Transparent Soft PVC Flexible Film: Properties and Versatile Applications in Packaging and Beyond

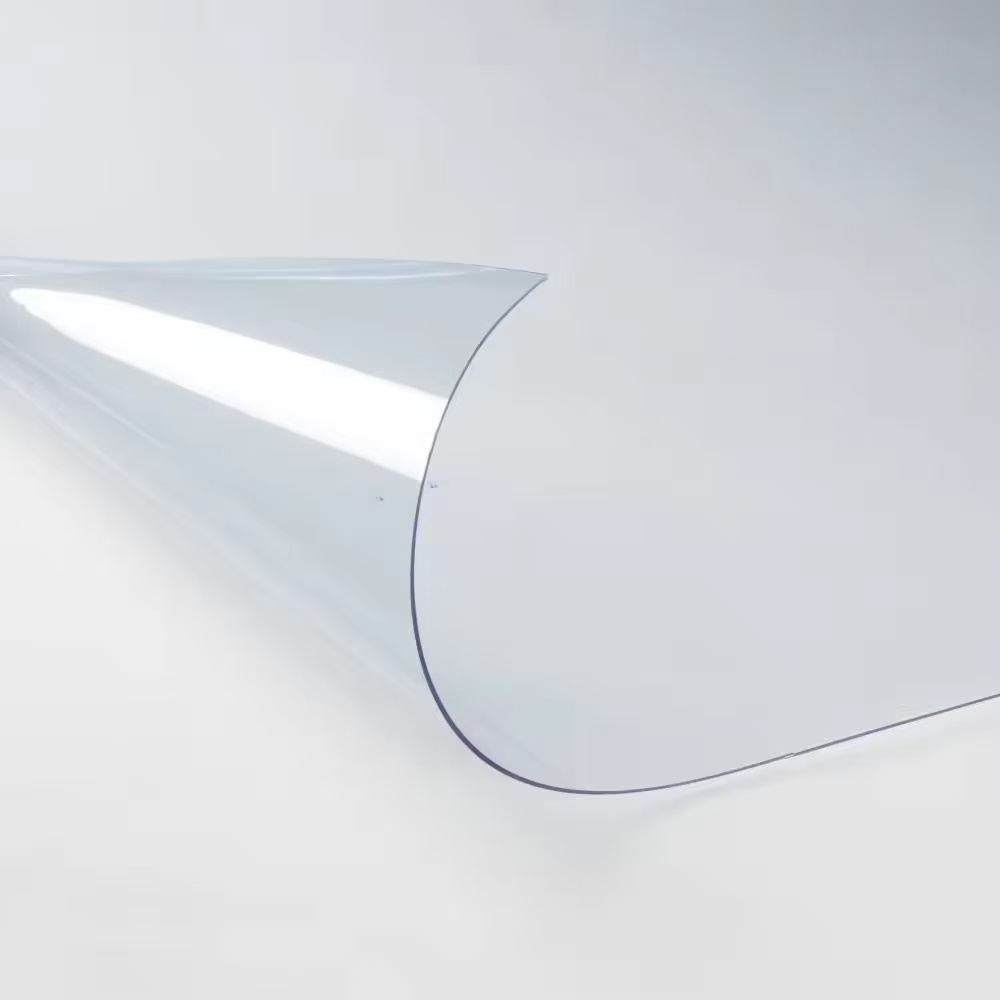

2025-08-13 17:30IntroductionTransparent soft PVC (Polyvinyl Chloride) flexible film is a cornerstone of modern material science, offering a unique blend of clarity, flexibility, and durability that makes it indispensable across a wide range of industries. Known for its adaptability, this soft, pliable film is engineered to meet the demanding requirements of applications such as medical packaging, food packaging,  and industrial uses. With its ability to combine aesthetic appeal with robust performance, transparent soft PVC flexible film has become a go-to solution for manufacturers seeking cost-effective, reliable, and visually appealing materials. This article delves into the properties of soft PVC flexible film and explores its diverse applications, supported by technical insights and practical examples.Properties of Transparent Soft PVC Flexible FilmSoft PVC flexible film is produced by plasticizing PVC resin with additives like phthalates or non-phthalate plasticizers, resulting in a pliable, transparent material with exceptional performance characteristics. Below are its key properties, which underpin its widespread use:High Transparency: Soft PVC film offers excellent optical clarity, with light transmission rates often exceeding 90%. This crystal-clear appearance enhances product visibility, making it ideal for applications where showcasing contents is critical, such as food packaging or medical device displays.

and industrial uses. With its ability to combine aesthetic appeal with robust performance, transparent soft PVC flexible film has become a go-to solution for manufacturers seeking cost-effective, reliable, and visually appealing materials. This article delves into the properties of soft PVC flexible film and explores its diverse applications, supported by technical insights and practical examples.Properties of Transparent Soft PVC Flexible FilmSoft PVC flexible film is produced by plasticizing PVC resin with additives like phthalates or non-phthalate plasticizers, resulting in a pliable, transparent material with exceptional performance characteristics. Below are its key properties, which underpin its widespread use:High Transparency: Soft PVC film offers excellent optical clarity, with light transmission rates often exceeding 90%. This crystal-clear appearance enhances product visibility, making it ideal for applications where showcasing contents is critical, such as food packaging or medical device displays.

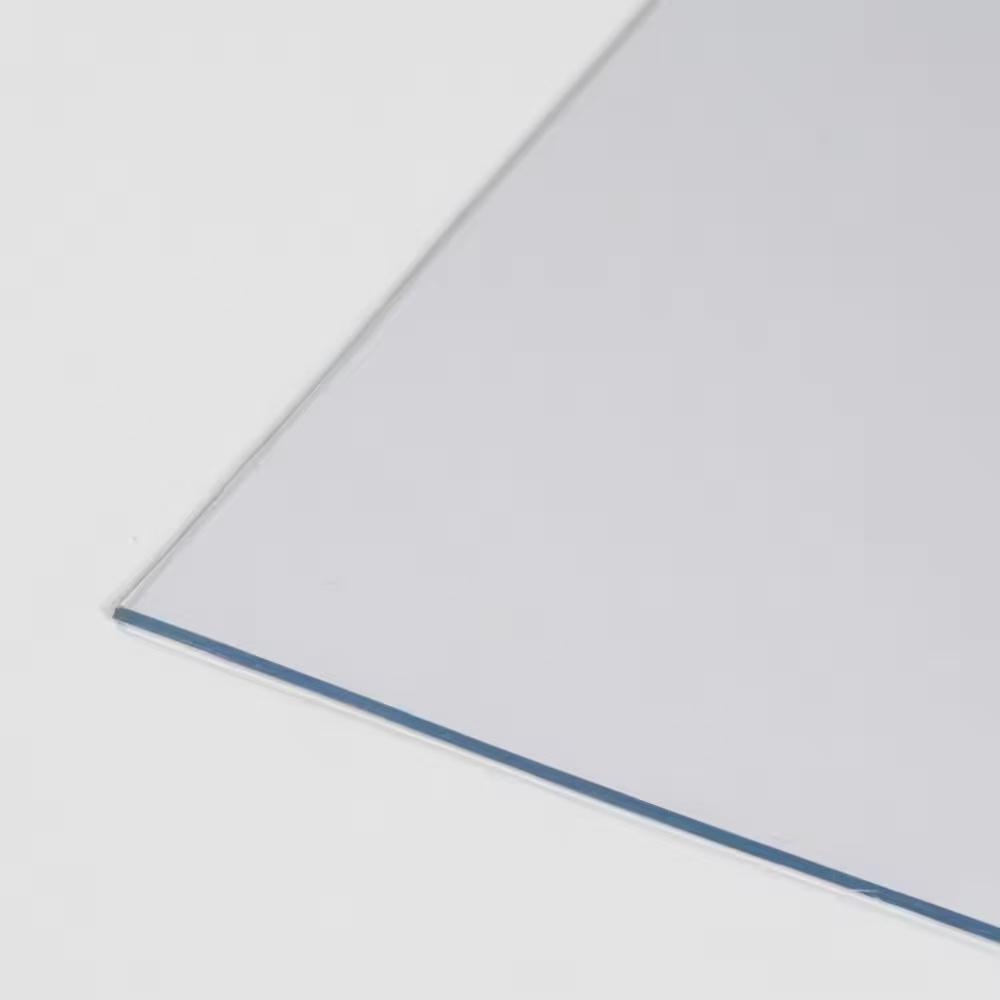

Flexibility and Elasticity: The addition of plasticizers, such as DEHP or DINP, imparts flexibility, allowing the film to conform to various shapes and sizes. With elongation at break typically ranging from 200–400%, soft PVC film is highly adaptable for wrapping, sealing, or forming applications.

Mechanical Strength: Despite its flexibility, soft PVC film maintains good tensile strength (approximately 15–30 MPa) and tear resistance. This balance ensures that the film can withstand handling and transportation stresses without compromising integrity.

Chemical Resistance: Soft PVC is resistant to acids, alkalis, oils, and many solvents, making it suitable for contact with diverse substances, from food products to medical solutions. This property ensures product safety and maintains film performance in challenging environments.

Thermal Stability: Soft PVC flexible film can operate within a temperature range of -20°C to 80°C, with some formulations stable up to 100°C. This makes it suitable for both refrigerated and ambient conditions, though it is less suited for high-temperature sterilization compared to rigid PVC.

Barrier Properties: While not as robust as multilayer films like PVC/EVOH/PE, soft PVC offers moderate oxygen and moisture barrier properties (OTR ≈ 100–500 cm³/m²·24h·0.1Mpa). Additives or coatings can enhance barrier performance for specific applications, such as food preservation.

Printability and Customization: The smooth surface of soft PVC film supports high-quality printing through techniques like flexography or screen printing. This enables vibrant branding, product information, or decorative designs, enhancing market appeal. The film can also be customized in thickness (typically 50–200 microns) and width to suit specific needs.

Regulatory Compliance: Soft PVC films are formulated to meet stringent standards, such as FDA regulations for food contact and USP <661> for pharmaceutical applications. Non-phthalate plasticizers are increasingly used to ensure safety and compliance with global health standards.

Cost-Effectiveness: Soft PVC is relatively inexpensive compared to alternatives like PET or PP, offering a cost-effective solution without sacrificing performance. Its ease of processing via extrusion or calendering further reduces production costs.

Applications of Transparent Soft PVC Flexible FilmThe versatility of transparent soft PVC flexible film makes it a preferred material in medical, food, and industrial applications. Below, we explore these uses in detail, highlighting how the film’s properties address specific industry needs.1. Medical PackagingIn the medical and pharmaceutical sectors, transparent soft PVC flexible film is widely used for packaging devices, IV bags, and drug delivery systems, where clarity, safety, and flexibility are critical.Clarity for Inspection: The high transparency of soft PVC film allows healthcare professionals to visually inspect contents, such as IV fluids or medical tubing, for clarity or contamination. For example, a saline IV bag made from soft PVC film ensures that any particulates or discoloration are easily detectable, enhancing patient safety.

Flexibility for Conformability: The film’s pliability enables it to form flexible, leak-proof containers like IV bags or blister packs for liquid medications. Its elasticity ensures that these containers can withstand squeezing or pressure without rupturing. A typical IV bag, with a thickness of 150–200 microns, relies on soft PVC’s flexibility to deliver fluids effectively.

Sterility and Safety: Soft PVC films are compatible with sterilization methods like ethylene oxide (EtO) or gamma radiation, ensuring sterility for medical applications. Non-phthalate plasticizers, such as citrate-based alternatives, comply with regulations like REACH and FDA, making the film safe for direct contact with medical solutions.

Cost-Effective Production: The affordability of soft PVC enables mass production of medical packaging, such as blood bags or dialysis kits, without compromising quality. This is critical in healthcare, where cost pressures are significant. Industry data indicates that soft PVC accounts for approximately 40% of flexible medical packaging materials due to its balance of cost and performance.

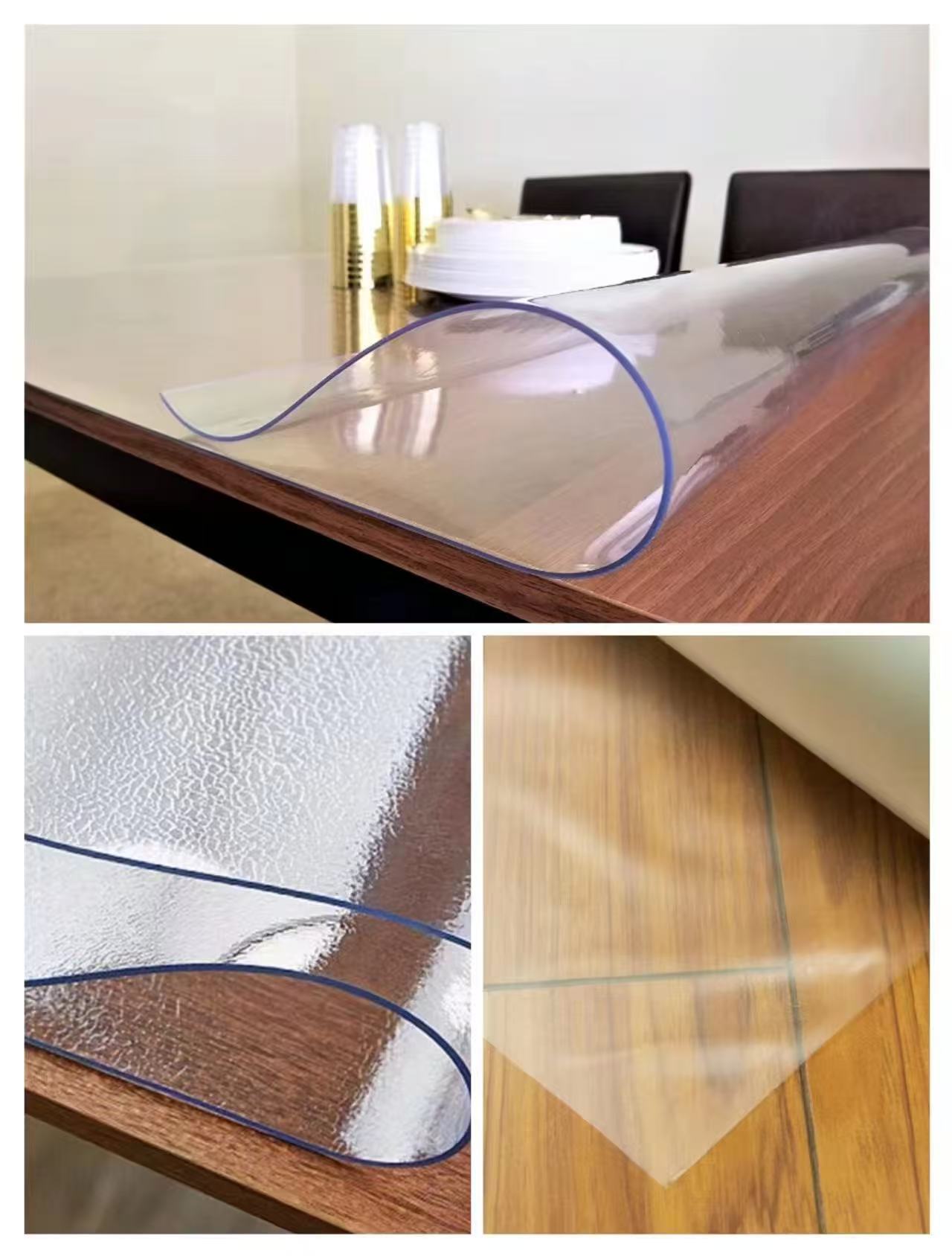

2. Food PackagingTransparent soft PVC flexible film is a staple in food packaging, used for wrapping fresh produce, meats, and ready-to-eat products, where clarity, hygiene, and shelf-life extension are paramount.Visual Appeal: The film’s clarity enhances the presentation of food products, allowing consumers to see the freshness and quality of items like fruits, vegetables, or deli meats. For instance, a tray of strawberries wrapped in soft PVC film showcases the vibrant red color, boosting consumer appeal in retail settings.

Cling Properties: Soft PVC’s inherent clinginess, enhanced by plasticizers, ensures a tight seal around food products, preventing air exposure and reducing spoilage. This is particularly valuable for cling wrap applications, where the film conforms to irregular shapes like cheese blocks or meat cuts.

Barrier Performance: While soft PVC offers moderate barrier properties, additives like vinyl acetate copolymers can improve oxygen and moisture resistance, extending shelf life. For example, a soft PVC wrap for fresh herbs maintains moisture levels, keeping the product fresh for up to 10–14 days longer than unpackaged herbs.

Regulatory Compliance: Soft PVC films for food contact are formulated to meet FDA and EU regulations, ensuring they are free from harmful substances. This is critical for applications like meat packaging, where direct contact with fatty tissues requires chemical stability.

3. Industrial ApplicationsIn industrial settings, transparent soft PVC flexible film is used for protective covers, insulation, and packaging, leveraging its durability, flexibility, and clarity.Protective Covers: Soft PVC film is used to create transparent protective covers for machinery, equipment, or electronic components. Its clarity allows for easy inspection, while its flexibility ensures a snug fit. For example, a soft PVC cover for a control panel protects against dust and moisture while allowing operators to view displays clearly.

Future OutlookThe future of transparent soft PVC flexible film is promising, driven by innovations in sustainability and performance. Bio-based plasticizers and recyclable PVC formulations are addressing environmental concerns, while advancements in barrier coatings are enhancing the film’s protective capabilities. Smart packaging solutions, such as films with embedded sensors for freshness monitoring, could further expand its applications. Additionally, improvements in printing technologies will enable even more vibrant and durable designs, strengthening the film’s role in branding and consumer engagement.ConclusionTransparent soft PVC flexible film is a dynamic and versatile material that meets the diverse needs of medical, food, and industrial applications. Its high transparency, flexibility, and durability, combined with cost-effectiveness and regulatory compliance, make it an ideal choice for packaging and protective solutions. From ensuring the safety of IV fluids to enhancing the appeal of fresh produce and protecting industrial components, soft PVC film delivers unmatched performance. As innovations in sustainability and technology continue to evolve, this remarkable material will remain a vital component of modern packaging, balancing functionality, aesthetics, and environmental responsibility in an ever-changing market.