Unveiling the Properties and Applications of Transparent CPP Film

2025-07-30 17:20Transparent cast polypropylene (CPP) film is a versatile and widely used material in modern industries,  celebrated for its exceptional clarity, flexibility, and heat-sealability. Derived from polypropylene, CPP film is produced through a casting process that results in a smooth, glossy finish, making it a preferred choice for applications requiring both aesthetic appeal and functional performance. This article delves into the key characteristics of transparent CPP film and explores its diverse applications across sectors such as packaging, agriculture,

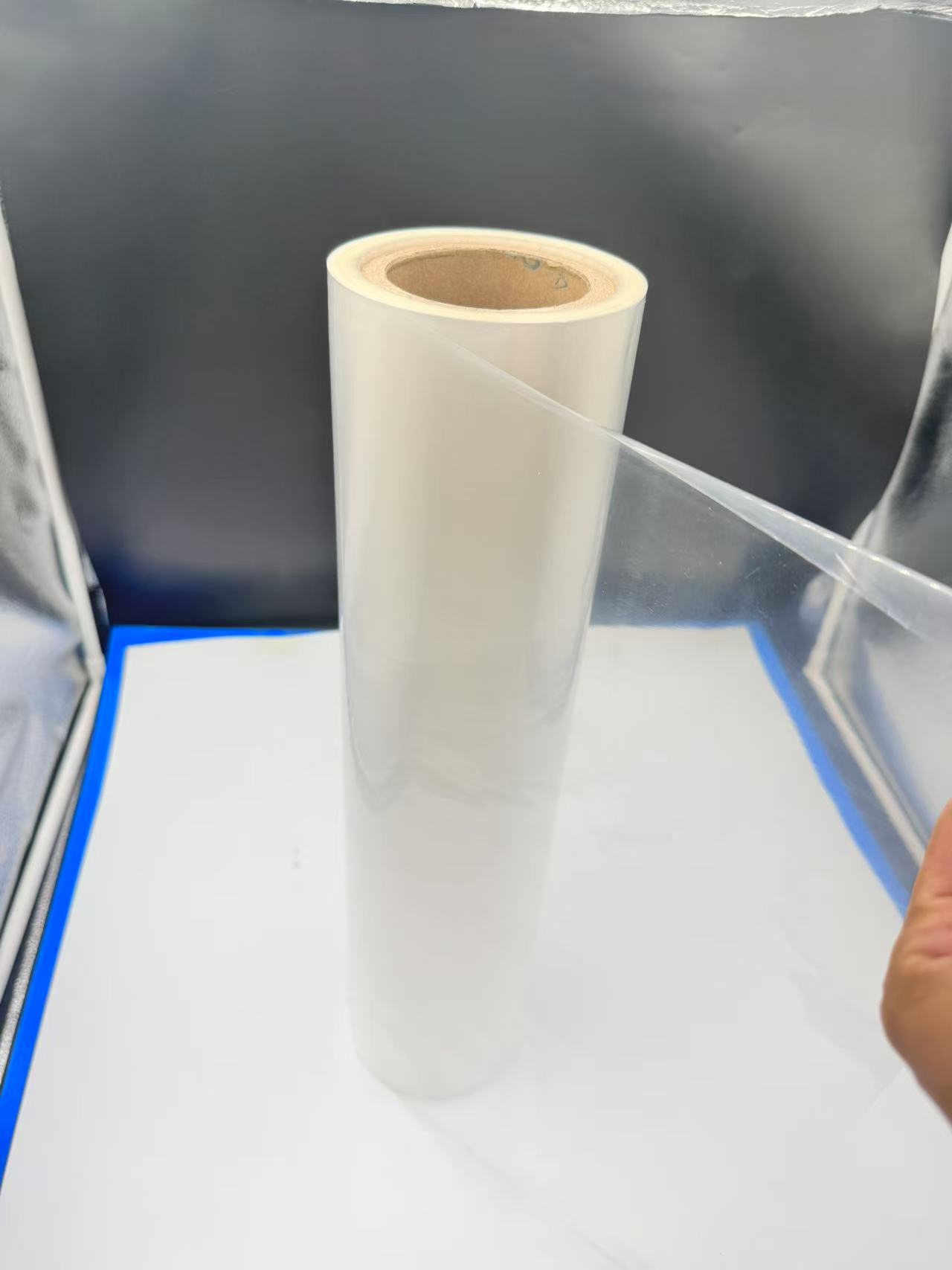

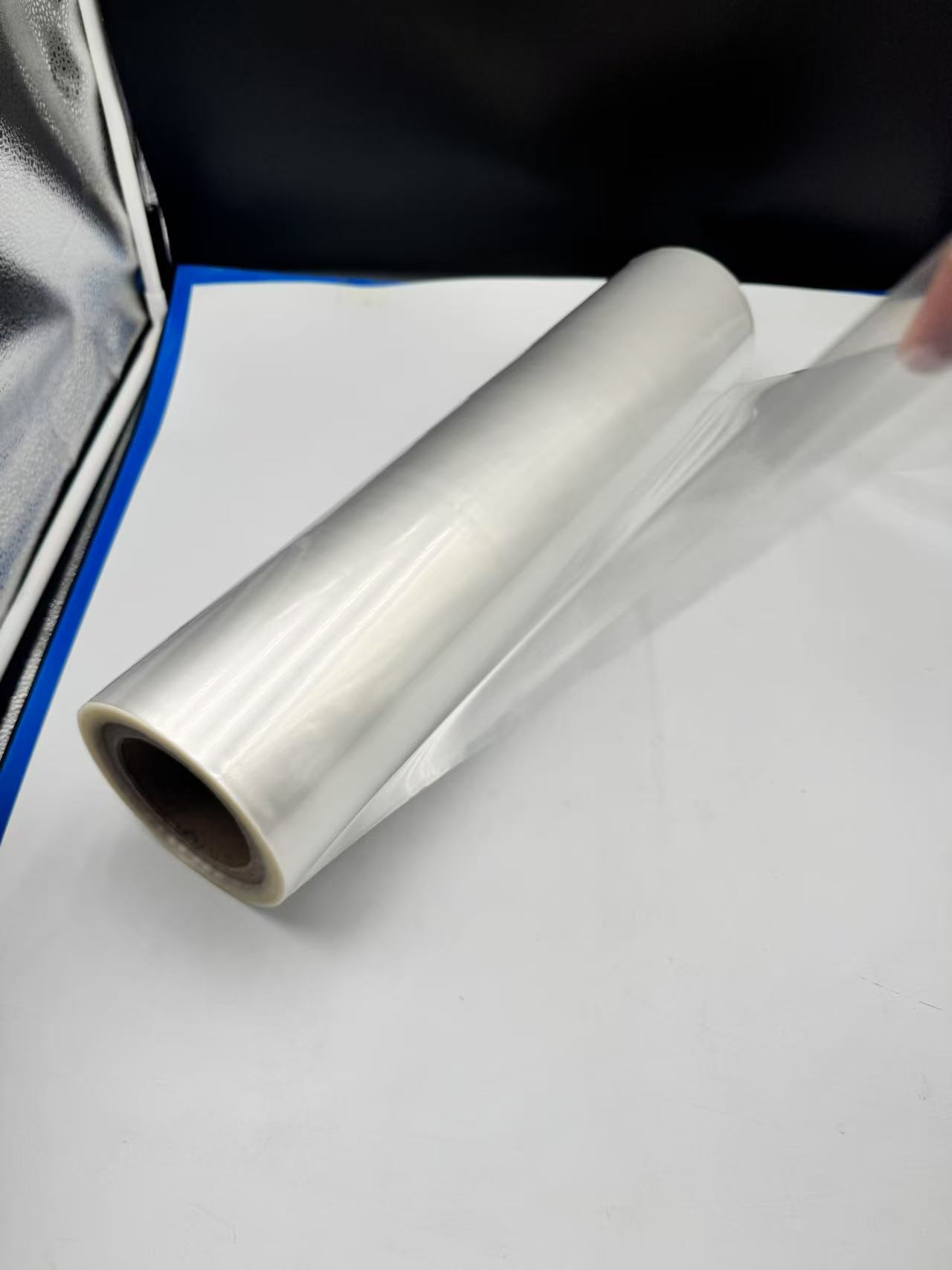

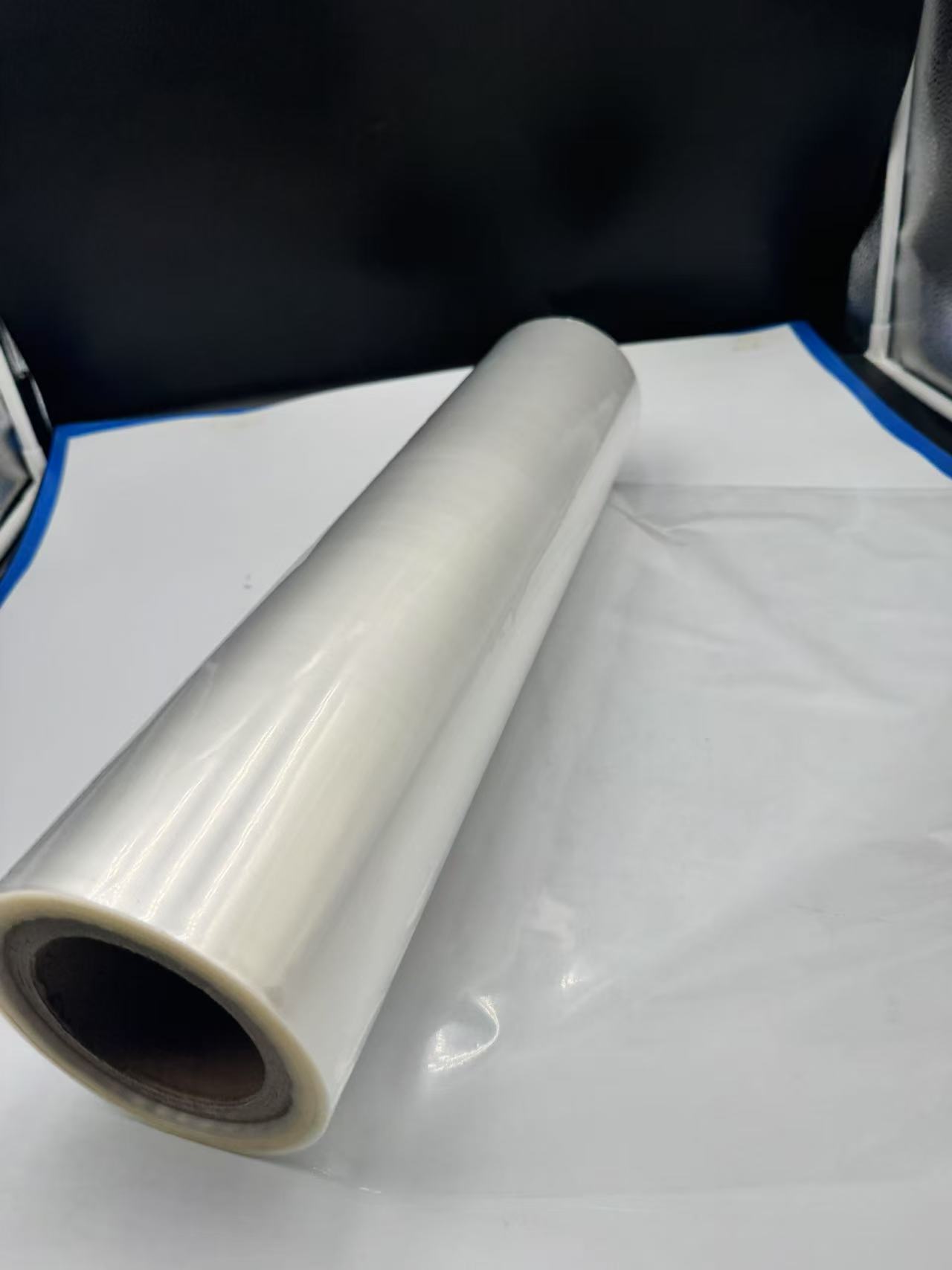

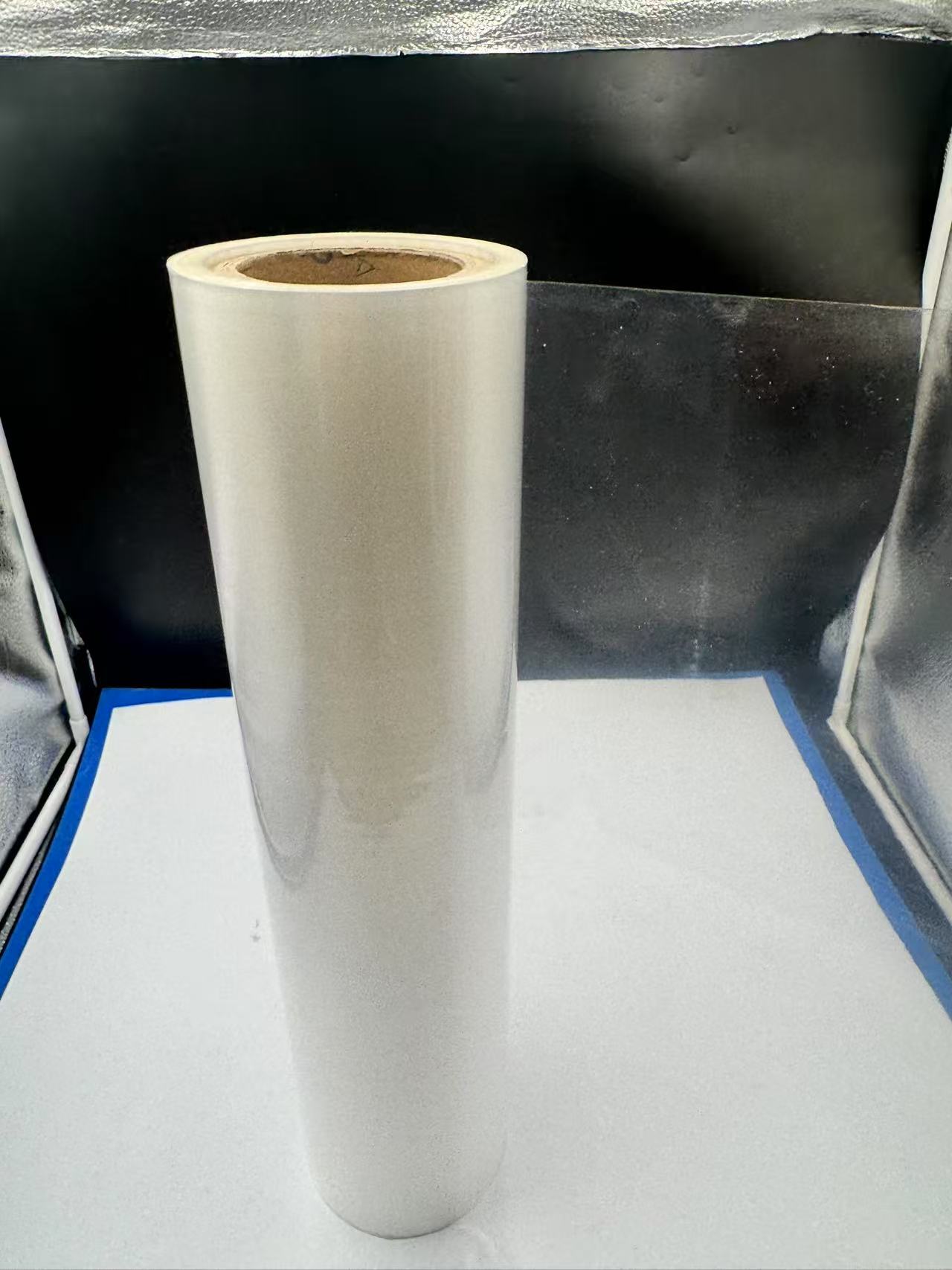

celebrated for its exceptional clarity, flexibility, and heat-sealability. Derived from polypropylene, CPP film is produced through a casting process that results in a smooth, glossy finish, making it a preferred choice for applications requiring both aesthetic appeal and functional performance. This article delves into the key characteristics of transparent CPP film and explores its diverse applications across sectors such as packaging, agriculture, and medical industries, highlighting its significance in meeting modern demands.Characteristics of Transparent CPP FilmSuperior Clarity and Gloss

and medical industries, highlighting its significance in meeting modern demands.Characteristics of Transparent CPP FilmSuperior Clarity and Gloss

Transparent CPP film is renowned for its high optical clarity, which rivals that of glass in certain applications. Its glossy surface enhances the visual appeal of products, making it ideal for packaging where showcasing contents is crucial. The film’s ability to transmit light with minimal haze ensures that items remain clearly visible, which is particularly valuable in retail settings. Studies indicate that CPP films can achieve light transmission rates exceeding 90%, making them a top choice for applications requiring transparency.

Excellent Heat-Sealability

One of the standout features of transparent CPP film is its superior heat-sealability. The film forms strong, reliable seals at relatively low temperatures, which is critical for high-speed packaging processes. This property ensures airtight and secure packaging, particularly for food and pharmaceutical products, where maintaining freshness and preventing contamination are paramount. The heat-seal strength of CPP film can be tailored during manufacturing to meet specific requirements, offering versatility for various applications.

Flexibility and Toughness

Transparent CPP film combines flexibility with impressive mechanical strength. It is resistant to punctures, tears, and abrasions, making it suitable for demanding environments. Its flexibility allows it to conform to a wide range of shapes, from rigid containers to irregularly shaped products. According to material testing data, CPP films exhibit tensile strengths ranging from 20 to 40 MPa, depending on thickness and formulation, ensuring durability without sacrificing pliability.

Moisture and Chemical Resistance

CPP film offers excellent resistance to moisture, oils, and certain chemicals, making it a reliable barrier material. This property is particularly valuable in packaging applications, where it protects contents from humidity and external contaminants. Unlike some other plastics, transparent CPP film maintains its integrity when exposed to greasy or oily substances, which is why it is commonly used for food packaging. Its chemical resistance also makes it suitable for industrial and medical applications.

Cost-Effectiveness and Processability

Transparent CPP film is economical to produce and process, offering a cost-effective alternative to materials like polyethylene terephthalate (PET) or polyvinyl chloride (PVC). Its compatibility with high-speed manufacturing equipment reduces production costs, while its ability to be printed, laminated, or metallized enhances its versatility. Additionally, CPP film is recyclable, aligning with growing sustainability trends. Advances in recycling technologies have improved the ability to repurpose CPP film, reducing its environmental footprint.

Applications of Transparent CPP FilmThe unique properties of transparent CPP film have led to its widespread adoption across various industries. Below are some of its most prominent applications, illustrating its adaptability and practical value.Food Packaging

Transparent CPP film is a cornerstone of the food packaging industry, where its clarity, heat-sealability, and barrier properties shine. It is commonly used for flexible packaging, such as pouches, wraps, and bags for snacks, baked goods, and fresh produce. The film’s ability to form strong seals ensures product freshness, while its transparency allows consumers to inspect the contents. For instance, CPP film is used in lamination with other materials to create multi-layer pouches for products like frozen foods, extending shelf life. Market reports project that the demand for CPP films in food packaging will continue to grow due to their cost-effectiveness and performance.

Medical and Pharmaceutical Packaging

In the medical and pharmaceutical sectors, transparent CPP film is used for sterile packaging, such as blister packs and pouches for medical devices. Its chemical resistance and ability to maintain a sterile environment make it ideal for protecting sensitive products. The film’s clarity allows for easy inspection of contents, ensuring quality control in healthcare settings. Additionally, its flexibility enables the creation of soft, user-friendly packaging for items like syringes or bandages, enhancing patient safety and convenience.

Industrial Applications

Transparent CPP film is employed in industrial settings for protective coverings and wrapping materials. Its toughness and resistance to moisture make it suitable for shielding machinery, equipment, or components during storage or transport. The film’s clarity is advantageous in scenarios where visibility is needed, such as for quality checks or inventory management. In some cases, CPP film is used as a release liner in adhesive manufacturing, where its smooth surface prevents sticking and ensures easy handling.

Agricultural Uses

In agriculture, transparent CPP film is utilized for greenhouse coverings, mulching, and crop protection. Its light-transmitting properties allow sunlight to reach plants, promoting growth, while its durability protects crops from environmental factors like wind or rain. For mulching, CPP film helps retain soil moisture, control weeds, and regulate temperature, improving crop yields. Its affordability and ease of installation make it a practical choice for large-scale farming operations.

Retail and Consumer Goods

Transparent CPP film is widely used in retail for product displays and protective packaging. Its glossy finish and clarity enhance the visual appeal of items like cosmetics, electronics, or stationery, making them more attractive to consumers. The film is often used for shrink-wrapping products or creating window-like packaging that showcases contents while providing protection. Its ability to be printed with vibrant designs further enhances its role in branding and marketing.

Advantages Over Alternative MaterialsTransparent CPP film offers distinct advantages over other materials like polyethylene (PE), PVC, or BOPP (biaxially oriented polypropylene). Compared to PE, CPP film provides better clarity and heat-sealability, making it preferable for high-quality packaging. Unlike PVC, which may raise environmental concerns due to plasticizers, CPP film is considered more eco-friendly and easier to recycle. Compared to BOPP, CPP film is softer and more flexible, allowing for better conformability to complex shapes.

These advantages make CPP film a versatile and competitive option in the market.Challenges and ConsiderationsWhile transparent CPP film is highly versatile, it faces some challenges. Its barrier properties, while excellent for moisture, are less effective against gases like oxygen compared to materials like EVOH or PVDC. To address this, CPP film is often laminated with other materials to enhance its gas barrier performance, though this can increase costs. Additionally, while CPP film is recyclable, the infrastructure for recycling polypropylene varies by region, limiting its sustainability in some markets.Another consideration is its performance in extreme temperatures. While CPP film is suitable for a wide temperature range, it may soften at very high temperatures, which could affect its performance in certain applications. Manufacturers mitigate this by using additives or co-extrusion techniques to enhance thermal stability.Future Trends and Innovations