Exploring the Properties and Versatile Applications of PVC/PVDC Film in Modern Packaging

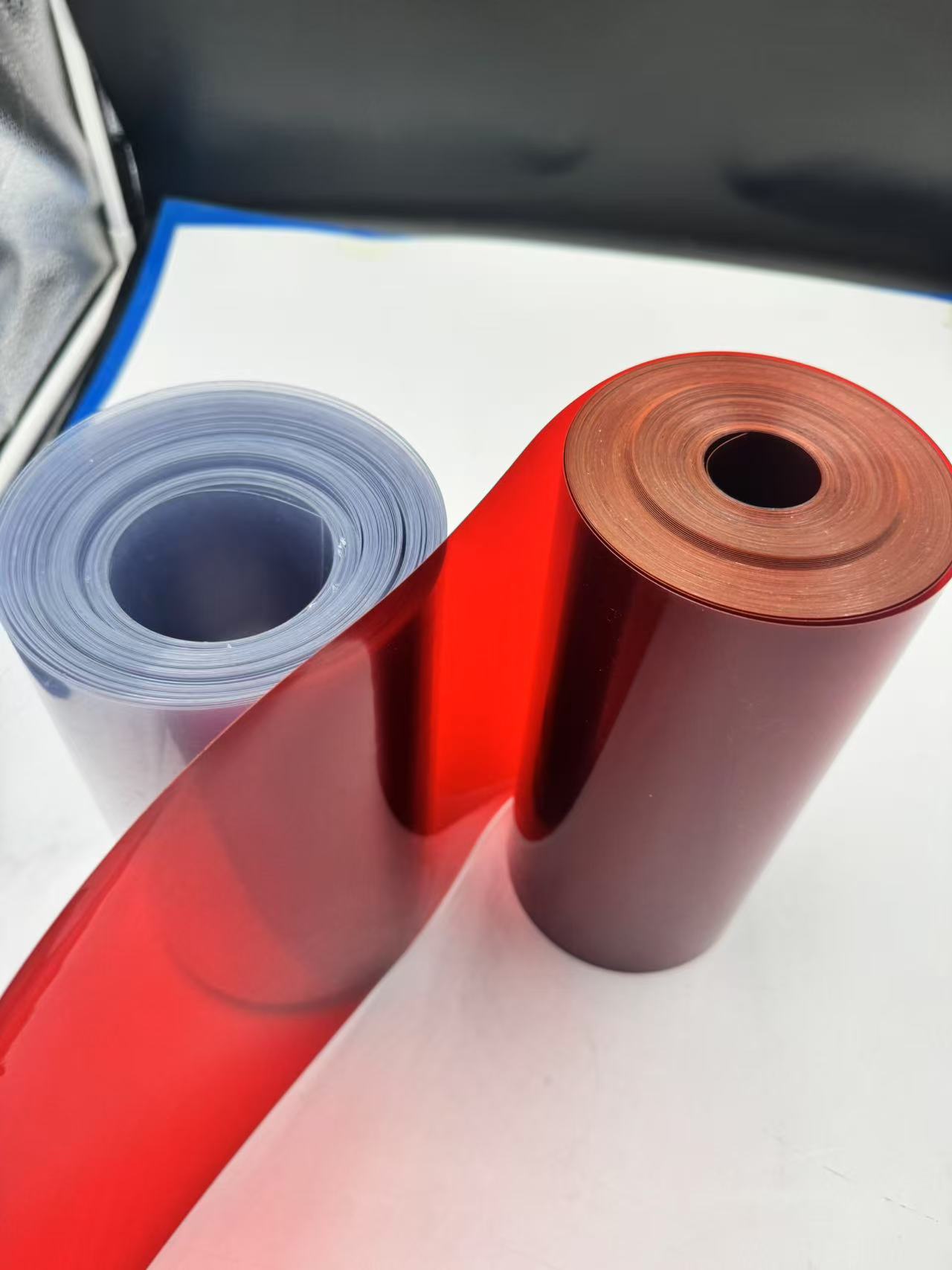

2025-08-11 17:33IntroductionPVC/PVDC film, a multilayer composite of polyvinyl chloride (PVC) and polyvinylidene chloride (PVDC), is a high-performance material widely recognized for its exceptional barrier properties, transparency, and versatility in packaging applications. By combining the flexibility and clarity of PVC with the superior gas and moisture resistance of PVDC, this film has become a go-to solution for industries requiring robust protection and aesthetic appeal,  such as food, pharmaceuticals, and technical products. This article explores the characteristics of PVC/PVDC film and its diverse applications, with a focus on high-barrier packaging, providing detailed insights and real-world examples to illustrate its impact.Characteristics of PVC/PVDC FilmPVC/PVDC film is typically produced through co-extrusion or lamination, where a thin layer of PVDC is integrated with PVC to enhance barrier performance. The resulting film, available in thicknesses ranging from 20 to 250 μm, offers a unique combination of properties that make it ideal for demanding packaging requirements.Outstanding Barrier Properties

such as food, pharmaceuticals, and technical products. This article explores the characteristics of PVC/PVDC film and its diverse applications, with a focus on high-barrier packaging, providing detailed insights and real-world examples to illustrate its impact.Characteristics of PVC/PVDC FilmPVC/PVDC film is typically produced through co-extrusion or lamination, where a thin layer of PVDC is integrated with PVC to enhance barrier performance. The resulting film, available in thicknesses ranging from 20 to 250 μm, offers a unique combination of properties that make it ideal for demanding packaging requirements.Outstanding Barrier Properties

The hallmark of PVC/PVDC film is its exceptional barrier against oxygen, water vapor, and aromas. PVDC, with its tightly packed molecular structure, achieves oxygen transmission rates (OTR) as low as 0.1–5 cc/m²/day and water vapor transmission rates (WVTR) of 0.5–4 g/m²/day, depending on the film’s composition and thickness. These properties make it one of the most effective barrier films available, extending the shelf life of perishable goods by up to 60% compared to standard packaging materials. For example, in food packaging, PVC/PVDC film prevents oxidative rancidity in fatty products like cheese or nuts, preserving flavor and texture.

High Transparency and Visual Appeal

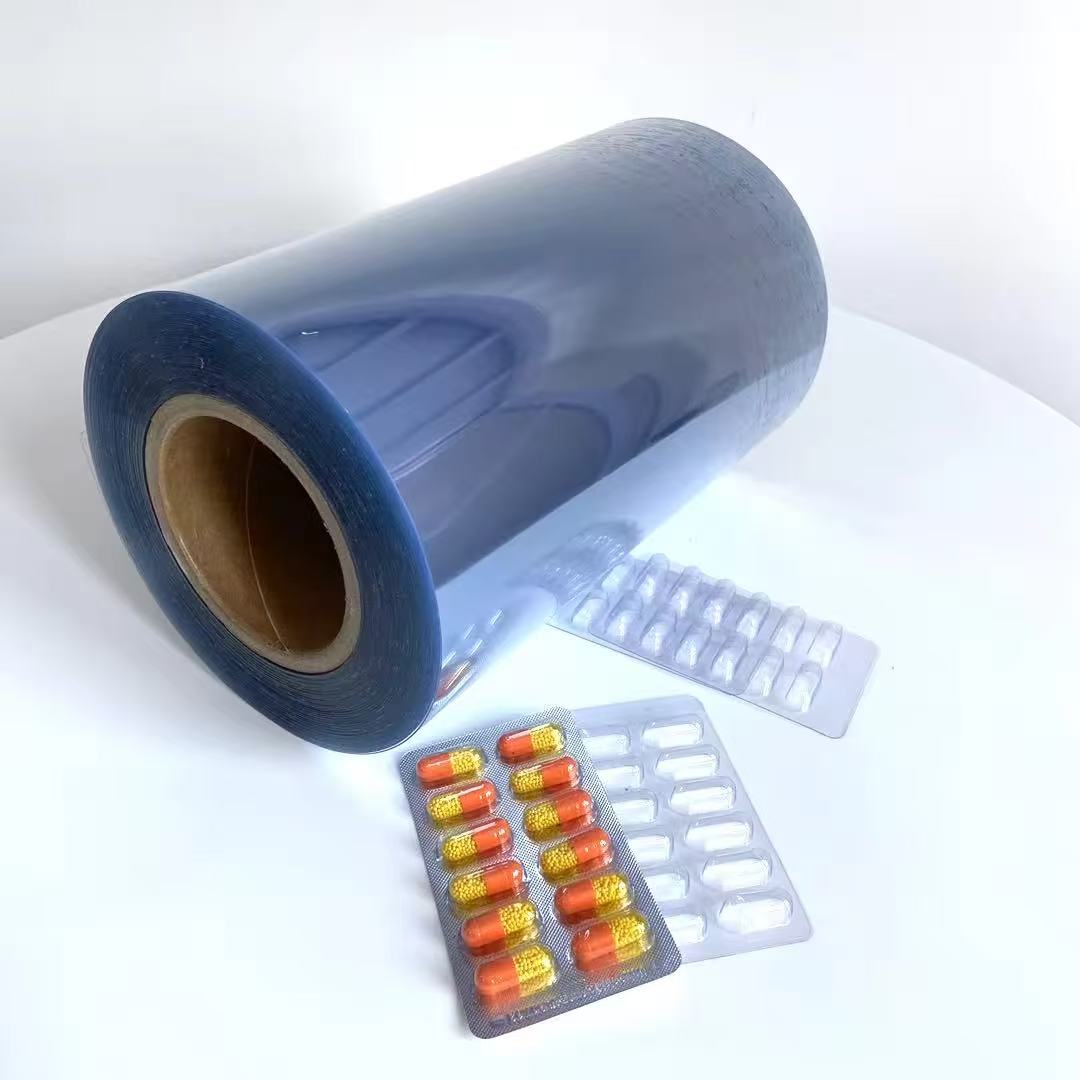

PVC/PVDC film offers excellent clarity, allowing consumers to view packaged products without compromising protection. This transparency is critical in retail environments, where visual inspection drives purchasing decisions. For instance, in pharmaceutical blister packs, the film’s clarity ensures patients can see the tablets, enhancing trust in the product’s quality. The film’s glossy finish also adds a premium aesthetic, making it a favorite for high-value goods like gourmet snacks or medical devices.

Mechanical Strength and Flexibility

The PVC component provides PVC/PVDC film with flexibility and durability, enabling it to withstand handling, transportation, and forming processes. The film resists punctures and tears, making it suitable for packaging sharp or rigid items, such as medical instruments or frozen foods with jagged edges. Its flexibility allows it to conform to complex shapes during thermoforming, ensuring a snug fit in applications like blister packaging or tray lidding.

Thermal Stability and Processability

PVC/PVDC film performs reliably across a wide temperature range, from freezing conditions (-20°C) to sterilization processes (up to 120°C). This thermal stability makes it suitable for applications like frozen food packaging and autoclavable medical packaging. The film’s compatibility with high-speed packaging machines, due to its excellent sealability and low sealing temperatures, enhances production efficiency. For example, in blister packaging lines, PVC/PVDC film ensures consistent sealing with aluminum foil, reducing downtime and waste.

Chemical Resistance and Safety

PVC/PVDC film is highly resistant to oils, fats, acids, and alkalis, making it ideal for packaging products with aggressive contents, such as sauces or chemical reagents. Its inert nature ensures compliance with food safety regulations (e.g., FDA and EU standards) and pharmaceutical requirements, preventing migration of harmful substances into the product. This chemical stability is particularly valuable in pharmaceutical applications, where product integrity is paramount.

Customizability

PVC/PVDC film can be tailored to specific needs through variations in PVDC coating thickness, color tinting, or the addition of features like UV resistance or printability. For instance, a thicker PVDC layer enhances barrier performance for long-shelf-life products, while a tinted film may be used for light-sensitive pharmaceuticals. The film’s versatility allows manufacturers to balance cost and performance, making it adaptable to a wide range of applications.

Applications of PVC/PVDC FilmThe unique properties of PVC/PVDC film make it a preferred choice across multiple industries, particularly in high-barrier packaging for food, pharmaceuticals, and technical products.1. High-Barrier Food PackagingPVC/PVDC film is extensively used in food packaging to extend shelf life, maintain freshness, and protect against external factors like oxygen and moisture.Fresh and Processed Foods: In modified atmosphere packaging (MAP), PVC/PVDC film is used to create trays and lidding films for products like fresh meats, poultry, seafood, and cheeses. The film’s low OTR prevents oxidation, while its moisture barrier properties reduce weight loss in products like fresh beef, extending shelf life by up to 45 days. For example, a supermarket chain uses PVC/PVDC film to package deli meats, ensuring the product remains fresh and visually appealing during extended display periods.

Snack Foods and Confectionery: For snacks like nuts, chips, and chocolates, PVC/PVDC film protects against rancidity caused by oxygen exposure and moisture-induced texture degradation. Its clarity enhances the product’s visual appeal, while its puncture resistance ensures durability during shipping. A notable example is the use of PVC/PVDC film for packaging premium chocolates, where the film’s aroma barrier preserves the delicate flavors.

Ready-to-Eat Meals: PVC/PVDC film is used in lidding applications for microwaveable trays, offering a balance of barrier performance and heat resistance. The film’s transparency allows consumers to inspect meal contents, while its strong seals prevent leaks during heating, enhancing convenience and safety.

2. Pharmaceutical Blister PackagingPVC/PVDC film is a cornerstone of pharmaceutical blister packaging, where its high-barrier properties and clarity ensure the safety and visibility of medications.Tablet and Capsule Protection: In blister packs, PVC/PVDC film forms the base layer, sealed against aluminum foil to create individual cavities for tablets or capsules. The film’s low OTR and WVTR protect sensitive medications, such as vitamins or antibiotics, from degradation due to moisture or oxygen. For example, a leading pharmaceutical company uses PVC/PVDC film to package moisture-sensitive drugs, ensuring a shelf life of up to three years.

Regulatory Compliance: The film’s compliance with stringent regulations, such as USP <661> for container safety, makes it ideal for pharmaceutical applications. Its chemical inertness prevents interactions with active ingredients, ensuring patient safety. Additionally, the film’s clarity allows for easy inspection of tablets, reducing the risk of dispensing errors.

Custom Features: PVC/PVDC film can be customized with child-resistant or senior-friendly peelable layers, enhancing usability. Tinted variants protect light-sensitive drugs, such as certain cardiovascular medications, from UV degradation.

3. Medical Device PackagingPVC/PVDC film is widely used in the packaging of sterile medical devices, where its barrier properties and durability ensure product safety and integrity.Sterile Packaging: The film is used in pouches and trays for devices like syringes, catheters, and surgical tools. Its high barrier against moisture and microbes ensures sterility during storage and transport, meeting standards like ISO 11607 for sterile barrier systems. For instance, a medical device manufacturer uses PVC/PVDC film to package disposable scalpels, maintaining sterility until the point of use.

Transparency for Inspection: The film’s clarity allows healthcare professionals to visually inspect devices without breaking the sterile barrier, ensuring quality control. Its puncture resistance protects sharp instruments, reducing the risk of packaging failure.

4. Technical and Industrial ApplicationsBeyond food and pharmaceuticals, PVC/PVDC film is used in technical applications requiring robust protection and chemical resistance.Electronics and Precision Components: The film’s anti-static and dustproof properties make it suitable for packaging sensitive electronics, such as circuit boards or connectors. Its moisture barrier protects against corrosion, while its flexibility allows it to wrap complex shapes securely.

Challenges and Future DirectionsDespite its advantages, PVC/PVDC film faces challenges, including environmental concerns related to PVC’s recyclability and the energy-intensive production of PVDC. However, ongoing research is focused on developing eco-friendly alternatives, such as bio-based PVDC coatings or fully recyclable PVC/PVDC films. Innovations like nanotechnology-enhanced barriers are also improving the film’s performance, reducing the required thickness and material use. As sustainability becomes a priority, the industry is exploring hybrid solutions that combine PVC/PVDC film with biodegradable substrates to meet regulatory and consumer demands.