PET DTF Transfer Film: Characteristics and Applications in Clothing Design

2025-04-16 15:54In the ever-evolving world of apparel design, where creativity and functionality intertwine, printing technologies play a pivotal role in bringing artistic visions to life. Among these, Direct-to-Film (DTF) printing, utilizing Polyethylene Terephthalate (PET) DTF transfer film, has emerged as a game-changer. This innovative medium allows designers to produce vibrant, durable, and intricate patterns on a wide range of fabrics, revolutionizing the custom clothing industry. This article delves into the characteristics of PET DTF transfer film and explores its transformative applications in clothing design, offering insights into why it has become a preferred choice for designers and manufacturers alike.

Characteristics of PET DTF Transfer Film

PET DTF transfer film is a specialized medium designed for DTF printing, distinguished by its unique properties that ensure high-quality transfers. Below are the key characteristics that make PET DTF film stand out:

1. Specialized Coating for Ink Absorption

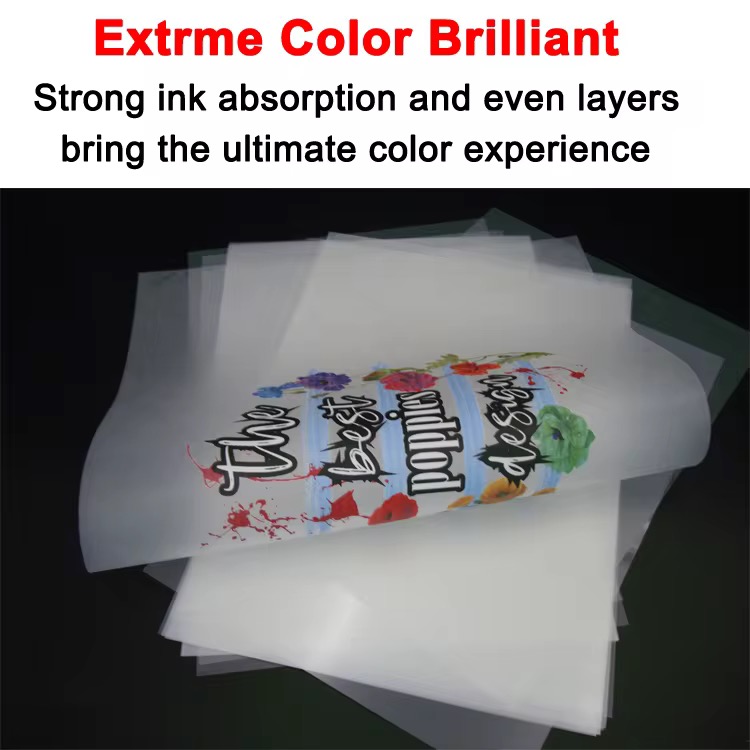

Unlike standard PET films, PET DTF transfer film features a matte, frosted surface with a specialized ink-absorbing coating. This coating ensures that DTF inks—typically water-based CMYK and white pigment inks—adhere effectively without bleeding or smudging. The coating’s high ink-load capacity allows for sharp, detailed prints, even with fine lines or complex designs. A stable release layer within the coating facilitates easy peeling after heat pressing, ensuring clean edges and vibrant colors.

2. Hot and Cold Peel Variants

PET DTF transfer film is available in hot-peel and cold-peel variants, catering to different production needs. Hot-peel films are peeled immediately after heat pressing, ideal for high-volume production on common fabrics like cotton T-shirts. Cold-peel films, peeled after cooling, are better suited for intricate designs or specialty materials like canvas or coated fabrics, offering greater precision and durability. This flexibility enhances the film’s adaptability across various workflows.

3. High-Temperature Resistance

The PET substrate in DTF transfer film is engineered to withstand the high temperatures (typically 140–160°C) and pressures of heat pressing without curling or melting. This durability ensures consistent transfer quality, even during prolonged exposure to heat, making it reliable for industrial applications.

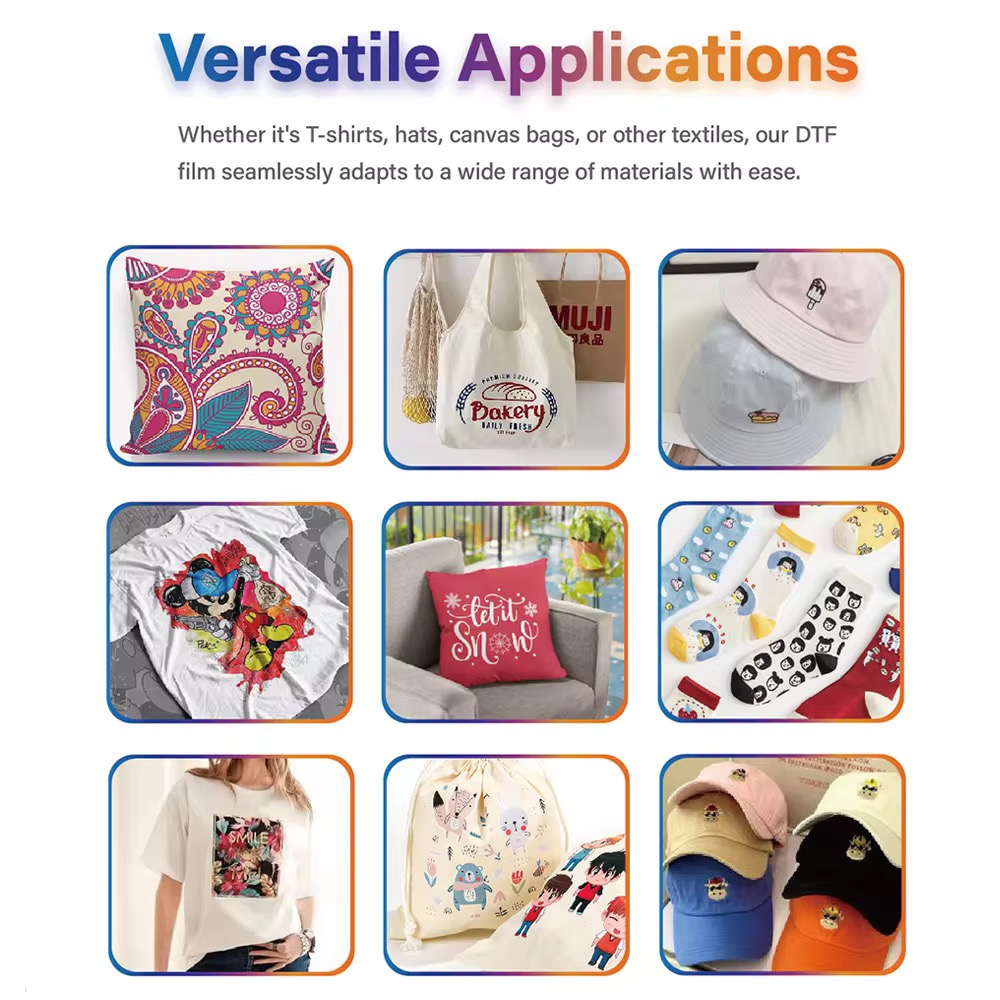

4. Versatility Across Fabrics

One of the standout features of PET DTF transfer film is its compatibility with a wide range of fabrics, including cotton, polyester, nylon, denim, spandex, and blends. Unlike sublimation, which is limited to polyester, or Direct-to-Garment (DTG) printing, which performs best on cotton, DTF printing with PET film excels on both light and dark fabrics, as well as synthetic and natural fibers. This versatility opens up endless possibilities for clothing designers.

5. Special Effect Options

PET DTF transfer film is available in various specialty variants, such as glitter, metallic, luminous, and holographic films, which add unique visual effects to designs. For instance, luminous DTF film absorbs light and glows in the dark, while metallic films create a shimmering, high-end finish. These options allow designers to push creative boundaries, offering apparel that stands out in both aesthetic and functional contexts.

6. Durability and Washability

The combination of PET DTF transfer film, DTF inks, and hot-melt adhesive powder results in prints that are highly durable. The adhesive powder bonds the design securely to the fabric, resisting cracking, peeling, or fading even after multiple washes. Reflective and metallic DTF films, in particular, maintain their shine and visual impact over time, ensuring long-lasting quality.

7. Eco-Friendly Attributes

PET DTF transfer film uses water-based inks, which are more environmentally friendly than solvent-based alternatives. Additionally, the process generates minimal waste, as excess adhesive powder can be shaken off and reused. However, the non-biodegradable nature of PET films prompts designers to consider sustainable practices, such as choosing recyclable films or optimizing production to reduce material waste.

Applications of PET DTF Transfer Film in Clothing Design

The unique characteristics of PET DTF transfer film make it an ideal tool for creating stunning clothing designs. Its applications span casual wear, sportswear, fashion apparel, and even specialty garments, offering designers unparalleled flexibility. Below are some key ways PET DTF film is used in clothing design:

1. Vibrant, Full-Color Prints for Casual Apparel

PET DTF transfer film excels at producing photographic-quality prints with vibrant colors and intricate details, making it perfect for T-shirts, hoodies, and tank tops. The ability to print white ink as a backing layer ensures that colors pop on dark fabrics, eliminating the need for pretreatment required in DTG printing. For example, a streetwear brand can use PET DTF film to print bold, multicolored graphics on black cotton T-shirts, achieving a professional finish without the high setup costs of screen printing.

2. Specialty Effects for Fashion-Forward Designs

The availability of specialty PET DTF films, such as glitter, gold/silver foil, and luminous variants, allows designers to create eye-catching apparel for fashion-conscious consumers. For instance, a designer might use gold DTF film to add a luxurious, metallic sheen to a dress, or luminous film to create glow-in-the-dark patterns on children’s clothing. These effects are particularly popular in festival wear, athleisure, and kids’ fashion, where unique aesthetics drive demand.

3. Personalized and Small-Batch Production

PET DTF transfer film is cost-effective for small to medium print runs, as it eliminates the need for expensive screen setups. This makes it ideal for personalized clothing, such as custom team uniforms, event merchandise, or individualized gifts. Designers can upload digital designs in formats like PNG, PDF, or PSD, print them onto PET DTF film, and transfer them to garments in minutes. This agility supports the growing trend of print-on-demand fashion, where consumers seek unique, made-to-order apparel.

4. Functional Prints for Sportswear and Workwear

Reflective and high-gloss PET DTF films are widely used in sportswear and workwear for their functional properties. Reflective films enhance visibility for night runners or cyclists, while luminous films add safety features to outdoor gear. For example, a sportswear brand might use reflective DTF film to print logos on running jackets, ensuring athletes are visible in low-light conditions. The durability and washability of these prints ensure they withstand rigorous use and frequent washing.

5. Complex Designs on Challenging Fabrics

PET DTF transfer film’s ability to adhere to synthetic fabrics like polyester, nylon, and spandex makes it a go-to choice for technical apparel, such as swimwear, yoga pants, and outerwear. The film’s matte finish and flexible inks ensure a soft, breathable feel, even on stretchy fabrics. For instance, a designer creating yoga leggings can use PET DTF film to print intricate mandala patterns that stretch with the fabric without cracking, enhancing both aesthetics and comfort.

6. Eco-Conscious Design Options

As sustainability becomes a priority in fashion, PET DTF transfer film supports eco-conscious design by enabling precise, waste-minimizing prints. Designers can create gang sheets—multiple designs printed on a single sheet of PET DTF film—to optimize material usage. Additionally, the use of water-based inks aligns with environmentally friendly practices, appealing to brands aiming to reduce their ecological footprint.

Practical Considerations for Using PET DTF Transfer Film

To maximize the potential of PET DTF transfer film in clothing design, designers and manufacturers must consider several practical aspects:

1. Choosing the Right Film

Selecting the appropriate PET DTF film depends on the fabric, design complexity, and desired effect. For lightweight cotton T-shirts, a thinner film (around 75 microns) offers a soft, flexible feel. For heavier fabrics like denim, thicker films (around 90 microns) provide durability. Specialty films, such as holographic or luminous, should be chosen based on the design’s aesthetic goals.

2. Optimizing the Printing Process

The DTF printing process involves printing the design onto PET DTF film, applying hot-melt adhesive powder, curing the powder, and heat pressing the film onto the fabric. Proper equipment, such as a DTF printer, heat press, and powder shaker, is essential for consistent results. Designers must ensure the ink-absorbing coating is handled carefully to avoid scratches, and the film should be stored in a cool, dry environment (68–82°F, 40–60% RH) to maintain quality.

3. Heat Press Settings

Correct heat press settings are critical for successful transfers. A temperature of 150–160°C, medium pressure, and a pressing time of 10–15 seconds are typical for most fabrics. For delicate materials, lower temperatures and longer pressing times may be required. Testing on sample fabrics ensures optimal adhesion and prevents scorching.