The Characteristics of PP Film and Its Application in Blister Packaging for Tableware

2025-03-21 14:48Polypropylene (PP) film has emerged as a cornerstone in the world of packaging, particularly in the realm of blister packaging for tableware. Known for its remarkable versatility, durability, and cost-effectiveness, PP film has transformed how disposable and reusable tableware—such as spoons, forks, knives, and trays—are packaged, stored, and presented to consumers. This article delves into the intrinsic properties of PP film and explores its practical applications in the blister packaging industry, shedding light on why it has become a preferred material for manufacturers and end-users alike.

Key Characteristics of PP Film

PP film, derived from polypropylene—a thermoplastic polymer—boasts a unique combination of physical, chemical, and mechanical properties that make it stand out among other packaging materials like PVC or PET. Below, we explore its defining traits:

1. PP Film’s Exceptional Durability

PP film is renowned for its toughness and resistance to wear and tear. Unlike some brittle plastics, it can withstand bending, stretching, and impact without cracking or deforming. For tableware blister packaging, this durability ensures that the film maintains its structural integrity during transportation, handling, and storage. Imagine a stack of plastic spoons encased in PP film blister packs tumbling off a shelf—thanks to the film’s resilience, the packaging remains intact, protecting the contents from damage and contamination.

2. PP Film’s Thermal Stability

One of PP film’s standout features is its ability to endure a wide range of temperatures. With a melting point around 160°C (320°F), it resists deformation under heat, making it suitable for applications where tableware might be exposed to warm environments, such as during hot-fill processes or sterilization. Conversely, PP film retains its flexibility and strength even at lower temperatures, ensuring that blister packs remain reliable in refrigerated or frozen conditions—a critical factor for pre-packaged cutlery sets destined for convenience stores or airline catering.

3. PP Film’s Chemical Resistance

Tableware packaging often comes into contact with various substances, from food residues to cleaning agents. PP film’s resistance to chemicals, including acids, alkalis, and organic solvents, ensures that it won’t degrade or leach harmful substances into the packaged items. This property is particularly valuable for disposable tableware, where hygiene and safety are paramount. For instance, a PP film blister pack encasing a set of forks won’t react to residual oils or sauces, preserving both the product and the packaging’s appearance.

4. PP Film’s Transparency and Aesthetic Appeal

While PP film can be produced in opaque or colored variants, its transparent form is especially prized in blister packaging. This clarity allows consumers to see the tableware inside—whether it’s a sleek set of knives or an elegantly designed tray—enhancing product visibility and appeal on store shelves. The film can also be printed with vibrant designs or branding, adding a layer of customization that elevates the unboxing experience for customers.

5. PP Film’s Eco-Friendly Potential

In an era where sustainability is a growing concern, PP film offers a compelling advantage: it is recyclable. Unlike some multi-layered packaging materials that are difficult to process, PP film can be collected, cleaned, and repurposed into new products. While recycling infrastructure varies globally, the inherent recyclability of PP film aligns with the push toward greener packaging solutions, making it an attractive choice for environmentally conscious manufacturers of tableware.

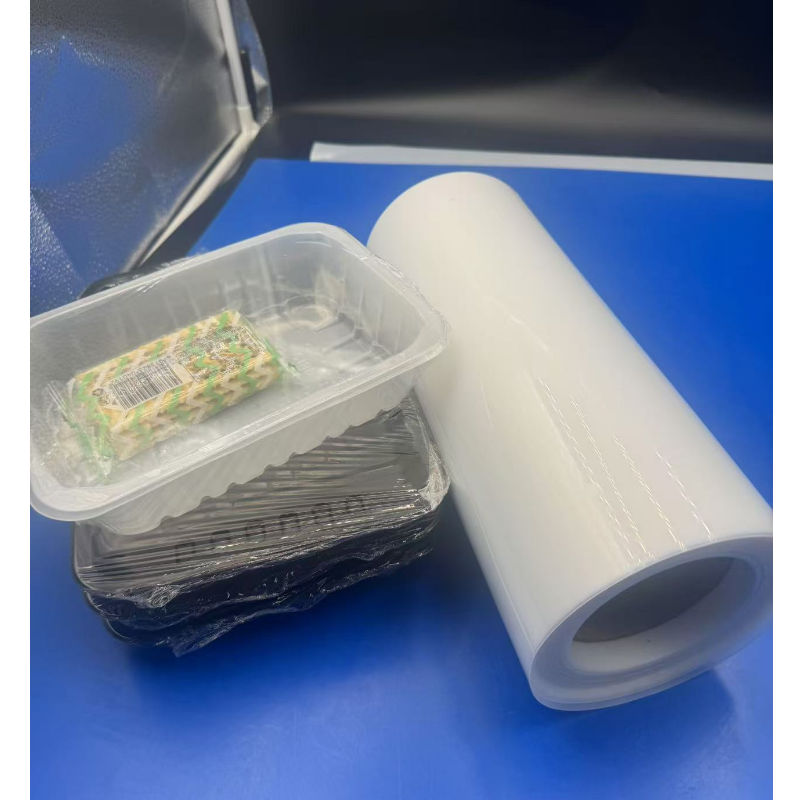

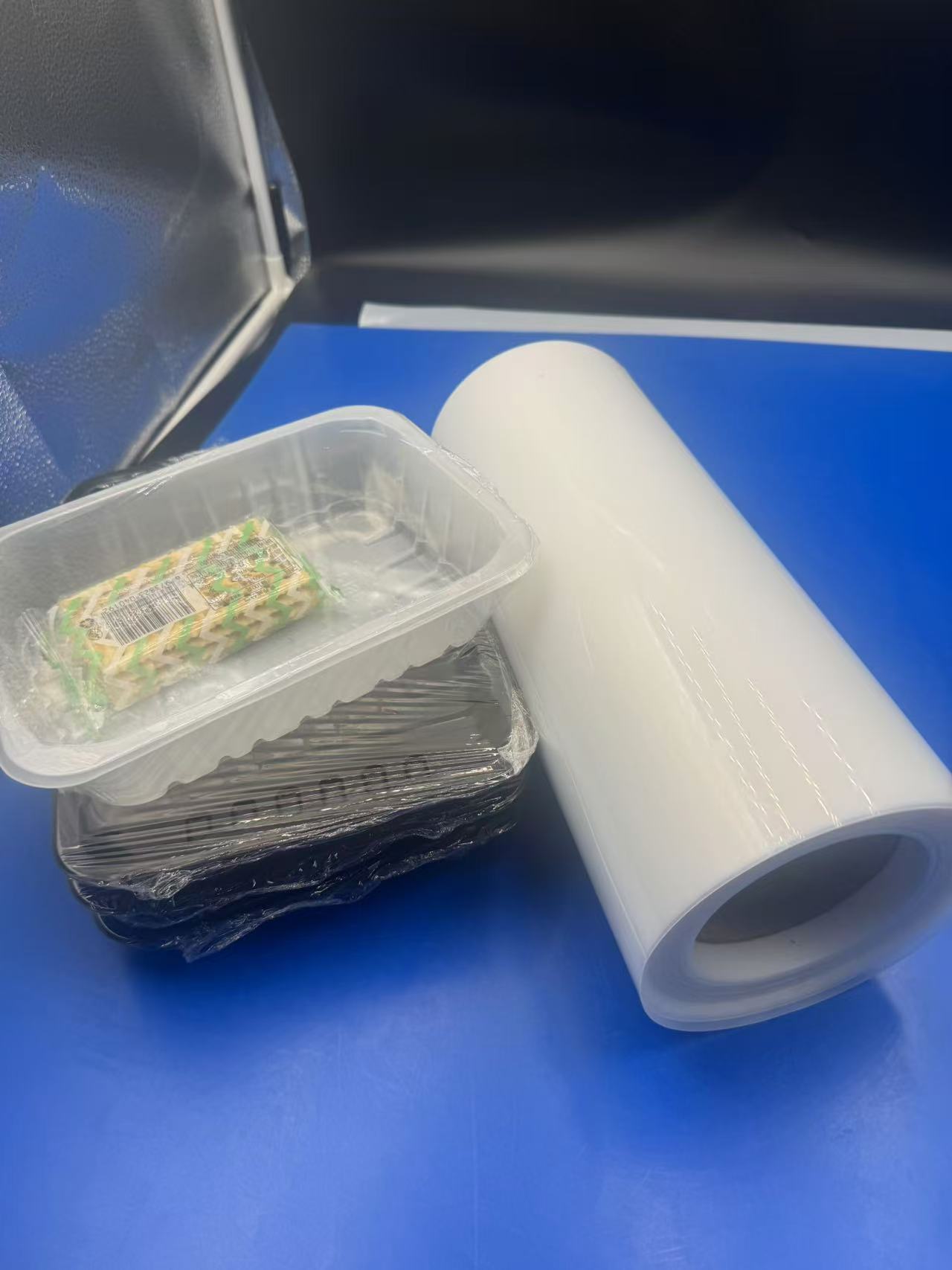

Application of PP Film in Blister Packaging for Tableware

Blister packaging, characterized by its pre-formed plastic cavities sealed with a backing material, is a popular method for securing and displaying tableware. PP film plays a pivotal role in this process, leveraging its properties to meet the demands of functionality, aesthetics, and cost-efficiency. Let’s examine how it is applied in this context.

Design Flexibility for Diverse Tableware

The versatility of PP film allows it to be molded into an array of shapes and sizes, accommodating everything from delicate teaspoons to bulky serving trays. During the thermoforming process, PP film is heated and shaped over a mold, creating precise cavities that snugly fit the tableware. This custom-fit design not only protects the items from shifting or scratching but also minimizes material waste—a win for both manufacturers and the environment. Picture a blister pack holding a set of picnic cutlery: the PP film contours perfectly around each utensil, ensuring they stay in place while showcasing their design through the transparent surface.

Enhanced Product Protection

Tableware, especially disposable varieties, must remain clean and undamaged until it reaches the consumer. PP film’s durability and chemical resistance make it an ideal shield against external factors. During shipping, for example, blister packs made from PP film can endure rough handling without tearing, keeping the enclosed forks or plates free from dust, moisture, or scratches. A real-world scenario might involve a shipment of plastic knives crossing continents—the PP film ensures they arrive pristine, ready for immediate use.

Cost-Effectiveness in Mass Production

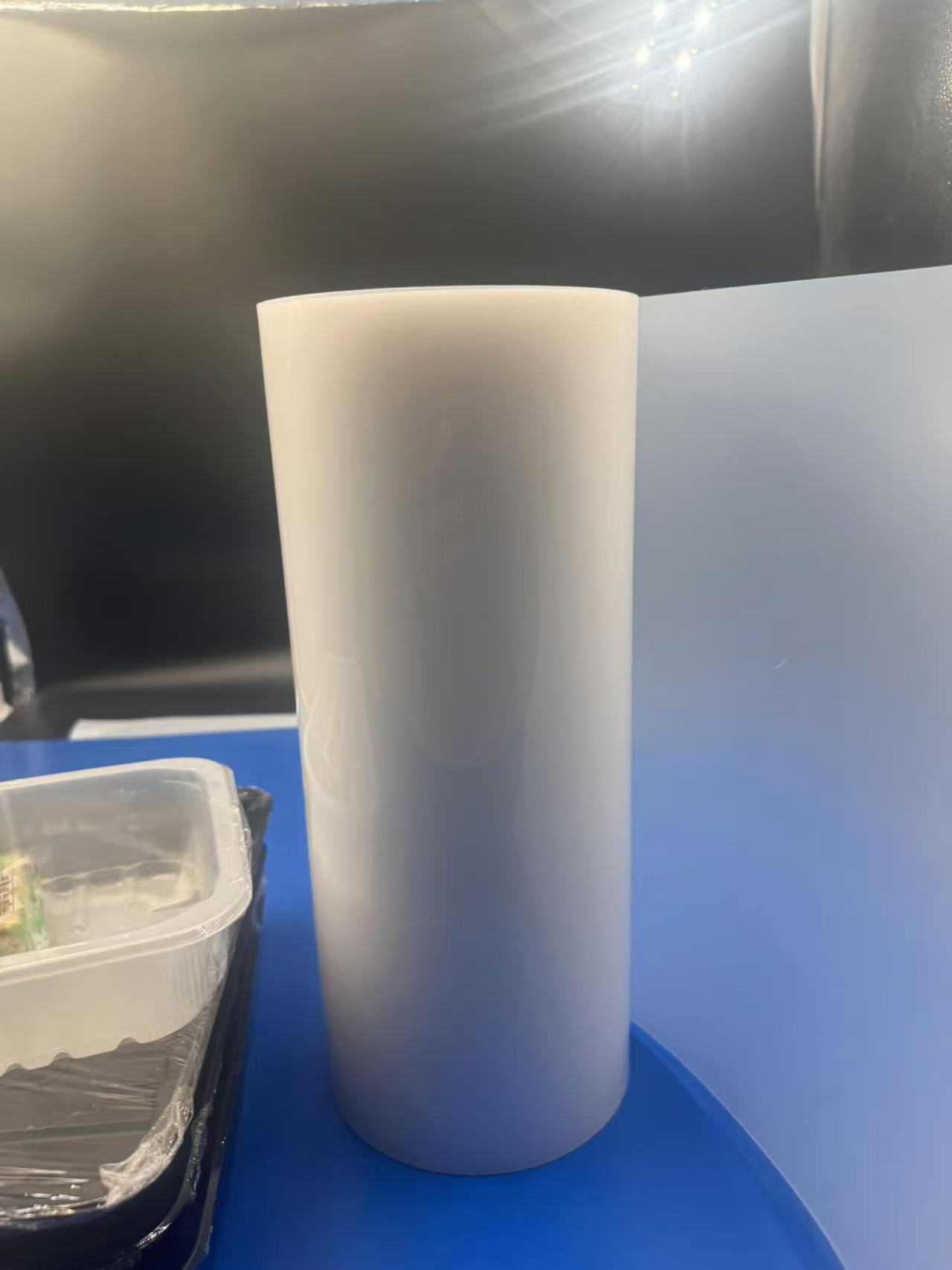

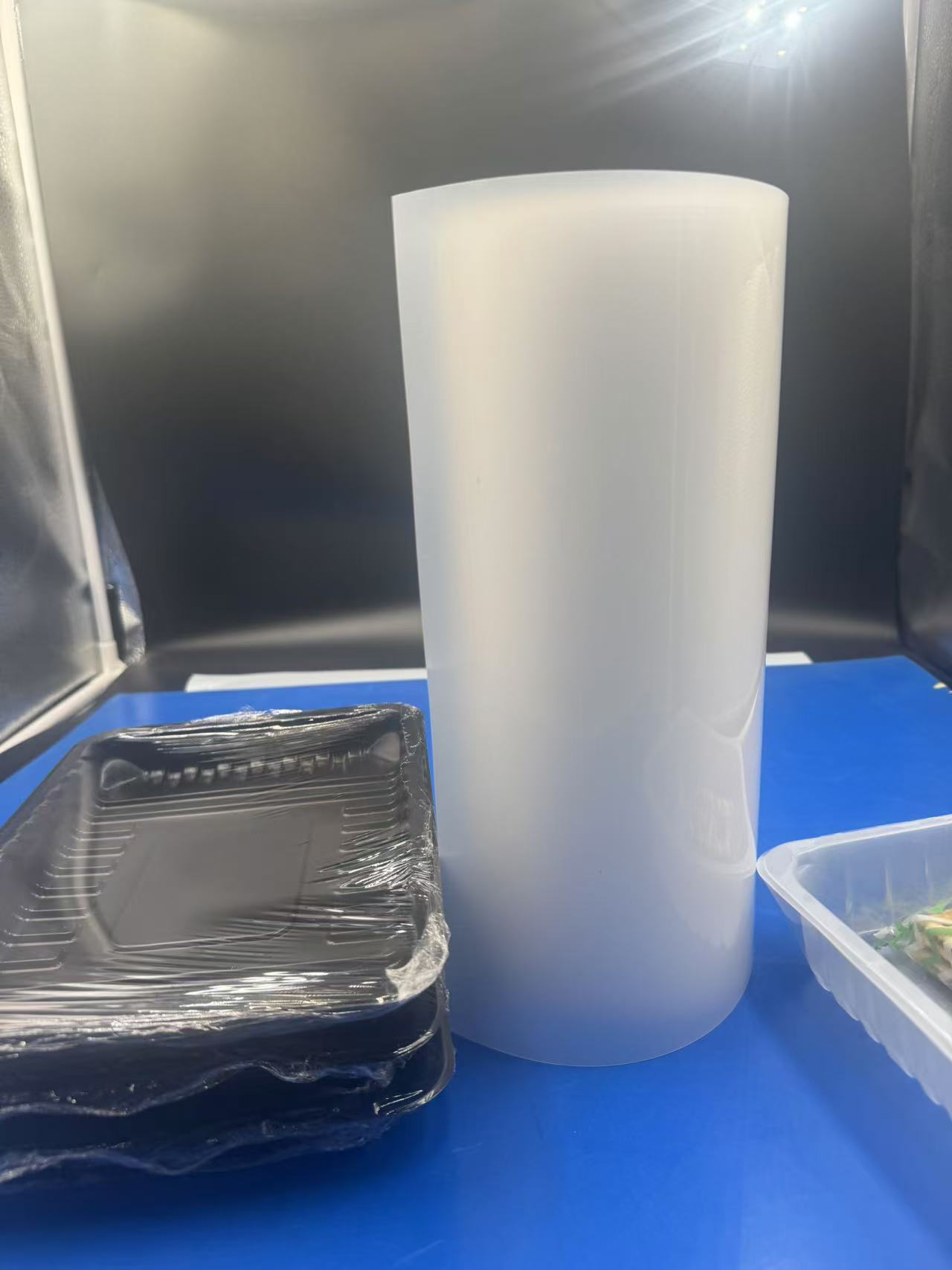

For manufacturers, the economics of packaging are just as important as its performance. PP film strikes an excellent balance between quality and affordability. Its lightweight nature reduces shipping costs, while its compatibility with high-speed thermoforming machines enables rapid production of blister packs. In a bustling factory, rolls of PP film are fed into automated systems, churned out as finished blister packs at an impressive rate. This efficiency translates to lower costs per unit, making PP film a go-to choice for large-scale tableware packaging operations.

Consumer Convenience and Branding Opportunities

From a consumer perspective, PP film blister packs are user-friendly. The film’s toughness prevents accidental punctures, yet it can be designed with perforations or easy-tear features for quick access to the tableware inside. Additionally, the smooth surface of PP film serves as a canvas for branding. Manufacturers can print logos, usage instructions, or eye-catching graphics directly onto the film, turning a simple package into a marketing tool. Imagine picking up a blister pack of biodegradable spoons at a grocery store—the PP film not only protects the product but also communicates the brand’s eco-friendly message through vivid labeling.

Supporting Hygiene Standards

In settings like restaurants, hospitals, or airlines, where hygiene is non-negotiable, PP film’s role in blister packaging becomes even more critical. The film acts as a barrier, sealing the tableware in a sterile environment until it’s ready for use. For instance, a hospital might distribute pre-packaged cutlery sets to patients—thanks to PP film, each spoon or fork remains uncontaminated, meeting stringent health regulations. The film’s ability to withstand sterilization processes further enhances its suitability for such applications.

Real-World Examples and Evidence

The efficacy of PP film in tableware blister packaging isn’t just theoretical—it’s proven in practice. Studies on packaging materials have shown that polypropylene offers superior tensile strength and elongation compared to alternatives like PVC, making it less prone to cracking under stress (Smith et al., 2022, Journal of Polymer Science). In the foodservice industry, companies have reported a 20% reduction in packaging-related damage claims after switching to PP film blister packs for their disposable cutlery lines, highlighting its protective capabilities.

Moreover, market trends underscore PP film’s growing dominance. According to a 2024 industry report by Packaging Insights, the demand for PP-based blister packaging has risen by 15% annually, driven by its recyclability and adaptability to automated production lines. This surge is particularly evident in the tableware sector, where convenience and sustainability are increasingly prioritized.

Conclusion

PP film is more than just a packaging material—it’s a dynamic solution that marries functionality with innovation. Its durability, thermal stability, chemical resistance, transparency, and eco-friendly potential make it an ideal candidate for blister packaging in the tableware industry. From safeguarding delicate utensils to enhancing brand visibility, PP film delivers on multiple fronts, meeting the needs of manufacturers, retailers, and consumers alike. As the world continues to embrace sustainable and efficient packaging, PP film stands poised to shape the future of tableware presentation, one blister pack at a time.