Characteristics and Applications of PP Trays in Diverse Industries

2025-08-15 17:24Polypropylene (PP) trays, crafted from a robust thermoplastic polymer, have emerged as a cornerstone in modern packaging and storage solutions across various industries. Known for their durability, versatility, and cost-effectiveness, PP trays are revolutionizing how businesses handle, transport, and present products. This article delves into the defining characteristics of PP trays and explores their extensive applications, supported by practical examples and industry insights, to highlight why they are a preferred choice for countless applications.Characteristics of PP TraysPP trays are made from polypropylene, a semi-crystalline thermoplastic polymer with the chemical formula (C3H6)n, known for its exceptional mechanical and chemical properties. Below are the key characteristics that make PP trays stand out:Durability and Strength: PP trays are engineered to withstand significant mechanical stress without cracking or deforming. Their high impact resistance ensures they can endure rough handling during transportation or storage. For instance, in the food industry, PP trays protect delicate items like fresh produce or baked goods, ensuring they reach consumers in pristine condition. Their robust nature allows them to support heavy loads, making them suitable for industrial applications like automotive parts storage.

applications.Characteristics of PP TraysPP trays are made from polypropylene, a semi-crystalline thermoplastic polymer with the chemical formula (C3H6)n, known for its exceptional mechanical and chemical properties. Below are the key characteristics that make PP trays stand out:Durability and Strength: PP trays are engineered to withstand significant mechanical stress without cracking or deforming. Their high impact resistance ensures they can endure rough handling during transportation or storage. For instance, in the food industry, PP trays protect delicate items like fresh produce or baked goods, ensuring they reach consumers in pristine condition. Their robust nature allows them to support heavy loads, making them suitable for industrial applications like automotive parts storage.

Lightweight Design: Despite their strength, PP trays are remarkably lightweight, with a density ranging from 0.895 to 0.92 g/cm³, making them one of the lightest commercial plastics. This feature reduces transportation costs and enhances ease of handling, which is particularly beneficial for high-volume logistics operations. For example, e-commerce businesses use lightweight PP trays to minimize shipping expenses while ensuring product safety.

Chemical and Moisture Resistance: PP trays exhibit excellent resistance to water, oils, acids, alkalis, and other chemicals, making them ideal for environments where exposure to corrosive substances is common. This property is crucial in the pharmaceutical industry, where PP trays are used to store and transport sterile medical supplies without degradation. Similarly, in the food sector, their moisture resistance prevents spoilage of perishable items like meat and seafood.

Heat Resistance: With a melting point typically between 160°C and 167°C, PP trays can withstand high temperatures, making them suitable for microwave-safe food containers and sterilization processes. This characteristic allows PP trays to transition seamlessly from refrigeration to heating, as seen in ready-to-eat meal packaging that consumers can heat directly in the tray.

Recyclability and Sustainability: PP trays are 100% recyclable, marked with recycling code #5, which supports sustainable packaging initiatives. Their long lifespan and reusability reduce the need for frequent replacements, and their lightweight nature contributes to lower carbon emissions during transport. Innovations in bio-based polypropylene, derived from renewable feedstocks, are further enhancing their environmental credentials.

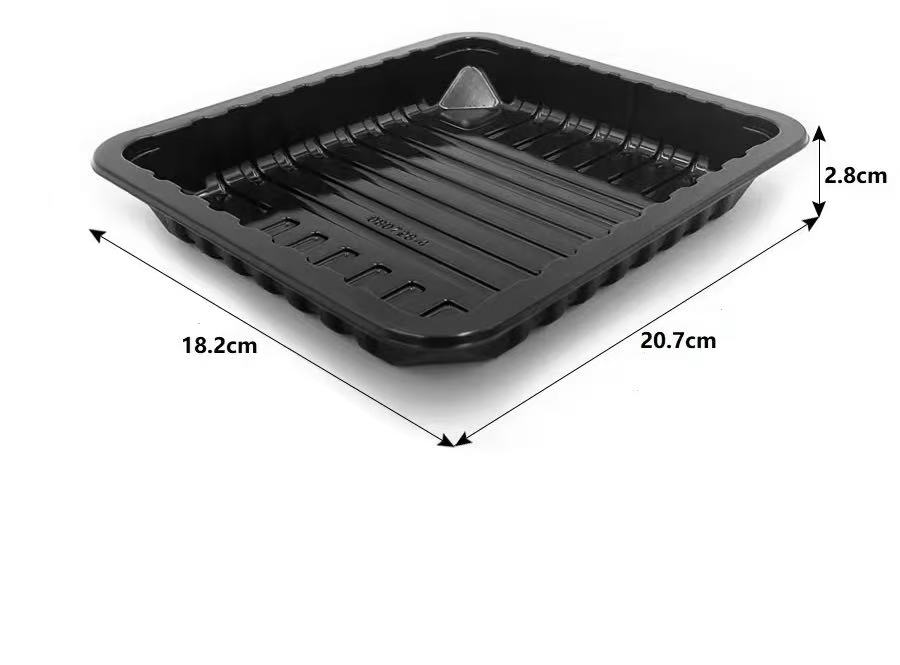

Customizability: PP trays can be molded into various shapes, sizes, and colors to meet specific industry needs. Manufacturers can incorporate features like compartments, stackable designs, or even smart technologies such as QR codes for supply chain tracking. This flexibility makes PP trays adaptable for both functional and aesthetic purposes, such as retail display trays that enhance product visibility.

Cost-Effectiveness: PP trays offer an excellent balance of performance and affordability. Their durability reduces replacement costs, and their lightweight design lowers shipping expenses. Businesses benefit from economies of scale, as PP trays can be produced in large quantities at a relatively low cost, making them an economical choice for industries ranging from food to electronics.

Applications of PP Trays Across IndustriesThe versatility of PP trays stems from their ability to meet diverse industry requirements, from food safety to industrial durability. Below are some key applications, supported by real-world examples.Food and Beverage IndustryPP trays are a staple in food packaging due to their safety, heat resistance, and ability to preserve freshness. They are widely used for:Fresh Produce Packaging: PP trays protect fruits and vegetables during transit, maintaining freshness by preventing moisture ingress. For example, supermarkets use transparent PP trays to showcase vibrant produce like berries or tomatoes, enhancing visual appeal while ensuring durability.

Meat and Seafood Storage: The moisture and chemical resistance of PP trays make them ideal for storing perishable items. Clamshell PP trays are commonly used for packaging fresh fish, preventing leaks and maintaining hygiene during transport.

Ready-to-Eat Meals: PP trays are popular for microwaveable meals, as their high heat resistance allows consumers to reheat food directly in the tray. Fast-food chains often use PP trays for takeout meals, combining convenience with durability.

Beverage Cups and Lids: PP trays are molded into cups and lids for beverages like coffee or yogurt drinks. Their non-toxic nature ensures food safety, making them a preferred choice for single-use and reusable containers.

Pharmaceutical IndustryIn the pharmaceutical sector, PP trays are valued for their sterility and chemical resistance. Key applications include:Medication Packaging: PP trays provide a secure, sterile environment for tablets, capsules, and syringes. Their ability to withstand sterilization processes, such as steam or autoclaving, ensures compliance with stringent medical standards.

Medical Equipment Storage: Hospitals use PP trays to organize and transport surgical tools, leveraging their durability and resistance to cleaning agents. For instance, PP trays are used in mammography or dental applications to hold delicate instruments securely.

E-Commerce and RetailPP trays play a crucial role in protecting products during shipping and enhancing retail displays:Product Protection: In e-commerce, PP trays cushion fragile items like electronics or cosmetics, reducing damage and return rates. Their lightweight design lowers shipping costs, benefiting businesses with high-volume logistics.

Display Packaging: Retail stores use PP trays to create visually appealing product displays. For example, cosmetic brands use custom PP trays to showcase lipsticks or skincare products, combining functionality with aesthetic appeal.

Industrial and Automotive SectorsPP trays are used for organizing and transporting components in industrial settings:Component Storage: In manufacturing, PP trays organize small parts like screws or electronic components, improving inventory management. Their durability ensures they withstand repeated use in harsh industrial environments.

Automotive Parts: PP trays are used to transport delicate automotive components, such as sensors or connectors, protecting them from damage during shipping. Their chemical resistance is particularly valuable in environments exposed to oils or solvents.

Household and Consumer GoodsPP trays are found in everyday household products due to their durability and versatility:Storage Solutions: PP trays are used in households for organizing items like utensils, craft supplies, or toiletries. Their stackable designs maximize space efficiency in homes and offices.

Disposable Tableware: PP trays are increasingly used in disposable tableware for events or catering, offering a balance of affordability and functionality. For example, PP trays are used for serving snacks at parties, combining convenience with easy cleanup.

Environmental and Economic BenefitsPP trays contribute significantly to sustainability and cost savings, making them a smart choice for businesses and consumers alike.Reducing Waste: By extending the shelf life of perishable goods, PP trays help minimize food waste, a major environmental concern. Their recyclability further supports a circular economy, as used trays can be reprocessed into new products. For instance, initiatives like the Polypropylene Recycling Coalition have improved PP recovery rates, with over 65% of U.S. households now having access to PP recycling programs.

Economic Advantages: The long lifespan of PP trays reduces replacement costs, and their lightweight nature lowers fuel consumption during transport. Businesses benefit from reduced product damage, as PP trays ensure goods arrive in perfect condition, minimizing returns and enhancing customer satisfaction.

Conclusion

PP trays are a versatile, durable, and sustainable solution that meets the diverse needs of industries ranging from food and pharmaceuticals to e-commerce and manufacturing. Their lightweight design, chemical resistance, and recyclability make them an ideal choice for businesses seeking cost-effective and eco-friendly packaging. As innovations continue to enhance their performance and sustainability, PP trays are poised to play an even greater role in shaping the future of packaging. Businesses looking to optimize their operations should explore PP tray solutions, leveraging their unique properties to enhance product protection, reduce costs, and support a greener future.Word count: ~2000 words