PET Printable Film: Revolutionizing Printing Across Industries

2025-02-12 15:34PET Printable Film: Characteristics and Applications

Introduction

Printable Polyethylene Terephthalate (PET) film has carved out a significant niche in the printing industry due to its unique blend of durability, clarity, and printability. This article delves into the characteristics of PET printable film and its extensive applications, from advanced medical imaging like 4D ultrasounds, to office printing, advertising, and packaging solutions.

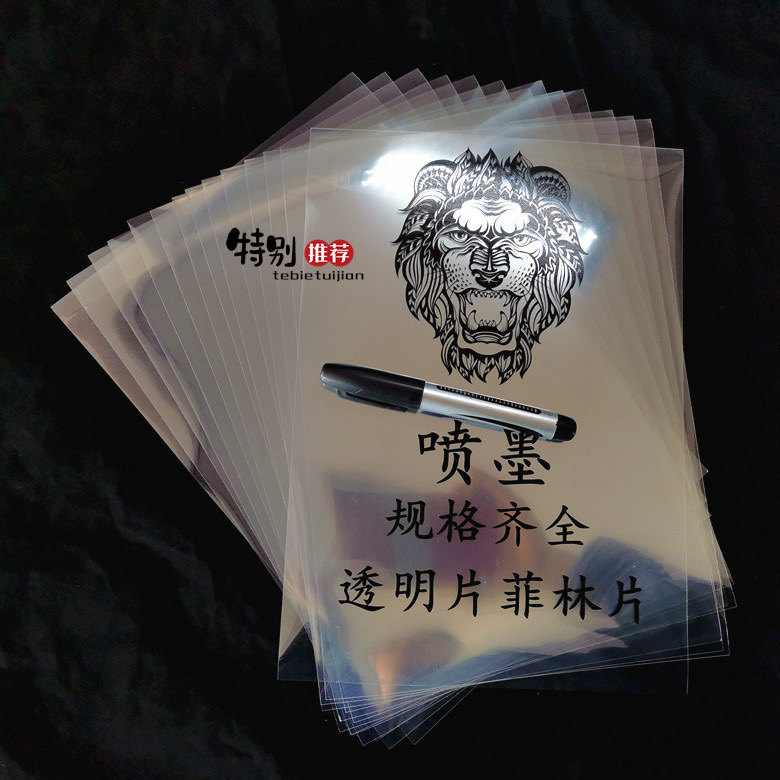

Characteristics of PET Printable Film

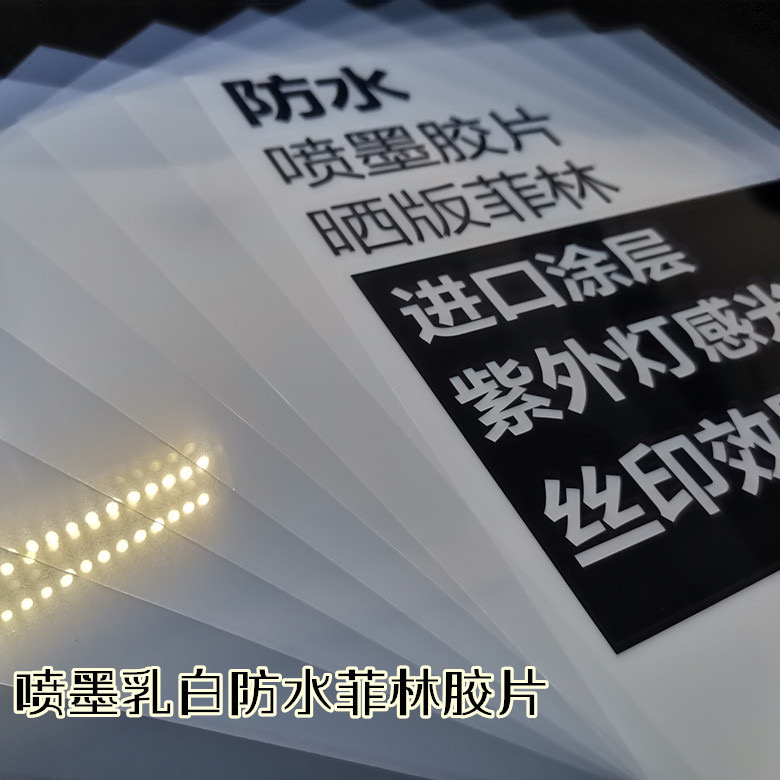

1. Durability:

Tear and Wear Resistance: PET films are known for their toughness, making them resistant to tears, punctures, and general wear, which is crucial for applications requiring longevity.

Chemical Resistance: They withstand exposure to various chemicals, which is essential for prints that might encounter cleaning agents or environmental contaminants.

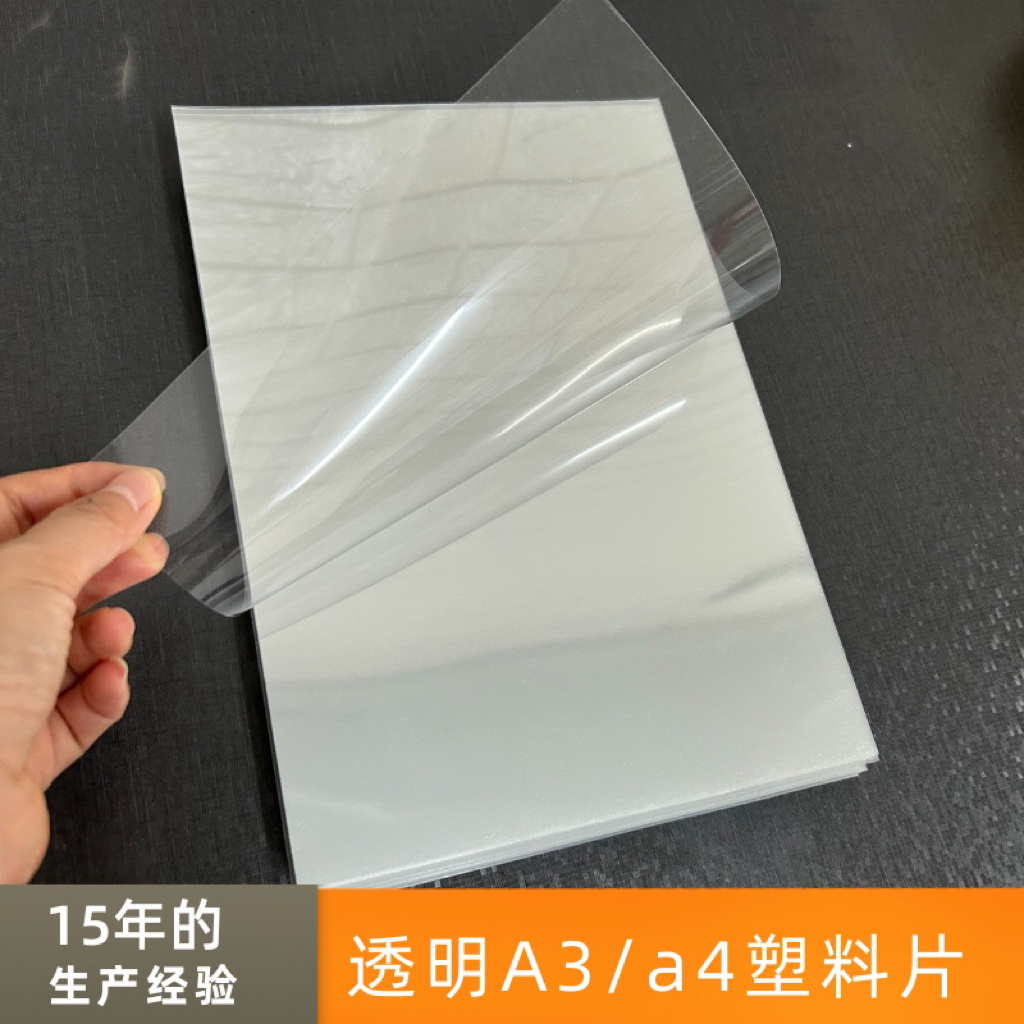

2. Optical Clarity:

PET films offer exceptional transparency, ensuring that printed images are vivid and clear, which is particularly important for applications where visual appeal or detail is paramount.

3. Heat Resistance:

The material can withstand high temperatures without deforming, allowing for use in environments where heat might be an issue, like in packaging or during the printing process itself.

4. Printability:

PET films accept a wide range of inks, including UV, solvent, and latex, offering versatility in printing methods. This trait is vital for achieving high-quality prints across various applications.

5. Flexibility:

Despite its strength, PET film retains flexibility, which is beneficial for applications requiring the film to conform to different shapes or surfaces.

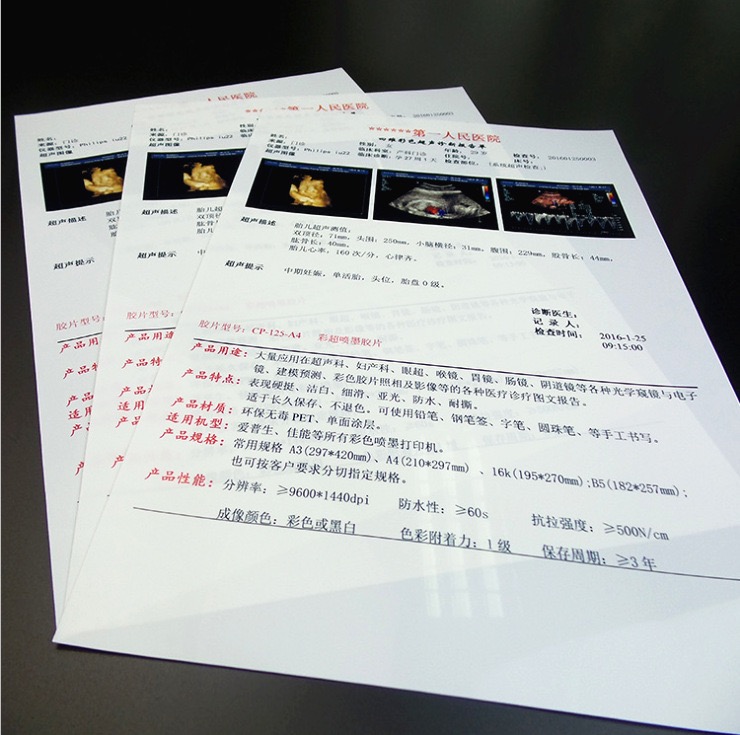

Applications in Medical 4D Ultrasound Printing

High-Quality Image Reproduction:

In the medical field, especially with 4D ultrasound imaging, PET printable film is used to produce high-resolution prints that capture detailed images of fetal development. The clarity and durability ensure these images are preserved for medical records or patient keepsakes.

Durability for Long-term Storage:

The archival quality of PET films means that these prints can be stored for years without degradation, essential for medical documentation.

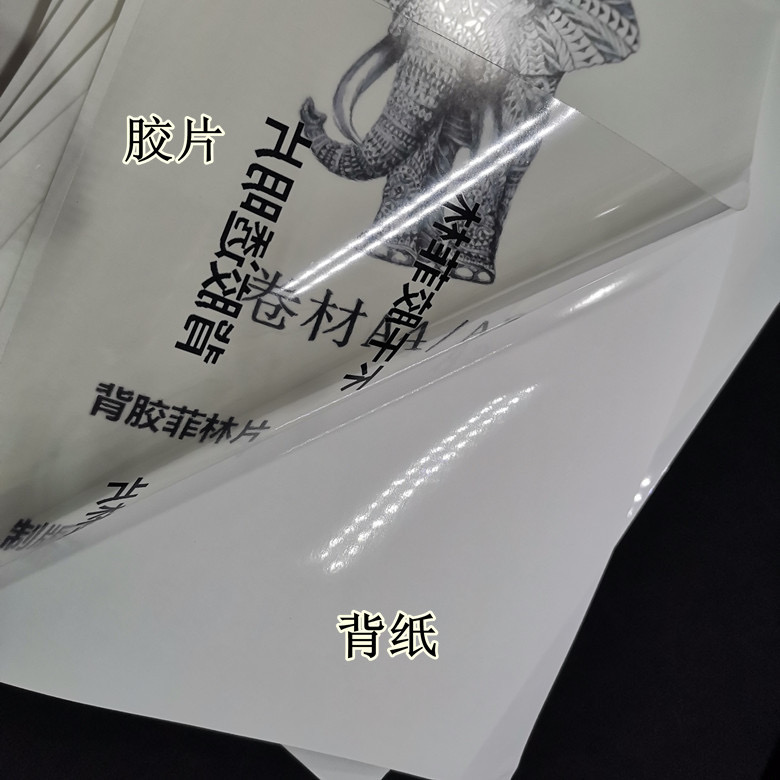

Office Printing

Versatile Use in Office Settings:

PET films are used for creating durable, long-lasting documents like charts, graphs, or presentations that require frequent handling or display. The ability to print on both sides further enhances their utility in office environments.

Eco-Friendly Options:

With increasing environmental awareness, some PET films are designed to be recyclable, offering an eco-friendly alternative for office supplies.

Advertising Printing

Outdoor and Indoor Advertising:

The weather-resistant nature of PET film makes it ideal for outdoor advertising like billboards, banners, or signage. Indoor applications include point-of-sale displays, where durability and visual impact are key.

Vivid Colors and Detailing:

Thanks to its excellent printability, PET film can produce ads with vibrant colors and fine details, crucial for brand visibility and consumer engagement.

Printing for Packaging

Enhanced Product Presentation:

In packaging, PET printable films are used to create labels or decorative elements that not only protect the product but also enhance its visual appeal on the shelf. The clarity of PET allows for see-through packaging that showcases the product.

Barrier Properties:

When used in multi-layer packaging, PET can contribute to moisture and gas barriers, extending the shelf life of packaged goods, especially in food and pharmaceuticals.

Customization and Branding:

The ability to print directly onto PET film allows for highly customized packaging, which is increasingly important in branding strategies where packaging is part of the consumer experience.

Conclusion

Printable PET film stands out in the printing industry for its blend of practical and aesthetic qualities. Its applications span from critical medical imaging to everyday office use, advertising, and innovative packaging. The versatility of PET film, coupled with its environmental considerations, positions it as a material of choice for future developments in printing technology. As we move towards more sustainable and visually impactful solutions, PET printable film will likely continue to play a pivotal role across various industries, enhancing both functionality and beauty in printed products.