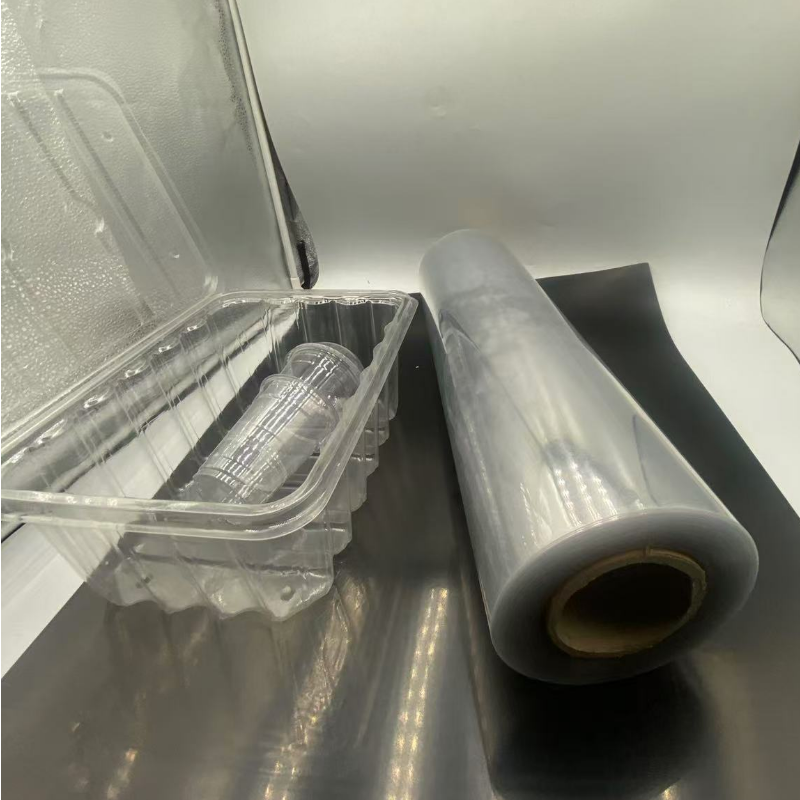

Transparent PCR PET Film; Food Blister Packaging; Sustainability; Barrier Properties; Product Protection

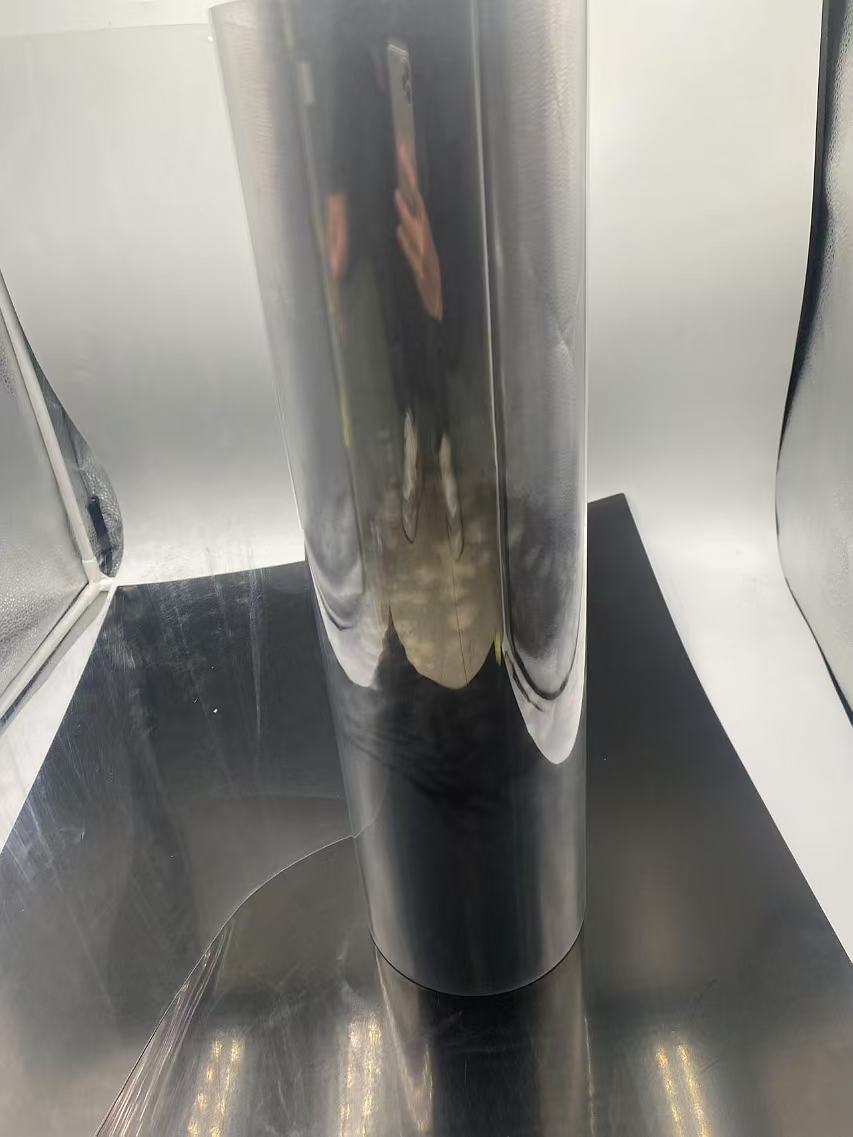

2024-12-20 16:14The Diverse Applications of Transparent PCR PET Film Abstract: This paper goes in-depth into the manifold and varied applications of transparent PCR PET film in industries, with special attention paid to food blister packaging. To begin with, it covers the unique properties of the film,

such as outstanding transparency, superior strength, recyclability, and barrier characteristics. It explains, with detailed analysis and a plethora of practical examples, how the Transparent PCR PET Film not only meets the stringent requirements of modern packaging but also contributes to sustainable development and product protection, from food and beverages to electronics and pharmaceuticals.

Keywords: Transparent PCR PET Film; Food Blister Packaging; Sustainability; Barrier Properties; Product Protection

1. Introduction

Transparent PCR PET Film has emerged as a game-changer in this era of the environment and product quality going hand in hand. Its remarkable material has seen massive demand in the marketplace as companies look for sustainable packaging solutions that do not compromise functionality. The ability of the material to combine the advantages of recycled content with the necessary properties for various applications has drawn interest from multiple industries in it.

2. Properties of Transparent PCR PET Film

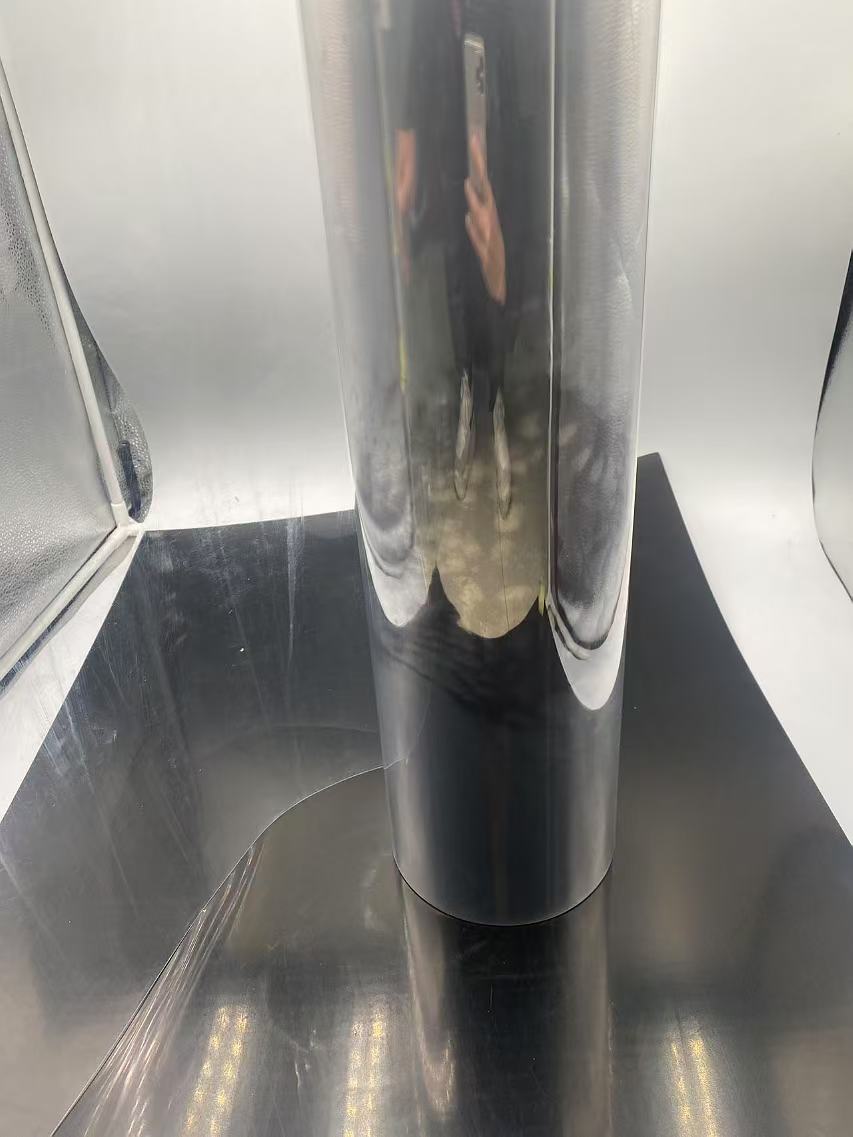

2.1 Transparency

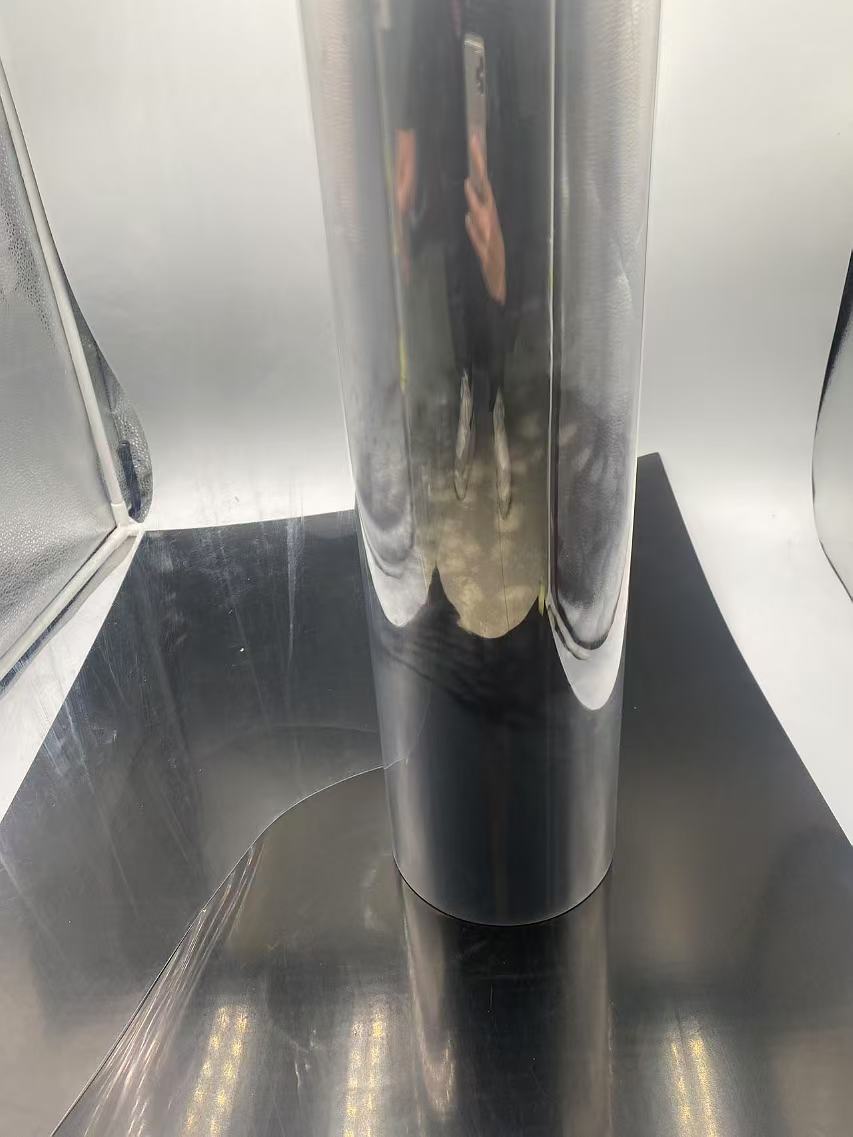

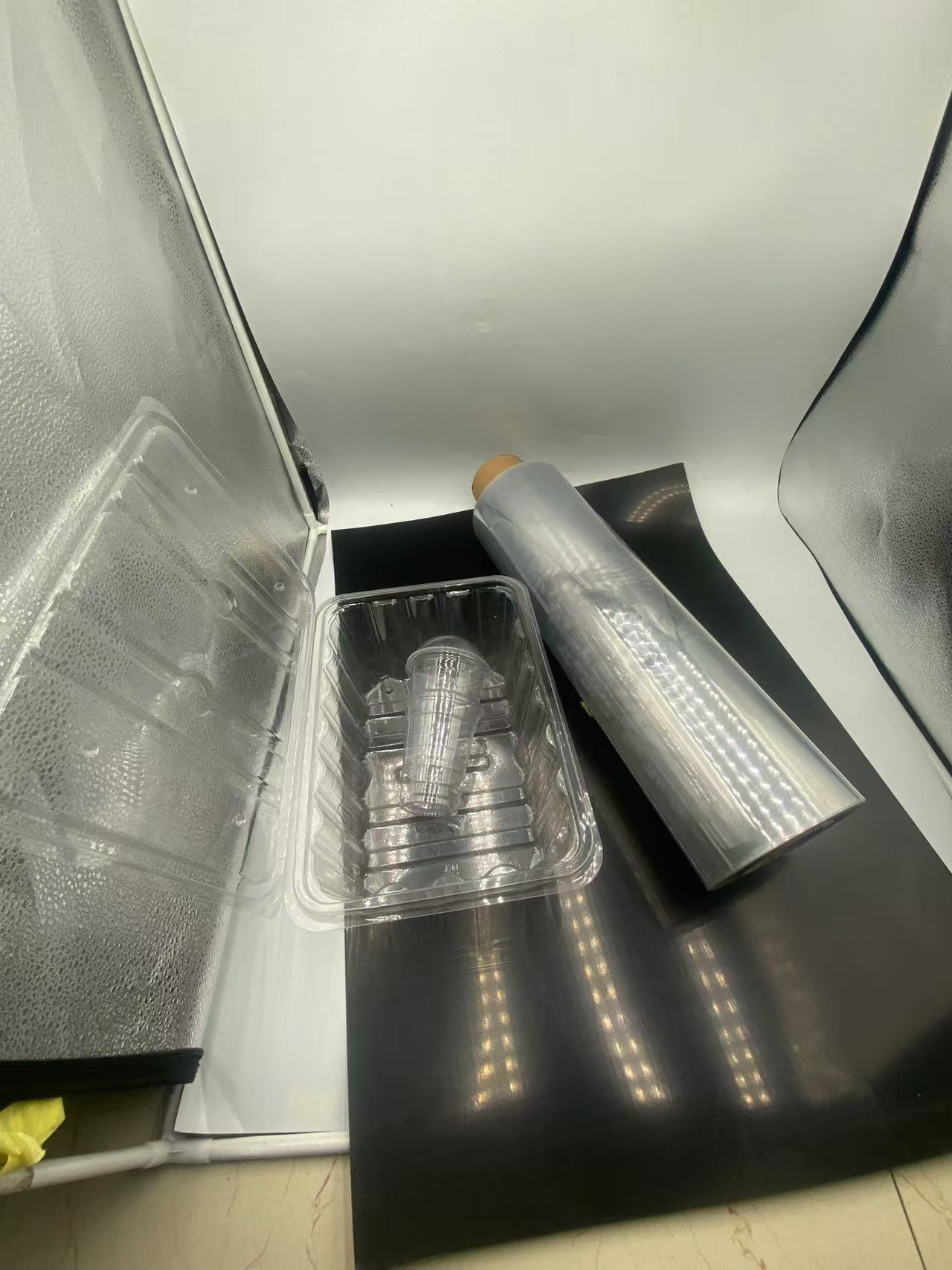

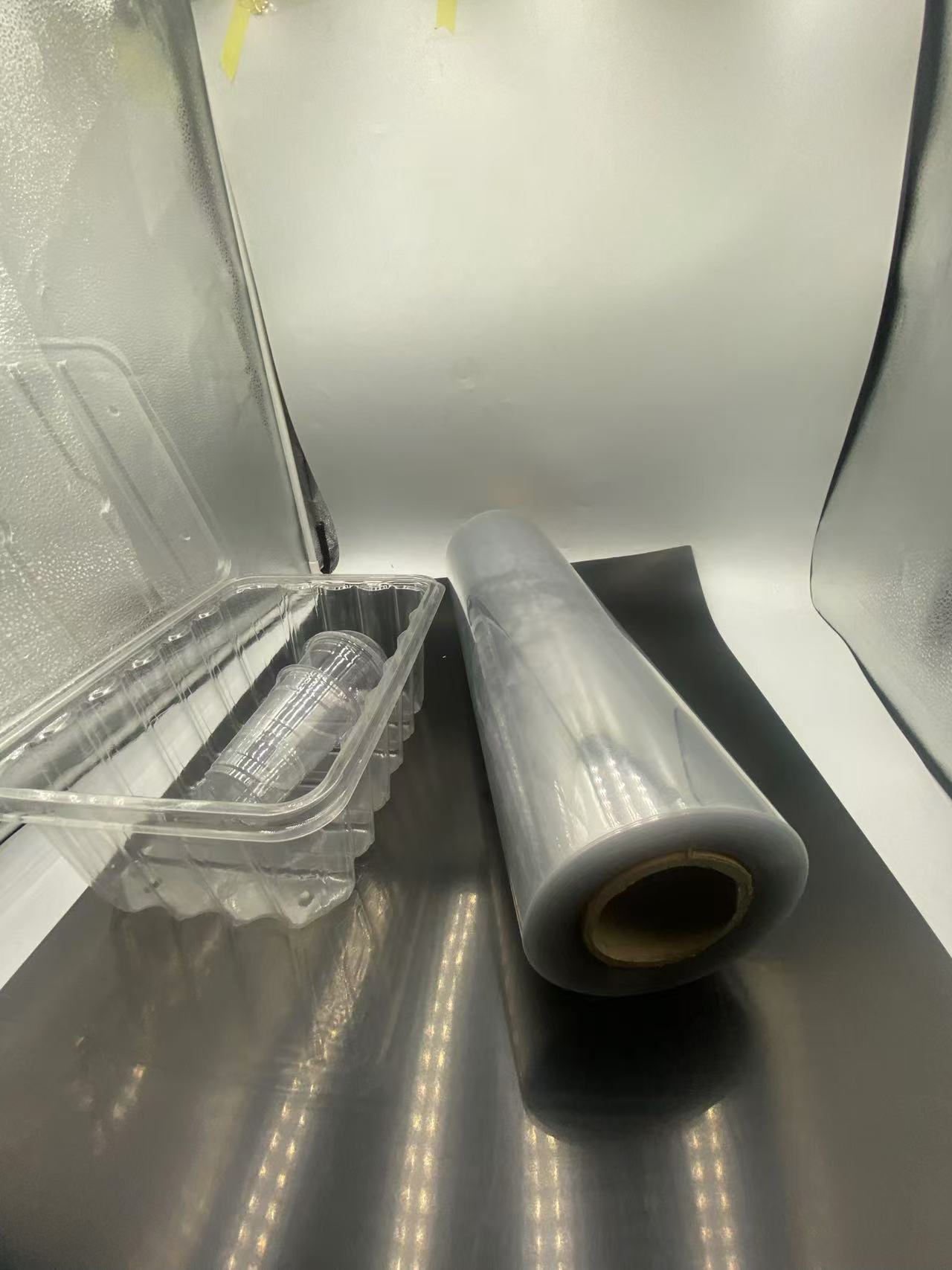

The transparency of the transparent PCR PET film is beyond compare. The contents in it are viewed with absolute clarity, thus making the material a material of paramount relevance in packaging that calls for product visibility. In the food industry, for example, it's very easy to tell how good something tastes, the color, or even its texture-be it a fresh fruit, pastry, or a snack. The clarity does not only improve in appeal but also trust amongst the consumers since they are certain of what they purchase. In the case of electronics packaging, it allows for a clear display of the device's features and design, which is critical for marketing and consumer decision-making.

2.2 Strength and Durability

Despite being made from recycled materials, Transparent PCR PET Film exhibits excellent strength and durability. It can bear the rigors of handling, transportation, and storage without easily tearing or deforming. This property is critical in protecting the packaged products. With either heavily fragile goods packed-like glassware, precise mechanisms, or other highly sensible apparatus, the film provides excellent protection. It can withhold shocks and stresses during transit without letting the products inside the package get damaged to a stage that renders them unsellable. Tensile strength is quite good enough to keep all of its contents tightly held up, so that nothing displaces or gets damaged from within. 2.3 Recyclability

The main benefits of using Transparent PCR PET Film are its recyclability and reuse. Being a post-consumer recycled material, it contributes to the circular economy by reducing the demand for virgin plastics. When appropriately recycled, it can be transformed back into new packaging or other useful products, thereby minimizing waste and environmental impact. This aspect is of particular importance in the current global push toward sustainable manufacturing and consumption. This material, therefore, helps packaging companies in meeting their environmental objectives and commitments to regulations while at the same time maintaining the quality of their packaging solutions.

2.4 Barrier Properties

The transparent PCR PET film also has very good barrier properties. It effectively bars the ingress of moisture, oxygen, and other gases that are known to cause spoilage and deterioration of many products. In the food and beverage industry, this is important for maintaining freshness and flavor. For instance, in the packaging of snacks, such as chips or crackers, the film does not allow moisture to get inside the package and make it soggy; hence, it keeps them crispy. For carbonated drinks, it retains the carbonation in the drink, making it fizzy for a longer period. In the pharmaceutical and cosmetic industries, barrier properties protect the active ingredients and formulations from oxidation and other chemical reactions, maintaining their potency and quality.

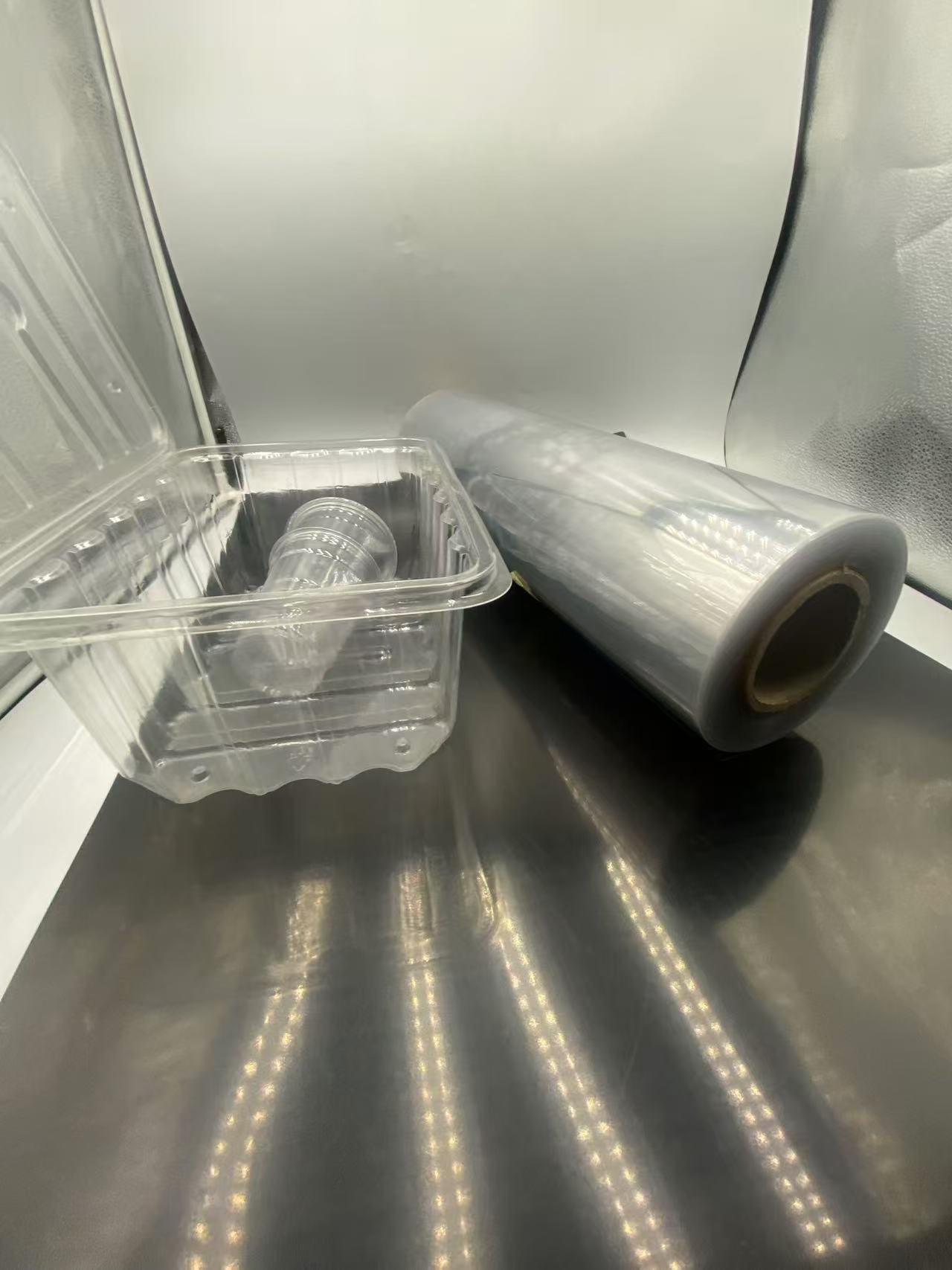

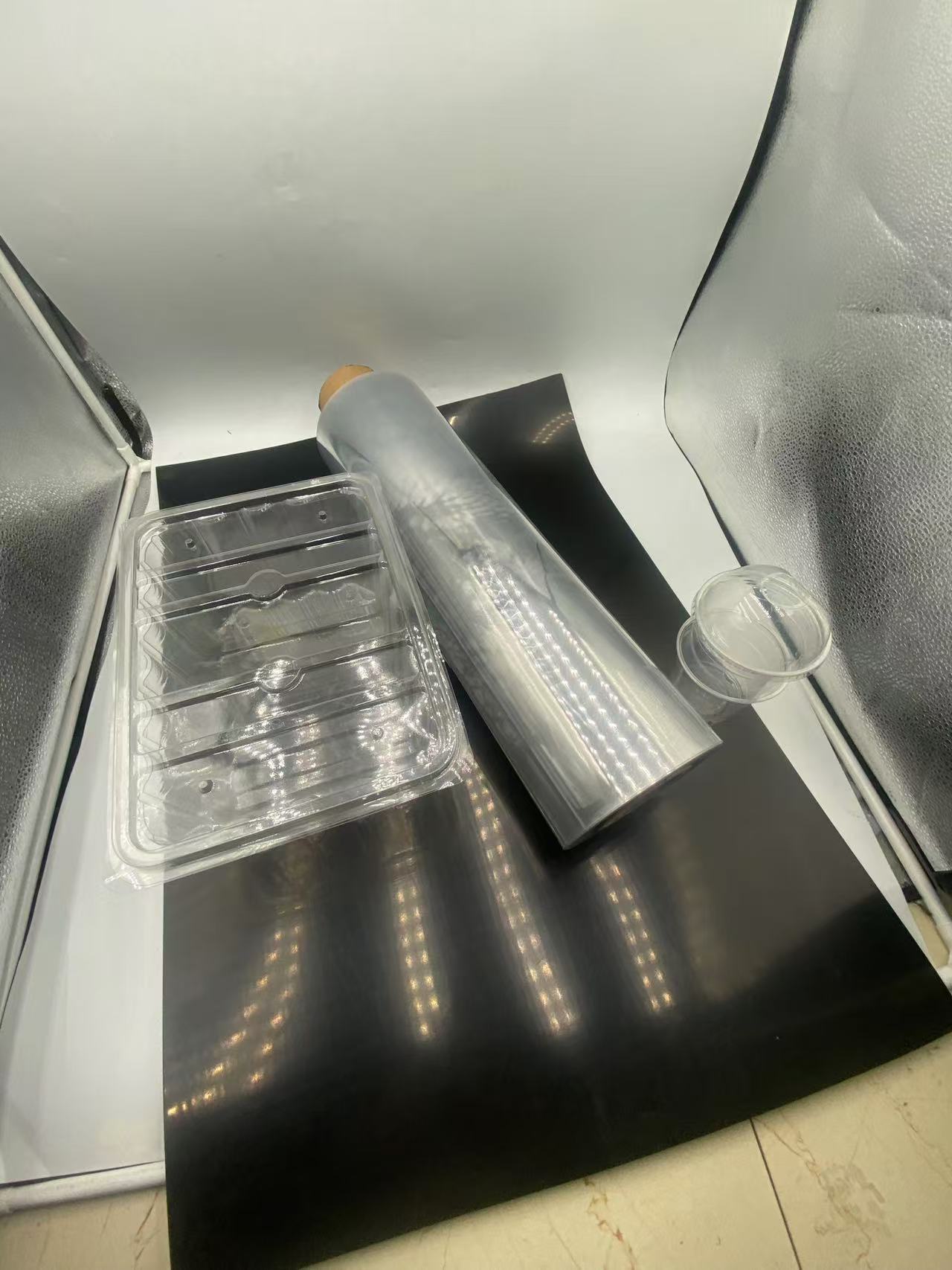

3. Application in Food Blister Packaging

3.1 Bakery and Confectionery

In the bakery and confectionery sector, Transparent PCR PET Film is widely used. For freshly baked bread, it serves to retain the softness and moisture, preventing the crust from getting hard too quickly. Transparency of the film helps the golden brown color and tempting texture of the bread to be highlighted, thus attracting customers. In cakes and pastries, not only does the film prevent any physical damage, but it also maintains the freshness and appearance of the products. For instance, a fragile cream-filled cake can be safely enclosed in the film since it prevents the cream from smudging or drying up while still allowing the attractive decoration on top to be viewed. In the packaging of chocolates and candies, this barrier property of the film is crucial for maintaining flavor and texture. This keeps the chocolates from blooming-the common white film arising from a change in either temperature or moisture that eventually shows on the surface. In essence, it serves as a separative medium preventing the candies from sticking together.

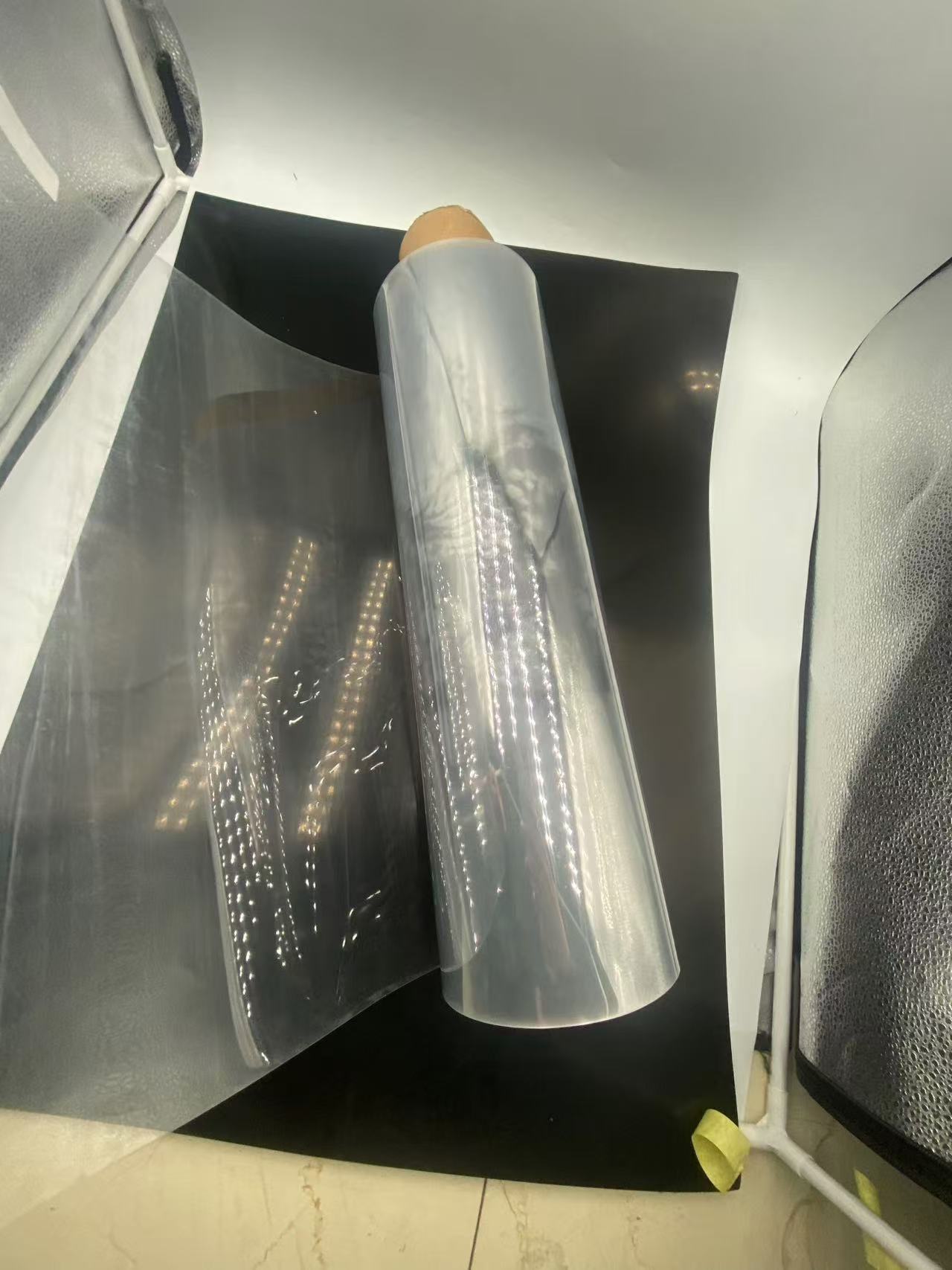

3.2 Fresh Produce

Transparent PCR PET Film has recently found its usage in packaging fresh produce. Designed appropriately with perforations that will help in proper gas exchange necessary to sustain the freshness of vegetables and fruits. For example, in the case of strawberry packaging, this film protects the strawberries against bruising and moisture loss by allowing just the correct amount of oxygen and carbon dioxide to pass through the film. This slows the ripening process down and keeps the berries fresh for an extended period. In the case of leafy greens, such as lettuce and spinach, the film keeps the greens crisp and fresh. The transparency of the film allows consumers to see through it and observe the quality of the produce they are buying, a factor very important in fresh produce marketing.

3.3 Processed Foods

In the case of ready-to-eat meals, tinned foods, and dehydrated foodstuffs, Transparent PCR PET Film can be used. It is a shielding layer that saves the food from external adulteration, moisture, and light. The film can be used in the packaging of canned soups or sauces to cover and prevent scratches on, and possible damage to, the can, providing some additional information about the product and branding. The same barrier properties of the film would prevent the nuts and fruits from moisture absorption and turning rancid. The transparency of the film allows for clear labeling and display of the nutritional information and ingredients, which is essential for consumer awareness and regulatory requirements.

4. Application in Non-Food Packaging

4.1 Electronics Packaging

In the electronics industry, Transparent PCR PET Film is used to package a variety of products. It protects delicate components such as circuit boards, chips, and displays from physical damage, dust, and static electricity. The transparency of the film allows for easy inspection of the components during manufacturing and quality control processes. For example, in packaging smartphones or tablets, it can serve as a screen protector or an outer wrap that displays the sleekness of the device while protecting it from scratches and fingerprints. The film provides a stable and protective environment for electronic components such as capacitors and resistors during storage and transportation; this ensures that they reach the assembly line in perfect condition. 4.2 Pharmaceutical Packaging The Transparent PCR PET Film used in pharmaceutical packaging is for blister packs that hold tablets and capsules. The transparency of the film facilitates easy visual inspection of the drugs for any defects or foreign particles. Barrier properties shield the drugs against moisture, oxygen, and light, which may result in their degradation and potency reduction. Like packaging for aspirin or vitamins, the film helps to protect the stability of the active ingredients in such medications through to expiration dates. Further, the recyclability of the film meets the environmental imperatives of the pharmaceutical industry, which is increasingly striving for sustainable packaging solutions.

4.3 Cosmetic Packaging

In the cosmetic industry, Transparent PCR PET Film is used in packaging everything from lipsticks and mascaras to creams and lotions. Transparency of the film allows for the beautiful colors and textures of cosmetics to be shown off, which appeals to consumers. The barrier properties protect the formulations against oxidation and microbial contamination that could affect the quality and shelf life of the products. For example, in the packaging of a high-end moisturizer, the film helps to keep the cream fresh and effective by preventing the ingress of air and moisture. The film can also be printed with elegant designs and branding elements, enhancing the overall aesthetic appeal of the cosmetic packaging.

5. Packaging Design and Innovation

5.1 Shape and Size Customization

Transparent PCR PET Film offers great flexibility in packaging design. It can be molded into various shapes and sizes to meet the specific requirements of different products. It is used in the packaging of irregularly shaped items, such as toys or novelty products, by thermoforming the film to create a custom-fit enclosure. Within the food industry, it allows for unique blister pack designs, which can be used either for individual servings or for special occasion products. The possibility of changing the shape and size of packaging enhances not only the appearance but also the functionality and protection of goods. 5.2 Tamper-Evident and Child-Resistant Packaging The film can be integrated into tamper-evident and child-resistant packaging designs. The transparent nature of the PCR PET film also allows special seals and closures to be made for pharmaceutical and food products to indicate whether or not the product has been opened or tampered with before reaching the consumer. In the case of child-resistant packaging, the film can be combined with other materials and mechanisms to make it difficult for children to access the contents, while still allowing adults to open it easily. This is crucial for the safety of consumers, especially in the case of products that may be harmful if ingested by children.

5.3 Printed and Decorated Packaging

The transparent PCR PET Film allows for printing high-quality graphics, text, and branding elements. This makes the packaging design creative and very eye-catching. In the food and beverage industry, the film can be printed with appetizing images of the products, nutritional information, and promotional offers. In the cosmetic and electronics industries, it is used to display elegant logos, product features, and user instructions. The printing technology has reached such a level that even brilliant colors and fine images can be reproduced on the film, which will add value to the marketing and communication of the package.

6. Quality Control and Regulatory Compliance

6.1 Quality Control Measures

To ensure the quality of Transparent PCR PET Film, manufacturers put in place rigorous quality control measures. Among them are tests for thickness, transparency, strength, and barrier properties of the film. The film is further inspected for any imperfections or impurities that could impact its functionality. Samples of the film, for instance, would be taken to a quality control laboratory for tests using special equipment that measures the tensile strength, oxygen, and moisture transmission rate, and optical clarity. Any deviations from set quality standards are then identified and corrected before the film is used in packaging applications.

6.2 Regulatory Compliance

Packaging with Transparent PCR PET Film has to meet various regulatory requirements. In the food and pharmaceutical industries, food contact safety and standards of packaging of drugs are two of the strict regulations to be met by the film. For example, a European Union movie package must comply with EU directives on food contact materials specifying limits on the level of migration of substances from package to food or drugs, as well as regulations affecting industries such as electronics in cases of packaging materials against the buildup of electrostatic and incorrect protection of electronic components. Manufacturers must ensure that their products of Transparent PCR PET Film comply with all regulatory requirements, which may apply, so as to avoid legal complications and ensure the safety of consumers.

7. Environmental Impact and Sustainability

7.1 Recycling and Circular Economy

Recyclability is one of the prime aspects of the environmental impact and sustainability of Transparent PCR PET Film. Recycling of the film decreases the requirement for virgin PET resin, thus reducing consumption of fossil fuels and, correspondingly, the emission of greenhouse gases while producing new plastics. In the concept of a circular economy model, the recycled film could be utilized in the production of packaging or other plastic products, closing the loop and therefore minimising waste. For instance, a company using Transparent PCR PET Film for packaging its products can encourage consumers to recycle the packaging and then collaborate with recycling facilities to manufacture the recycled film into new packaging materials for its products.

7.2 Life Cycle Assessment

The LCA of Transparent PCR PET Film reflects its overall environmental impact. The LCA takes into account the entire life cycle of the film, from the collection of post-consumer PET bottles to the production of the film, its use in packaging, and its final disposal or recycling. By conducting an LCA, manufacturers can identify areas where they can improve the environmental performance of the film. For instance, they can optimize the recycling process by using less energy and generating less waste or improve the production process in order to minimize the pollutants emitted. LCA will also provide information worthy of consideration by consumers and regulators concerned with the environmental impact of the film.

8. Future Trends and Developments

8.1 Advanced Recycling Technologies

In the future, advanced recycling technologies will likely be developed and adopted in the case of Transparent PCR PET Film. These can recover an even higher percentage of post-consumer PET and produce a better quality of recycled film. For example, new chemical recycling could degrade PET into its monomers and then re-polymerize them into new films with enhanced properties. This would further enhance the sustainability of the film and increase its applications in industries that are more demanding in nature.

8.2 Smart Packaging with PCR PET Film

Transparent PCR PET Film can be used in smart packaging. For instance, sensors could be embedded in the film to monitor the temperature, moisture, or freshness of the packaged products. This would be very helpful for the food and pharmaceutical industries, where product quality and safety are paramount. The film could also be prepared to have self-healing properties, which would automatically heal minor scratches or punctures, extending the shelf life and integrity of the packaging. These smart packaging features would enhance functionality and value for Transparent PCR PET Film in modern packaging applications.

8.3 New Applications and Market Expansion

As research and development continue, new applications for Transparent PCR PET Film are likely to emerge. It could be used in areas such as sustainable building materials, where its transparency and strength could be utilized in the construction of energy-efficient windows or facades. In the automotive industry, it could be used for interior trim or lightweight packaging of automotive components. The market for Transparent PCR PET Film will continue to grow as more industries realize its potential and consumer demand for green packaging increases.

9. Conclusion

Transparent PCR PET Film has proven to be a highly versatile and sustainable material with a wide range of applications in food and non-food packaging. Its unique properties of transparency, strength, recyclability, and barrier characteristics make it ideal for the protection and presentation of a wide variety of products. At the same time, like with any other material, a number of challenges arise with regard to quality control, regulatory compliance, and environmental impact. By addressing these challenges and embracing future trends such as advanced recycling, smart packaging, and new applications, Transparent PCR PET Film can continue to make significant contributions to the packaging industry and to sustainable development as a whole. It is a material that holds great promise for the future, offering a balance between functionality and environmental responsibility.