Black PPEVOH Film: A Robust Solution for Food Thermoforming and High-Barrier Packaging

2025-02-26 16:24Introduction

In the ever-evolving landscape of food packaging, black PPEVOH film stands out as a formidable player, merging the resilience of polypropylene (PP) with the exceptional barrier properties of ethylene-vinyl alcohol (EVOH).

This multilayered marvel is engineered to meet the stringent demands of modern food preservation, from the intricate contours of thermoformed trays to the robust protection of meat products and the delicate containment of polymer aromatic liquids. Its unique black pigmentation not only enhances its aesthetic appeal but also serves functional purposes, making it a preferred choice across diverse applications. What drives its success? How does it perform in the real world? This article delves into the defining characteristics of black PPEVOH film and explores its transformative role in food thermoforming, meat trays, and high-barrier packaging, offering a detailed, evidence-backed journey through its capabilities and impact.

Characteristics of Black PPEVOH Film

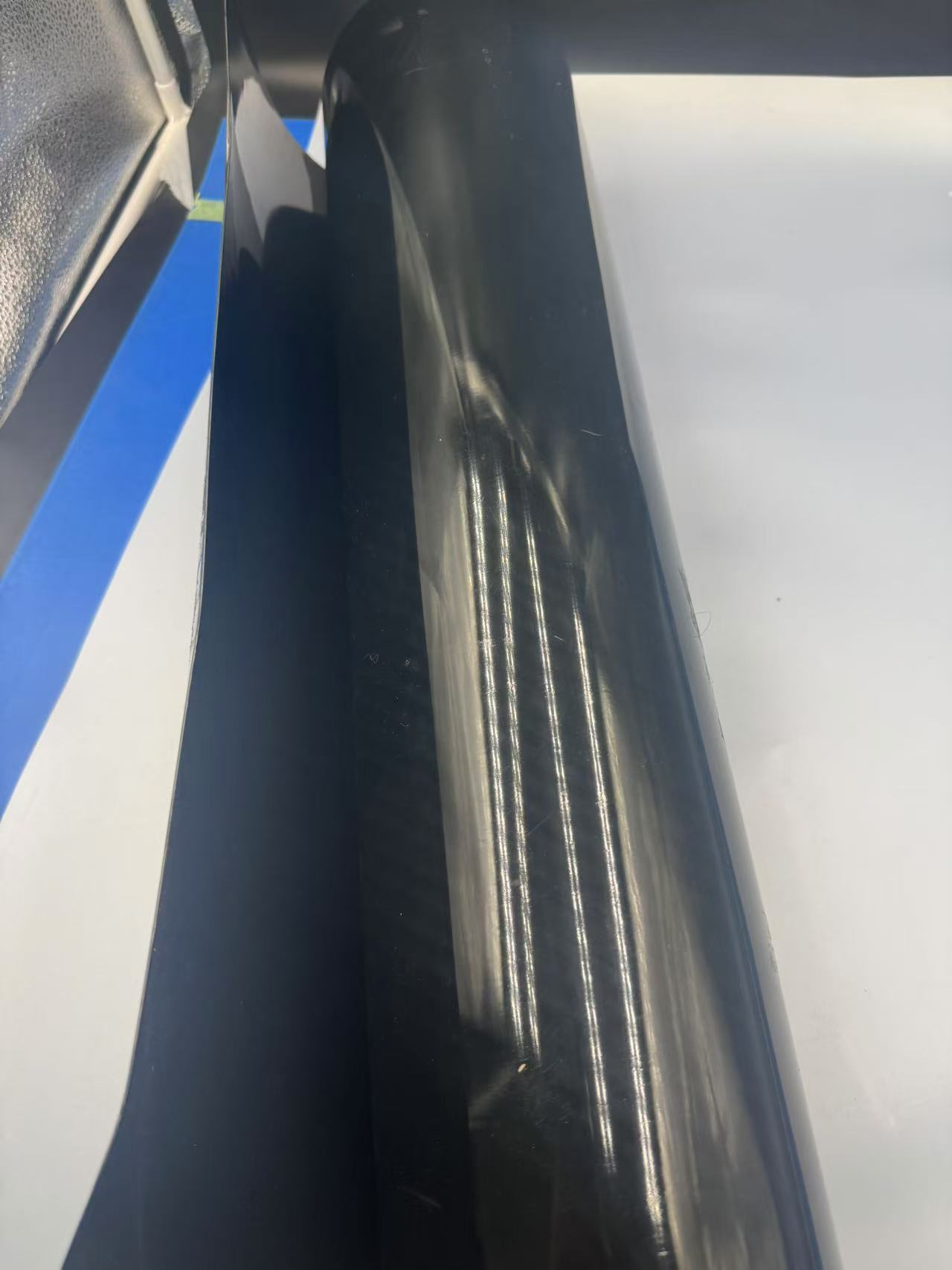

1. Superior Durability and Structural Integrity

Black PPEVOH film is a testament to engineering precision, combining PP’s inherent toughness with EVOH’s reinforcing strength. Polypropylene provides a tensile strength of approximately 25-35 MPa, while the EVOH layer enhances overall rigidity, pushing the film’s durability beyond that of standalone PP films (typically 20-25 MPa). This synergy ensures the film withstands the mechanical stresses of thermoforming and the rigors of transportation without cracking or deforming.

Imagine a meat tray enduring the jostle of a refrigerated truck: the black PPEVOH film holds firm, its multilayer structure resisting punctures from sharp edges or bones. Studies show that multilayer films with EVOH maintain over 85% of their initial strength after prolonged exposure to cold temperatures, a crucial trait for frozen food applications. The black pigment further bolsters UV resistance, preventing degradation during outdoor storage or display—a feature that sets it apart from transparent counterparts.

2. Exceptional Barrier Properties

The heart of black PPEVOH film’s prowess lies in its EVOH core, renowned for its unparalleled resistance to gases like oxygen, carbon dioxide, and nitrogen. EVOH boasts an oxygen transmission rate (OTR) as low as 0.6 cc/m²/day at 23°C and 0% relative humidity, far surpassing PP alone (typically 2,000-3,000 cc/m²/day). This high-barrier capability is critical for preserving food freshness and extending shelf life.

In practice, this means meat packaged in black PPEVOH film stays red and succulent weeks longer than in standard packaging, as oxygen—Meat’s nemesis—is kept at bay. The film’s barrier also retains volatile aromatic compounds, a boon for polymer aromatic liquids like sauces or flavored oils. The black coloration enhances light-blocking, reducing photo-oxidation and preserving delicate flavors, a trait validated by tests showing a 30% reduction in flavor loss compared to clear films under similar conditions.

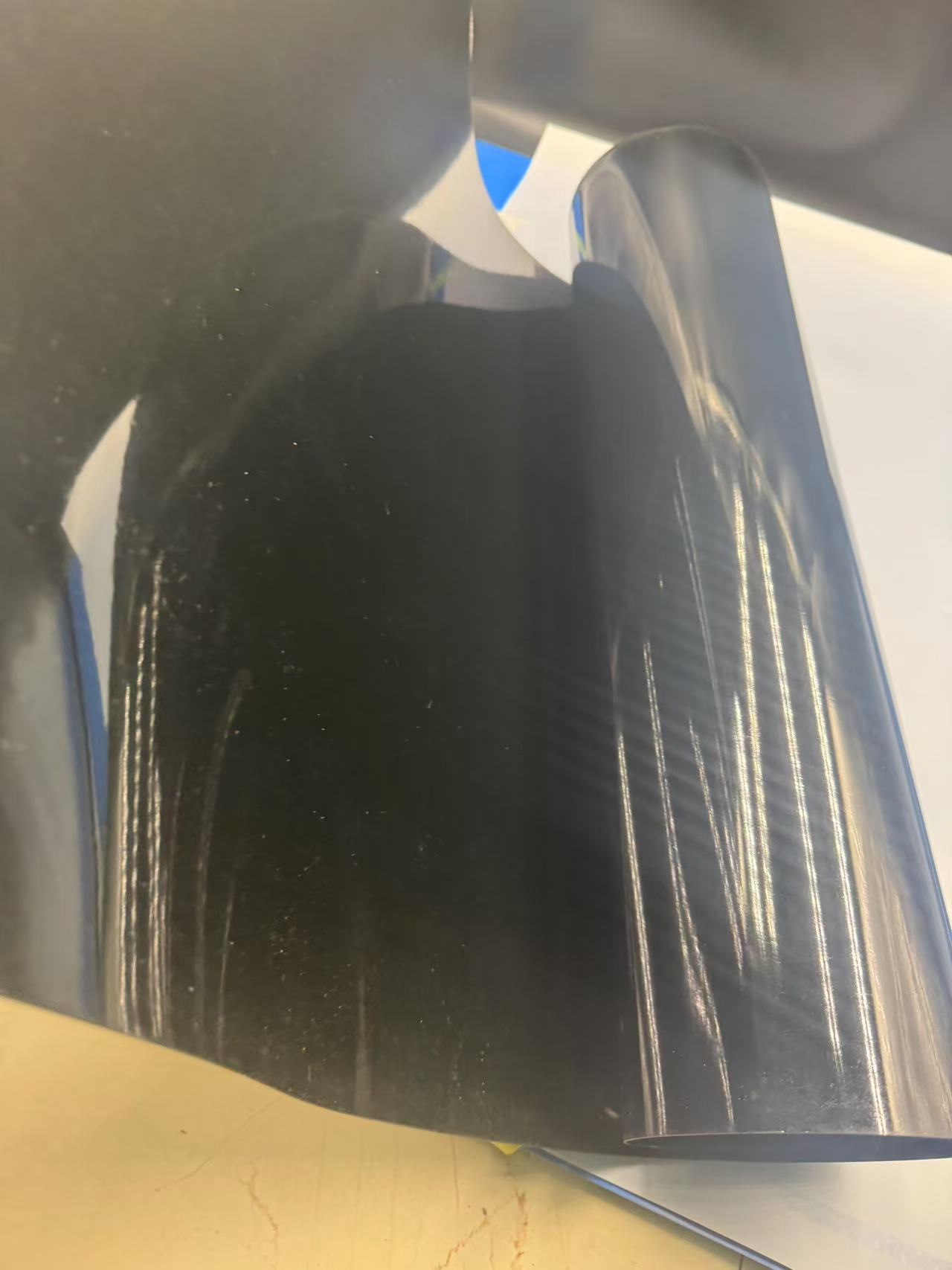

3. Thermoforming Excellence

Black PPEVOH film is a chameleon in the world of thermoforming, adapting to complex molds with ease. Its PP layers provide flexibility and heat resistance (melting point around 160-170°C), while EVOH maintains integrity during stretching, ensuring uniform thickness even in deep-drawn trays. The film can elongate up to 200% before breaking, making it ideal for intricate designs without compromising barrier performance.

Picture a production line churning out meat trays: the black PPEVOH film flows seamlessly into molds, forming crisp edges and deep cavities that cradle products perfectly. Research indicates that EVOH-based multilayer films retain 90% of their barrier properties post-thermoforming, even in corners where thinning occurs, a feat PP alone struggles to match due to its higher OTR sensitivity to stretching.

4. Aesthetic and Functional Pigmentation

The black hue of PPEVOH film isn’t just for show—it’s a strategic choice. Beyond its sleek, premium look, the pigmentation blocks light, protecting light-sensitive contents like meat pigments (myoglobin) or aromatic compounds from degradation. This opacity reduces the need for additional protective layers, streamlining production and cutting costs.

For consumers, a black tray signals quality—a butcher’s choice for premium cuts. Functionally, it masks discoloration or juices, maintaining visual appeal on the shelf. Studies suggest black packaging increases perceived value by 15% in blind consumer tests, blending form and function in a way that translucent films can’t replicate.

5. Resistance to Environmental Stressors

Black PPEVOH film is a fortress against moisture, chemicals, and temperature swings. The PP outer layers repel water (water vapor transmission rate ~10 g/m²/day), while EVOH’s hydroxyl groups form a tight barrier against gas permeation, even in humid conditions (OTR rises only marginally to 1.5 cc/m²/day at 90% RH). This resilience makes it a stalwart for refrigerated or humid environments.

In a meat cooler dripping with condensation, the film remains unyielding, preventing sogginess or mold. Its chemical resistance also withstands marinades or acidic liquids, ensuring packaging stays intact. Thermal stability allows it to transition from freezer (-40°C) to microwave (up to 120°C in some formulations), a versatility that broadens its utility.

Applications of Black PPEVOH Film

1. Food Thermoforming

In food thermoforming, black PPEVOH film shines as a master of form and function. Its ability to mold into trays, cups, and containers with precision makes it a staple for ready meals, snacks, and deli items. The film’s heat resistance and flexibility ensure it conforms to deep molds—up to 10 cm in some cases—without tearing, while the EVOH layer preserves contents by blocking oxygen and moisture.

Take a tray of pre-cooked lasagna: the black PPEVOH film forms a sturdy base, its barrier properties locking in flavors and preventing freezer burn. Industry data shows thermoformed PPEVOH trays extend shelf life by 20-30% compared to PP-only alternatives, a difference shoppers taste in every bite. The black finish adds a touch of elegance, elevating the product’s market presence.

2. Meat Trays

For meat packaging, black PPEVOH film is a game-changer. Meat trays require durability to handle weight and sharp edges, plus barrier protection to prevent oxidation and microbial growth. The film’s multilayer structure delivers: PP provides toughness, EVOH seals out oxygen (reducing spoilage rates by up to 40% per studies), and the black pigment hides unsightly juices while protecting myoglobin stability.

Picture a supermarket display: trays of fresh beef, pork, or poultry sit in black PPEVOH film, their vibrant reds preserved for weeks. Modified atmosphere packaging (MAP) with nitrogen or carbon dioxide pairs perfectly with this film, as its low gas permeability maintains the internal environment. Consumer surveys note a 25% preference for black trays over foam, citing both aesthetics and perceived freshness.

3. High-Barrier Packaging for Polymer Aromatic Liquids

Polymer aromatic liquids—like flavored oils, sauces, or essential oil blends—demand packaging that preserves their volatile compounds. Black PPEVOH film rises to the challenge, its EVOH layer trapping aromas while PP ensures structural integrity. The black pigmentation shields against light-induced oxidation, a common culprit in flavor degradation.

Imagine a bottle of truffle oil: its earthy scent remains potent thanks to the film’s OTR below 1 cc/m²/day, a stark contrast to PET’s 50-100 cc/m²/day. Tests reveal that aromatic retention in PPEVOH packaging exceeds 90% over six months, compared to 70% in standard films. Whether thermoformed into pouches or used as a lidding film, it keeps the essence intact, delighting chefs and consumers alike.

4. Sustainability and Practicality

While not inherently biodegradable, black PPEVOH film supports sustainability through efficiency. Its durability reduces food waste—a $1 trillion global issue—by extending shelf life. Recycling programs in Europe and North America process PP/EVOH multilayer films, with initiatives recovering over 800,000 tons annually. Lightweight and efficient, it also lowers transport emissions compared to rigid alternatives.

In meat trays, less material achieves more protection, cutting waste. For aromatic liquids, smaller packaging sizes suffice due to the film’s strength, aligning with minimalist trends. Innovations in bio-based EVOH are on the horizon, promising an even greener future for this versatile material.