Characteristics and Applications of Transparent PVC/PET Label Films

2025-07-14 16:44Transparent label films, specifically those made from polyvinyl chloride (PVC) and polyethylene terephthalate (PET), have become indispensable in the world of packaging, branding, and product presentation. These materials, known for their clarity, strength, and versatility, play a critical role in industries ranging from food and beverage to pharmaceuticals and consumer goods.

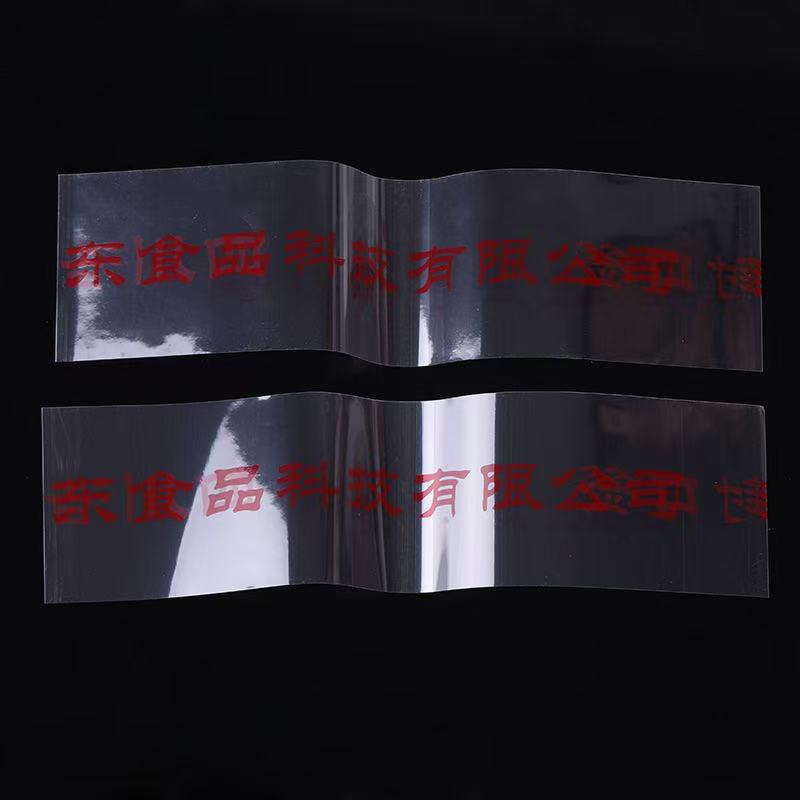

This article explores the unique characteristics of transparent PVC/PET label films and their diverse applications, highlighting why they are preferred choices in modern labeling solutions.Characteristics of Transparent PVC/PET Label FilmsTransparent PVC Label FilmTransparent PVC label film is a synthetic plastic polymer derived from vinyl chloride monomers through a process called suspension polymerization. Its defining characteristics include:Clarity and Gloss: Transparent PVC label film offers good clarity, though slightly less than PET, making it suitable for applications where product visibility is important but not the primary focus. Its glossy finish enhances the aesthetic appeal of labels, making products stand out on shelves.

Durability and Flexibility: PVC is known for its rigidity and durability, capable of withstanding harsh impacts and extreme temperatures ranging from -40°C to +110°C. Its flexibility allows it to conform to various container shapes, making it ideal for curved surfaces like bottles.

Weather and UV Resistance: Transparent PVC label films exhibit excellent resistance to weathering and ultraviolet (UV) radiation, ensuring labels remain vibrant and intact even in outdoor conditions. Some PVC labels boast a durability of up to seven years.

Adhesion Properties: PVC labels typically use permanent adhesives, providing strong adhesion to a variety of substrates, including non-polar surfaces like plastic bottles and corrugated boards. The minimum application temperature ranges from 0°C to +5°C, ensuring reliable performance in diverse environments.

Cost-Effectiveness: Compared to PET, PVC is generally more affordable, making it a preferred choice for applications where budget constraints are a consideration. However, its environmental footprint is a point of concern due to challenges in recycling.

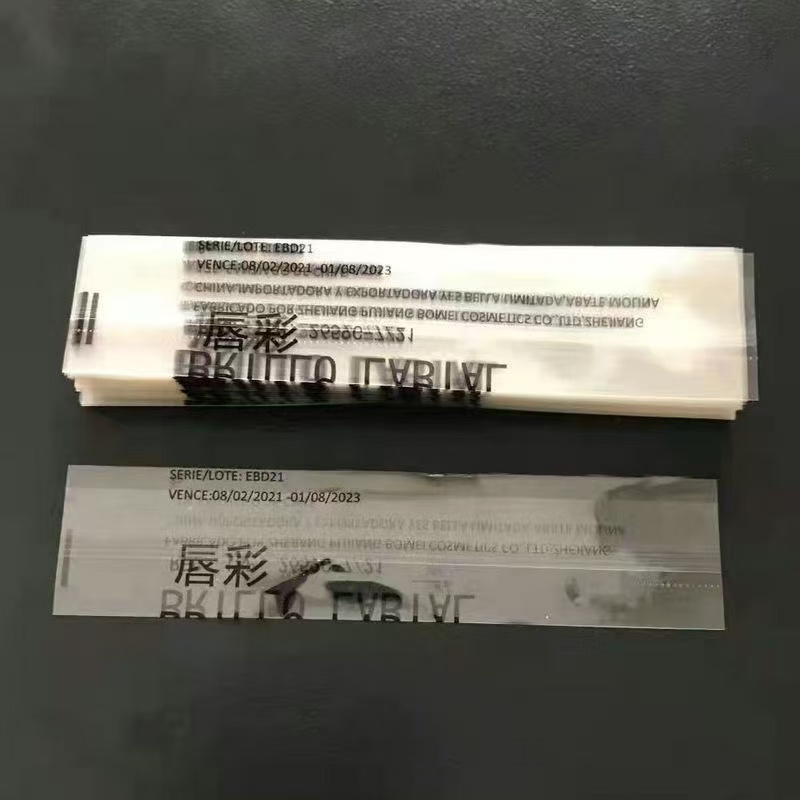

Transparent PET Label FilmTransparent PET label film, made from polyethylene terephthalate, is a thermoplastic polyester resin celebrated for its superior properties. Its key characteristics include:Exceptional Clarity and Gloss: PET label films are renowned for their crystal-clear transparency and high gloss, offering a premium "no-label" look that enhances product visibility. This makes them ideal for showcasing contents, such as beverages or cosmetics, where visual appeal is critical.

High Tensile Strength: PET films have excellent tensile strength and tear resistance, making them robust for demanding packaging applications. Their mechanical strength is three times higher than that of polycarbonate (PC), ensuring durability during handling and transport.

Recyclability and Sustainability: PET is one of the most recycled plastics globally, with options like recycled PET (rPET) containing 30%–100% post-consumer waste. This eco-friendly attribute aligns with the growing demand for sustainable packaging solutions.

Chemical and Moisture Resistance: PET films provide excellent barriers against moisture, gases, and chemicals, making them suitable for food, beverage, and pharmaceutical packaging. They are inert and do not react with contents, ensuring product safety.

Heat Resistance and Printability: PET films offer superior heat resistance, with service temperatures up to +80°C and excellent printability for high-quality graphics. Their ability to take on colorants and adhesives ensures vibrant, long-lasting labels.

Applications of Transparent PVC/PET Label FilmsThe unique properties of transparent PVC/PET label films make them versatile for a wide range of applications. Below, we explore their uses across various industries, supported by specific examples and their practical benefits.1. Food and Beverage PackagingBoth PVC and PET label films are widely used in food and beverage packaging due to their clarity and safety. Transparent PET label films are particularly favored for their food-safe properties and recyclability. For instance, PET shrink labels are commonly used on beverage bottles, such as water, soft drinks, and juices, due to their high clarity and ability to conform tightly to contoured shapes, achieving up to 78% shrinkage without the problematic “smile effect” on bottle bottoms.

A practical example is the use of transparent PET label films on premium water bottles. The crystal-clear finish allows consumers to see the purity of the water, while the label’s durability ensures it remains intact during transportation and storage. PET’s recyclability also appeals to environmentally conscious brands, with some using rPET labels to reduce their carbon footprint.

PVC label films, while less common for food due to toxicity concerns, are used for non-food items like household chemical bottles. Their flexibility and weather resistance make them ideal for labeling dishwashing liquids or cleaning products, where labels must withstand moisture and frequent handling.

2. Pharmaceutical and Medical LabelingIn the pharmaceutical industry, transparent PET label films are preferred for their chemical inertness and high clarity, which ensure accurate product identification and compliance with regulatory standards. PET labels are used on medicine bottles, syringes, and medical device packaging, where their resistance to chemicals and low-temperature performance (down to -40°C) is critical for chilled products.

For example, PET labels on insulin vials provide clear visibility of dosage instructions while maintaining adhesion in refrigerated conditions. Their durability ensures that critical information remains legible throughout the product’s lifecycle. PVC labels, while less common in direct pharmaceutical applications due to recycling challenges, are used for promotional or secondary labeling in medical settings, such as on equipment packaging, due to their cost-effectiveness.

3. Consumer Goods and ElectronicsTransparent PET label films are extensively used in consumer goods and electronics for their aesthetic appeal and protective qualities. Their high tensile strength and puncture resistance make them ideal for protecting screens, lenses, and components during manufacturing and shipping. For instance, PET self-adhesive films are used as protective layers for LCD panels, touchscreens, and mobile phone displays, ensuring scratch-free surfaces.

A vivid example is the use of PET films in smartphone packaging, where transparent labels showcase the device’s design while providing a protective barrier. PET’s excellent printability allows for vibrant branding, such as holographic effects or barcodes, enhancing both functionality and visual appeal.

PVC label films are used in consumer goods where cost is a priority, such as promotional labels on household appliances. Their flexibility allows them to adhere to irregular surfaces, like curved plastic casings, while their UV resistance ensures longevity in retail environments.

4. Industrial and Automotive ApplicationsIn industrial and automotive sectors, both PVC and PET label films serve specialized purposes. Transparent PVC label films are used for durable labels on motor oil containers and industrial chemical bottles, where their weather resistance and adhesion to non-polar surfaces are critical. These labels often endure harsh conditions, such as exposure to oils and extreme temperatures, without peeling or fading.

PET label films, particularly those with top coatings, are used for high-performance applications like electrical and electronic labels. For example, clear PET films with superior ink adhesion are used for barcode labels on circuit boards, ensuring readability and durability in high-temperature environments. Their dimensional stability and chemical resistance make them ideal for automotive parts labeling, where precision and longevity are paramount.

5. Decorative and Promotional LabelingBoth PVC and PET label films excel in decorative and promotional applications. Transparent PVC label films are popular for promotional labels due to their affordability and flexibility. They are used on products like shampoo bottles or cosmetic containers, where vibrant designs and weather resistance enhance shelf appeal. PVC’s ability to mimic textures like wood grain or metal adds a premium touch to budget-friendly products.

PET label films, with their superior clarity and printability, are used for high-end promotional labels, such as holographic or glitter stickers. These labels create a luxurious, eye-catching effect, often seen on premium cosmetics or alcoholic beverages. For instance, PET’s high gloss and ability to produce iridescent effects make it a favorite for wine bottle labels, where the “no-label” look enhances brand sophistication.

Comparing PVC and PET Label Films: A Practical PerspectiveWhile both materials share similarities, their differences guide their application:Environmental Impact: PET is the clear winner in sustainability, being widely recyclable and often made from rPET. PVC, however, faces recycling challenges due to potential contamination and the release of harmful chemicals during disposal.

Cost: PVC is generally more cost-effective, making it suitable for budget-conscious applications. PET, while slightly more expensive due to its oil-based composition, offers long-term savings through recyclability and durability.

Performance: PET outperforms PVC in clarity, strength, and chemical resistance, making it ideal for food-safe and high-performance applications. PVC’s flexibility and lower cost make it suitable for non-food, promotional, or industrial uses.

Future Trends and InnovationsThe future of transparent PVC/PET label films is shaped by advancements in sustainability and technology. The rise of eco-friendly options, such as UPM Raflatac’s Vanish™ PCR labels with 90% recycled content, reflects the industry’s shift toward circular economies. Innovations in PET films, like wash-off labels, facilitate recycling by allowing clean separation of labels from containers, increasing the yield of recoverable PET flakes.

Additionally, advancements in printing technologies, such as UV ink and barcode printing on PET films, enhance their functionality for smart packaging. For example, PET labels with embedded RFID tags are gaining traction in retail for inventory tracking, combining transparency with cutting-edge functionality. PVC films, while lagging in sustainability, are seeing innovations in biodegradable formulations to address environmental concerns.ConclusionTransparent PVC/PET label films are pillars of modern packaging, offering a blend of clarity, durability, and versatility that caters to diverse industries. PET stands out for its recyclability, superior clarity, and food-safe properties, making it the go-to choice for premium and sustainable applications. PVC, with its cost-effectiveness and flexibility, remains a staple for promotional and industrial uses. By understanding their characteristics and applications, businesses can make informed choices to enhance product presentation, protect contents, and align with sustainability goals. As technology and environmental priorities evolve, these materials will continue to shape the future of labeling with innovation and impact.