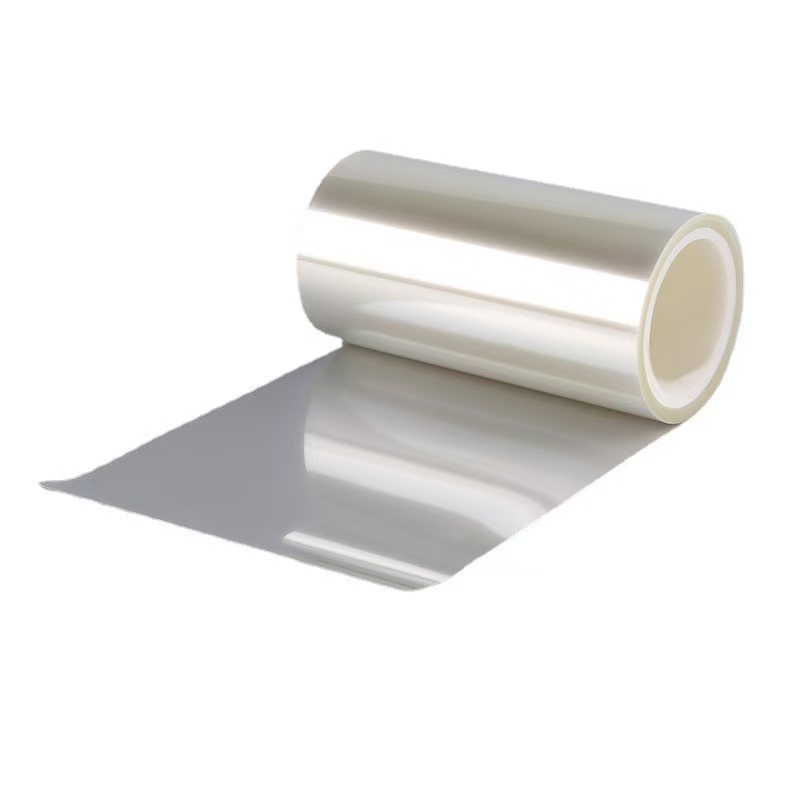

Properties and Versatile Applications of Transparent High-Temperature Resistant PET Film

2025-08-27 17:03Polyethylene Terephthalate (PET) film, particularly transparent high-temperature resistant PET film, has emerged as a cornerstone material in modern industrial and consumer applications due to its exceptional physical, chemical, and thermal properties. Known for its clarity, durability, and versatility, PET film is widely utilized across industries such as food packaging, electronics, medical devices, and industrial manufacturing. When enhanced with specialized features like heat resistance and antistatic properties, PET film becomes an indispensable solution for high-performance applications, including heat-resistant barrier films and antistatic packaging. This article explores the key properties of transparent high-temperature resistant PET film and its diverse applications, providing a detailed and evidence-based analysis of its role in modern technology and packaging solutions.Key Properties of Transparent High-Temperature Resistant PET Film

electronics, medical devices, and industrial manufacturing. When enhanced with specialized features like heat resistance and antistatic properties, PET film becomes an indispensable solution for high-performance applications, including heat-resistant barrier films and antistatic packaging. This article explores the key properties of transparent high-temperature resistant PET film and its diverse applications, providing a detailed and evidence-based analysis of its role in modern technology and packaging solutions.Key Properties of Transparent High-Temperature Resistant PET Film

Transparent high-temperature resistant PET film is a biaxially oriented polyester film derived from polyethylene terephthalate, offering a unique combination of mechanical, thermal, and chemical attributes. Below are its primary properties, which make it a preferred material for demanding applications:High Thermal Stability: PET transparent film exhibits remarkable heat resistance, typically withstanding temperatures from -70°C to 200°C, with some specialized grades enduring up to 250°C for short durations. For instance, HOSTAPHAN® RBB, a temperature-stable PET film, can tolerate 220°C for up to two hours, making it suitable for ovenable applications like roasting or baking. This thermal stability ensures that the film maintains its structural integrity and clarity under extreme conditions, such as in microwave or oven-ready packaging.

Exceptional Transparency and Optical Clarity: With a light transmission rate often exceeding 90%, PET transparent film provides crystal-clear visibility, enhancing product presentation in packaging applications. Its non-yellowing nature and consistent color retention make it ideal for applications requiring aesthetic appeal, such as food packaging or protective overlays for displays.

Mechanical Strength and Dimensional Stability: PET film boasts high tensile strength and impact resistance, surpassing many other thermoplastics. Its density of approximately 1.38–1.4 g/cm³ contributes to its rigidity and durability, making it suitable for both flexible and rigid packaging formats. The film’s dimensional stability ensures it resists stretching or shrinking, even under thermal or mechanical stress, which is critical for precision applications like electrical insulation.

Chemical and Barrier Properties: PET transparent film offers excellent resistance to alcohols, oils, greases, and diluted acids, making it a reliable barrier against environmental contaminants. While it has moderate moisture resistance, its oxygen transmission rate (OTR ≤ 120 cm³/(m²·24h·0.1Mpa)) enhances its ability to protect contents from oxidation, extending shelf life in food and pharmaceutical packaging. Specialized coatings, such as silica thin films, can further reduce water vapor transmission rates to as low as 0.02 g/m²·day, making it a high-performance barrier film.

Antistatic and Conductive Properties: In applications requiring protection from electrostatic discharge (ESD), PET film can be treated with antistatic coatings or conductive additives. These modifications prevent static buildup, which is critical for safeguarding sensitive electronic components like circuit boards and semiconductors. For example, antistatic PET packaging film is widely used in the electronics industry to reduce losses due to static-related damage.

Recyclability and Sustainability: PET film is highly recyclable, with recycled PET (R-PET) being used to produce sustainable packaging solutions. Its recyclability aligns with global sustainability goals, reducing environmental impact while maintaining performance. Amorphous PET (A-PET) and crystallized PET (C-PET) variants cater to different needs, with A-PET offering clarity for food containers and C-PET providing heat resistance for oven-safe trays.

Applications of Transparent High-Temperature Resistant PET FilmThe unique combination of properties in PET transparent film enables its use in a wide range of applications. Below, we explore its role in flexible packaging, heat-resistant barrier films, antistatic packaging, and other specialized uses.1. Flexible Packaging: Enhancing Product Protection and AppealPET transparent film is a staple in flexible packaging due to its clarity, strength, and barrier properties. It serves multiple roles within laminated structures:Outer Layer for Printing: As the outermost layer in packaging, PET film provides a smooth, high-clarity surface for vibrant, high-quality graphics. Its heat resistance (up to 250°C in some cases) ensures it withstands printing processes without deformation, making it ideal for food pouches, pharmaceutical packaging, and cosmetic products. For example, PET film is used in snack packaging to display contents clearly while protecting them from moisture and oxygen.

Middle Layer for Structural Integrity: In multilayer laminates, PET film enhances the structural strength and barrier properties of the package. Its low oxygen and moisture permeability keeps contents fresh, making it suitable for perishable goods like dairy products, meats, and ready-to-eat meals. Structures like PET/High-Density PET or Coated Paper/HSPET are commonly used for high-performance packaging.

Heat-Resistant Packaging: PET film’s ability to withstand high temperatures makes it ideal for microwaveable or oven-ready packaging. Unlike other films like RCPP, which melt at 150°C, PET film can endure temperatures up to 250°C, enabling its use in ready-meal trays and bakery packaging. For instance, Coated Paper/HSPET is used for bread packaging, combining a natural aesthetic with heat resistance.

2. Heat-Resistant Barrier Film: Applications in Harsh EnvironmentsHeat-resistant barrier films made from PET are critical in applications requiring thermal stability and protection from environmental factors. These films are used in:Ovenable Packaging: Transparent PET films like HOSTAPHAN® RBB are designed for ovenable applications, such as roasting bags or baking trays, withstanding temperatures up to 220°C for extended periods. These films are food-safe, free of harmful additives like antimony trioxide, and approved for food contact in the EU and US.