Characteristics and Applications of PET Metallized Film

2025-09-19 15:10 Key Characteristics of PET Metallized Film

Key Characteristics of PET Metallized FilmSuperior Barrier Properties

PET metallized film is renowned for its excellent barrier performance against moisture, oxygen, light, and gases. The metallized layer, typically aluminum, creates a reflective surface that blocks ultraviolet (UV) and infrared (IR) radiation, protecting sensitive products from degradation. For instance, studies indicate that PET metallized film can reduce oxygen transmission rates (OTR) to less than 1 cm³/m²/day and water vapor transmission rates (WVTR) to below 1 g/m²/day, significantly extending the shelf life of perishable goods compared to non-metallized films.Mechanical Strength and Flexibility

The PET substrate provides robust tensile strength and dimensional stability, allowing the film to withstand mechanical stresses during processing, handling, and transportation. Its flexibility enables it to conform to various shapes, making it ideal for blister packaging and complex container designs. The metallized layer does not compromise this flexibility, ensuring the film remains adaptable for diverse applications.

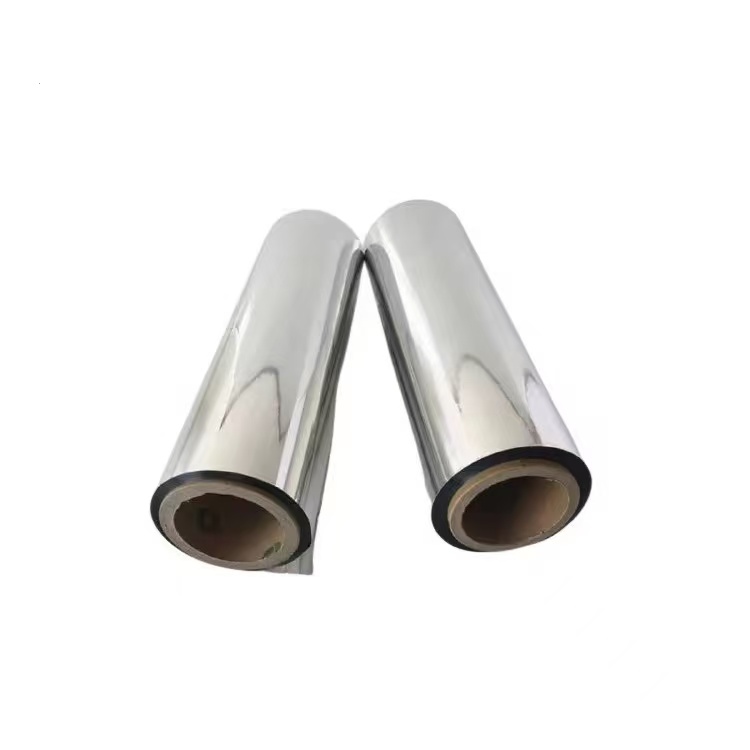

Aesthetic and Reflective Qualities

The shiny, mirror-like surface of PET metallized film enhances product visibility and brand appeal. Its reflective properties not only contribute to an upscale appearance but also provide functional benefits, such as heat reflection, which is critical in temperature-sensitive applications. This aesthetic versatility makes it a preferred choice for premium packaging.Antistatic and Conductive Properties

The metallized layer imparts antistatic properties, making PET metallized film suitable for packaging electronic components. By dissipating static charges, it prevents damage to sensitive devices caused by electrostatic discharge (ESD). This property is particularly valuable in industries requiring high precision and reliability, such as electronics manufacturing.

Thermal Stability and Recyclability

PET metallized film exhibits excellent thermal stability, withstanding temperatures typically ranging from -40°C to 120°C without compromising its integrity. While the metallized layer can complicate recycling, advancements in delamination technologies have improved the recyclability of PET-based films, aligning with growing sustainability demands.

2. Disposable Tableware PackagingIn the realm of disposable tableware, PET metallized film serves as a high-performance material for packaging items like cutlery, plates, and cups. Its durability ensures that the packaging remains intact during transportation and storage, while its barrier properties protect against contamination. For instance, in airline catering, PET metallized film is used to create sealed trays for in-flight meals, ensuring hygiene and freshness. The film’s lightweight nature reduces transportation costs, and its reflective surface minimizes heat absorption, keeping food at optimal temperatures. Moreover, the film can be printed with vibrant designs, enhancing brand identity for disposable tableware manufacturers. A notable case is the use of PET metallized film in eco-friendly compostable tableware packaging, where it provides a balance of functionality and aesthetic appeal while supporting sustainability goals.

2. Disposable Tableware PackagingIn the realm of disposable tableware, PET metallized film serves as a high-performance material for packaging items like cutlery, plates, and cups. Its durability ensures that the packaging remains intact during transportation and storage, while its barrier properties protect against contamination. For instance, in airline catering, PET metallized film is used to create sealed trays for in-flight meals, ensuring hygiene and freshness. The film’s lightweight nature reduces transportation costs, and its reflective surface minimizes heat absorption, keeping food at optimal temperatures. Moreover, the film can be printed with vibrant designs, enhancing brand identity for disposable tableware manufacturers. A notable case is the use of PET metallized film in eco-friendly compostable tableware packaging, where it provides a balance of functionality and aesthetic appeal while supporting sustainability goals. 3. Antistatic Packaging for ElectronicsThe electronics industry relies heavily on PET metallized film for antistatic packaging, particularly for sensitive components like integrated circuits, microchips, and circuit boards. The film’s conductive metallized layer dissipates static electricity, preventing damage from ESD, which can cost manufacturers millions annually. For example, PET metallized film is used in flexible pouches and trays for semiconductor packaging, ensuring safe storage and transportation. Its mechanical strength protects delicate components from physical damage, while its barrier properties shield against moisture and dust. A real-world application is seen in the packaging of smartphone components, where PET metallized film ensures reliability during global shipping. The film’s ability to be customized with specific antistatic coatings further enhances its suitability for high-tech applications.4. Other Emerging ApplicationsBeyond these primary uses, PET metallized film is finding applications in industries like pharmaceuticals, agriculture, and renewable energy. In pharmaceuticals, it is used for blister packaging of tablets and capsules, offering tamper-evident seals and UV protection. In agriculture, it serves as a reflective mulch film to enhance crop growth by optimizing light exposure. In solar energy, PET metallized film is incorporated into photovoltaic modules to improve efficiency through its reflective properties. These diverse applications highlight the material’s adaptability and growing relevance in innovative sectors.

3. Antistatic Packaging for ElectronicsThe electronics industry relies heavily on PET metallized film for antistatic packaging, particularly for sensitive components like integrated circuits, microchips, and circuit boards. The film’s conductive metallized layer dissipates static electricity, preventing damage from ESD, which can cost manufacturers millions annually. For example, PET metallized film is used in flexible pouches and trays for semiconductor packaging, ensuring safe storage and transportation. Its mechanical strength protects delicate components from physical damage, while its barrier properties shield against moisture and dust. A real-world application is seen in the packaging of smartphone components, where PET metallized film ensures reliability during global shipping. The film’s ability to be customized with specific antistatic coatings further enhances its suitability for high-tech applications.4. Other Emerging ApplicationsBeyond these primary uses, PET metallized film is finding applications in industries like pharmaceuticals, agriculture, and renewable energy. In pharmaceuticals, it is used for blister packaging of tablets and capsules, offering tamper-evident seals and UV protection. In agriculture, it serves as a reflective mulch film to enhance crop growth by optimizing light exposure. In solar energy, PET metallized film is incorporated into photovoltaic modules to improve efficiency through its reflective properties. These diverse applications highlight the material’s adaptability and growing relevance in innovative sectors. Technical Insights and Performance MetricsTo quantify the performance of PET metallized film, consider its key metrics:

Technical Insights and Performance MetricsTo quantify the performance of PET metallized film, consider its key metrics:Oxygen Transmission Rate (OTR): Typically <1 cm³/m²/day, compared to 50–100 cm³/m²/day for standard PET films.

Water Vapor Transmission Rate (WVTR): Often <1 g/m²/day, versus 10–20 g/m²/day for non-metallized PET.

Surface Resistivity: Antistatic grades achieve resistivity of 10⁶–10⁹ ohms/sq, suitable for ESD protection.

Tensile Strength: Approximately 200–250 MPa, ensuring durability in high-stress applications. These metrics underscore why PET metallized film outperforms alternatives like standard PET or polypropylene films in demanding environments.

ConclusionPET metallized film is a powerhouse material that blends functionality, aesthetics, and versatility. Its superior barrier properties, mechanical strength, and antistatic capabilities make it indispensable in food blister packaging, disposable tableware, and antistatic electronics packaging. As industries prioritize sustainability and innovation, PET metallized film is poised to evolve, with new formulations and recycling technologies enhancing its appeal. Whether protecting delicate electronics or preserving the freshness of gourmet foods, this material continues to shape the future of packaging with its remarkable performance and adaptability.

ConclusionPET metallized film is a powerhouse material that blends functionality, aesthetics, and versatility. Its superior barrier properties, mechanical strength, and antistatic capabilities make it indispensable in food blister packaging, disposable tableware, and antistatic electronics packaging. As industries prioritize sustainability and innovation, PET metallized film is poised to evolve, with new formulations and recycling technologies enhancing its appeal. Whether protecting delicate electronics or preserving the freshness of gourmet foods, this material continues to shape the future of packaging with its remarkable performance and adaptability.