall by 25%. The film's print receptivity allows flexographic inks to render intricate designs, from nutritional facts to playful mascots, all while its strength handles the crunch of automated filling lines. Heat-sealing ensures tamper-evidence: a firm tug reveals if meddlers have pried. In bakery aisles, BOPP sleeves around baguettes prevent staleness; the film's breathability vents ethylene gas, delaying ripening without sogginess. One vivid case: a European bakery chain reported 15% less waste after switching to BOPP over foil, as the clarity let bakers spot overproofing early.Disposable Tableware Packaging: Hygiene in a HurryShift to the fast-paced world of disposables, where transparent BOPP film wraps utensils in a hygienic embrace, ready for the grab-and-go life. In catering halls or airline galleys, plastic forks and knives arrive sheathed in BOPP sleeves, their sterility visible at a glance. This transparency isn't vanity; it's verification. A quick peek confirms no dust or dents, instilling confidence in users from picnickers to pilots. The film's slim profile—often 15 microns—allows nesting of dozens per pack without bulk, yet its tear resistance ensures single servings dispense cleanly, no wrestling required.Picture a wedding reception: hundreds of BOPP-wrapped sets laid out like silver soldiers, gleaming under chandeliers. As guests snag one, the film's low-friction glide prevents static cling, utensils emerging pristine. Heat-sealability here creates mini-fortresses; seals withstand 80°C dishwater splashes, protecting against contamination. For eco-conscious twists, biodegradable additives in BOPP variants degrade 40% faster in compost, easing landfill burdens without compromising clarity. In schools, where lunch lines buzz with energy, BOPP packs of spoons keep counts accurate—transparent counts prevent over-dispensing, saving pennies that add up.Durability shines in transit: stacked pallets of tableware rumble across oceans in BOPP overwraps, arriving unbent. One logistics firm noted zero breakage over 10,000 shipments, crediting the film's impact strength. And for customization, printed warnings like "Single Use Only" adhere sharply, promoting responsible disposal. In essence, for disposable tableware, BOPP film isn't just packaging—it's a promise of purity, turning everyday essentials into reliable allies in the rush of modern meals.

To truly appreciate transparent BOPP film's versatility, let's dissect its properties with the precision of a materials engineer and the flair of a storyteller. Start with optical clarity, the film's signature trait. Measured by ASTM D1003 standards, its transmittance often hits 92%, far surpassing PVC films at 85%. This isn't mere aesthetics; in retail, where first impressions sell, clarity boosts impulse buys by 20-30%, as shoppers can inspect products without peeling back layers. Envision a fruit vendor at a morning market: strawberries nestled in a BOPP pouch, their juicy facets sparkling like rubies, drawing crowds before the dew even dries.Mechanical fortitude follows suit. The biaxial orientation creates a balanced isotropy—strength in both directions prevents warping under stress. In lab tests, a 20-micron BOPP film endures over 200% elongation before breaking, a resilience that echoes in real-world chaos: think of a courier's van swerving on a rainy highway, packages jostling like sailors in a storm, yet arriving intact. Barrier performance is equally compelling. Its oxygen transmission rate (OTRR) hovers at 1500-2000 cm³/m²/day, sufficient to curb oxidation in perishables without the full impermeability of metallized films, which can trap gases and accelerate spoilage. For moisture, the low WVTR means a loaf of bread wrapped in BOPP stays soft for days longer than in paper, reducing food waste that plagues households worldwide..Food Packaging: Preserving the Palette of PlentyNowhere does transparent BOPP film flex its muscles more than in food packaging, where it safeguards nutrition while seducing the senses. In an era of farm-to-table transparency—pun intended—this film turns groceries into gallery pieces. Take fresh produce: bagged salads in supermarkets owe their week-long crispness to BOPP's barrier magic. A single layer, often laminated with a sealant like polyethylene for added moisture lock, extends shelf life by 50% versus loose storage. Visualize a head of iceberg lettuce, its leaves unfurling like green sails through the film's veil, moisture beads harmlessly repelled, flavors locked in.For snacks, the story amplifies. Crisps and nuts in stand-up pouches gleam with printed graphics—bold reds and golds that pop against the film's gloss, boosting brand recall by 25%. The film's print receptivity allows flexographic inks to render intricate designs, from nutritional facts to playful mascots, all while its strength handles the crunch of automated filling lines. Heat-sealing ensures tamper-evidence: a firm tug reveals if meddlers have pried. In bakery aisles, BOPP sleeves around baguettes prevent staleness; the film's breathability vents ethylene gas, delaying ripening without sogginess. One vivid case: a European bakery chain reported 15% less waste after switching to BOPP over foil, as the clarity let bakers spot overproofing early.Disposable Tableware Packaging: Hygiene in a HurryShift to the fast-paced world of disposables, where transparent BOPP film wraps utensils in a hygienic embrace, ready for the grab-and-go life. In catering halls or airline galleys, plastic forks and knives arrive sheathed in BOPP sleeves, their sterility visible at a glance. This transparency isn't vanity; it's verification. A quick peek confirms no dust or dents, instilling confidence in users from picnickers to pilots. The film's slim profile—often 15 microns—allows nesting of dozens per pack without bulk, yet its tear resistance ensures single servings dispense cleanly, no wrestling required.Picture a wedding reception: hundreds of BOPP-wrapped sets laid out like silver soldiers, gleaming under chandeliers. As guests snag one, the film's low-friction glide prevents static cling, utensils emerging pristine. Heat-sealability here creates mini-fortresses; seals withstand 80°C dishwater splashes, protecting against contamination. For eco-conscious twists, biodegradable additives in BOPP variants degrade 40% faster in compost, easing landfill burdens without compromising clarity. In schools, where lunch lines buzz with energy, BOPP packs of spoons keep counts accurate—transparent counts prevent over-dispensing, saving pennies that add up.Durability shines in transit: stacked pallets of tableware rumble across oceans in BOPP overwraps, arriving unbent. One logistics firm noted zero breakage over 10,000 shipments, crediting the film's impact strength. And for customization, printed warnings like "Single Use Only" adhere sharply, promoting responsible disposal. In essence, for disposable tableware, BOPP film isn't just packaging—it's a promise of purity, turning everyday essentials into reliable allies in the rush of modern meals. Conclusion: A Clear Future UnwrappedTransparent BOPP film stands as a testament to ingenuity's quiet triumphs: a material that reveals as it protects, strengthens without shadowing. From the verdant crunch of packaged greens to the sterile snap of a fork wrapper, and the silent shield over silicon souls, its properties—clarity, resilience, barrier brilliance—interweave with applications that touch billions daily. As sustainability pressures mount, innovations like recycled-content blends promise an even greener horizon, without dimming its shine.In a world veiled by uncertainties, transparent BOPP film offers unclouded assurance. It's the unsung hero in your shopping cart, the guardian in your gadget drawer, the enabler of effortless eats. Next time you tear open a pack, pause: beneath that fleeting rip lies a legacy of science serving society, clear as day.

Conclusion: A Clear Future UnwrappedTransparent BOPP film stands as a testament to ingenuity's quiet triumphs: a material that reveals as it protects, strengthens without shadowing. From the verdant crunch of packaged greens to the sterile snap of a fork wrapper, and the silent shield over silicon souls, its properties—clarity, resilience, barrier brilliance—interweave with applications that touch billions daily. As sustainability pressures mount, innovations like recycled-content blends promise an even greener horizon, without dimming its shine.In a world veiled by uncertainties, transparent BOPP film offers unclouded assurance. It's the unsung hero in your shopping cart, the guardian in your gadget drawer, the enabler of effortless eats. Next time you tear open a pack, pause: beneath that fleeting rip lies a legacy of science serving society, clear as day.

Get the latest price? We'll respond as soon as possible(within 12 hours)