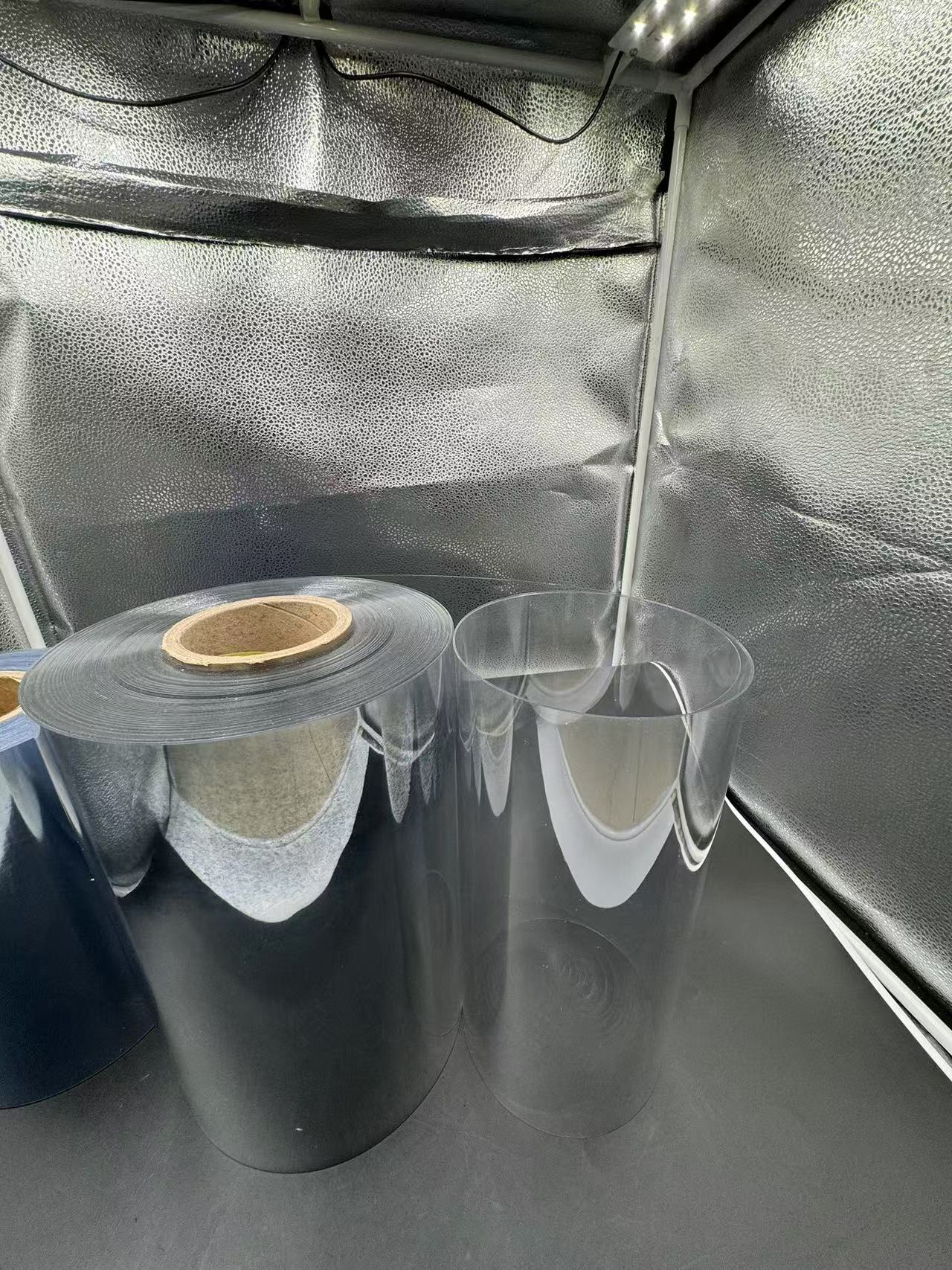

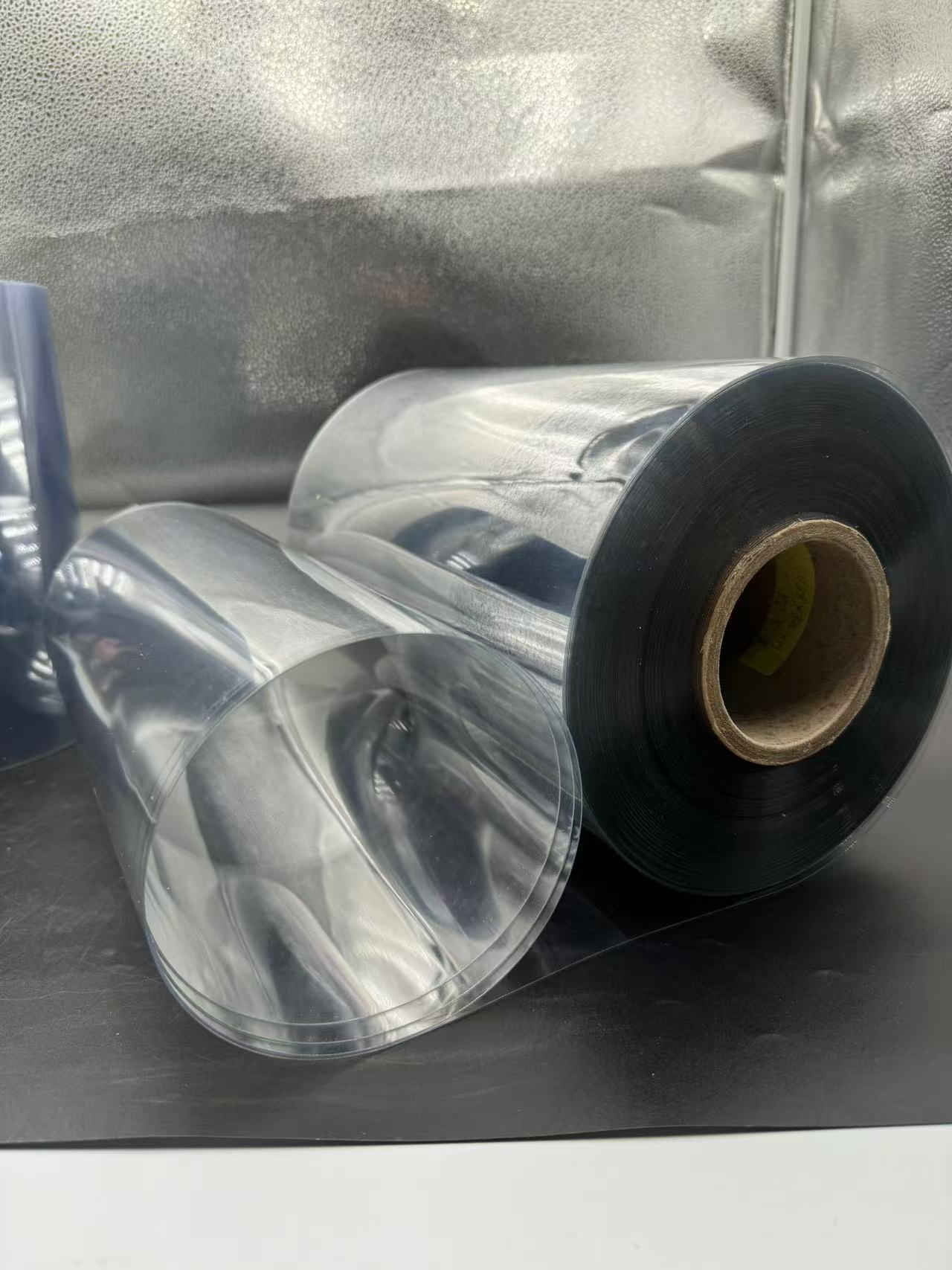

T186 The Application of Transparent PVC Film in Pharmaceutical Packaging Introduction

2024-11-22 15:06The Application of Transparent PVC Film in Pharmaceutical Packaging

Introduction

In the pharmaceutical industry, packaging plays a crucial role in safeguarding the integrity, potency, and safety of medications. Transparent PVC (polyvinyl chloride) film has emerged as a widely used material in pharmaceutical packaging due to its unique combination of properties. This article will explore in detail the various aspects of using transparent PVC film in pharmaceutical packaging, including its material characteristics, manufacturing process, different packaging applications, advantages, and potential concerns.

Material Properties of Transparent PVC Film

Chemical Composition and Structure

Transparent PVC film is composed of vinyl chloride monomers polymerized to form long - chain molecules. The molecular structure of PVC contains carbon - chlorine bonds, which contribute to its characteristic properties. These bonds give the film a certain degree of stability and chemical resistance. The polymerization process can be carefully controlled to achieve the desired molecular weight and chain length, thereby influencing the physical and chemical properties of the final film.

Transparency

The transparency of PVC film is one of its most outstanding features. It allows for clear visibility of the pharmaceutical products packaged within. This is of great significance as it enables healthcare providers and consumers to easily identify the medication, check for any physical defects or foreign particles, and verify the dosage form. The high - level transparency is maintained over time and under different environmental conditions, providing a reliable window for visual inspection.

Mechanical Properties

PVC film exhibits good mechanical strength. It has a notable tensile strength that enables it to withstand stretching forces during handling, packaging processes, and transportation. The film also possesses flexibility, which allows it to conform to the shape of the pharmaceutical products or packaging containers. This flexibility is beneficial in preventing cracks and breaks during handling and ensuring a snug fit. Additionally, the film has a certain level of puncture resistance, safeguarding it against accidental damage from sharp objects.

Barrier Properties

In pharmaceutical packaging, barrier properties are crucial. Transparent PVC film offers protection against moisture, gases, and other environmental factors. It can act as a barrier to prevent the ingress of moisture, which is essential for maintaining the stability and efficacy of many medications. For example, moisture can cause hydrolysis of certain drugs or promote the growth of microorganisms. The film also provides some resistance to gases like oxygen and carbon dioxide, helping to preserve the chemical integrity of the pharmaceuticals.

Chemical Resistance

PVC film is highly resistant to many common chemicals. It can withstand contact with a variety of substances that may be present in the pharmaceutical environment, such as alcohols, acids, and alkalis. This chemical resistance is valuable in ensuring that the film does not react with the medications or any substances used in the packaging or storage process. It helps to maintain the purity and quality of the drugs.

Thermal Properties

PVC film has specific thermal properties relevant to pharmaceutical packaging. It has a relatively low melting point, which allows it to be easily heat - sealed. Heat sealing is a common method used in packaging to create a secure and airtight enclosure. However, the film's thermal stability also needs to be considered, especially in applications where the packaged products may be exposed to elevated temperatures during storage or transportation. Special formulations or additives can be used to improve the film's thermal resistance if required.

Manufacturing Process of Transparent PVC Film for Pharmaceutical Packaging

Raw Material Preparation

The production of transparent PVC film for pharmaceutical packaging starts with the careful selection of high - quality vinyl chloride monomer. The purity of the monomer is of utmost importance as it directly impacts the quality of the resulting film. Along with the monomer, a variety of additives are incorporated. These include plasticizers to enhance the flexibility of the film, stabilizers to improve its thermal stability and prevent degradation during processing and storage, and lubricants to facilitate the extrusion process. The proper selection and proportioning of these additives are based on the specific requirements of the film for pharmaceutical packaging applications.

Extrusion Process

Once the raw materials are prepared, they are thoroughly mixed and fed into an extruder. The extruder heats the mixture to a molten state under precisely controlled temperature and pressure conditions. The temperature profile within the extruder is adjusted to ensure uniform melting of the PVC resin and proper dispersion of the additives. The molten PVC is then forced through a die to form a continuous sheet of film. The design of the die and the extrusion speed are carefully calibrated to achieve the desired thickness and width of the film. During the extrusion process, the molten film also undergoes cooling and calibration systems to maintain its uniformity and dimensional stability.

Calendering or Casting (Optional)

In some manufacturing scenarios, the extruded PVC film may undergo either calendering or casting processes. Calendering involves passing the film through a series of rollers to further refine its thickness, smoothness, and surface quality. This process can enhance the mechanical properties and appearance of the film. Casting, on the other hand, is a method where the molten PVC is spread onto a moving belt or drum to form the film. This technique can be utilized to achieve specific surface textures or to incorporate additional layers or coatings during the film - forming process.

Quality Control and Finishing

After the film is formed, it undergoes rigorous quality control procedures. The thickness of the film is measured using highly accurate instruments to ensure it meets the specific requirements. The transparency, mechanical strength, and barrier properties are also thoroughly tested. Any defects or non - conformities are identified and corrected. The film may then be wound onto rolls for storage or further processing. In some cases, additional finishing operations such as surface treatment to improve printability or the application of anti - static coatings may be carried out to enhance the film's functionality in pharmaceutical packaging applications.

Applications of Transparent PVC Film in Pharmaceutical Packaging

Blister Packs

Unit - Dose Packaging

Transparent PVC film is commonly used in blister packs for unit - dose pharmaceutical packaging. The film is heat - sealed to a backing material, usually aluminum foil or a composite material. Each cavity in the blister pack holds a single dose of a medication, such as a tablet or a capsule. The transparency of the PVC film allows for easy identification of the drug and its dosage form. For example, a patient can quickly recognize the shape and color of a tablet through the clear film, which helps in ensuring the correct medication is taken. The blister pack also provides protection against moisture, light, and physical damage, maintaining the integrity of the drug until it is ready to be consumed.

Child - Resistant Packaging

In some cases, blister packs made with transparent PVC film are designed to be child - resistant. This is achieved by incorporating special features such as push - through or peel - off mechanisms that are difficult for children to operate but easy for adults. The PVC film remains an essential part of the packaging as it provides the necessary transparency for visual inspection while also contributing to the overall strength and durability of the child - resistant design. For example, a blister pack of a potentially harmful medication can be made child - resistant using a combination of PVC film and a specific closure system, reducing the risk of accidental ingestion by children.

Strip Packs

Strip packs are another application of transparent PVC film in pharmaceutical packaging. These packs are used for packaging multiple doses of a medication in a single strip. The PVC film is folded and sealed around the tablets or capsules, creating a compact and convenient packaging format. The transparency of the film allows for easy counting of the doses and visual inspection of the medications. Strip packs are often used for over - the - counter medications and are popular due to their ease of use and portability. For instance, a strip pack of pain relievers can be easily carried in a purse or pocket, and the patient can quickly access the required dose.

Bottles and Jars

Transparent PVC film can be used as a shrink wrap or a tamper - evident seal for pharmaceutical bottles and jars. The film is applied around the neck or the cap of the container and then shrunk using heat. This provides a secure seal that indicates if the package has been opened or tampered with. The transparency of the PVC film allows for the label on the bottle or jar to be visible, and it also gives an added layer of protection against dust and moisture. For example, a bottle of cough syrup with a transparent PVC shrink wrap around the cap looks more professional and gives the consumer confidence that the product has not been tampered with.

Advantages of Using Transparent PVC Film in Pharmaceutical Packaging

Visual Inspection and Identification

The transparency of the PVC film allows for easy visual inspection of the pharmaceutical products. Healthcare providers can quickly check the quality and integrity of the medications before dispensing them. Consumers can also identify the drugs and verify their dosage forms, which is crucial for patient safety. This visual inspection capability helps in reducing the risk of medication errors and ensures that the correct product is being used.

Product Protection

The PVC film provides effective protection for pharmaceuticals. It acts as a barrier against moisture, gases, and light, which can degrade the quality and potency of the drugs. By preventing moisture ingress, it helps in maintaining the stability of many medications. The film also protects the products from physical damage during handling, transportation, and storage. For example, a blister pack made with PVC film can protect tablets from being crushed or damaged in transit.

Packaging Flexibility

Transparent PVC film offers great flexibility in pharmaceutical packaging design. It can be easily formed into different shapes and sizes to accommodate various pharmaceutical products. Whether it's a small tablet or a large capsule, the film can be customized to create the appropriate packaging. It can also be combined with other materials, such as aluminum foil or paperboard, to create more complex and functional packaging systems.

Cost - effectiveness

Using transparent PVC film in pharmaceutical packaging can be a cost - effective solution. The film itself is relatively inexpensive compared to some other packaging materials. The manufacturing processes for PVC film - based packaging, such as blister packing and strip packing, are also well - established and efficient, which can help in reducing production costs. Additionally, the durability and protection provided by the film can result in fewer product losses due to damage or spoilage, further contributing to cost savings.

Printability and Branding

The surface of transparent PVC film can be easily printed on, allowing for clear and attractive labeling and branding. Pharmaceutical companies can print product information, dosage instructions, and their logos on the film. This helps in enhancing the brand image and providing important information to the consumers. The clear and smooth surface of the film ensures good print quality, making the packaging more appealing and informative.

Case Studies of Transparent PVC Film in Pharmaceutical Packaging Applications

Case Study 1: Blister Pack for a New Antibiotic

A pharmaceutical company developed a new antibiotic and chose to package it in a blister pack made with transparent PVC film. The transparency of the film allowed healthcare providers to easily identify the tablets and verify the dosage. The blister pack provided excellent protection against moisture and light, ensuring the stability of the antibiotic. The child - resistant design of the blister pack, which incorporated PVC film, met the safety requirements and gave parents peace of mind. The product was well - received in the market, and the packaging was credited with enhancing the overall quality and safety of the medication.

Case Study 2: Strip Pack for Over - the - Counter Pain Relievers

An over - the - counter pain reliever manufacturer switched to using strip packs made with transparent PVC film. The transparency of the film made it easy for consumers to count the doses and visually inspect the tablets. The strip packs were more convenient and portable than the previous packaging format. The PVC film also provided sufficient protection against moisture and physical damage. The manufacturer noticed an increase in sales as the new packaging was more appealing to consumers and met their needs for ease of use.

Case Study 3: Shrink Wrap for Pharmaceutical Bottles

A company that produces a variety of pharmaceutical bottles started using transparent PVC film as a shrink wrap for their products. The shrink wrap provided a tamper - evident seal, which was important for ensuring the safety and integrity of the medications. The transparency of the film allowed the labels on the bottles to be clearly visible, and it added an extra layer of protection against dust and moisture. The company reported a reduction in product returns due to damaged or tampered - with bottles, and the overall appearance of the packaged products was improved.

Challenges and Solutions in Using Transparent PVC Film in Pharmaceutical Packaging

Environmental Concerns

One of the main challenges in using PVC film in pharmaceutical packaging is its environmental impact. PVC is not easily biodegradable, and its disposal can pose a problem. To address this, efforts can be made to recycle the PVC film. Some recycling programs are being developed to collect and process used pharmaceutical packaging made from PVC. Additionally, manufacturers can explore the use of more environmentally friendly alternatives to PVC or develop biodegradable versions of PVC film. Another approach is to design the packaging in such a way that it is easier to disassemble and recycle, for example, by using removable adhesives or designing for disassembly.

Adhesion and Lamination Issues

In some cases, ensuring proper adhesion between the PVC film and other packaging materials, such as aluminum foil in blister packs, can be a challenge. If the adhesion is not strong enough, the layers may separate, compromising the integrity of the packaging. To overcome this, careful selection of adhesives and optimization of the lamination process parameters, such as temperature, pressure, and curing time, are essential. Testing and quality control measures should be in place to ensure consistent adhesion quality.

Chemical Compatibility

Although PVC film has good chemical resistance, there may be some concerns regarding its chemical compatibility with certain drugs or additives. Some medications may have active ingredients or excipients that could potentially interact with the PVC film. To address this, manufacturers need to conduct thorough compatibility studies before using PVC film for a particular pharmaceutical product. They can also consider using special coatings or additives in the PVC film to improve its chemical compatibility.

Regulatory Compliance

The pharmaceutical industry is highly regulated, and packaging materials must comply with strict regulatory requirements. Transparent PVC film used in pharmaceutical packaging must meet standards related to safety, purity, and barrier properties. Manufacturers need to ensure that their production processes and the final product meet all relevant regulatory standards through proper testing and documentation. This includes tests for migration of substances from the film into the drug, which could affect its quality and safety.

Conclusion

Transparent PVC film has proven to be a valuable material in pharmaceutical packaging. Its unique properties, including transparency, mechanical strength, barrier protection, chemical resistance, and printability, make it suitable for a wide range of packaging applications such as blister packs, strip packs, and bottle seals. Despite the challenges related to environmental concerns, adhesion, chemical compatibility, and regulatory compliance, there are solutions available to address them. With continued research and development, the use of transparent PVC film in pharmaceutical packaging is expected to evolve and continue to provide effective and efficient packaging solutions for the pharmaceutical industry. As the industry focuses on patient safety, product quality, and cost - effectiveness, the proper utilization of transparent PVC film can contribute to meeting these goals and ensuring the integrity and availability of medications in the market.

请用英语写一篇关于透明PET膜,在蔬菜,水果,礼品包装方面的使用文章 要生动真实具体!5000字左右!谢谢

The Application of Transparent PET Film in Vegetable, Fruit, and Gift Packaging

Introduction

In the realm of packaging, the choice of material is crucial in determining the protection, presentation, and overall quality of the packaged items. Transparent PET (polyethylene terephthalate) film has emerged as a popular and versatile option, particularly in the packaging of vegetables, fruits, and gifts. Its unique combination of properties makes it an ideal candidate for these applications, ensuring that the contents are not only well-preserved but also attractively displayed.

Material Properties of Transparent PET Film

Chemical Composition and Structure

Transparent PET film is composed of polyethylene terephthalate polymers. The molecular structure of PET consists of repeating units of ester linkages between terephthalic acid and ethylene glycol. This structure imparts several desirable characteristics to the film. It is a thermoplastic material, which means it can be melted and reformed, allowing for various manufacturing processes. The presence of the ester groups gives PET good chemical resistance and stability.

Transparency and Clarity

One of the most prominent features of transparent PET film is its excellent transparency and clarity. It allows for a clear and unobstructed view of the contents, which is highly advantageous in the packaging of vegetables, fruits, and gifts. When used for packaging fresh produce, consumers can easily assess the quality, ripeness, and freshness of the items. In gift packaging, the transparency showcases the beauty and elegance of the gift, enhancing its visual appeal. The high level of clarity is maintained over time and under different environmental conditions, ensuring that the packaged items always look their best.

Mechanical Properties

PET film exhibits strong mechanical properties. It has a relatively high tensile strength, enabling it to withstand stretching and pulling forces without tearing easily. This is especially important in the packaging process, as it allows the film to be formed and sealed without damage. The film also has good flexibility, which means it can conform to the shape of the packaged objects. For example, when wrapping irregularly shaped fruits or vegetables, the PET film can adapt and provide a snug fit, protecting the items from external impacts and scratches. Additionally, the film has a certain degree of puncture resistance, safeguarding the contents from accidental punctures that could occur during handling or transportation.

Barrier Properties

In terms of barrier properties, transparent PET film offers significant protection. It acts as a barrier against moisture, gases, and odors. In the case of vegetable and fruit packaging, it helps to maintain the freshness and quality of the produce. By preventing moisture loss, it keeps the fruits and vegetables hydrated and crisp. It also restricts the entry of oxygen and carbon dioxide, which can slow down the ripening process and prevent spoilage. For gift packaging, the barrier properties protect the contents from external contaminants and maintain their integrity. For example, a delicate piece of jewelry or a scented candle packaged in PET film will be shielded from moisture and odors that could affect their quality.

Heat Resistance

PET film has good heat resistance, which is beneficial in certain packaging applications. It can withstand relatively high temperatures without deforming or losing its integrity. This property is useful in processes such as heat-sealing, where the film is used to create a secure and airtight package. It also allows for the packaging of hot-fill products, although the specific heat resistance may vary depending on the thickness and formulation of the film. For example, in the packaging of some prepared fruit juices or sauces that are filled hot, the PET film can handle the initial heat and then provide a stable enclosure during cooling and storage.

Chemical Resistance

The chemical resistance of PET film is another valuable property. It is resistant to a wide range of acids, alkalis, and common solvents. This makes it suitable for packaging a variety of items, including those with acidic or alkaline properties. In the context of vegetable and fruit packaging, it can come into contact with natural acids present in the produce without reacting or degrading. For gift packaging, it can withstand contact with any potential chemicals in perfumes, lotions, or other cosmetic products that might be included in a gift set.

Manufacturing Process of Transparent PET Film

Raw Material Preparation

The production of transparent PET film begins with the careful selection and preparation of high-quality polyethylene terephthalate resin. The resin is typically sourced from petrochemical feedstocks and undergoes purification processes to ensure its purity and consistency. Additives may be incorporated into the resin to enhance specific properties of the film. For example, antioxidants are added to prevent degradation during processing and storage, and plasticizers may be used to adjust the flexibility of the film. The resin and additives are then thoroughly mixed in a blender or extruder to create a homogeneous blend.

Extrusion Process

The blended raw materials are fed into an extruder, where they are heated and melted. The extruder consists of a screw that rotates within a heated barrel, gradually increasing the temperature of the material as it moves forward. The molten PET is then forced through a flat die, which determines the width and thickness of the emerging film. The die is carefully designed to ensure a uniform flow of the molten material, resulting in a consistent film thickness.

Orientation Process

After extrusion, the PET film undergoes an orientation process to enhance its mechanical and optical properties. This involves stretching the film in both the machine direction (MD) and the transverse direction (TD). The stretching is carried out at a temperature above the glass transition temperature of PET but below its melting point. Biaxial orientation, which stretches the film in both directions simultaneously, is commonly used. This process aligns the polymer chains in the film, increasing its tensile strength, modulus, and clarity. The degree of stretching and the temperature conditions are precisely controlled to achieve the desired properties.

Heat Setting

Following the orientation process, the film is heat-set. Heat setting involves heating the oriented film to a specific temperature and holding it for a certain period. This step stabilizes the molecular structure of the film, reducing its shrinkage tendency and improving its dimensional stability. The heat-setting temperature and time are carefully optimized based on the thickness and desired properties of the film.

Surface Treatment and Quality Control

The surface of the PET film may undergo treatment to improve its adhesion properties, especially if it is to be printed or laminated. Corona treatment is a common method, where the film is exposed to a high-voltage electrical discharge, creating a more reactive surface. After surface treatment, the film undergoes rigorous quality control procedures. The thickness is measured using precision instruments to ensure it meets the specified requirements. The transparency, mechanical strength, and barrier properties are also tested. Any defects such as pinholes, scratches, or non-uniform thickness are detected and the defective portions are removed or the entire roll is rejected. The film is then wound onto rolls of the appropriate size and length, ready for further processing into packaging materials.

Applications of Transparent PET Film in Vegetable and Fruit Packaging

Packaging of Fresh Produce

Transparent PET film is widely used in packaging fresh vegetables and fruits. For example, in the packaging of strawberries, the film is used to create clamshell containers. The transparency of the film allows consumers to see the bright red, juicy strawberries, which is highly appealing. The film provides a protective barrier against moisture loss, preventing the strawberries from drying out and losing their firmness. It also restricts the entry of oxygen, which can slow down the ripening process and extend the shelf life of the berries.

For leafy greens such as lettuce and spinach, PET film bags are often used. The film keeps the greens fresh by maintaining the right moisture balance. It allows for a small amount of gas exchange to prevent the build-up of ethylene gas, which can cause premature spoilage. The clear view of the greens through the film gives consumers confidence in the quality of the product.

Modified Atmosphere Packaging (MAP)

In modified atmosphere packaging, transparent PET film is used in combination with other materials to create a specific gas environment within the package. For example, in the packaging of apples, a PET film pouch may be used with a gas mixture of reduced oxygen and increased carbon dioxide levels. The PET film helps to maintain this modified atmosphere, which can significantly extend the storage life of the apples. The transparency of the film allows for visual inspection of the apples without disturbing the internal gas environment.

Packaging of Cut Fruits and Vegetables

For pre-cut fruits and vegetables, such as sliced melons or carrot sticks, PET film is used to create sealed trays or pouches. The film protects the cut surfaces from drying out and from contamination by bacteria and other microorganisms. The barrier properties of the film also help to maintain the flavor and nutritional value of the cut produce. The transparency enables consumers to easily identify the contents and assess their freshness.

Applications of Transparent PET Film in Gift Packaging

Wrapping of Small Gifts

Transparent PET film is ideal for wrapping small gifts such as jewelry, watches, and small trinkets. The transparency of the film showcases the beauty and elegance of the gift item. It can be easily formed around the object, providing a smooth and clear enclosure. The film's flexibility allows for creative wrapping styles, and it can be tied with a decorative ribbon or bow to enhance the presentation. For example, a delicate silver necklace wrapped in a clear PET film with a satin bow looks both luxurious and inviting.

Packaging of Gift Sets

For gift sets that contain multiple items, such as a set of perfumes, cosmetics, or gourmet food items, PET film is used to create boxes or sleeves. The film protects the contents from damage and provides a clear view of the items inside. It can be printed with decorative designs or the brand logo, adding a personalized touch to the gift. For instance, a gift set of high-end chocolates packaged in a PET film box with a beautiful printed design on the film looks both sophisticated and appetizing.

Decorative Pouches and Bags

PET film is also used to create decorative pouches and bags for gifts. These can be used for small gifts like candles, soaps, or stationery items. The film can be made in different colors or with added decorative elements such as glitter or embossed patterns. The transparency still allows for a peek at the contents, creating an element of anticipation. For example, a scented candle in a transparent PET film pouch with a glittery finish is both visually appealing and practical.

Advantages of Using Transparent PET Film in Packaging

Product Protection

The combination of the mechanical strength and barrier properties of transparent PET film provides excellent protection for the packaged items. In the case of vegetables and fruits, it helps to maintain their freshness, texture, and nutritional value. For gifts, it protects them from damage during handling, transportation, and storage. The film acts as a shield against moisture, gases, odors, and physical impacts, ensuring that the contents reach the end-user in optimal condition.

Visual Appeal and Marketing

The transparency of PET film is a significant advantage in marketing. In the grocery store, the clear view of the fresh produce through the film can attract consumers and influence their purchasing decisions. For gift packaging, it showcases the beauty and quality of the gift, making it more desirable. The smooth and clear surface of the film also allows for high-quality printing and decoration, enabling brands to create eye-catching and informative packaging. Whether it's a label with the name of a fruit variety or a beautifully designed gift box with a brand logo, the PET film enhances the visual impact.

Versatility in Packaging Design

PET film is highly versatile in terms of packaging design. It can be formed into different shapes and sizes, from flat sheets for wrapping to three-dimensional containers like clamshells and trays. It can be combined with other materials such as paperboard or plastic trays to create hybrid packaging systems. For example, a gift box made of paperboard with a transparent PET film window provides both structural strength and a clear view of the contents. The film can also be used in flexible packaging formats like bags and pouches, offering a wide range of options for different packaging needs.

Durability and Longevity

PET film has good durability and a relatively long shelf life. It can withstand the rigors of the supply chain, including handling, stacking, and transportation. In the case of long-term storage of gift items or perishable produce, the film maintains its integrity and protective properties. This durability reduces the risk of packaging failure and product damage, providing peace of mind for both manufacturers and consumers.

Recyclability

PET is a widely recyclable material, and transparent PET film is no exception. After use, the film can be collected and recycled into new products. This makes it an environmentally friendly choice compared to some non-recyclable packaging materials. The recycling process helps to conserve resources and reduce waste, aligning with the growing trend towards sustainable packaging.

Case Studies of Transparent PET Film in Packaging Applications

Case Study 1: Vegetable Packaging for a Supermarket Chain

A large supermarket chain decided to switch from traditional plastic bags to transparent PET film bags for packaging their leafy greens. After the switch, they noticed a significant reduction in the amount of spoiled produce. The PET film bags maintained the freshness of the greens better by controlling moisture and gas exchange. The transparency of the bags also allowed consumers to see the quality of the greens, leading to increased sales. The supermarket chain reported higher customer satisfaction and a decrease in waste, resulting in cost savings.

Case Study 2: Fruit Packaging for an Exporter

An exporter of tropical fruits started using transparent PET film clamshells for packaging their mangoes. The clamshells provided excellent protection against physical damage during transportation and storage. The modified atmosphere created within the clamshells using PET film extended the shelf life of the mangoes, allowing them to reach international markets in better condition. The clear view of the mangoes through the film made them more attractive to consumers overseas, leading to increased demand and higher profits for the exporter.

Case Study 3: Gift Packaging for a Luxury Brand

A luxury brand of watches started using transparent PET film boxes for packaging their high-end timepieces. The film boxes enhanced the presentation of the watches, highlighting their elegance and craftsmanship. The durability of the PET film ensured that the watches were well-protected during shipping and handling. The brand noticed an increase in customer perception of the quality of their products, and the unique packaging became a signature of their brand. The recyclability of the PET film also aligned with the brand's commitment to sustainability, further enhancing its image.

Challenges and Solutions in Using Transparent PET Film in Packaging

Cost Considerations

The production of transparent PET film can be relatively expensive compared to some other packaging materials. To address this, manufacturers can look for ways to optimize the manufacturing process, such as improving the efficiency of extrusion and orientation. Bulk purchasing of raw materials and negotiating better deals with suppliers can also help to reduce costs. Additionally, considering the long-term benefits of the film, such as extended shelf life and reduced product waste, can justify the higher initial investment.

Environmental Impact

Although PET is recyclable, the recycling rate of PET film is still relatively low in some areas. To improve this, efforts should be made to increase consumer awareness about the recyclability of PET film and to improve the collection and recycling infrastructure. Manufacturers can also explore the use of bio-based PET or other more sustainable alternatives. Another approach is to design the packaging in such a way that it is easier to recycle, for example, by using fewer layers or avoiding complex laminations.

Heat Sealability

In some cases, achieving consistent and reliable heat sealability of PET film can be a challenge. Different products and packaging designs may require specific heat seal conditions. To overcome this, manufacturers can conduct extensive testing to determine the optimal heat seal parameters for different applications. They can also work with equipment suppliers to ensure that the packaging machinery is compatible with the film's heat seal requirements. Additionally, using additives or modifying the film's composition can improve its heat sealability.

Printing and Labeling

Printing on PET film can sometimes be difficult due to its smooth surface and low surface energy. Ink may not adhere well, resulting in poor print quality. To address this, surface treatment methods such as corona treatment or plasma treatment can be used. These treatments increase the surface energy of the film, improving the adhesion of ink. Additionally, special inks and printing techniques that are compatible with PET film can be employed to ensure clear and durable printing.

Conclusion

Transparent PET film has proven to be a valuable asset in the packaging of vegetables, fruits, and gifts. Its unique combination of properties, including transparency, mechanical strength, barrier protection, heat resistance, chemical resistance, and recyclability, makes it an ideal choice for a wide range of packaging applications. Despite the challenges related to cost, environmental impact, heat sealability, and printing, there are solutions available to overcome them. As the demand for sustainable, attractive, and functional packaging continues to grow, transparent PET film is likely to play an even more significant role in the future. With ongoing research and development, the performance and environmental friendliness of PET film-based packaging can be further enhanced, providing better packaging solutions for both producers and consumers.