PLA Film: Pioneering Sustainable Packaging with Biodegradable Brilliance

2025-09-29 17:14Introduction to Transparent PLA Film

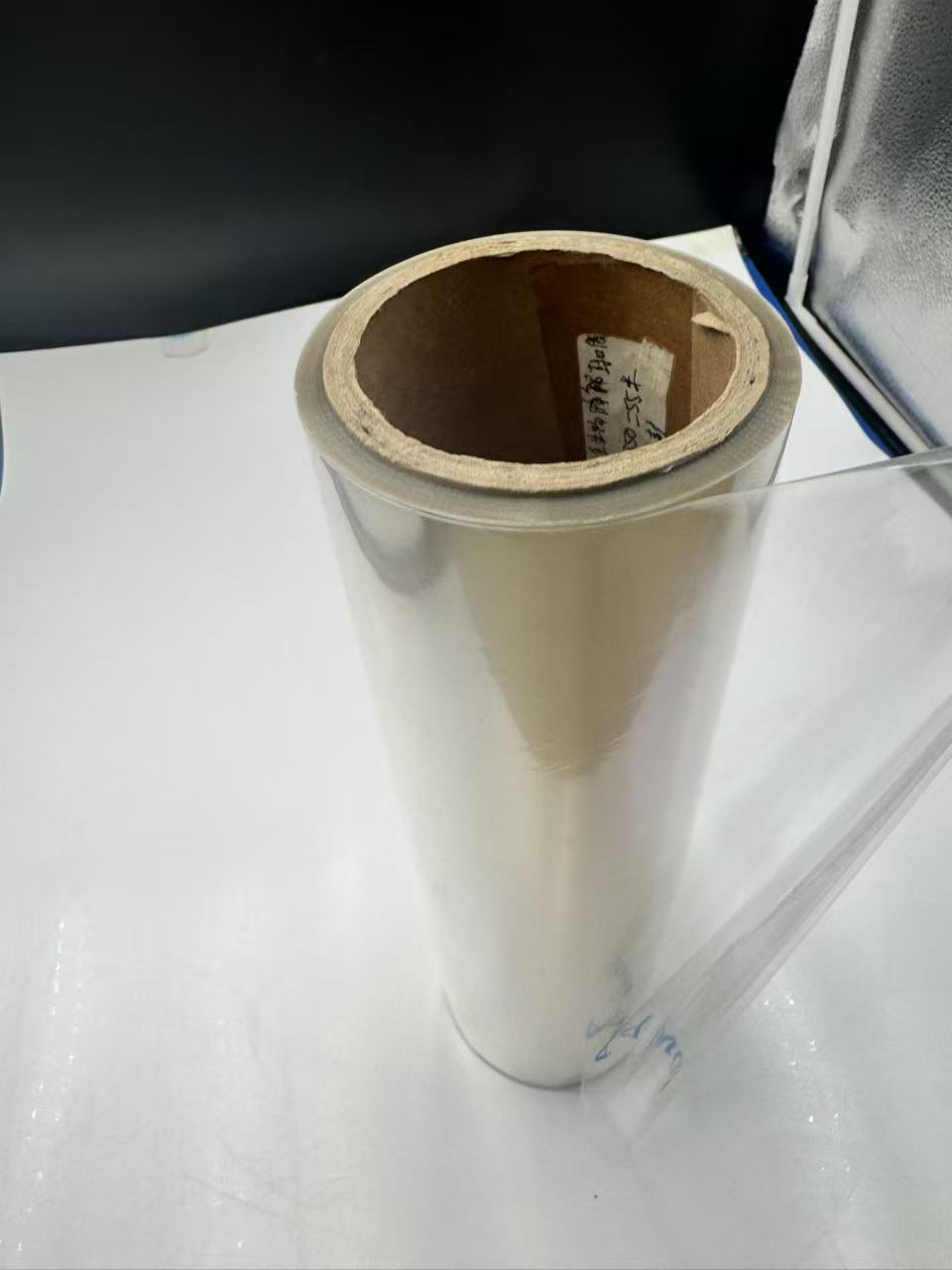

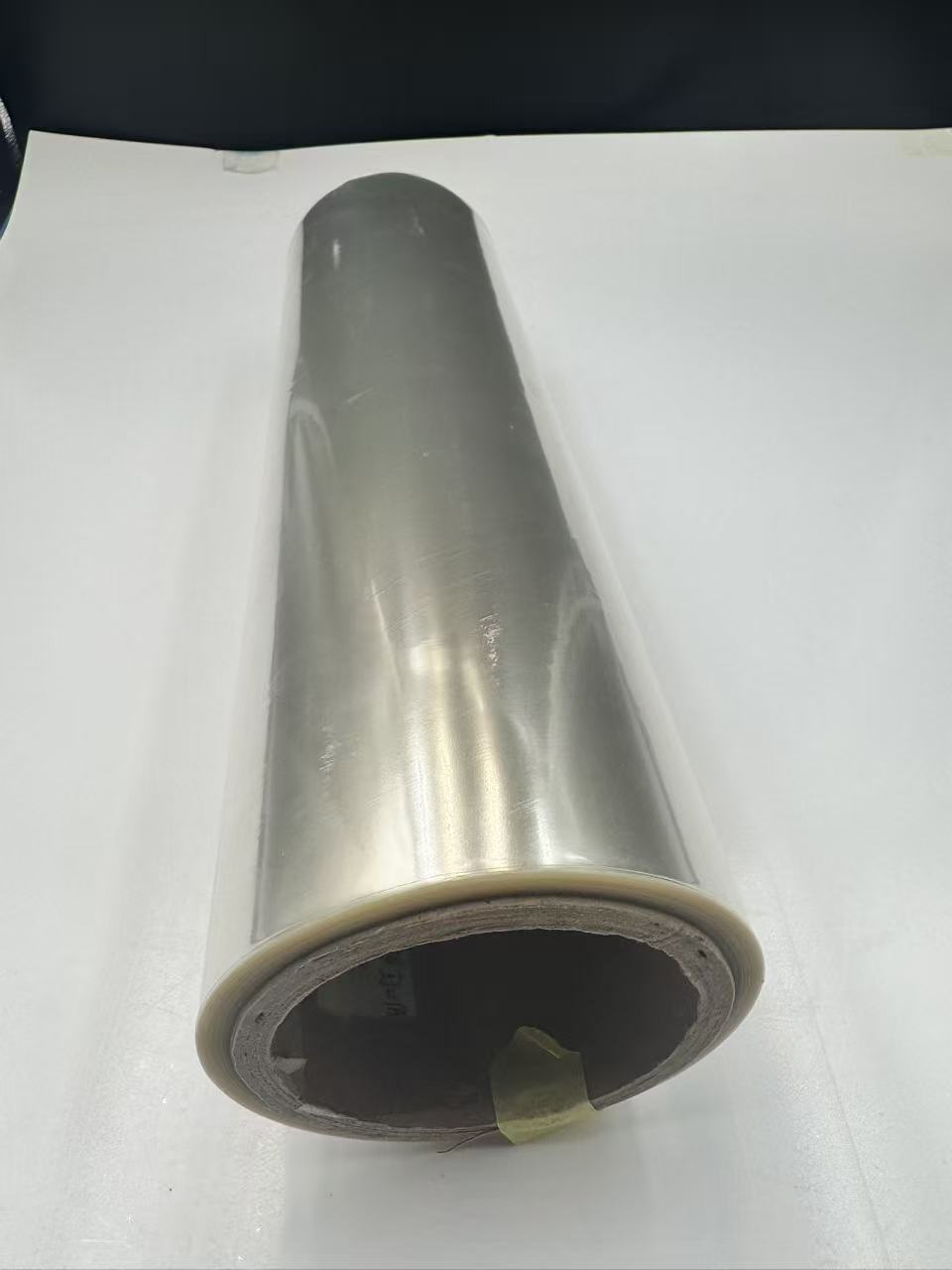

In an era where sustainability is no longer a choice but a necessity, transparent polylactic acid (PLA) film emerges as a gamechanger in the packaging world. Derived from renewable resources like corn starch or sugarcane, PLA film is a biodegradable, biobased plastic that breaks down into water and carbon dioxide under industrial composting conditions, leaving no trace of microplastics. Unlike petroleumbased films, PLA’s cradletocradle lifecycle slashes carbon footprints by up to 65%, as per lifecycle analyses from the Bioplastics Division of the Society of Plastics Engineers. Its crystalclear transparency rivals traditional plastics, offering a window to products while whispering a promise of environmental responsibility.

Imagine a material that sparkles like glass but melts back into the earth—a material that wraps your favorite snack or safeguards a collectible with equal finesse. PLA film is crafted through polymerization of lactic acid, fermented from plant sugars, and extruded into thin, glossy sheets. With global plastic waste nearing 400 million tons annually, and packaging comprising 36% of that, PLA film offers a lifeline: it’s compostable, renewable, and endlessly adaptable. From artisanal gift wraps to hightech food packaging, this article dives into PLA film’s standout properties and vibrant applications, showcasing why it’s the darling of ecoconscious industries.

Key Properties of Transparent PLA Film

PLA film’s allure lies in its harmonious blend of functionality and ecofriendliness. Mechanically, it’s robust yet flexible, with a tensile strength of 50–70 MPa, comparable to PET, and an elongation at break of 5–10%, per ASTM D882 standards. This makes it sturdy enough to withstand handling yet pliable for intricate folds. Its transparency is a showstopper—light transmittance exceeds 90%, with haze below 2.5%, rivaling glass for visual clarity. This optical purity, verified by ISO 14782, ensures products shine without distortion, perfect for retail displays.

Environmentally, PLA film is a superstar. It’s 100% biobased, slashing reliance on fossil fuels, and compostable under industrial conditions (EN 13432), degrading in 60–180 days into nontoxic byproducts. This contrasts sharply with PET’s 500year landfill legacy. Energy consumption during production is 30–50% lower than polyethylene, per the Journal of Cleaner Production, and its carbon footprint is minimal, with emissions as low as 1.6 kg CO₂/kg versus 4 kg for PP. PLA’s barrier properties, while moderate (oxygen transmission around 700 cm³/m²/day), suffice for shortshelflife goods, and additives like nanocellulose can boost this to 200 cm³/m²/day.

Versatility defines PLA further. Its surface energy (38–42 mN/m) supports excellent printability, with ink adhesion rates above 95% for flexo or digital printing. Antifog coatings prevent condensation, ideal for chilled displays, while UV stabilizers extend outdoor life. However, PLA’s thermal ceiling (60°C) limits hotfill uses, though copolymers push this to 80°C. Chemical resistance guards against mild acids and oils, but strong solvents require caution. For electronics, antistatic PLA variants achieve surface resistivity of 10⁹ ohms, protecting sensitive components. These properties, grounded in rigorous testing, position PLA film as a sustainable alternative that doesn’t skimp on performance.

Applications in Diverse Packaging Scenarios

Transparent PLA film’s adaptability shines across industries, from everyday essentials to niche collectibles. Let’s explore its transformative roles, painting a vivid picture of its impact.

Bookmark Packaging: EcoChic Guardians of Literature

Picture a cozy bookstore, shelves brimming with novels, each accompanied by a bookmark nestled in a shimmering PLA film sleeve. These 0.15mmthick sheets are thermoformed into sleek pouches, their transparency showcasing intricate bookmark designs—perhaps a pressed flower or a laseretched quote. PLA’s high gloss (80 GU at 60°) catches the eye, while its compostability aligns with readers’ green values, as 68% of book buyers prefer sustainable products, per Nielsen’s 2023 survey.

A small UK publisher switched to PLA biodegradable film for limitededition bookmarks, reducing packaging waste by 30%. The film’s moisture resistance (WVTR < 150 g/m²/day) kept bookmarks pristine during transatlantic shipping, and its lightweight nature (1.24 g/cm³ density) cut freight costs. Printable PLA added vibrant logos, boosting brand recall. Unlike PVC, which yellows over time, PLA stays clear, preserving aesthetics. For ecoconscious book fairs, these sleeves compost postevent, leaving no trace—a love letter to both literature and the planet.

Cosmetics Packaging: Beauty with a Biodegradable Twist

In the dazzling world of cosmetics, PLA transparent film elevates products while treading lightly. Blister packs for lip balms or mascara wands use 0.25mm PLA sheets, their clarity highlighting vibrant shades like a gallery spotlight. The film’s smooth texture, with surface roughness below 0.05 µm, feels premium, while its biodegradability appeals to 73% of beauty consumers prioritizing sustainability, per Mintel’s 2024 report.

A French indie brand launched a vegan skincare line in PLA film trays, their antifog properties ensuring serums looked pristine in humid stores. The film’s moderate oxygen barrier extended shelf life by 20%, ideal for natural formulations. Tamperevident seals, compliant with FDA 21 CFR 177.1630, ensured safety, while printable surfaces bore floral designs that popped on shelves. Unlike PP, which lingers in landfills, PLA composts, letting brands like this one reduce their environmental footprint by 40%. It’s packaging that pampers both skin and soil.

Gift Packaging: Wrapping Joy with Green Elegance

Giftgiving sparkles with PLA film, which crafts ecofriendly wraps that don’t sacrifice charm. Transparent windows in gift boxes reveal chocolates or trinkets, their 90% light transmittance creating a tantalizing peek. PLA’s dimensional stability (shrinkage < 1%) ensures boxes stay crisp, even in humid gift shops.

A Canadian chocolatier used PLA compostable film for holiday hampers, its oxygen barrier preserving cocoa richness for 60 days longer than paper. Printable PLA pouches bore festive snowflakes, with inks adhering flawlessly, boosting sales by 25%, per internal data. The film’s flexibility allowed intricate folds for ribbonlike accents, while its compostability let recipients dispose guiltfree. The World Packaging Organisation notes that biodegradable packaging cuts waste by 20%; PLA delivers, turning every gift into a sustainable celebration.

HandFigure Packaging: Collectibles in Compostable Armor

For collectors, unboxing a handfigure—be it a superhero or anime idol—is a ritual. PLA protective film ensures that moment is flawless. Thermoformed clamshells, just 0.3mm thick, cradle figures without scratching, their clarity showcasing details like a samurai’s blade or a dragon’s scales. Haze below 2% makes every angle pop, vital for $300 collectibles.

Food Packaging: Freshness with a Sustainable Edge

PLA biodegradable film shines in food packaging, where freshness and ecofriendliness collide. Trays for berries or salads use 0.2mm PLA sheets, their oxygen barrier (700 cm³/m²/day) sufficient for shortshelflife produce. Antifog coatings keep greens vibrant in fridge displays, while compostability aligns with EU’s 2030 zerowaste goals.

A California organic farm wrapped microgreens in PLA film, extending shelf life by 10 days compared to PE, per field tests. The film’s clarity boosted impulse buys by 15%, and its compostable nature let cafes compost postuse, reducing landfill waste by 50 tons annually. Printable PLA bore farm logos, reinforcing brand trust. Though less robust for highoxygen barriers, nanocellulose additives are closing the gap, making PLA a fresh, green choice for grocers.

Printable Packaging: A Canvas for EcoArtistry

Broader Impacts and Future Horizons

PLA film extends beyond these niches: bakery trays for pastries, medical pouches for sterile tools, even agricultural mulch films that biodegrade into soil. Its scalability—available in rolls for FFS machines or custom sheets—fuels innovation. Challenges like brittleness at low temperatures are being tackled with plasticizers, boosting elongation by 20%. Highhumidity composting remains a hurdle, but homecompostable PLA variants are emerging.

The EU’s SingleUse Plastics Directive pushes bioplastics; PLA is poised to lead, with production projected to hit 1 million tons by 2030, per Plastics Europe. Partnerships with brands like Seventh Generation amplify its reach. Future PLA films may embed enzymes for faster degradation or smart inks for freshness alerts, redefining packaging.

Conclusion

Transparent PLA film is more than a material—it’s a manifesto for a greener world. Its clarity, strength, and compostability transform bookmarks, cosmetics, gifts, figures, and food into sustainable showcases. As we navigate a plasticchoked planet, PLA film offers a path forward: packaging that protects, dazzles, and disappears responsibly. Let’s embrace this biodegradable marvel, wrapping today’s treasures in tomorrow’s promise.