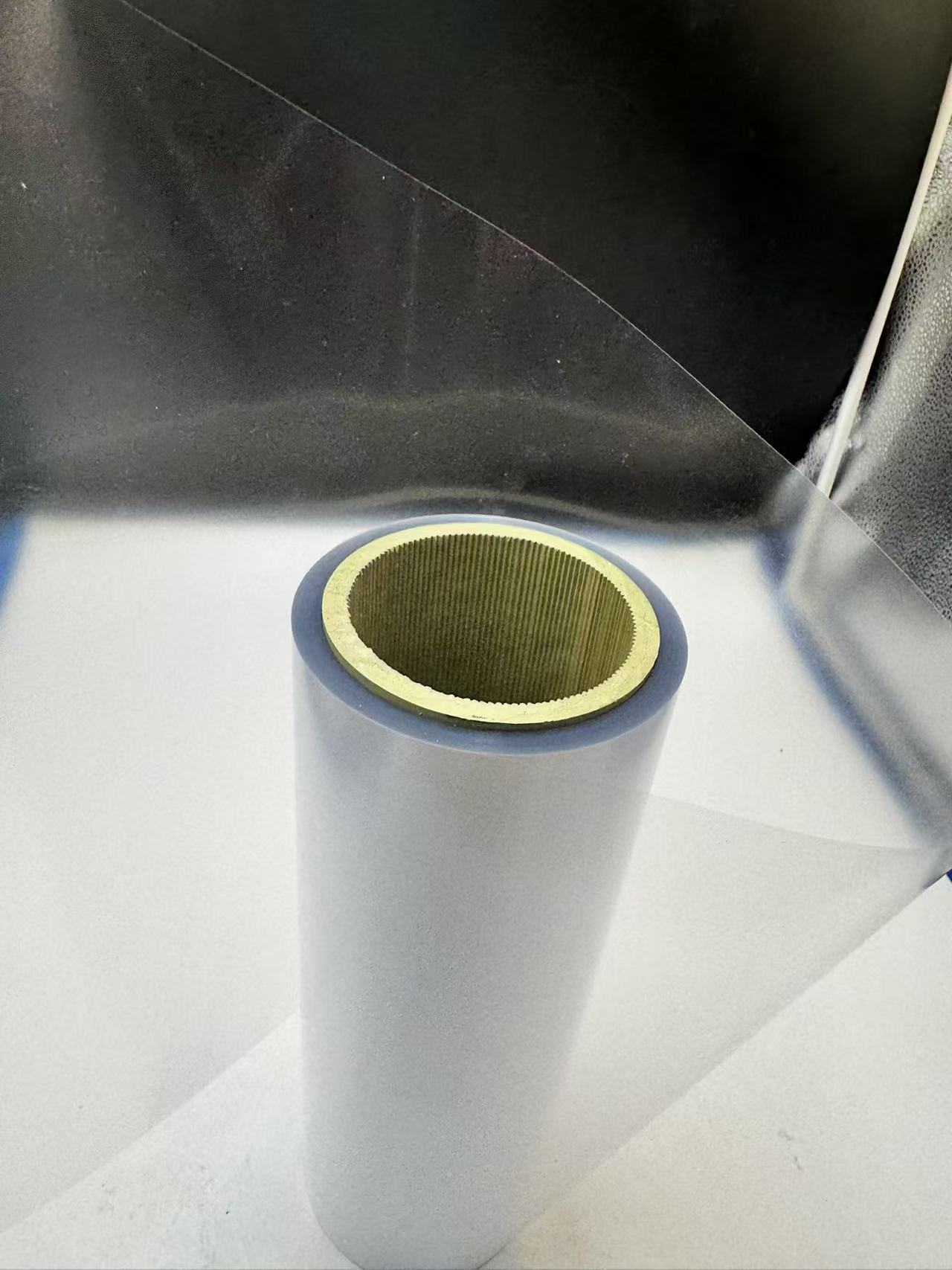

Transparent PVC Laminated Film: Characteristics and Applications Across Industries

2025-07-15 17:29Introduction

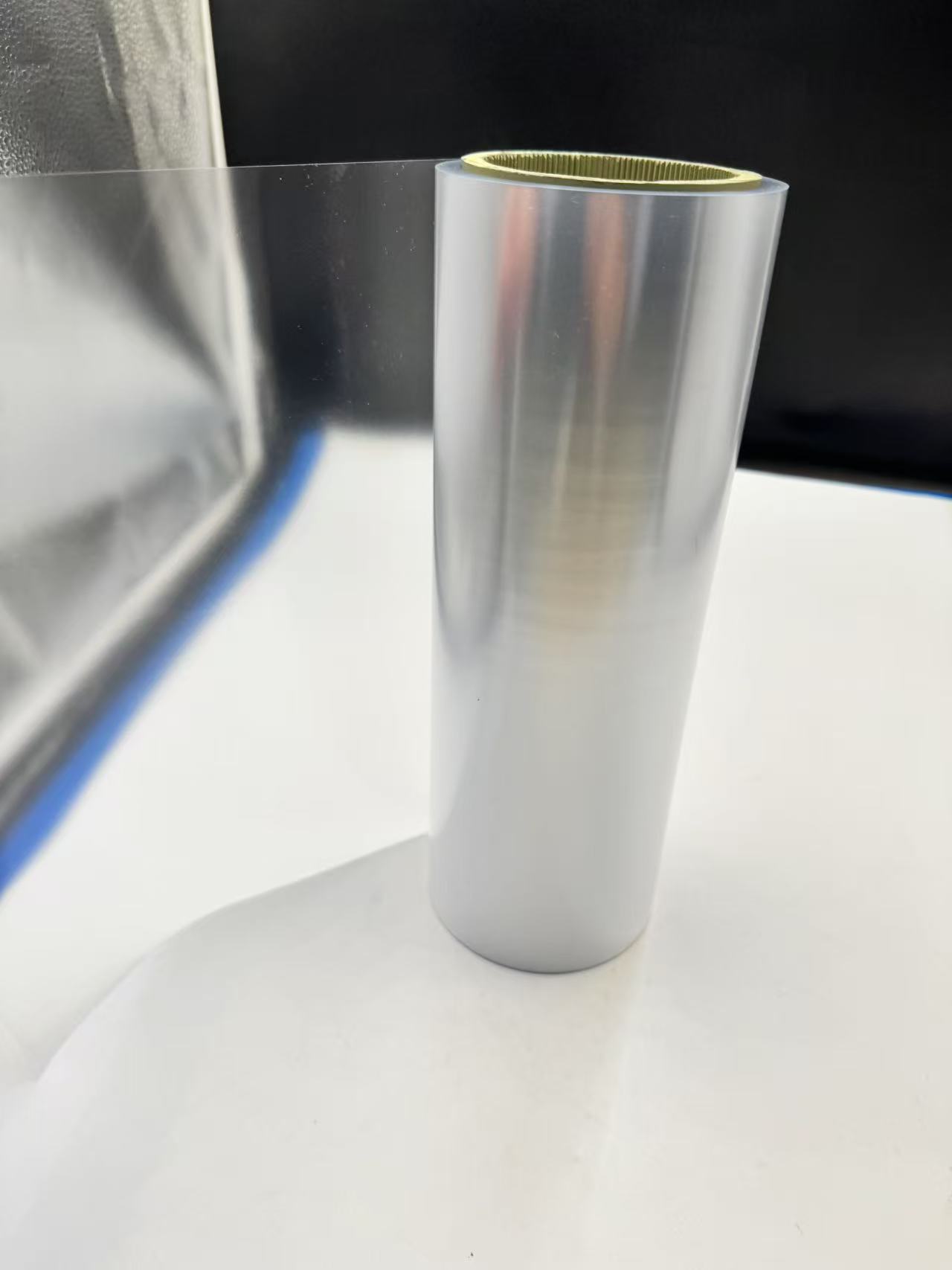

Transparent PVC laminated film, a versatile and widely used material in the packaging industry, combines the inherent strengths of polyvinyl chloride (PVC) with advanced lamination technologies to create a robust, adaptable, and cost-effective solution. Known for its clarity, durability, and excellent barrier properties, this material has become a cornerstone in applications ranging from pharmaceutical packaging to food and industrial uses. By laminating PVC with other materials such as polyethylene (PE), polyvinylidene chloride (PVDC), or aluminum foil, the resulting composite film enhances its functionality, making it suitable for protecting sensitive products from environmental factors like moisture, oxygen, and light. This article explores the characteristics of transparent PVC laminated film and its critical role in pharmaceutical packaging and other industries, supported by technical insights and practical examples. Characteristics of Transparent PVC Laminated FilmClarity and Aesthetic Appeal

this material has become a cornerstone in applications ranging from pharmaceutical packaging to food and industrial uses. By laminating PVC with other materials such as polyethylene (PE), polyvinylidene chloride (PVDC), or aluminum foil, the resulting composite film enhances its functionality, making it suitable for protecting sensitive products from environmental factors like moisture, oxygen, and light. This article explores the characteristics of transparent PVC laminated film and its critical role in pharmaceutical packaging and other industries, supported by technical insights and practical examples. Characteristics of Transparent PVC Laminated FilmClarity and Aesthetic Appeal

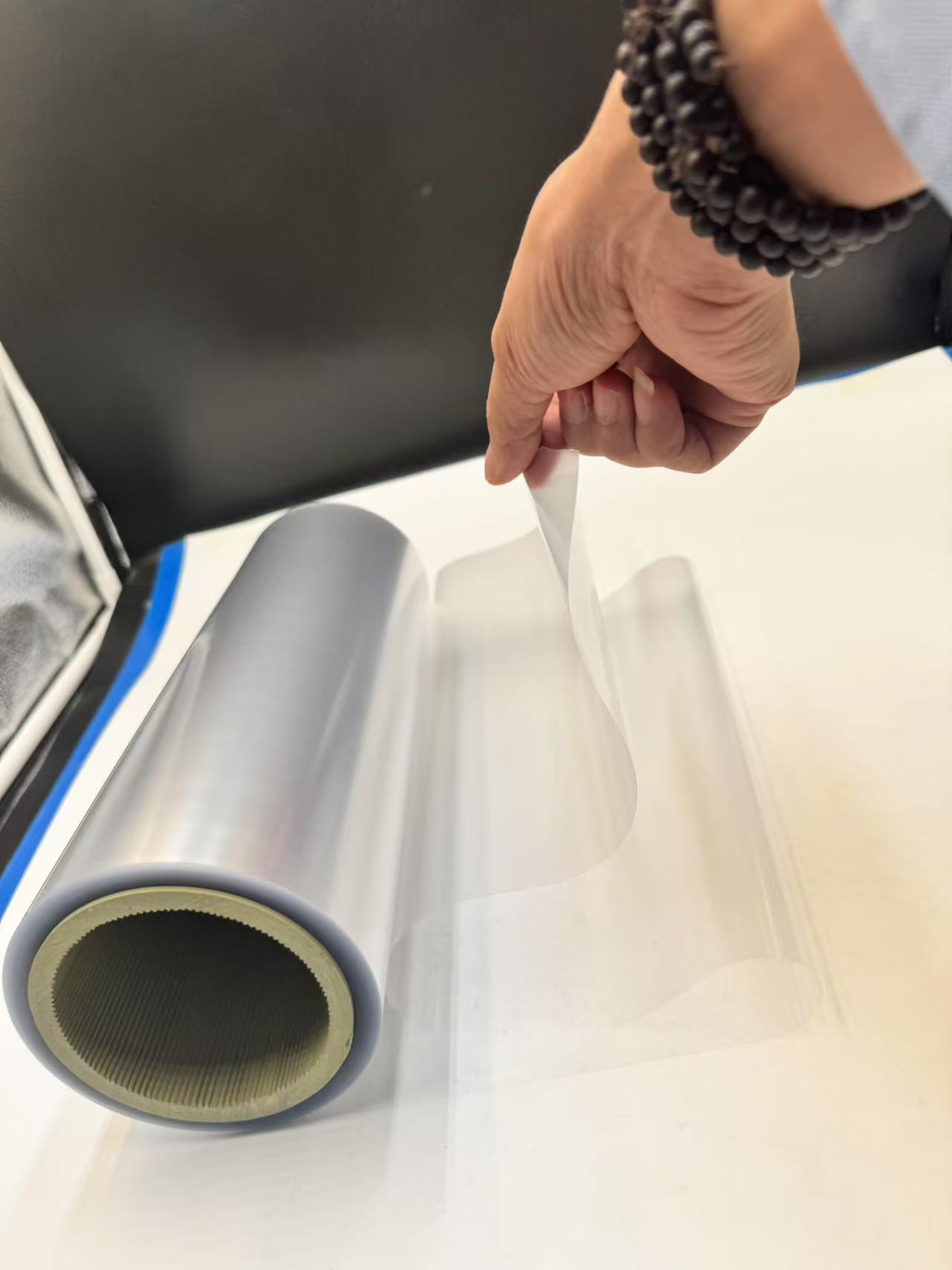

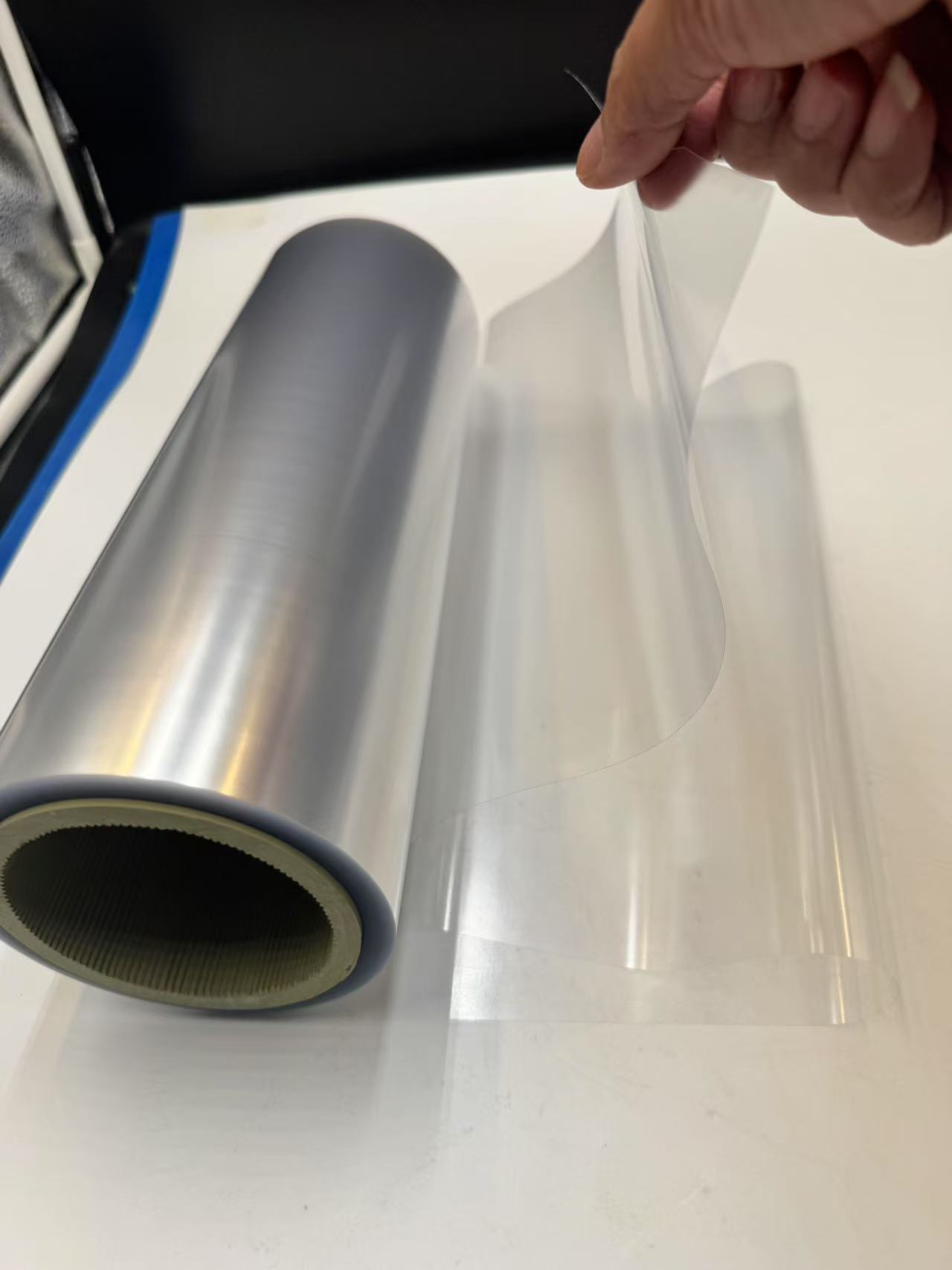

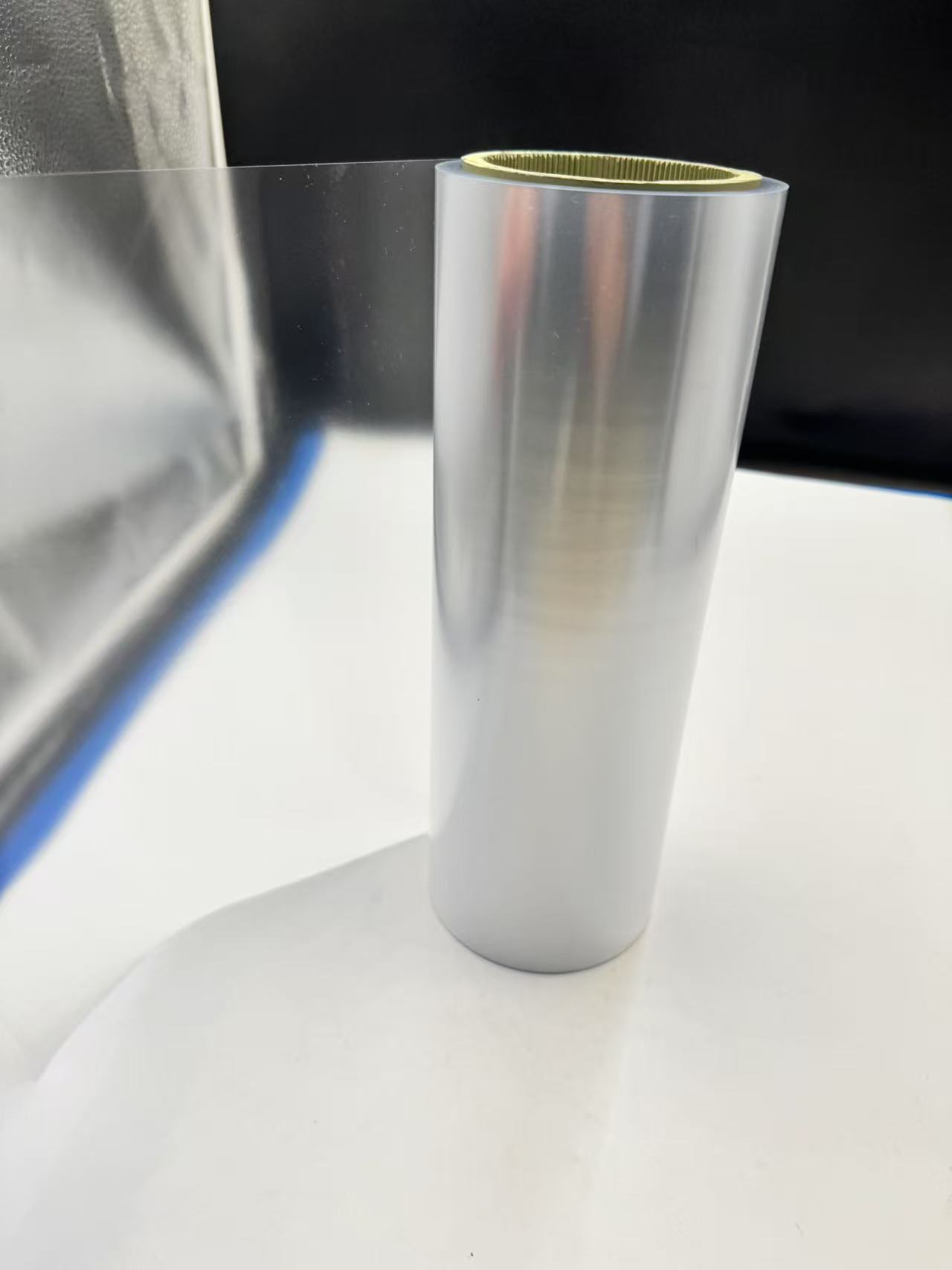

Transparent PVC laminated film is prized for its high transparency, allowing clear visibility of the packaged contents. This clarity is essential in industries like pharmaceuticals, where healthcare professionals and patients need to identify medications easily without opening the package. The glossy finish of the film enhances the visual appeal, making it ideal for retail packaging where product presentation is critical. According to industry standards, transparent PVC laminated films comply with tests like GB/T 2410-1980 for light transmittance and haze, ensuring consistent clarity and gloss ().

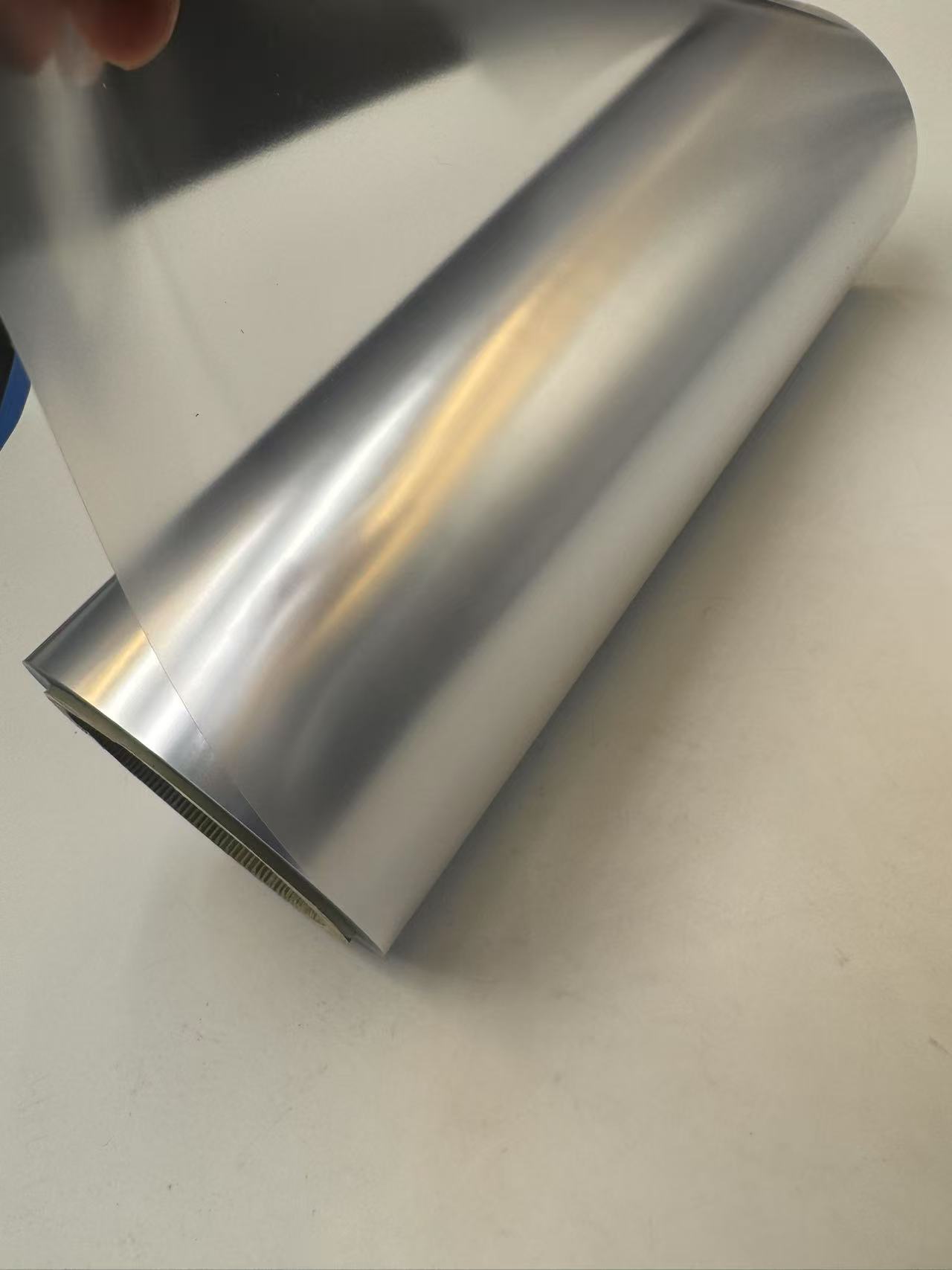

Superior Barrier Properties

The lamination process enhances PVC’s natural resistance to moisture, oxygen, and light. When coated with materials like PVDC or combined with aluminum foil (e.g., OPA/AL/PVC laminated film), the film provides an exceptional barrier against water vapor, gases, and UV light. For instance, PVDC-coated PVC laminated films exhibit low water vapor transmission rates (WVTR) and oxygen transmission rates (OTR), crucial for preserving the stability of moisture- and oxygen-sensitive pharmaceuticals (,). This makes them ideal for blister packaging, where maintaining drug efficacy over extended shelf life is paramount.

Thermoformability and Flexibility

Transparent PVC laminated film is highly flexible and easily thermoformed into complex shapes, such as blister cavities for tablets and capsules. Its ability to conform to various shapes during the thermoforming process ensures precise packaging for individual doses, improving user convenience and compliance. The film’s gradual formability under heat makes it compatible with standard blister packing machines, both flatbed and rotary, ensuring dimensional stability and ease of processing (,).

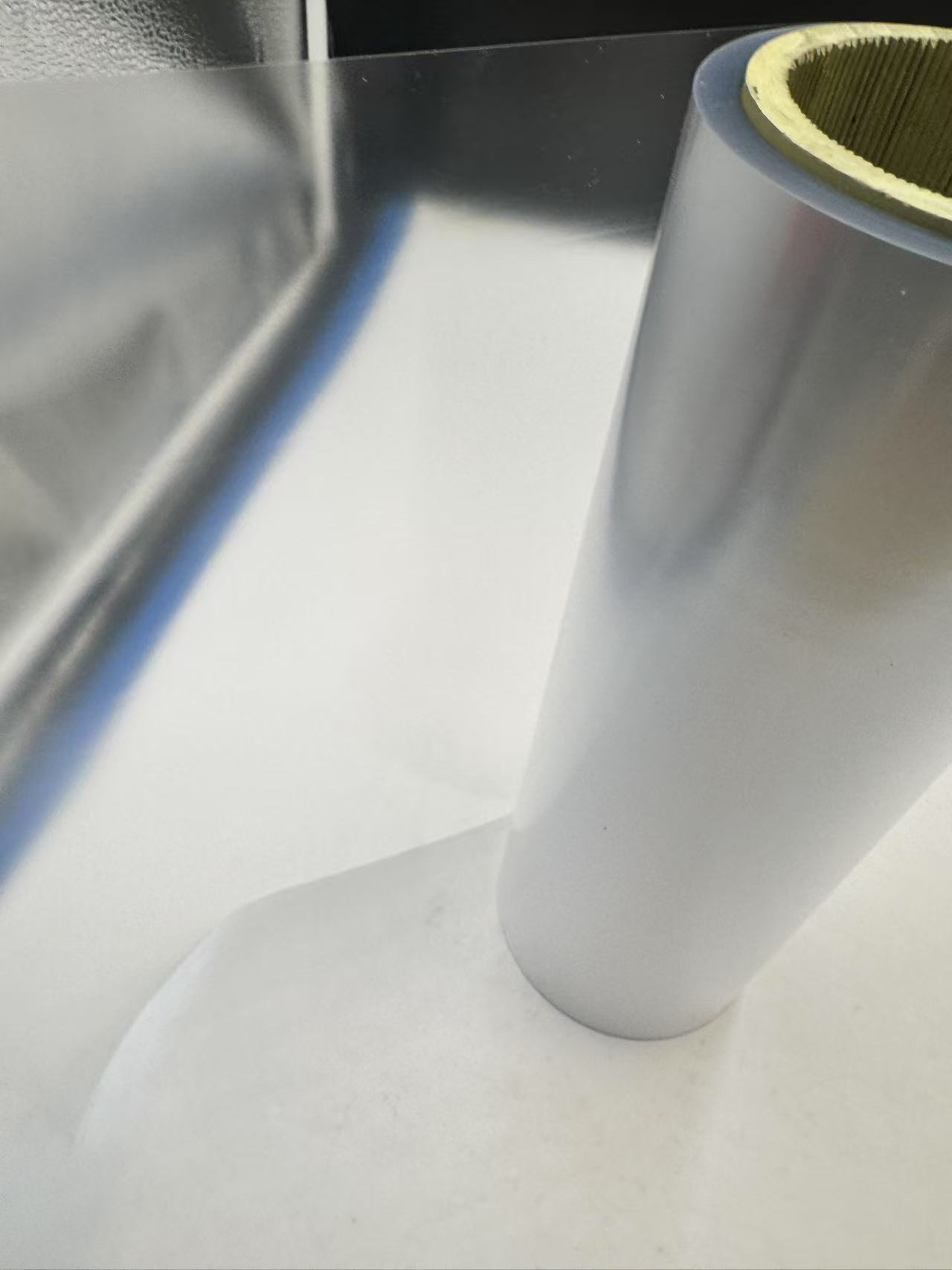

Durability and Chemical Resistance

PVC laminated films are robust, offering resistance to abrasion, impact, and harsh handling conditions during transportation. The addition of layers like PE or PVDC enhances chemical resistance, protecting contents from corrosive substances or environmental degradation. This durability is particularly valuable in pharmaceutical applications, where the film must withstand rigorous handling while maintaining sterility (). Moreover, PVC’s compatibility with sterilization processes, such as radiation sterilization, ensures its suitability for cleanroom environments ().

Cost-Effectiveness and Customizability

Compared to alternatives like glass or metal, transparent PVC laminated film is lightweight and requires less energy for manufacturing and transportation, reducing overall costs. Its versatility allows for customization in thickness (ranging from 0.01 mm to 0.5 mm), color, and coating weight, catering to specific product needs (). The film can also be printed with product information, such as dosage instructions or expiration dates, enhancing functionality without compromising aesthetics ().

Applications of Transparent PVC Laminated Film1. Pharmaceutical PackagingTransparent PVC laminated film is a cornerstone of pharmaceutical packaging, particularly for blister packs used to store tablets, capsules, and other solid-dose medications. Its excellent barrier properties protect drugs from moisture, oxygen, and light, which can degrade active ingredients or reduce efficacy. For example, PVDC-coated PVC laminated films are widely used for hygroscopic drugs, as they maintain low WVTR to prevent moisture-induced degradation ().

In blister packaging, the film is thermoformed into cavities that hold individual doses, sealed with aluminum foil (PTP lidding foil) to ensure airtight protection. This setup not only extends shelf life but also enhances patient compliance by allowing easy identification of medications through the transparent film. For instance, a 0.25 mm thick PVDC-coated PVC laminated film with a 90 g/m² PVDC coating is commonly used for packaging sensitive drugs, meeting stringent standards like YBB00212005 for pharmaceutical blister packaging ().

Beyond tablets, transparent PVC laminated film is used for packaging medical devices, such as syringes and diagnostic kits, where sterility and visibility are critical. Its ability to be sterilized and its resistance to chemical interactions ensure that the packaged products remain uncontaminated (). Additionally, laminated films like PVC/PE/PVDC are used for suppository packaging, offering easy heat-sealing and chemical resistance to protect delicate formulations ().

2. Food PackagingWhile primarily known for pharmaceutical applications, transparent PVC laminated film also plays a significant role in food packaging. Its oxygen and moisture barrier properties help preserve the freshness, aroma, and nutritional value of food products like meat, cheese, and snacks. For example, PVDC-coated PVC laminated films are used for wrapping cheese to prevent moisture loss and maintain flavor (). The film’s clarity allows consumers to inspect the product, while its durability ensures protection during transportation and storage.

The film’s lightweight nature and cost-effectiveness make it a preferred choice over heavier materials like glass, reducing fuel consumption during transport and minimizing waste (). In applications like cling film, PVC laminated films prevent contamination and extend shelf life by providing an effective barrier against germs and environmental factors.

3. Industrial and Consumer Goods PackagingTransparent PVC laminated film is used in industrial applications for packaging electronics, tools, and consumer goods. Its anti-static properties, achieved through specialized coatings or laser perforation, make it suitable for protecting sensitive electronic components from electrostatic discharge (ESD). For instance, trials with Malaysian semiconductor manufacturers showed a 90% reduction in static-related component damage using anti-static PVC laminated films ().

In consumer goods, the film’s flexibility and ability to be laminated with materials like PET or PP make it ideal for creating tamper-resistant seals or clamshell packaging. Its weatherproof and heat-resistant properties also make it suitable for outdoor applications, such as window covers or protective packaging for furniture ().

4. Emerging Trends and InnovationsThe field of transparent PVC laminated film is evolving with advancements in sustainability and functionality. Manufacturers are exploring halogen-free alternatives, such as polypropylene (PP)-based laminated films, to address environmental concerns while maintaining barrier properties (). Additionally, the integration of smart technologies, like RFID tags or NFC sensors, into PVC laminated films is being explored to enhance tracking and patient compliance in pharmaceutical packaging ().

Another promising development is the incorporation of bioactive compounds into the film to provide antimicrobial or antioxidant properties, particularly for food and pharmaceutical applications. Unlike traditional plastic films, biopolymer-laminated PVC films can be engineered to release active compounds, improving product stability and safety ().

Case Studies and Practical ExamplesPharmaceutical Blister Packaging in High-Humidity Environments

In regions with high humidity, such as Southeast Asia, transparent PVC/PVDC laminated films are critical for protecting hygroscopic drugs like antibiotics or vitamins. A pharmaceutical company in Malaysia reported a 30% increase in shelf life for tablets packaged in PVDC-coated PVC laminated films compared to standard PVC films, due to the enhanced moisture barrier (). The film’s clarity allowed healthcare providers to verify the drug’s condition, while its thermoformability ensured precise cavity formation for high-speed blister packing machines.

Sustainable Packaging for Medical Devices

A European medical device manufacturer adopted transparent PVC/PE laminated films for packaging disposable syringes. The film’s sterilizability and chemical resistance ensured compliance with ISO 15378 standards, while its transparency facilitated quality control inspections. By switching to a recyclable PVC-based laminate, the company reduced its environmental footprint without compromising performance ().

ConclusionTransparent PVC laminated film is a versatile, high-performance material that excels in pharmaceutical packaging and beyond. Its clarity, barrier properties, thermoformability, durability, and cost-effectiveness make it indispensable for protecting sensitive products like medications, food, and electronics. As industries demand safer, more sustainable packaging solutions, ongoing innovations in PVC laminated films will continue to drive their adoption. Whether safeguarding life-saving drugs or preserving the freshness of food, transparent PVC laminated film remains a vital tool in modern packaging, blending functionality with practicality in an ever-evolving landscape.