Revolutionizing Pet and Human Food Packaging with PP Pet Food Containers

2025-02-11 16:35Revolutionizing Pet and Human Food Packaging with PP Pet Food Containers

Introduction

In the dynamic world of packaging, where the preservation of quality, safety, and sustainability is paramount, Polypropylene pet food containers have emerged as a versatile solution. These containers, while highly useful for the packaging of pet food, are being used in significant applications in the food and snack industry broadly. The paper examines multidimensional uses of PP containers and their integration with composite films in the enhancement of functionality, safety, and attractiveness for a wide array of packaging applications.

Characteristics of PP Containers

Strength and Durability: PP has been identified with strength; it acts as a very strong physical barrier which is resistant to physical impacts-something very critical at points of transportation and storage. Such strength will ensure that whatever is packed-pet foods or snacks, and other edibles-are always well-protected from external jolts and punctures.

Chemical Resistance: The inertness of PP offers a wide field of chemical resistance, thus making sure the container does not react with the content inside-a very important factor in pet foods that may contain added vitamins, minerals, or preservatives. This resistance also encompasses cleaning agents for hygienic maintenance of the containers.

Transparence and Clarity: While the PP can be made opaque, its potential for transparence or translucency is relevant to expose the product inside, whether colorful pet treats, fresh snacks, or dry kibble. This transparency helps in consumer choice by allowing them to see what they are buying.

Heat Resistance: PP containers have excellent thermal stability, which is very important in hot filling processes or when packaging food that might later be reheated or used under fluctuating temperature conditions. This property is crucial for maintaining the integrity of both the container and the food product.

Lightweight: The lightweight nature of PP means less cost in shipping and less impact on the environment, making it quite an eco-friendly choice for bulk packaging, especially in the pet food industry where volume is high.

Recyclability: PP is highly recyclable and hence contributes to the sustainability initiatives in packaging. This has become a very vital aspect as both consumers and companies look towards greener solutions.

Applications in Pet Food, Food, and Snack Packaging

Packaging for Pet Foods:

• Dried and Wet Food for Pets: PP containers are really good at keeping both kibbles and wet food fresh. In the case of dry food, the barrier properties against moisture prevent degradation, while in the wet version, the sealability of PP ensures no leakage to maintain nutritional value and freshness.

• Treats and Supplements: The clear or translucent PP containers allow for easy visibility of treats, which usually are what draws the owner into wanting to know what they're buying. Moreover, PP resists fats and oils, something quite good when packaging those sorts of treats with higher fat contents.

Human Food and Snack Packaging:

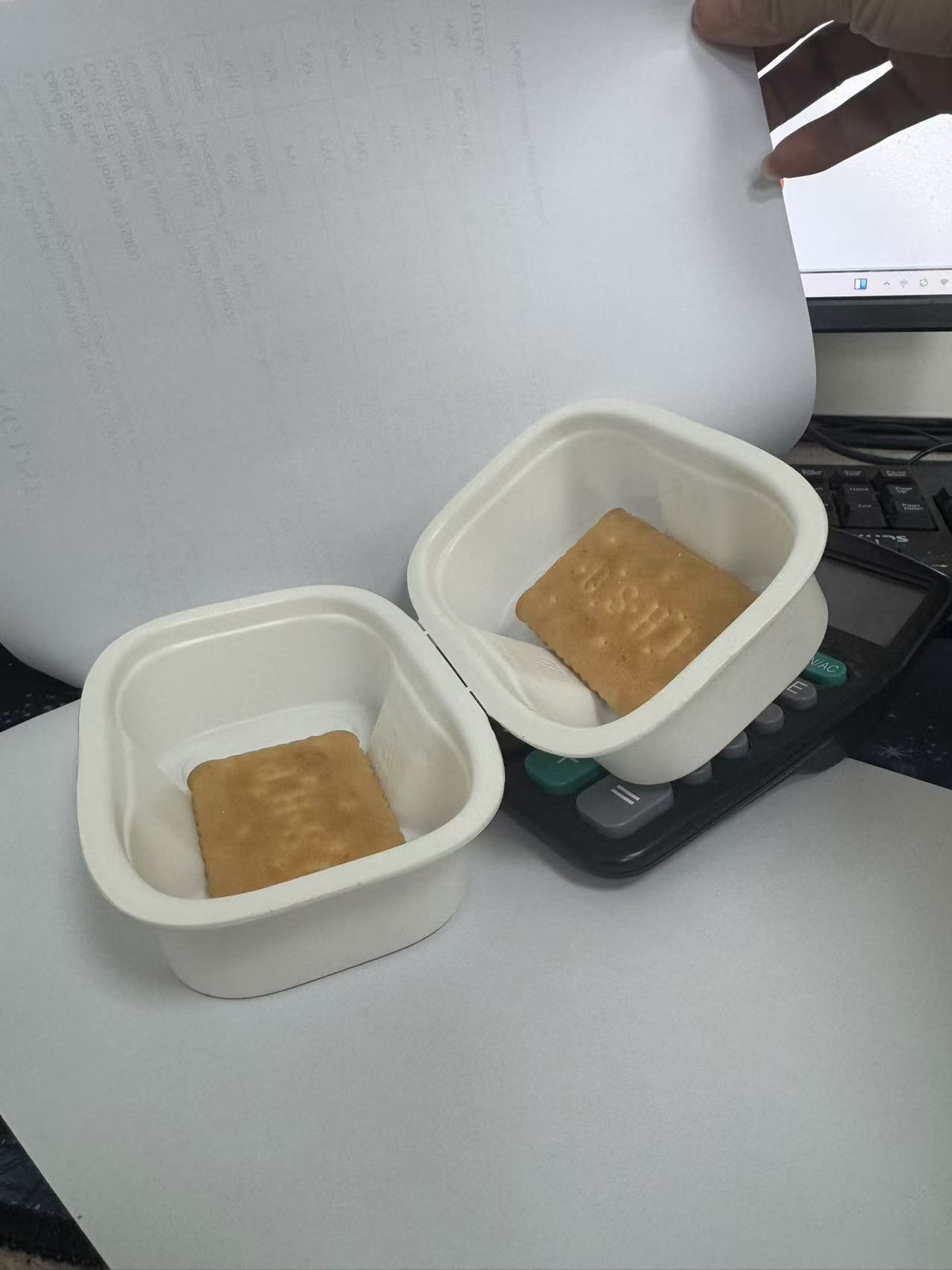

• Snacks: From chips to nuts, PP containers offer clean, durable, and aesthetically appealing packaging. The possibility of molding or shaping in various forms improves brand appearance on the shelf.

• Fresh Produce: For pre-cut fruits or vegetables, for example, PP containers can be applied along with the MAP, which prolongs the shelf life of a product simply by sustaining gases around a product.

• Ready Meals: Heat resistance enables it for use in the packaging of meals that may be microwaved or reheated without its container deforming and contaminating the food.

Composite Films Containing PP Containers

Improved Barrier Properties:

• Barrier to Oxygen and Moisture: Lamination of PP with films like EVOH-or metallized PET offers a good upgrade in barrier properties of containers for shelf life extension in perishable goods or sensitive pet foods.

• Light Protection: The additional layer for protection against UV light will avoid deterioration of its contents, very much useful and required for those products containing vitamins or natural colors.

Seal Integrity and Evidence of Tampering

• Seal Layers: Composite films can also contain sealant layers that give a stronger and more reliable seal to ensure that, once closed, the container stays secure until the consumer opens it.

• Tamper-Evident Features: Enhanced films can also feature peelable seals or tamper-evident bands that are important to consumer safety and confidence. This is especially critical in pet foods.

Printability and Branding:

• High-quality Graphics: A combination of PP with printable films enables bright graphics and branding important to stand out in competitive markets like pet food or snacks.

• Interactive Packaging: Incorporation of QR codes or any other interactive elements in packaging is enabled with the right composite film, offering additional engagement opportunities.

Innovating for Sustainability:

• Material Reduction: Composite films offer the possibility of material reduction by using thinner, strong packaging.

• Recycling-Friendly Design: Attention to designing the composites, which can easily be separated in order to support recyclability, would extend the life cycle for PP packaging according to the guiding principles of circular economy.

Conclusion

PP containers for pet foods, combined with strategic use of composite films, represent a true holistic solution in the packaging market, not limited to pet foods and snacks but generalized foods. In combination with the functionality offered by composite films, this balance of strength, resistance to most chemicals, clarity, and recyclability presents the PPs as a pretty smart choice with regard to the requirements of contemporary packaging. Without any doubt, continuing to move into the increasingly required sustainable but also effective way of packaging, changes in the further development of PP containers with parallel advanced film technologies will take place in food packaging.