The Characteristics and Applications of PE Black and White Film in Steel Plate Adhesive Protection

2025-04-10 11:12Polyethylene (PE) black and white film has emerged as a standout solution in the realm of surface protection, particularly for steel plates. This specialized protective film, crafted from polyethylene with a distinctive black-and-white layered structure, combines aesthetic ingenuity with robust functionality.  Its unique characteristics make it an ideal choice for safeguarding steel plates during manufacturing, transportation, and installation processes. In this article, we will explore the defining properties of PE black and white film and delve into its practical applications in steel plate adhesive protection, supported by vivid examples and logical reasoning.

Its unique characteristics make it an ideal choice for safeguarding steel plates during manufacturing, transportation, and installation processes. In this article, we will explore the defining properties of PE black and white film and delve into its practical applications in steel plate adhesive protection, supported by vivid examples and logical reasoning.

Characteristics of PE Black and White Film

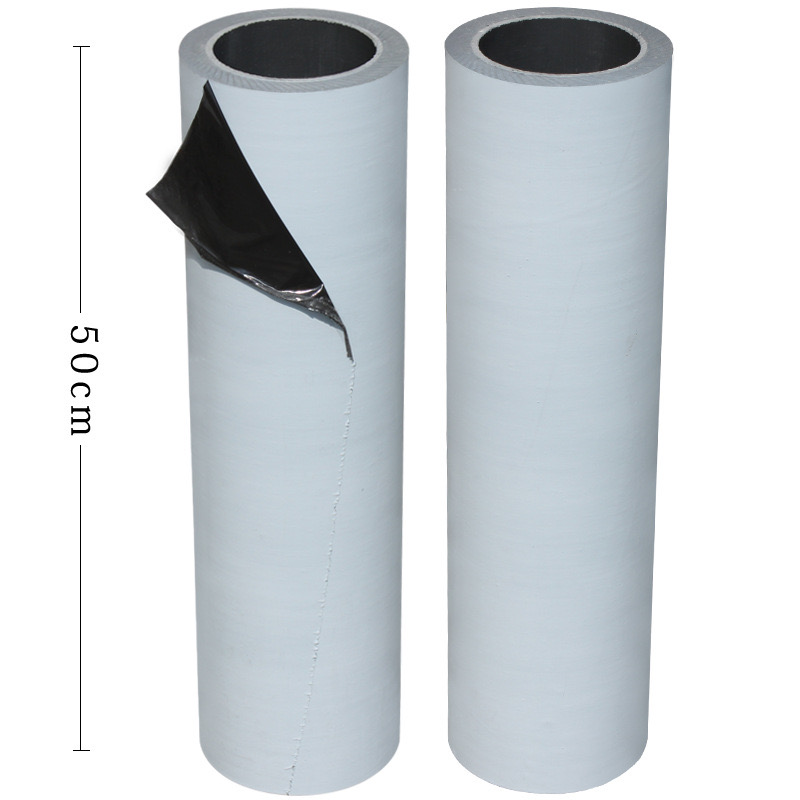

PE black and white film is a multilayered polyethylene film, typically produced through a co-extrusion process where one side is pigmented black and the other white. This dual-color design is not merely cosmetic—it serves a functional purpose that enhances its protective capabilities. Below are the key characteristics that distinguish this film:

Dual-Layer Thermal Regulation

The black-and-white configuration offers a clever thermal management system. The white outer layer reflects sunlight and UV rays, reducing heat buildup on the film’s surface. Meanwhile, the black inner layer, which adheres to the steel plate, absorbs residual heat, drawing it away from the protected surface. This synergy minimizes the risk of adhesive degradation under prolonged sun exposure, a common challenge with single-color films. For instance, during outdoor storage of steel plates in scorching summer conditions, the white layer deflects solar energy, while the black layer prevents heat from penetrating the steel, maintaining the adhesive’s integrity.

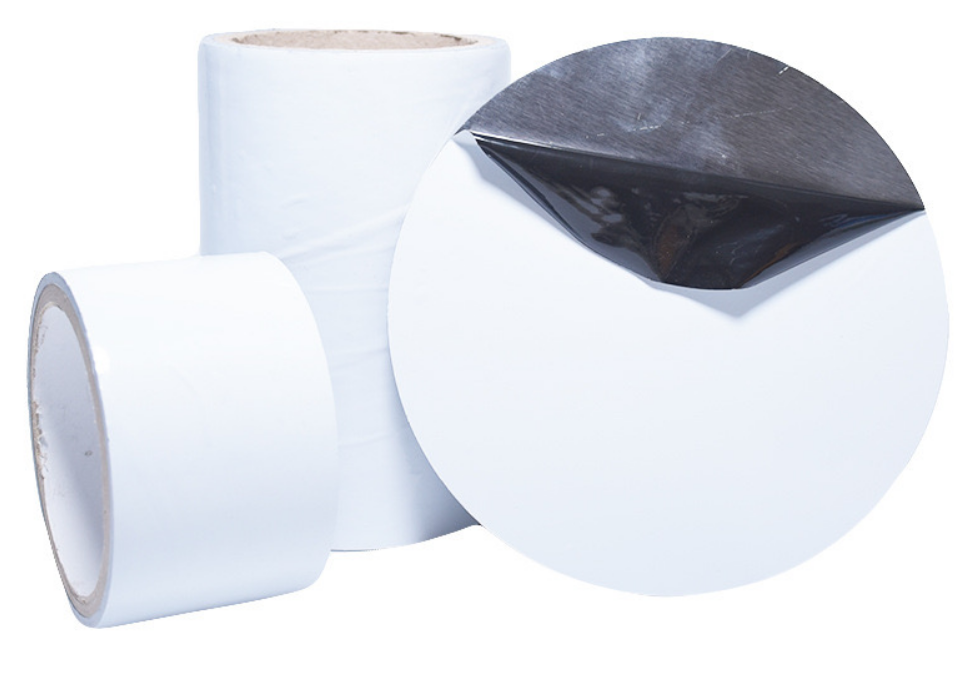

Excellent Adhesive Compatibility

PE black and white film is typically coated with a pressure-sensitive adhesive, such as acrylic or rubber-based glue, tailored to bond effectively with steel surfaces. The adhesive strikes a balance between strong adhesion and clean removability, ensuring it sticks firmly during use but peels off without leaving residue. This property is critical for steel plates, which often undergo processes like cutting, bending, or stamping—operations that demand a secure yet temporary protective layer. Imagine a steel plate being transported across continents: the film stays in place despite vibrations and jolts, yet when the plate reaches its destination, a worker can effortlessly remove it, revealing a pristine surface.

Durability and Flexibility

Made from low-density polyethylene (LDPE), PE black and white film boasts impressive tensile strength and elasticity. It can stretch and conform to irregular surfaces, such as the edges or corners of steel plates, without tearing. This flexibility ensures comprehensive coverage, even on plates with complex geometries. Additionally, its durability resists punctures and abrasions, protecting the steel from scratches during handling or machining. Picture a steel plate being loaded onto a truck: the film withstands the friction of straps and the occasional bump, keeping the surface unmarred.

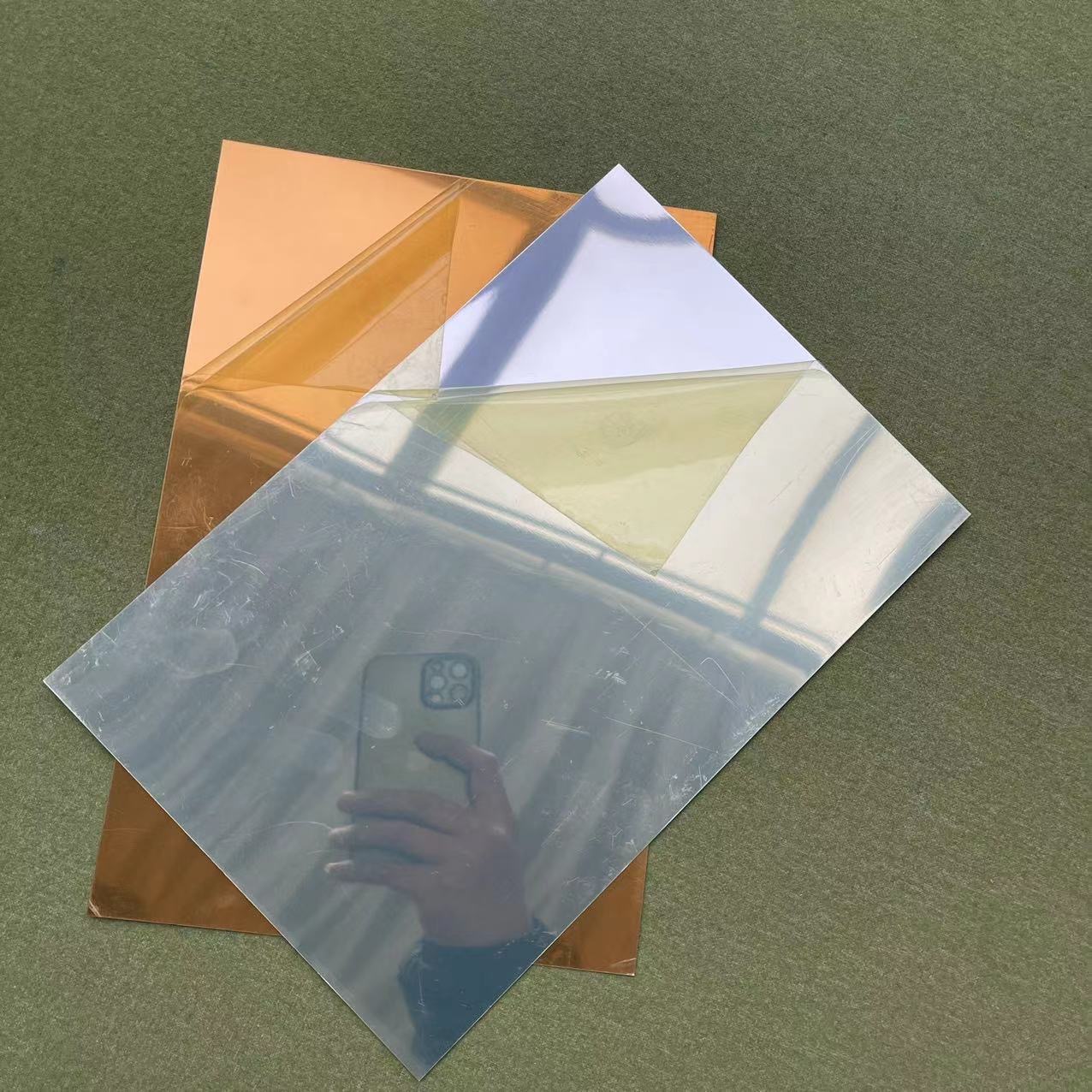

UV Resistance and Weatherability

The white layer’s UV-reflective properties, combined with stabilizers in the polyethylene, grant PE black and white film excellent resistance to ultraviolet radiation and weathering. This makes it suitable for steel plates stored outdoors for extended periods—sometimes months—without the film breaking down or transferring adhesive residue. In contrast, a standard transparent film might yellow and crack under similar conditions, compromising protection. For example, a construction site storing steel plates for a skyscraper project can rely on this film to maintain surface quality despite exposure to rain, wind, and sun.

Cost-Effectiveness and Eco-Friendliness

PE black and white film is relatively inexpensive to produce, thanks to the abundance of polyethylene and efficient manufacturing processes like co-extrusion. Its recyclability further enhances its appeal, aligning with modern sustainability goals. For industries handling large volumes of steel plates, such as automotive or shipbuilding, this translates to significant savings without sacrificing performance. A single roll of film can protect dozens of plates, reducing waste and replacement costs compared to less durable alternatives.

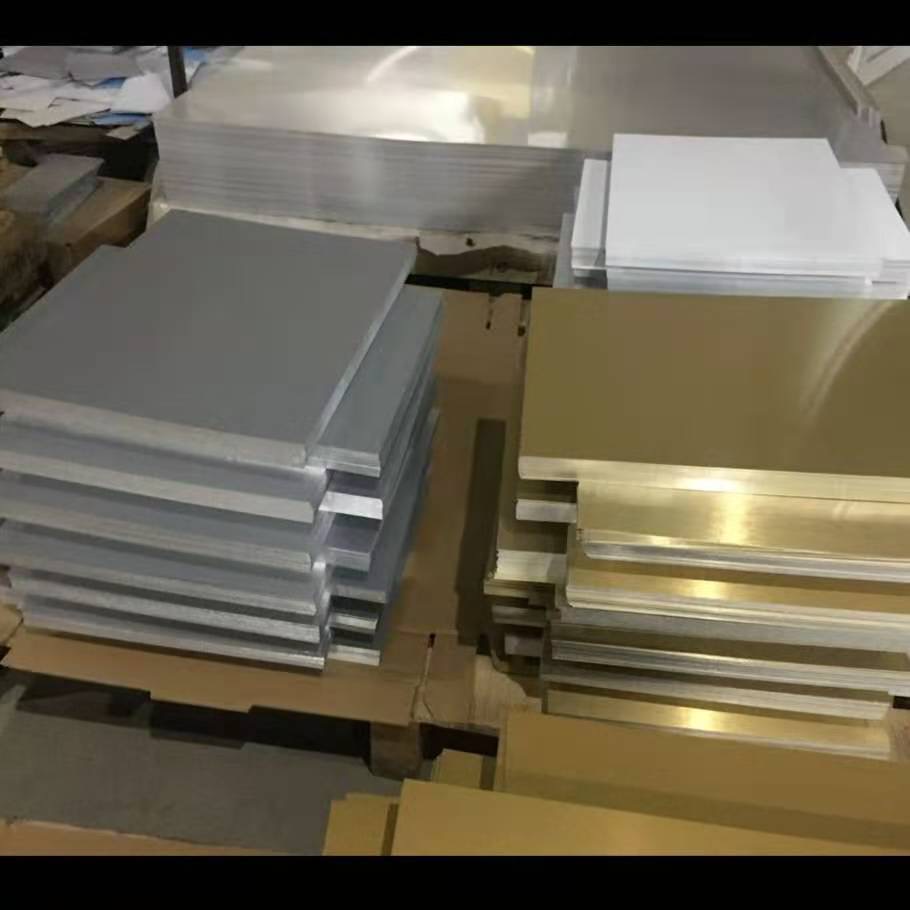

Applications in Steel Plate Adhesive Protection

The characteristics of PE black and white film make it a versatile tool for protecting steel plates across various stages of their lifecycle. Its adhesive-backed design ensures it adheres securely to steel surfaces, providing a temporary yet robust shield. Let’s examine how it excels in specific scenarios:

Protection During Manufacturing

Steel plates undergo rigorous processes—cutting, grinding, and forming—that expose them to potential damage. PE black and white film acts as a barrier, preventing scratches from tools or debris. For instance, during laser cutting, the film absorbs minor burns or splatter, preserving the steel’s finish. A manufacturer producing steel components for appliances can apply the film before processing, ensuring that each plate emerges spotless and ready for assembly. The film’s flexibility allows it to endure bending or stamping without peeling, a testament to its adaptability.