The Versatile World of PVC Film: Properties and Applications in Card Manufacturing

2025-03-28 17:15Polyvinyl chloride (PVC) film is a cornerstone material in the modern card industry, providing an unbeatable mix of strength, flexibility, and versatility. Gift cards, hotel keycards, membership cards, scratch-off tickets - PVC film is the preferred material for producing a wide variety of cards that are both functional and visually appealing. This article delves into the properties of PVC film and explores its specific applications in card-making, with a focus on products like loyalty cards, RFID cards, transport cards, and more. By examining its characteristics and real-world uses, we’ll uncover why PVC film is indispensable in this industry.

and versatility. Gift cards, hotel keycards, membership cards, scratch-off tickets - PVC film is the preferred material for producing a wide variety of cards that are both functional and visually appealing. This article delves into the properties of PVC film and explores its specific applications in card-making, with a focus on products like loyalty cards, RFID cards, transport cards, and more. By examining its characteristics and real-world uses, we’ll uncover why PVC film is indispensable in this industry.

Properties of PVC Film: A Foundation for Excellence PVC film is a flexible thermoplastic polymer. Its most significant properties are those that make it such an ideal material for card production: Durability: PVC film is very resistant to wear, which means that cards made from it have the ability to withstand heavy use, water exposure, and even bending without losing their shape. This durability makes it particularly valuable for items like hotel key cards or membership cards that are used on a daily basis.

Flexibility: While rigid enough to maintain shape, PVC film is sufficiently flexible to prevent cracking under pressure. This compromise is essential for cards that need to slide into wallets comfortably or endure several swipes.

Printability: One of the standouts of PVC film is its offset-print friendliness. It features a smooth surface that accepts ink readily, allowing vibrant, high-definition graphics that make gift cards, discount cards, or certificates more appealing. Opacity and Thickness Variants: PVC film comes in various thicknesses and opacities, as needed. For instance, a thickerand more opaque film can be utilized for transport cards to conceal chips inserted inside, whereas a lighter film is suitable for slim business cards.

Lamination Compatibility: PVC film can be paired with laminating layers, which may be adhesive or non-adhesive, for that extra layer of protection. This enhances the card's durability and gives a glossy, professional finish suitable for prepaid cards or badges.

Chemical Resistance: PVC film is chemically resistant to damage from oils, grease, and mild chemicals, hence suitable for cards exposed to diverse environments, e.g., door access cards in industrial settings.

These properties collectively make PVC film a material that balances practicality and performance to meet the diverse demands of card manufacturing.

PVC Film in Card Manufacturing: Practical Uses Let us explore how PVC film is applied in the production of various types of cards, drawing on real examples of PVC film types and their respective uses.

1. Gift Cards and Loyalty Cards

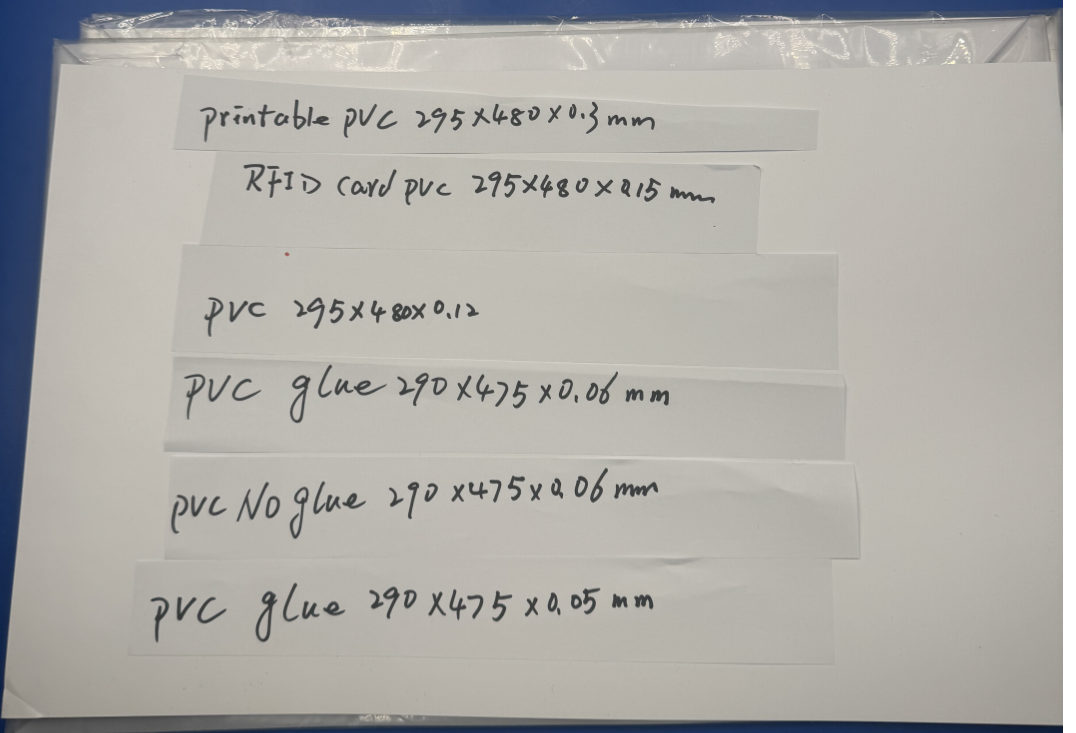

Gift cards and loyalty cards are a ubiquitous element in retail, incentivizing customers and facilitating brand loyalty. A common one for these is PVC film base, white, for offset printing, 295x480x0.3 mm. At a thickness of 0.3 mm, this film is ideally durable without being too bulky. A white face provides a blank canvas to offset printing, with intricate designs possible—a coffee shop loyalty card with a logo in bright colors, or a gift card with party-style graphics, for instance. Their durability ensures these cards survive repeated use, whether swiped at a checkout counter or inserted into a wallet. For example, imagine a bookstore creating a loyalty card with this PVC film. The card's crisp, printed design has a literary theme, while its rugged construction ensures it will endure hundreds of transactions, generating customer loyalty.

2. RFID Cards

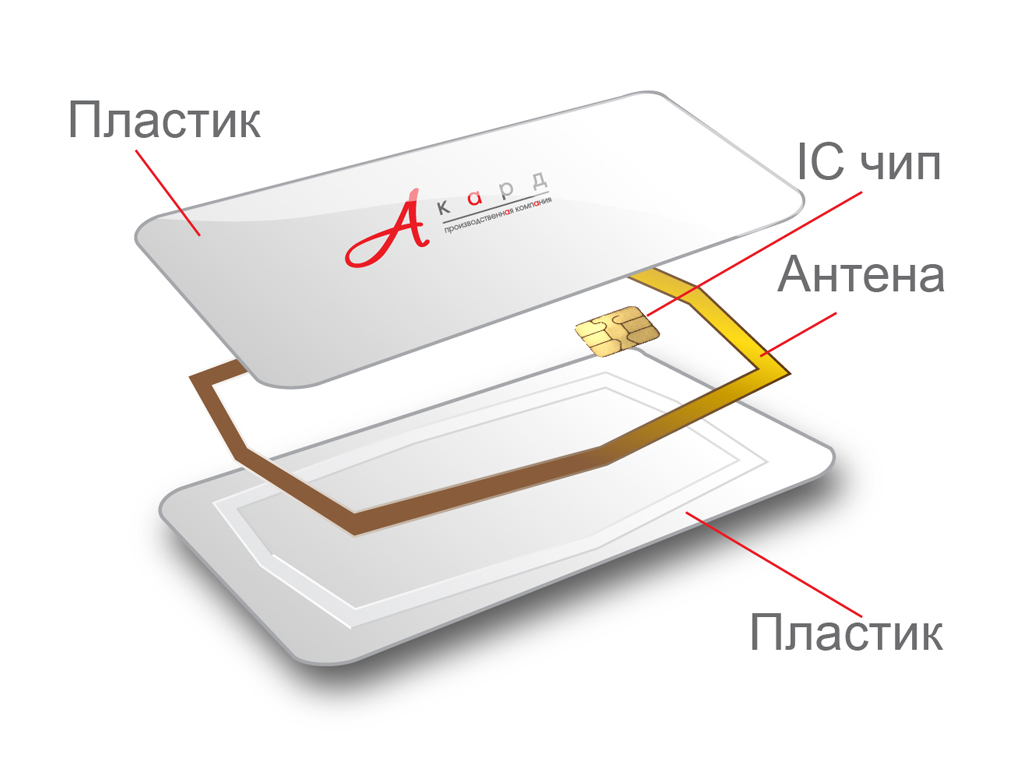

Radio-frequency identification (RFID) cards, used for contactless payment or access control, must be thinner but also robust. PVC film base, white, for offset print, 295x480x0.15 mm is perfect. Thin at 0.15 mm to accommodate an RFID chip without adding size, yet robust enough to protect the technology inside. Hotels often use these for key cards, where guests tap to enter rooms. The printability of the film allows for branding—a hotel logo, for example, or room number—while the flexibility will cause it to bend but not break. Consider a hotel guest swiping their smart RFID key card, produced from this PVC film, to enter their room. The light weight and glossy look of the card improve the guest experience while protecting the chip within.

3. Transport Cards

Public transport systems employ cards that are opaque and durable to protect magnetic stripes or embedded chips. PVC film base, white, offset print with improved opacity, 295x480x0.12 mm is produced for this purpose. Thinner at 0.12 mm than loyalty cards but with more opacity to conceal internal structures, it is ideal for metro cards or bus passes where the most important thing is security and durability. The offset print functionality allows public transportation authorities to add maps, timetables, or branding directly onto the card. Consider a daily commuter in a bustling city swiping their transportation card daily. Made from this PVC film, the card protects against fading from extensive use and safeguards the chip within, making travel hassle-free.

4. Lamination for Extra Durability

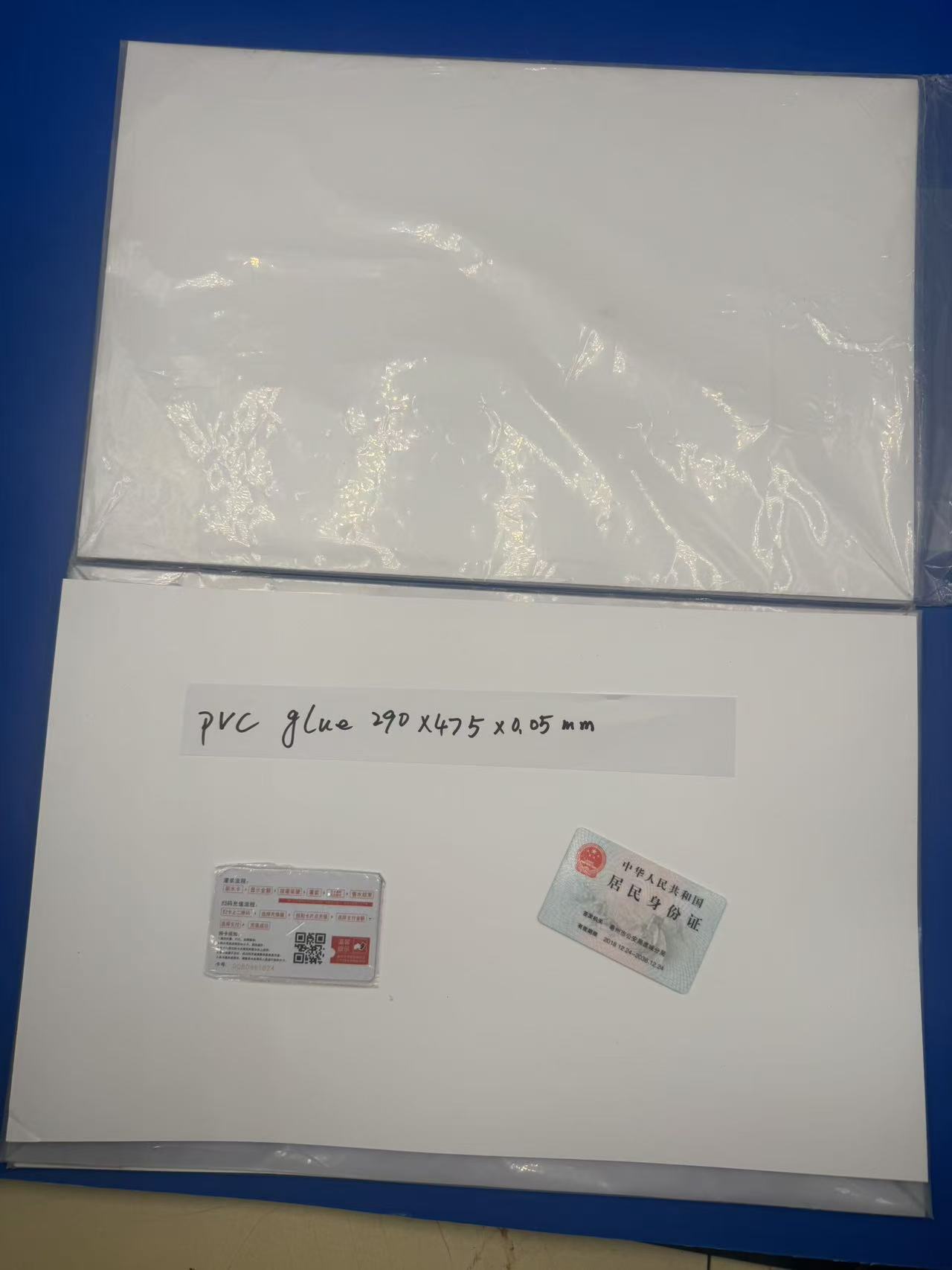

Lamination is a basic function in card production, adding strength and a quality feel. It manufactures three types of PVC laminating film—290x475x0.06 mm (no adhesive), 290x475x0.06 mm (adhesive), and 290x475x0.05 mm (strong adhesive)—to cater to diverse needs. The one without adhesive (0.06 mm) is good for firms that apply their own glue, offering production flexibility. For instance, a company that produces custom-made badges can use such a film, apply adhesive according to their process, make a glossy, durable badge for an employee.

The adhesive version (0.06 mm) is suitable for standard lamination of printed PVC bases, such as discount cards. Imagine a retailer sending out discount cards with a protective laminate that keeps the vibrant design in like-new condition despite frequent handling. While the 0.05 mm film with high adhesive content is the ideal choice for high-wear cards such as door access cards, where the extra bonding strength holds the laminate secure. A security firm can use this for access cards so that they can endure harsh conditions without peeling.

5. Business Cards, Certificates, and Prepaid Cards

The applicability of PVC film extends to business cards, certificates, and prepaid cards as well. A 0.3 mm PVC film business card is distinctively sturdy and shiny, unlike flimsy paper counterparts. A networking event attendee who receives a card such as this from a professional is definitely going to remember that professional, as the card does not fold and its image is not dulled. Certificates, such as employee appreciation certificates, utilize the printability and lamination possibilities of PVC film. A laminated certificate, obtained using the 0.06 mm adhesive film, is given a quality finish and shielded from wear and tear with time. Prepaid cards, such as phone or game credits, use the same specifications so that they last in wallets or pockets until they are redeemed.

6. Scratch-Off Cards and Badges

Scratch-off cards, whether for promotion or lottery use, utilize PVC film's ability to be paired with unique coatings. The 0.3 mm base provides a firm foundation, and lamination (e.g., 0.06 mm non-adhesive film) protects the printed design beneath the scratch layer. A consumer scratching off a prize reveal on a colorfully printed PVC card enjoys not just the excitement but also the high-end feel of the card. Badges, such as security badges or event badges, capitalize on the strength and printability of PVC film. A conference badge made of laminated PVC film withstands days of use, with the logo and attendee's name showing clearly through.

Why PVC Film Stands Out

PVC film's popularity lies in its flexibility. Manufacturers can select a single thickness, opacity, and lamination per card application, from the thin needs of RFID cards to the rugged needs of transport passes. Its low cost, coupled with high performance, has established it as an industry standard. Furthermore, the recyclability of PVC film equals growing sustainability requirements, with some producers now producing eco-friendly variants.

Conclusion

PVC film is more than a product—it is a solution that powers the creation of daily cards. Whether it's a gift card that puts a smile on someone's face, a hotel key card that unlocks rooms, or a scratch-off card that uncovers a prize, PVC film delivers consistency and appearance. Its properties—durability, flexibility, and printability—and tailored possibilities like the ones mentioned ensure it meets the different demands of card manufacturing. As design and technology evolve, PVC film will undoubtedly remain a ongoing undamental element, shaping the cards that connect us to services, rewards, and experiences.