Shining a Light on Translucent PVC Film: Revolutionizing Medical Packaging

2025-02-25 13:15Introduction: A Material That Sees Beyond the Surface

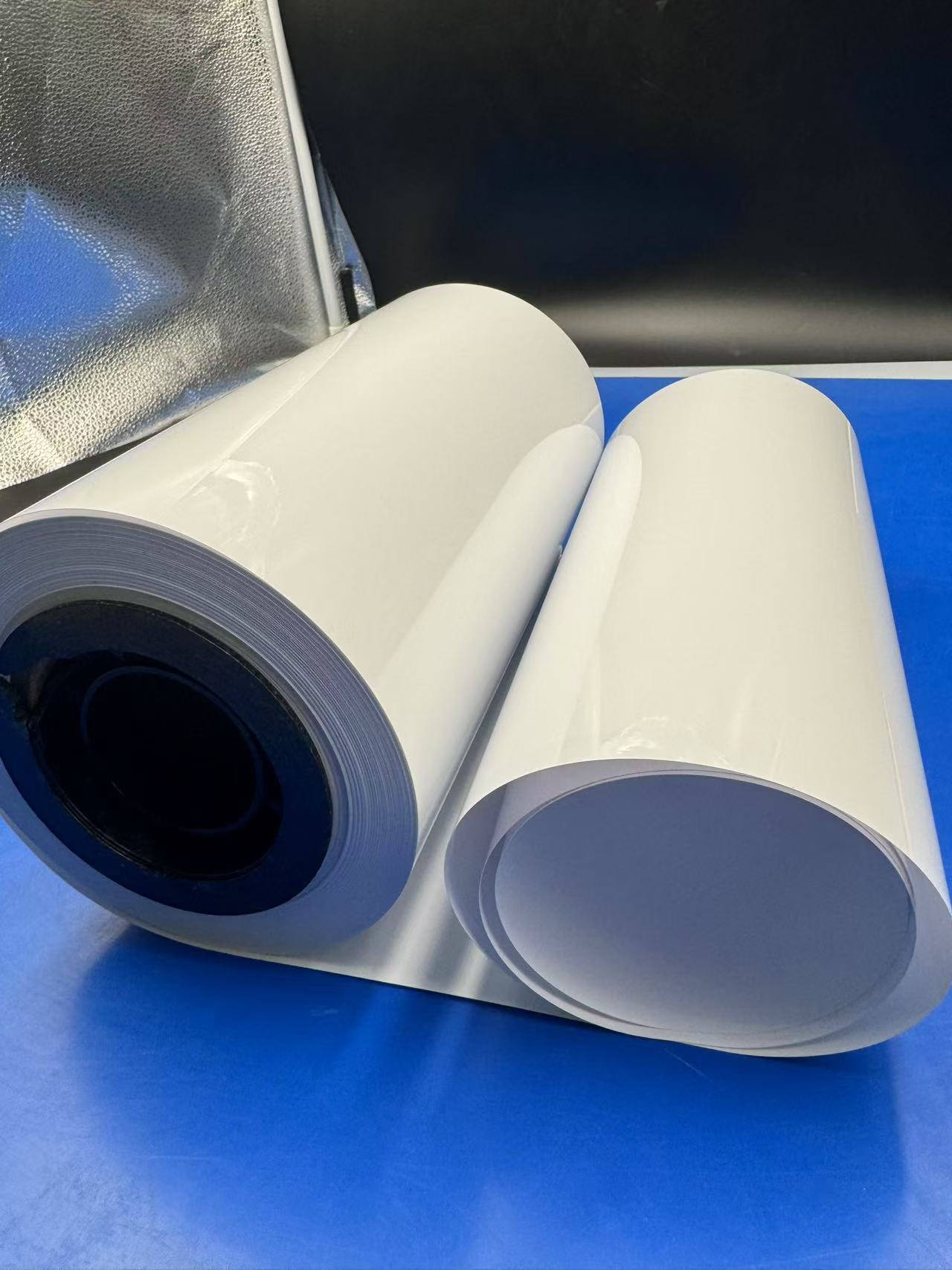

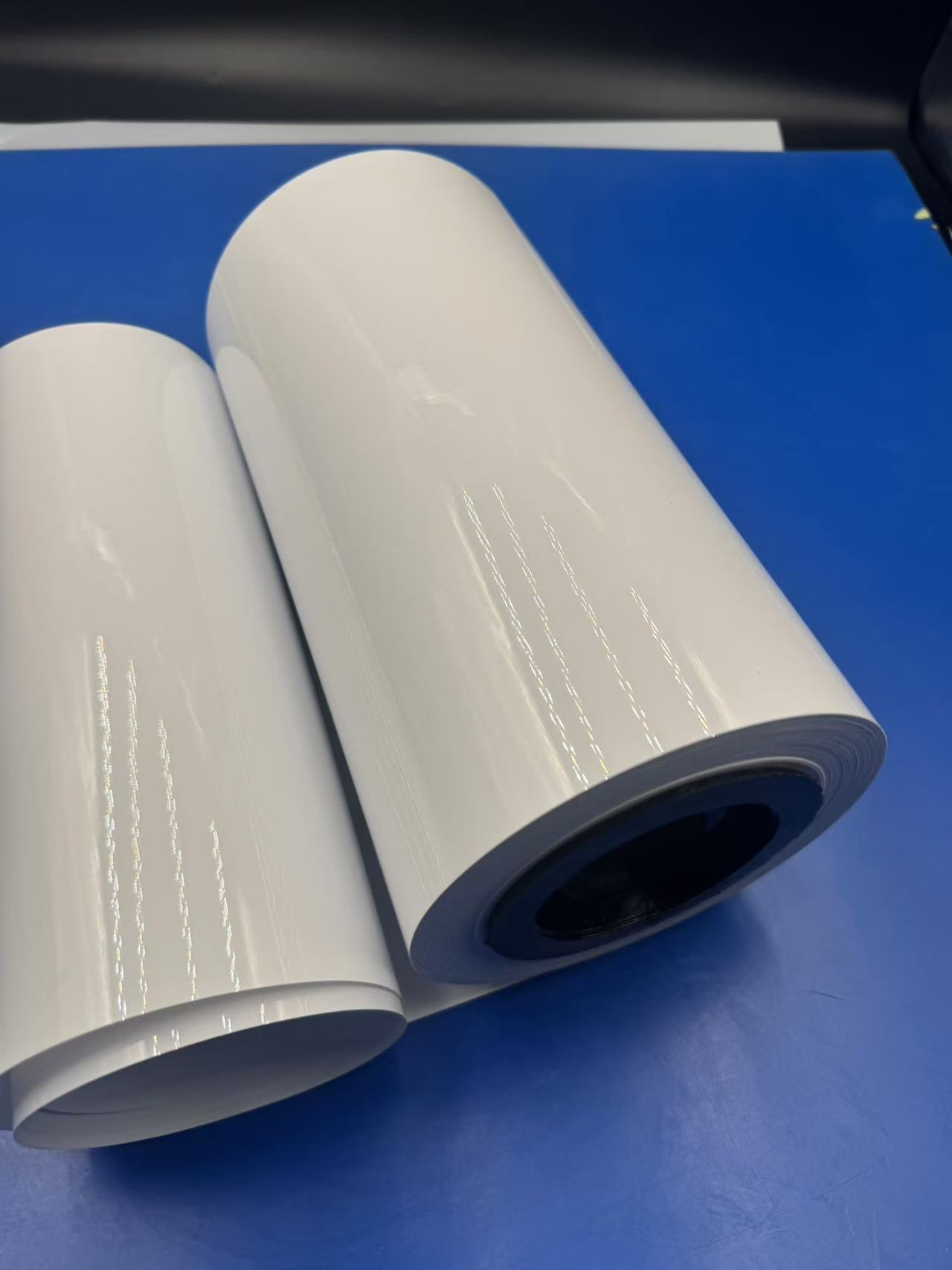

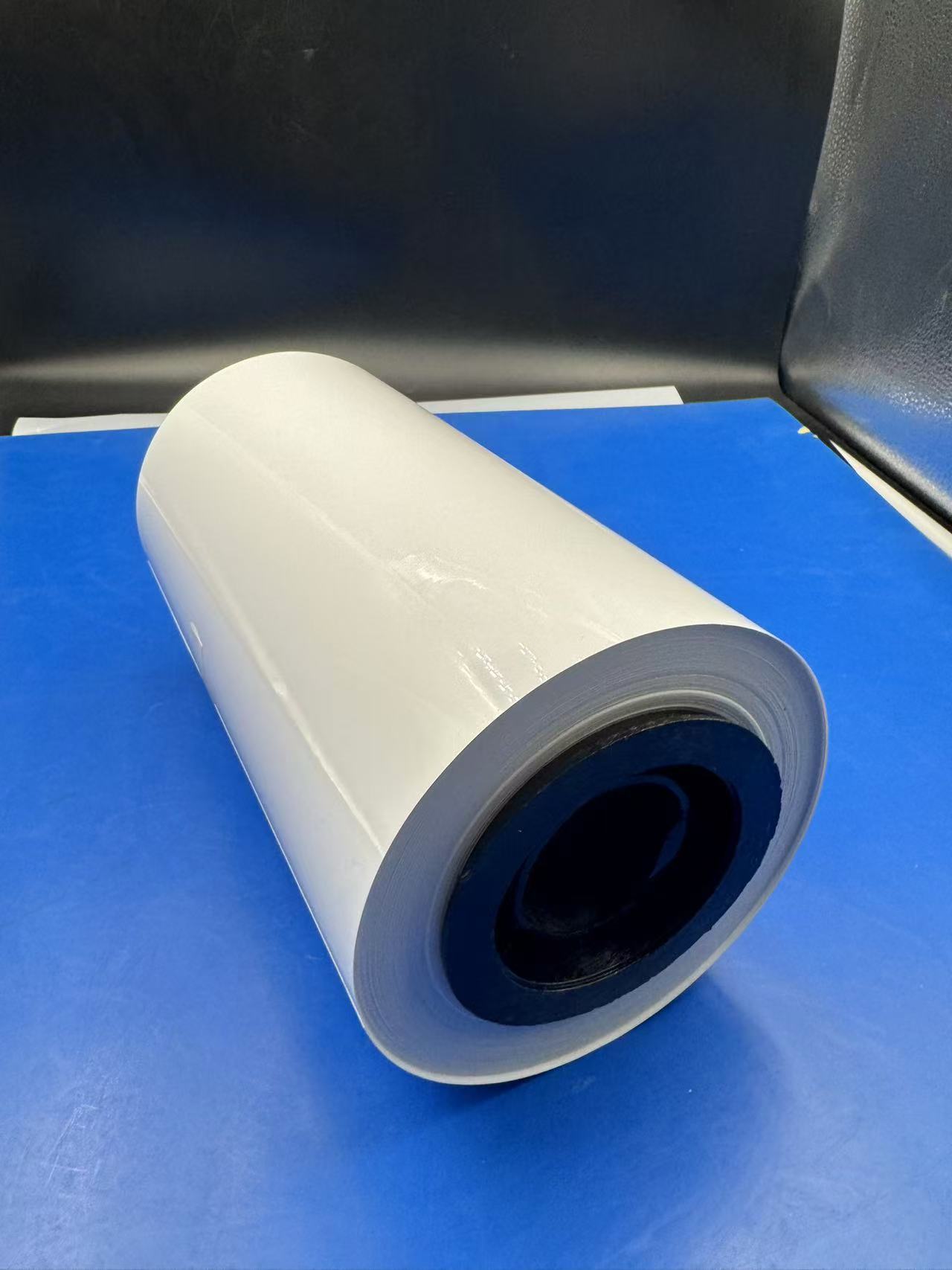

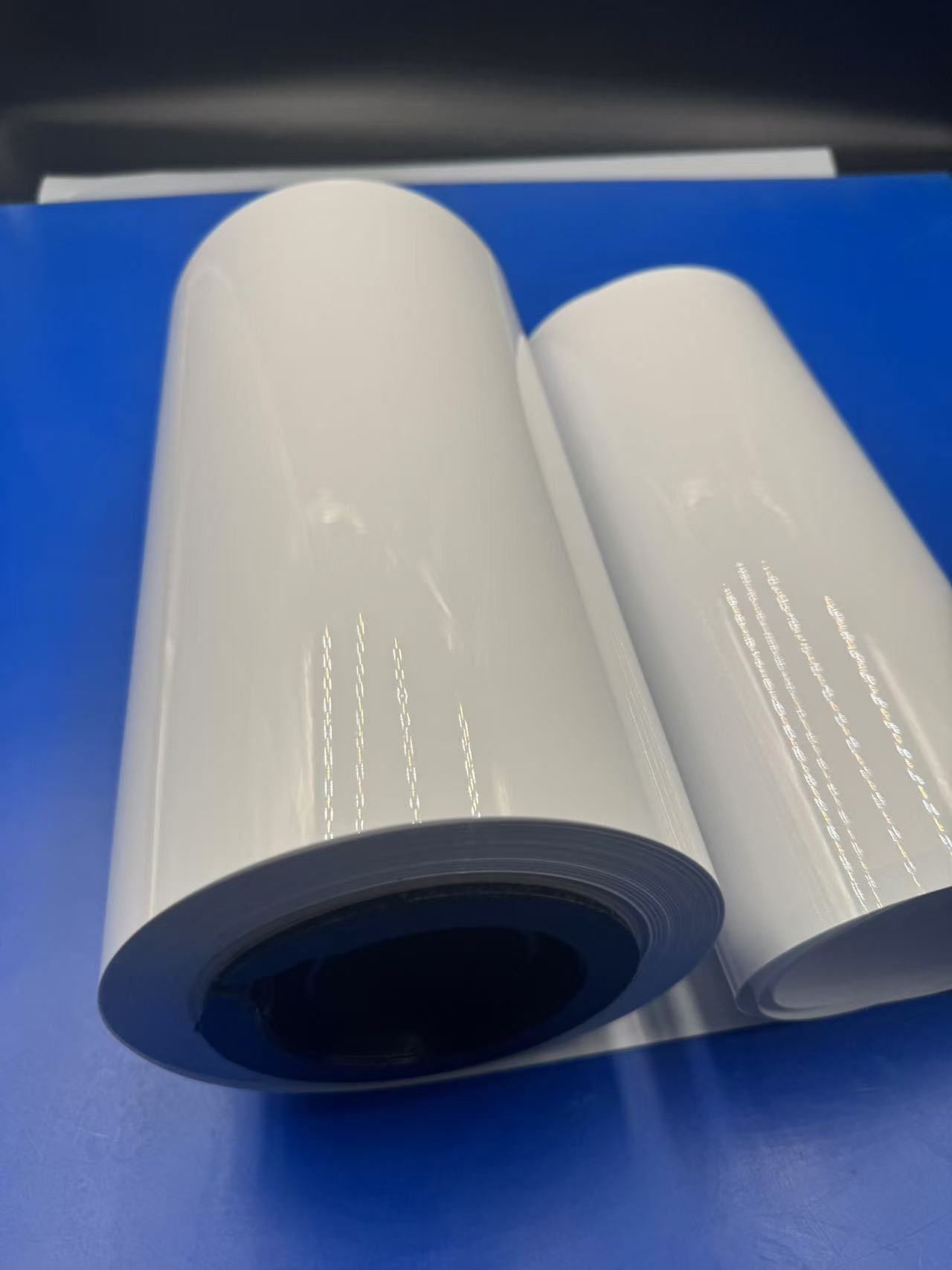

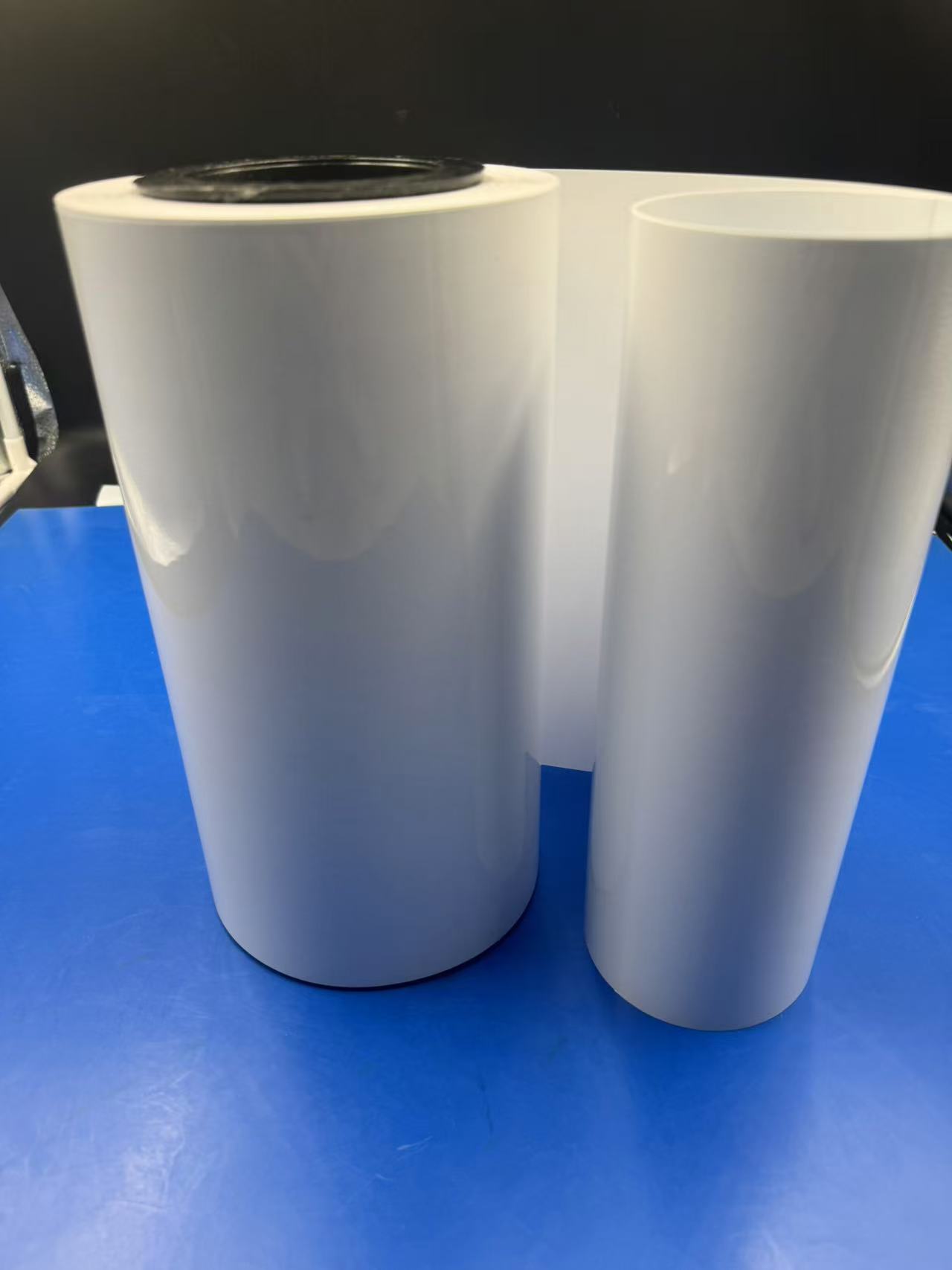

In the intricate world of medical packaging, materials don’t just hold things—they safeguard lives. Every pouch, bag, and wrap must balance sterility,  durability, and usability while meeting the unforgiving standards of healthcare. Enter translucent PVC film, a versatile polymer that has quietly become a linchpin in this field. Crafted from polyvinyl chloride (PVC), this film offers a frosted clarity that reveals just enough while concealing what matters, making it a star player in applications like urine bags, IV drips, and blood storage systems. Its journey from raw resin to lifesaving packaging is a tale of science meeting necessity, blending flexibility with resilience and visibility with privacy. In this exploration, we’ll uncover the standout properties of translucent PVC film, spotlight its critical role in medical applications—especially urinary systems—and dive into how lamination and innovation elevate its performance, proving it’s more than just a sheet of plastic.

durability, and usability while meeting the unforgiving standards of healthcare. Enter translucent PVC film, a versatile polymer that has quietly become a linchpin in this field. Crafted from polyvinyl chloride (PVC), this film offers a frosted clarity that reveals just enough while concealing what matters, making it a star player in applications like urine bags, IV drips, and blood storage systems. Its journey from raw resin to lifesaving packaging is a tale of science meeting necessity, blending flexibility with resilience and visibility with privacy. In this exploration, we’ll uncover the standout properties of translucent PVC film, spotlight its critical role in medical applications—especially urinary systems—and dive into how lamination and innovation elevate its performance, proving it’s more than just a sheet of plastic.

Characteristics of Translucent PVC Film

Translucent PVC film isn’t your average plastic—it’s a carefully engineered marvel designed to meet the unique demands of medicine. Its properties weave together practicality and performance, making it a go-to choice for healthcare professionals worldwide. Let’s peel back the layers to see what sets it apart.

Translucency: A Window with Boundaries

Unlike crystal-clear plastics that bare all, translucent PVC film offers a diffused, semi-opaque glow. Light scatters through its surface, softening details while still letting caregivers peek inside. Picture a urine bag hanging bedside: the fluid level is visible for monitoring kidney output, yet the contents remain discreet, honoring patient dignity. This balance is no accident—manufacturers fine-tune the film’s opacity, often to a light transmission rate of 50-70%, ensuring it’s neither too revealing nor too obscure. In a hospital ward buzzing with activity, this subtle clarity keeps care efficient without compromising privacy.

Biocompatibility: Safe for the Body

In medicine, contact with fluids or tissues demands harmony, not hostility. Translucent PVC film is formulated with medical-grade plasticizers—like DEHP-free alternatives—to ensure it won’t provoke reactions when touching blood, urine, or skin. Rigorous testing, compliant with standards like ISO 10993, confirms its stability: it doesn’t leach harmful compounds into saline or degrade when holding antibiotics. For a blood bag, this means the precious cargo stays uncontaminated, ready to transfuse without a hitch. It’s a silent promise of safety woven into every micron.

Sterilizability: Cleanliness Under Pressure

Sterility is non-negotiable in medicine, and translucent PVC film rises to the challenge. It endures autoclaving at 121°C (250°F) for 15-20 minutes, gamma radiation up to 25 kGy, or ethylene oxide gas cycles without warping or yellowing. A 100-micron film might lose just 5% of its tensile strength post-sterilization—barely a blip for its robust frame. This versatility lets manufacturers choose the method that fits their process, whether it’s steaming IV bags or irradiating catheter kits, ensuring every package emerges pristine.

Applications of Translucent PVC Film in Medical Packaging

Translucent PVC film doesn’t just sit pretty—it works hard, especially in medical settings where every detail counts. From bedside to battlefield, its applications reveal a material that’s as practical as it is ingenious. Let’s zoom in, starting with its starring role in urinary systems.

Urinary Bag Systems: Clarity Meets Care

Urine bags are unsung heroes of patient monitoring, and translucent PVC film is their backbone. Its frosted finish lets nurses track output—vital for spotting dehydration or kidney issues—without exposing too much. A typical 2-liter bag, made from 150-micron film, holds up to 2 kg of fluid, its heat-sealed seams unyielding even when hung for hours. Durability is key: these bags twist with patient movement, dangle from hooks, and occasionally brush against rough surfaces, yet punctures are rare. Sterility seals the deal—each bag’s hermetic closure slashes infection risks tied to catheters, a concern that claims thousands of lives yearly. In home care, where patients manage their own systems, this reliability offers peace of mind.

IV Bags: Fluid Lifelines

IV drips keep patients hydrated and medicated, and translucent PVC film makes it possible. Its clarity tracks saline or drug levels—crucial when a nurse needs to swap a near-empty bag mid-shift. A 250-mL bag, weighing under 300 grams when full, flexes comfortably against an arm or stretcher, its toughness resisting jostles during transport. Heat-sealed ports ensure no leaks, even under the pressure of a fast drip. In emergencies, like a field hospital, this lightweight durability turns IV bags into portable lifelines, delivering fluids where seconds matter.

Blood Bags: Guardians of Life

Storing blood demands precision, and translucent PVC film delivers. Its biocompatibility cradles red cells without clotting or contamination, while its strength—often 200 microns thick—prevents breaches during centrifugation or shipping. The translucent veil lets technicians check for hemolysis (blood breakdown) without opening the bag, a sterility must. In a blood bank, where units stack and shuffle, the film’s resilience keeps each one intact, ready to save a life at a moment’s notice.

Other Uses: Beyond the Big Three

Translucent PVC film stretches beyond bags into wound dressings, surgical drapes, and catheter kits. A dressing might use a thin 50-micron layer, flexible enough to contour a knee yet tough against oozing fluids. Drapes shield operating fields, their chemical resistance shrugging off antiseptics. Each use leans on the film’s core strengths—visibility, durability, and safety—proving its worth across the medical spectrum.

The Role of Laminated Films: Elevating Performance

Translucent PVC film is a champ on its own, but lamination takes it to new heights. By pairing it with other polymers, manufacturers craft composite films that amplify its strengths and patch its weaknesses. Here’s how this teamwork pays off.

Barrier Boost: Keeping Threats Out

PVC’s moderate oxygen barrier—around 50 cm³/m²/day—gets a lift when laminated with polyethylene (PE) or polyamide, dropping to 5-10 cm³/m²/day. Moisture resistance tightens too, with water vapor rates falling below 2 g/m²/day. For a urine bag, this means less evaporation and better odor control; for an IV bag, it protects sensitive drugs from air degradation. Picture a morphine drip in a humid ward: the laminated film ensures every drop stays potent.

Added Durability: Tougher Than Ever

Lamination layers like PE add puncture resistance—crucial when a bag brushes a sharp edge. A 200-micron PVC/PE composite might withstand 50% more force than PVC alone, turning a fragile sheet into a rugged shield. The outer layer takes the brunt, while PVC keeps its translucent core intact. In blood bags, this combo survives rough handling, from freezer to ambulance, without a scratch.

Special Features: Tailored for the Task

Laminated films can pack extras: UV blockers for light-sensitive antibiotics, writable coatings for nurses to jot notes, or anti-fog layers for clear visibility in steamy conditions. A urine bag might sport a polyamide outer skin, boosting heat-seal strength for complex port designs. These tweaks turn a basic film into a custom tool, meeting niche medical needs with precision.

Sterilization and Compatibility: Ready for Anything

Lamination fine-tunes sterilization tolerance. A PVC/PE film might ace gamma radiation where pure PVC yellows, or a PVC/polyamide blend could handle autoclaving with less shrinkage. This flexibility lets manufacturers match the film to the job, ensuring every package—be it a syringe wrap or a dialysis pouch—emerges sterile and strong.

Innovations in Medical Packaging: The Future Unfolds

Translucent PVC film isn’t static—it’s evolving, driven by healthcare’s relentless push for better, smarter solutions. These innovations hint at a future where it shines even brighter.

Peelable and Resealable Designs

New PVC films feature peelable seals—think a urine bag that opens for sampling then reseals tightly. Multi-use systems benefit too, like a wound irrigation pouch that closes after each rinse. These designs blend convenience with sterility, cutting waste and boosting efficiency in busy wards.

Sustainability: Greening the Film

PVC’s environmental rap isn’t spotless, but progress is afoot. Recyclable blends, biodegradable additives, and reduced plasticizer use are shrinking its footprint. A pilot program might turn used IV bags into new film, closing the loop. As hospitals eye sustainability, translucent PVC film adapts, proving it can be kind to both patients and the planet.