Characteristics and Applications of White Polystyrene Antistatic Film in Modern Packaging Solutions

2025-08-05 17:04Introduction

Polystyrene (PS) is a versatile and widely used synthetic polymer known for its clarity, rigidity, and cost-effectiveness. Among its many forms, white polystyrene antistatic film (PS antistatic film) has emerged as a critical material in various packaging applications due to its unique combination of physical properties and antistatic capabilities. This film is specifically engineered to mitigate the risks associated with electrostatic discharge (ESD), making it an ideal choice for industries requiring high standards of safety and product integrity. This article explores the characteristics of white PS antistatic film and its applications in food blister packaging,

disposable cutlery packaging, and antistatic packaging, providing a comprehensive analysis supported by industry insights and practical examples.Characteristics of White PS Antistatic FilmWhite PS antistatic film is a specialized form of polystyrene that incorporates antistatic additives or coatings to reduce or eliminate static electricity buildup. Its key characteristics make it a preferred material in packaging applications:Antistatic Properties:

The defining feature of white PS antistatic film is its ability to control static electricity. Static buildup can attract dust, cause product contamination, or damage sensitive electronic components. By incorporating antistatic agents, such as polyethylene glycol esters or sodium alkane sulphonates, the film reduces surface resistivity, typically achieving an electrostatic index in the range of 10^9 to 10^11 ohms/square for standard antistatic applications, or 10^3 to 10^6 ohms/square for conductive variants. This property ensures that the film prevents electrostatic discharge, protecting both the packaged product and the end-user.

Mechanical Strength and Rigidity:

Polystyrene is inherently rigid and brittle, providing excellent structural support for packaging. White PS antistatic film maintains this rigidity, making it suitable for creating robust trays, containers, and blister packs that protect contents from physical damage during transport and storage. Its high-impact variants, such as high-impact polystyrene (HIPS), enhance toughness, allowing the film to withstand mechanical stress without cracking.

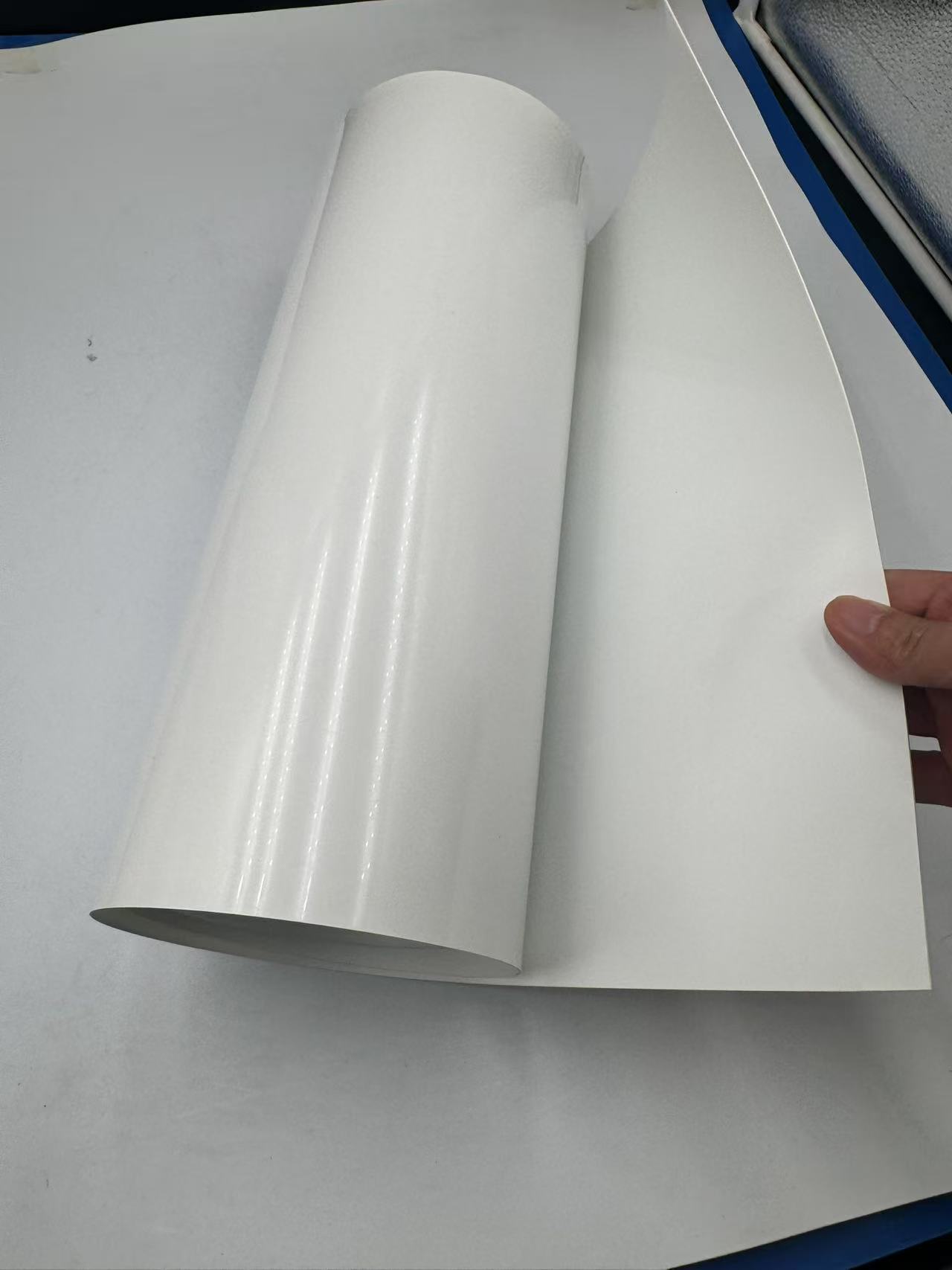

Aesthetic Appeal and Customization:

The white color of the film, often achieved through additives like titanium dioxide or calcium carbonate, provides a clean, professional appearance that is visually appealing for food and consumer goods packaging. This color also enhances opacity, which is beneficial for protecting light-sensitive products. Additionally, PS antistatic film can be customized in terms of thickness (typically 0.2–2 mm) and surface texture to meet specific packaging requirements.

Cost-Effectiveness:

Polystyrene is one of the most economical plastics per unit weight, making white PS antistatic film a cost-effective solution for large-scale packaging applications. Its low production cost, combined with the ability to be thermoformed into complex shapes, ensures that manufacturers can produce high-quality packaging without significant financial investment.

Barrier Properties and Chemical Stability:

While polystyrene is a poor barrier to air and water vapor compared to materials like polyethylene terephthalate (PET), it offers sufficient protection against chemical and biological contaminants when used in food packaging. The addition of antistatic coatings or internal additives enhances its chemical stability, ensuring that it does not react with packaged contents.

Ease of Processing:

White PS antistatic film is highly amenable to thermoforming and vacuum forming processes, allowing manufacturers to create precise shapes such as trays, blisters, and containers. Its low melting point (around 100°C) facilitates easy molding, reducing energy costs during production.

Environmental Considerations:

While polystyrene is not biodegradable, advancements in recycling technologies have improved its environmental footprint. Compacted polystyrene foam can be recycled into pellets for use in construction materials or other applications. However, its lightweight nature and low density (typically 30 kg/m³ for foam) pose challenges for curbside recycling programs, necessitating specialized collection systems.

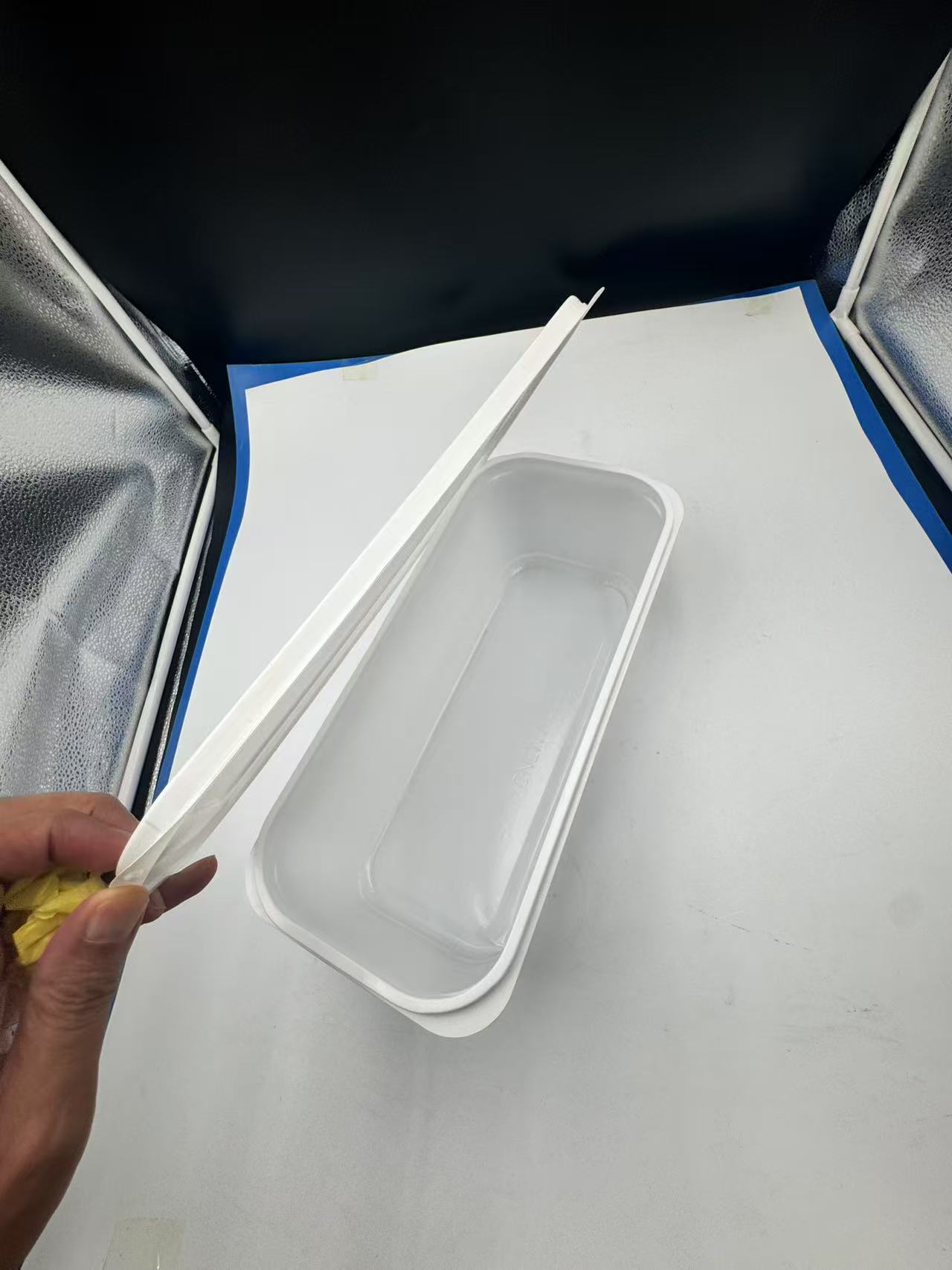

Applications of White PS Antistatic FilmWhite PS antistatic film finds extensive use across multiple industries due to its unique properties. Below, we explore its applications in food blister packaging, disposable cutlery packaging, and antistatic packaging, highlighting specific use cases and benefits.1. Food Blister PackagingBlister packaging is a widely used method for packaging food products, such as snacks, confectionery, and pre-portioned meals, due to its ability to protect contents while providing visibility and convenience. White PS antistatic film is particularly suited for this application due to its combination of rigidity, aesthetic appeal, and antistatic properties.Protection Against Contamination:

In food blister packaging, white PS antistatic film prevents static-induced dust attraction, which is critical for maintaining hygiene standards. Dust accumulation on packaging surfaces can contaminate food products during filling or sealing processes, leading to quality issues and consumer complaints. The antistatic properties of the film ensure a clean surface, reducing the risk of contamination.

Structural Integrity:

The rigidity of PS antistatic film allows it to form sturdy blister trays that protect delicate food items, such as chocolates or pastries, from crushing during transport. For example, a white PS antistatic blister tray can securely hold individual pieces of candy, ensuring they remain intact and visually appealing on store shelves.

Aesthetic and Branding Opportunities:

The white color of the film provides a neutral backdrop that enhances the visual appeal of packaged food products. Manufacturers can pair the film with transparent lids or printed graphics to create eye-catching packaging that aligns with brand identity. For instance, white PS antistatic trays are commonly used for premium baked goods, where the clean, professional appearance enhances perceived product quality.

Regulatory Compliance:

Polystyrene used in food contact applications is subject to strict regulations, such as those set by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). White PS antistatic film complies with these standards, with styrene monomer levels kept below 1% (0.5% for fatty foods) to ensure safety for consumers.

During the packaging of disposable cutlery, static electricity can cause plastic utensils to cling to each other or attract dust, complicating the packaging process and affecting product hygiene. White PS antistatic film, with its static-dissipative properties, ensures smooth handling and clean packaging, reducing production downtime and waste.

Lightweight and Durable:

The lightweight nature of polystyrene makes it an excellent choice for disposable cutlery packaging, minimizing transportation costs. Its rigidity ensures that the packaging maintains its shape, protecting the cutlery from bending or breaking. For example, white PS antistatic film can be thermoformed into trays that securely hold sets of cutlery, preventing movement during shipping.

Cost-Effective Mass Production:

The low cost of polystyrene allows manufacturers to produce large quantities of disposable cutlery packaging at a low price point, making it accessible for widespread use in fast-food chains and event catering. The ability to produce multiple trays simultaneously through thermoforming further enhances production efficiency.

White PS antistatic film, particularly in its conductive variant (10^3 to 10^6 ohms/square), acts as a Faraday cage, shielding electronic components from electrostatic fields. This is essential for protecting items like circuit boards, microchips, and sensors, which can be rendered inoperable by even small static discharges.

Case Example: A telecommunications company uses white PS antistatic film to create trays for packaging sensitive components, such as connectors and antennas. The trays are designed to fit precisely within shipping containers, providing both ESD protection and mechanical stability. The white color enhances visibility, making it easier for workers to inspect components during assembly.Challenges and Future DirectionsWhile white PS antistatic film offers numerous advantages, it also faces challenges that must be addressed to ensure its continued relevance in packaging applications:Environmental Concerns:

Polystyrene’s non-biodegradable nature and low recycling rates pose environmental challenges. Innovations in bio-based polymers and improved recycling infrastructure could mitigate these issues, allowing white PS antistatic film to remain competitive in a sustainability-focused market.

White PS antistatic film is a versatile and cost-effective material that plays a vital role in food blister packaging, disposable cutlery packaging, and antistatic packaging. Its antistatic properties, mechanical strength, and aesthetic appeal make it an ideal choice for protecting products from contamination, physical damage, and electrostatic discharge. While challenges such as environmental concerns and regulatory restrictions persist, ongoing innovations in recycling and polymer technology promise to enhance its sustainability and functionality. As industries continue to demand high-performance packaging solutions, white PS antistatic film will remain a cornerstone of modern packaging, balancing cost, performance, and safety.