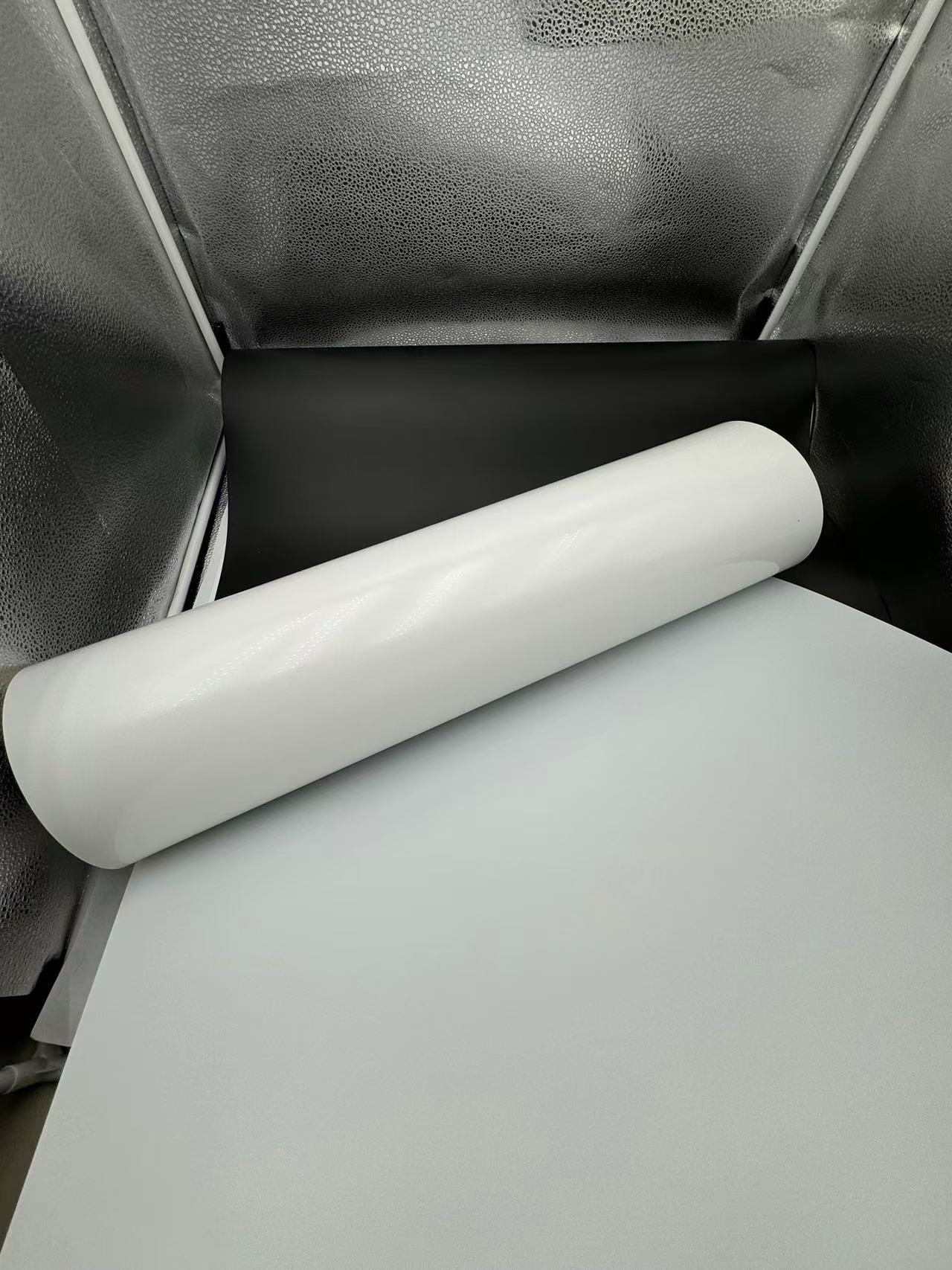

PSThe Versatile Application of White PS Rigid Film in Food Blister Packaging and Electronic Parts Packaging

2024-11-25 14:17The Versatile Application of White PS Rigid Film in Food Blister Packaging and Electronic Parts Packaging

Introduction

In the m odern packaging industry, the choice of appropriate materials is crucial to meet the diverse needs of different products. White PS (Polystyrene) rigid film has emerged as a significant player, finding extensive applications in food blister packaging and electronic parts packaging. Its unique combination of properties makes it an ideal candidate for safeguarding the integrity, quality, and presentation of the packaged items. This article delves into the various aspects of this remarkable material, exploring its characteristics, manufacturing process, applications, advantages, and the challenges it overcomes in each domain.

odern packaging industry, the choice of appropriate materials is crucial to meet the diverse needs of different products. White PS (Polystyrene) rigid film has emerged as a significant player, finding extensive applications in food blister packaging and electronic parts packaging. Its unique combination of properties makes it an ideal candidate for safeguarding the integrity, quality, and presentation of the packaged items. This article delves into the various aspects of this remarkable material, exploring its characteristics, manufacturing process, applications, advantages, and the challenges it overcomes in each domain.

Material Properties of White PS Rigid Film

Chemical Composition and Structure

White PS rigid film is derived from polystyrene, a synthetic polymer made from styrene monomers. The polymerization process results in a long-chain molecular structure, where the styrene units link together. This linear arrangement imparts rigidity to the film, giving it the strength to maintain its shape and resist deformation. The addition of certain additives during manufacturing is what confers the white color. These additives can be pigments or fillers that not only enhance the visual appearance but also may contribute to other properties such as UV resistance or improved barrier capabilities.

Rigidity and Mechanical Strength

The inherent rigidity of the PS film is one of its standout features. It has a high modulus of elasticity, which means it can withstand external forces without bending or flexing easily. In food blister packaging, this rigidity is essential for protecting delicate food items like bakery products, confectionery, and fresh produce. For instance, when used to package cookies, the rigid film prevents the cookies from getting crushed during handling and transportation. In electronic parts packaging, it safeguards components such as microchips, circuit boards, and connectors from physical damage due to impacts or pressure, ensuring their functionality remains intact until they reach the end-user.

Barrier Properties

White PS rigid film offers moderate barrier properties. It provides a certain level of protection against moisture, gases, and contaminants. In food packaging, it helps in maintaining the freshness of the product by reducing the ingress of oxygen and moisture, which can cause spoilage. For example, in the packaging of dried fruits, the film keeps the fruits from absorbing excess moisture and becoming soggy, thus prolonging their shelf life. In electronic parts packaging, the barrier against dust, moisture, and other airborne particles is vital to prevent short circuits and corrosion, protecting the sensitive electronics within.

Chemical Resistance

PS film exhibits good chemical resistance to a variety of substances. It can withstand contact with mild acids, alkalis, and many common solvents. In the food industry, this property ensures that the film does not react with the food items it encloses, maintaining the safety and quality of the packaged food. In the electronics sector, it is resistant to the chemicals used in cleaning agents and manufacturing processes, protecting the electronic parts during storage and transit. For example, when electronic components are cleaned with mild solvents before assembly, the PS film packaging remains unaffected.

Thermal Properties

The thermal properties of white PS rigid film are also noteworthy. It has a relatively low melting point, which allows for easy thermoforming, a common manufacturing process in packaging. This makes it suitable for creating custom shapes and sizes to fit different products snugly. However, its heat resistance is limited, so it is not ideal for applications where the packaged item may be exposed to high and sustained temperatures. In food packaging, it can handle the typical temperatures encountered in refrigeration and room temperature storage without issue. In electronics, it protects components during normal operating temperatures but may not be suitable for applications near heat sources like power generators.

Aesthetic Appeal

The white color of the film adds to its aesthetic appeal, especially in food packaging. It gives a clean, fresh look that can enhance the visual presentation of the product. For baked goods, the white backdrop can make the colors of the pastries or cakes stand out, attracting consumers on the store shelf. In electronics packaging, the white color can convey a sense of professionalism and quality, making the product more appealing to customers.

Manufacturing Process of White PS Rigid Film

Raw Material Preparation

The production of white PS rigid film begins with the careful selection of high-quality polystyrene resin. The resin is typically sourced from petrochemical plants and undergoes strict quality control to ensure its purity and consistency. Additives such as pigments for the white color, UV stabilizers to enhance the film's resistance to sunlight, and antioxidants to prevent degradation during processing and storage are then incorporated. These additives are thoroughly mixed with the polystyrene resin in precise proportions to achieve the desired properties of the final film.

Extrusion Process

Once the raw materials are prepared, they are fed into an extruder. The extruder is a cylindrical machine with a rotating screw that heats and melts the mixture as it moves through the barrel. The temperature inside the extruder is carefully controlled to ensure a uniform molten state. The molten polystyrene, along with the additives, is then forced through a flat die at the end of the extruder. The die determines the width and thickness of the emerging film, and the extrusion speed is adjusted to achieve the desired film dimensions.

Calendering or Casting

After extrusion, the film can undergo either calendering or casting processes. Calendering involves passing the molten film through a series of rollers that gradually reduce its thickness and improve its smoothness and surface finish. This process imparts additional strength and rigidity to the film. Casting, on the other hand, is where the molten material is poured onto a chilled casting drum or belt, allowing it to solidify quickly. The choice between calendering and casting depends on the specific requirements of the film, such as thickness, surface quality, and production volume.

Annealing and Cooling

To further enhance the mechanical properties and dimensional stability of the film, an annealing process may be carried out. Annealing involves heating the film to a specific temperature below its melting point and then slowly cooling it. This relieves internal stresses within the film and improves its overall performance. After annealing, the film is cooled to room temperature and wound onto large rolls, ready for further processing into packaging materials.

Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented. The thickness of the film is measured continuously using precision gauges to ensure it meets the specified standards. The mechanical strength, barrier properties, and color consistency are also tested in a laboratory setting. Any film that fails to meet the quality requirements is rejected to ensure only high-quality white PS rigid film reaches the market.

Applications of White PS Rigid Film in Food Blister Packaging

Bakery and Confectionery Packaging

White PS rigid film is widely used in packaging bakery products such as bread, cakes, pastries, and cookies. The rigidity of the film protects these delicate items from being crushed or deformed during handling and transportation. The white color enhances the visual appeal, making the baked goods look more appetizing on the store shelf. For example, a beautifully decorated cake packaged in a clear plastic tray with a white PS rigid film cover not only shows off the cake's design but also keeps it fresh and intact. In the case of cookies, the film can prevent them from breaking into pieces while maintaining their crispness by controlling moisture ingress.

Fresh Produce Packaging

For fresh fruits and vegetables, white PS rigid film is used in blister packs to protect and display the produce. The film provides a barrier against moisture loss, which helps in keeping the produce fresh for longer. For instance, strawberries packaged in a blister pack with white PS rigid film can retain their firmness and juiciness. The transparency of the blister pack, combined with the white backing, makes the fruits look more vibrant and inviting to consumers. Additionally, the rigidity of the film allows for stacking of the packages without damaging the contents.

Dairy Product Packaging

In the dairy industry, white PS rigid film is used for packaging items like cheese slices, yogurt cups, and butter portions. The film helps in maintaining the integrity of the dairy products by protecting them from external contaminants and controlling the exchange of gases. For cheese slices, the film keeps them from drying out or absorbing unwanted odors. The white color gives a clean and hygienic look, which is important for food products. The film can also be printed with nutritional information and branding, enhancing the product's marketability.

Applications of White PS Rigid Film in Electronic Parts Packaging

Microchip and Circuit Board Packaging

Microchips and circuit boards are highly sensitive electronic components that require careful packaging. White PS rigid film is used to create trays and boxes that protect these parts from physical damage, dust, and moisture. The rigidity of the film ensures that the components are held securely in place during transit and storage. For example, a tray made of white PS rigid film with individual compartments for microchips can prevent them from rubbing against each other, which could cause scratches or damage to the delicate circuitry. The film also provides a clean surface that is free from static electricity, reducing the risk of electrostatic discharge (ESD) damage to the components.

Connector and Cable Packaging

Connectors and cables used in electronics are packaged in white PS rigid film to keep them organized and protected. The film can be thermoformed into shapes that snugly fit the connectors and cables, preventing them from tangling or getting damaged. The barrier properties of the film protect the connectors from corrosion caused by moisture and prevent dust from clogging the connection points. The white color makes it easy to identify the packaged items in a warehouse or during assembly, improving efficiency in the electronics manufacturing and supply chain.

Display and Screen Packaging

Displays and screens, such as those used in smartphones, tablets, and monitors, are packaged with white PS rigid film to safeguard them from scratches, impacts, and environmental factors. The film is often used in combination with other packaging materials like foam inserts to provide comprehensive protection. The white color gives a professional and high-quality look to the packaging, enhancing the perceived value of the product. The rigidity of the film ensures that the screen is held firmly in place, reducing the risk of damage during handling.

Advantages of Using White PS Rigid Film in Packaging

Product Protection

The rigidity and barrier properties of white PS rigid film offer excellent protection for both food and electronic products. In food packaging, it keeps the products fresh, prevents physical damage, and protects against contaminants. In electronic parts packaging, it safeguards the components from physical harm, electrostatic discharge, moisture, and dust, ensuring their proper function when they reach the end-user.

Customizability

The film can be easily thermoformed into various shapes and sizes, allowing for custom packaging solutions. In food blister packaging, it can be molded to fit the unique contours of different food items. In electronic parts packaging, it can be designed to create compartments and trays that hold specific components securely, improving handling and storage efficiency.

Visual Appeal

The white color of the film adds to the visual attractiveness of the packaged products. In food packaging, it makes the products look more appealing and appetizing, which can increase sales. In electronics packaging, it gives a professional and clean look, enhancing the brand image and perceived quality of the product.

Cost - effectiveness

White PS rigid film is relatively inexpensive compared to some other packaging materials with similar properties. Its production process is well-established, and the raw materials are readily available, making it a cost-effective choice for many packaging applications, especially when large volumes are required.

Recyclability

Polystyrene is a recyclable material, and white PS rigid film can be recycled after use. This makes it an environmentally friendly option compared to non-recyclable packaging materials. Recycling white PS rigid film helps to reduce waste and conserve resources, aligning with the growing trend towards sustainable packaging.

Case Studies of White PS Rigid Film in Packaging Applications

Case Study 1: Bakery Chain's Packaging Upgrade

A popular bakery chain was facing issues with the freshness and presentation of its products. They decided to switch to white PS rigid film for packaging their pastries and cakes. The rigidity of the film protected the delicate baked goods from getting crushed during transportation and display. The white color enhanced the visual appeal, making the products more attractive to customers. After the switch, the bakery noticed a significant reduction in product damage and an increase in sales, as customers were more drawn to the well-packaged items.

Case Study 2: Electronics Manufacturer's Component Protection

An electronics manufacturer was having problems with the quality of their microchip shipments due to damage during transit. They adopted white PS rigid film for packaging the microchips in custom trays. The film's rigidity and ESD protection properties ensured that the microchips arrived at their destination in perfect condition. The manufacturer saw a decrease in the number of defective components and an improvement in customer satisfaction, leading to increased orders and business growth.

Case Study 3: Dairy Company's Sustainable Packaging Initiative

A dairy company was looking to reduce its environmental impact while maintaining the quality of its product packaging. They chose white PS rigid film for packaging their cheese slices and yogurt cups because of its recyclability. The film provided the necessary protection for the dairy products, and the company was able to promote its sustainable packaging efforts, which resonated with consumers. This led to increased brand loyalty and a positive impact on the company's reputation.

Challenges and Solutions in Using White PS Rigid Film in Packaging

Environmental Concerns

Although polystyrene is recyclable, it has been associated with environmental issues due to its slow degradation rate in landfills. To address this, efforts should be made to improve the recycling infrastructure and encourage consumers to recycle white PS rigid film properly. Additionally, manufacturers can explore the development of biodegradable versions of polystyrene or alternative materials with similar properties that are more environmentally friendly.

Heat Resistance Limitations

The limited heat resistance of white PS rigid film can be a problem in some applications. In food packaging, for example, it may not be suitable for hot - filled products or those that require sterilization at high temperatures. To overcome this, manufacturers can develop modified formulations of polystyrene with improved heat resistance or use the film in combination with other heat-resistant materials. In electronics, for applications near heat sources, additional heat shields or cooling mechanisms can be incorporated into the packaging design.

Printing and Labeling Difficulties

Printing on white PS rigid film can sometimes be challenging due to its smooth surface and low surface energy. Ink may not adhere well, resulting in poor print quality. To solve this, surface treatment methods such as corona treatment or plasma treatment can be used to increase the surface energy of the film, improving ink adhesion. Special inks and printing techniques that are compatible with polystyrene can also be employed to ensure clear and durable printing.

Brittleness at Low Temperatures

In cold environments, white PS rigid film may become brittle and more prone to cracking. This can be a concern in food packaging during refrigeration or in electronics packaging in cold storage conditions. To address this, additives can be incorporated into the polystyrene formulation to improve its flexibility at low temperatures. Another solution is to design the packaging with additional insulation or protective layers to minimize the exposure of the film to extreme cold.

Conclusion

White PS rigid film has proven to be a versatile and valuable material in the packaging of food and electronic products. Its unique combination of properties, including rigidity, barrier protection, visual appeal, cost - effectiveness, and recyclability, makes it an ideal choice for a wide range of applications. Despite the challenges it faces, such as environmental concerns, heat resistance limitations, and printing difficulties, there are solutions available to overcome them. As the packaging industry continues to evolve with a focus on sustainability, product protection, and aesthetics, white PS rigid film is likely to play an even more important role in the future, with ongoing research and development aimed at enhancing its performance and environmental friendliness.