Characteristics and Applications of Transparent High-Temperature PET Film in Diverse Industries

2025-08-19 17:15Transparent high-temperature PET (Polyethylene Terephthalate) film is a high-performance material celebrated for its exceptional thermal stability, clarity, and mechanical strength. Renowned for its ability to withstand elevated temperatures without compromising its structural integrity, transparent high-temperature PET film is a critical component in industries ranging from food packaging to medical sterilization and electrical insulation.  This article explores the distinctive characteristics of transparent high-temperature PET film and its transformative applications, highlighting its role in ensuring product safety, enhancing functionality, and supporting sustainability.Characteristics of Transparent High-Temperature PET FilmTransparent high-temperature PET film is produced by extruding PET resin and subjecting it to biaxial orientation, which aligns the molecular structure to enhance its thermal and mechanical properties. Specialized formulations and additives further improve its ability to withstand temperatures typically ranging from 150°C to 220°C, making it ideal for demanding applications. Below are the key characteristics that define transparent high-temperature PET film:Exceptional Thermal Stability:

This article explores the distinctive characteristics of transparent high-temperature PET film and its transformative applications, highlighting its role in ensuring product safety, enhancing functionality, and supporting sustainability.Characteristics of Transparent High-Temperature PET FilmTransparent high-temperature PET film is produced by extruding PET resin and subjecting it to biaxial orientation, which aligns the molecular structure to enhance its thermal and mechanical properties. Specialized formulations and additives further improve its ability to withstand temperatures typically ranging from 150°C to 220°C, making it ideal for demanding applications. Below are the key characteristics that define transparent high-temperature PET film:Exceptional Thermal Stability:

Unlike standard PET films, high-temperature PET film is engineered to maintain its physical and optical properties under extreme heat. It resists melting, warping, or degradation at temperatures up to 220°C, making it suitable for processes like sterilization, baking, or high-temperature lamination.

Superior Optical Clarity:

Transparent high-temperature PET film offers crystal-clear visibility, allowing products to be showcased without distortion. Its high transparency ensures that packaged items, such as food or medical devices, remain visually appealing, enhancing consumer trust and product marketability.

High Mechanical Strength and Flexibility:

The biaxial orientation process imparts excellent tensile strength and tear resistance to PET film, enabling it to withstand mechanical stress during processing, handling, or transportation. Its flexibility allows it to conform to complex shapes, making it ideal for applications like thermoforming or flexible circuits.

Excellent Barrier Properties:

Transparent high-temperature PET film provides a robust barrier against moisture, gases, and chemicals, protecting sensitive products from environmental degradation. Its low permeability to oxygen and water vapor extends the shelf life of food and pharmaceutical products, ensuring quality and safety.

Chemical and Electrical Resistance:

PET film is chemically inert, resisting interactions with acids, bases, and solvents, which makes it suitable for packaging aggressive substances or medical products. Its dielectric strength and insulation properties also make it a preferred material for electrical and electronic applications.

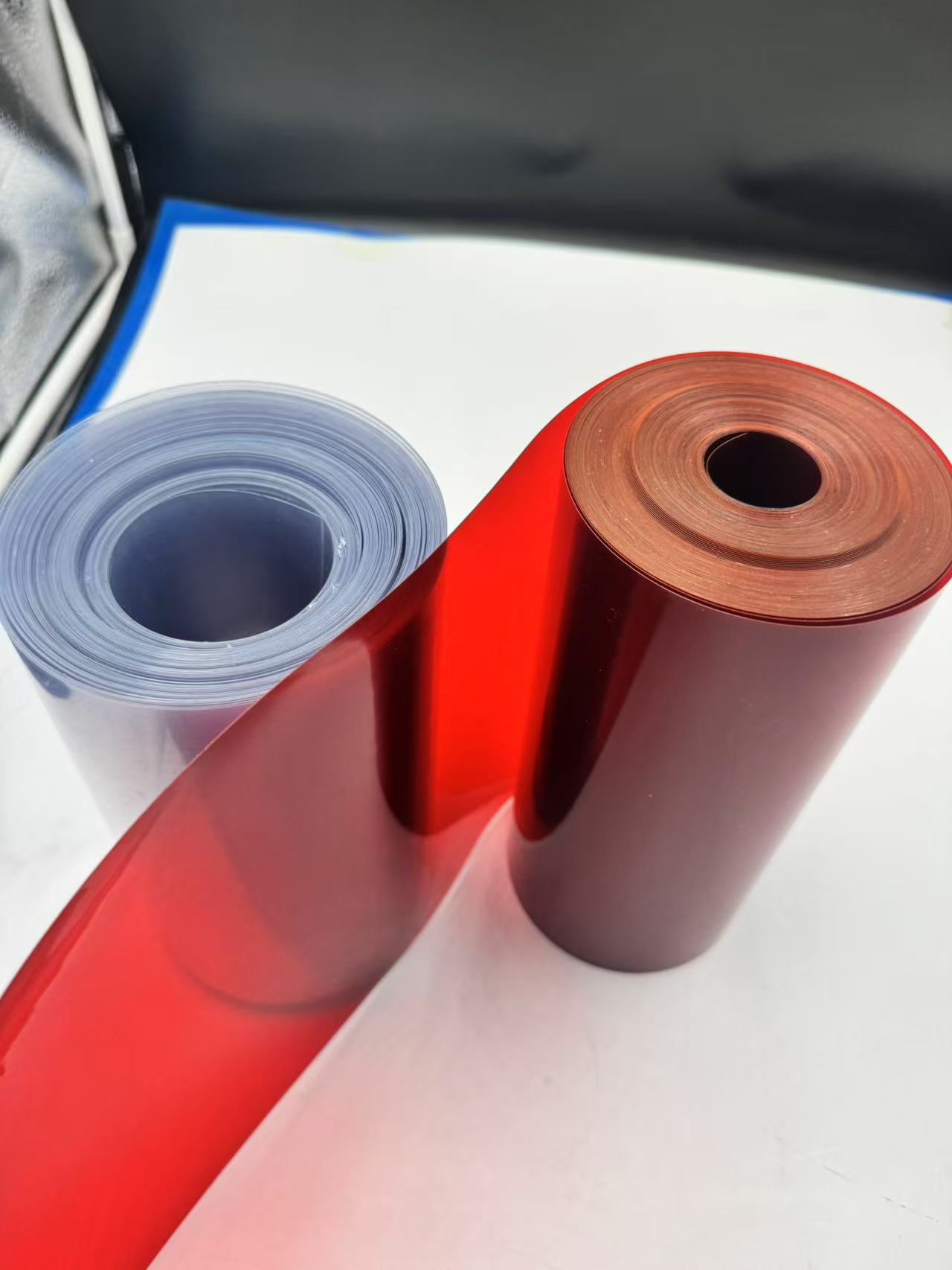

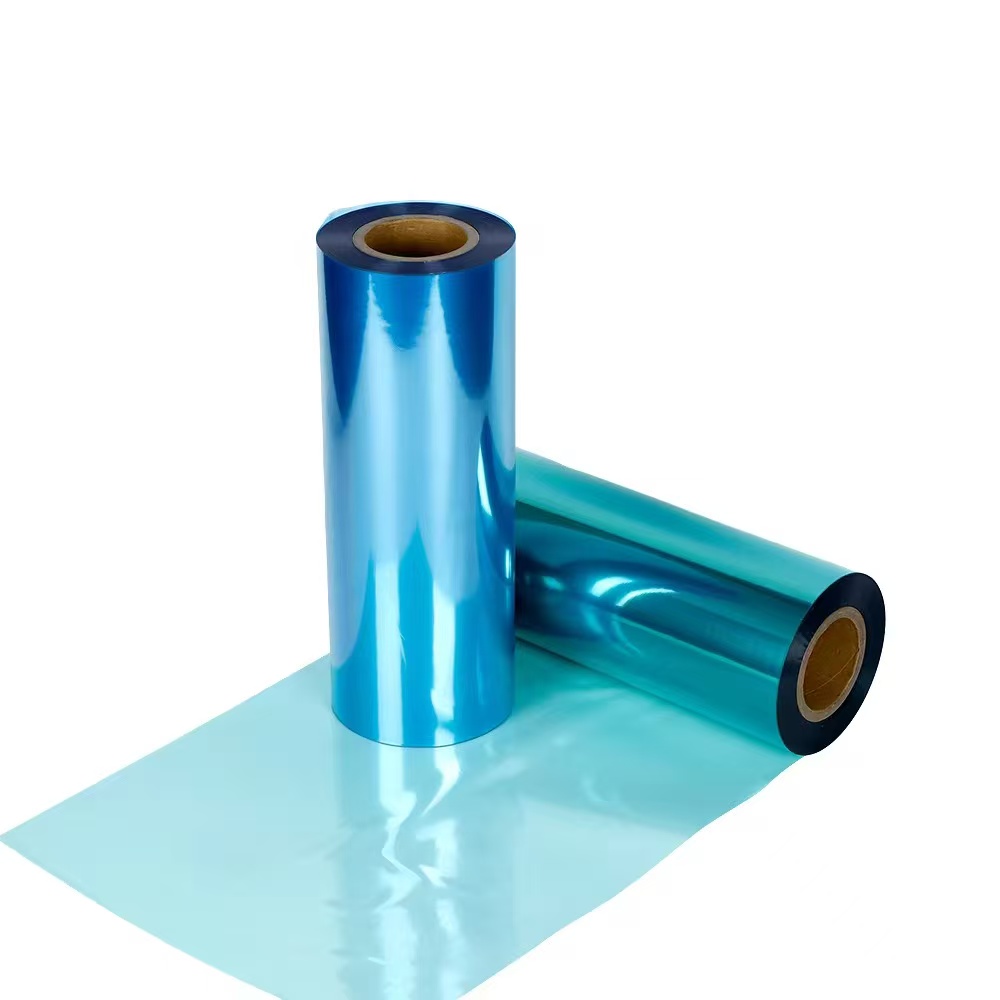

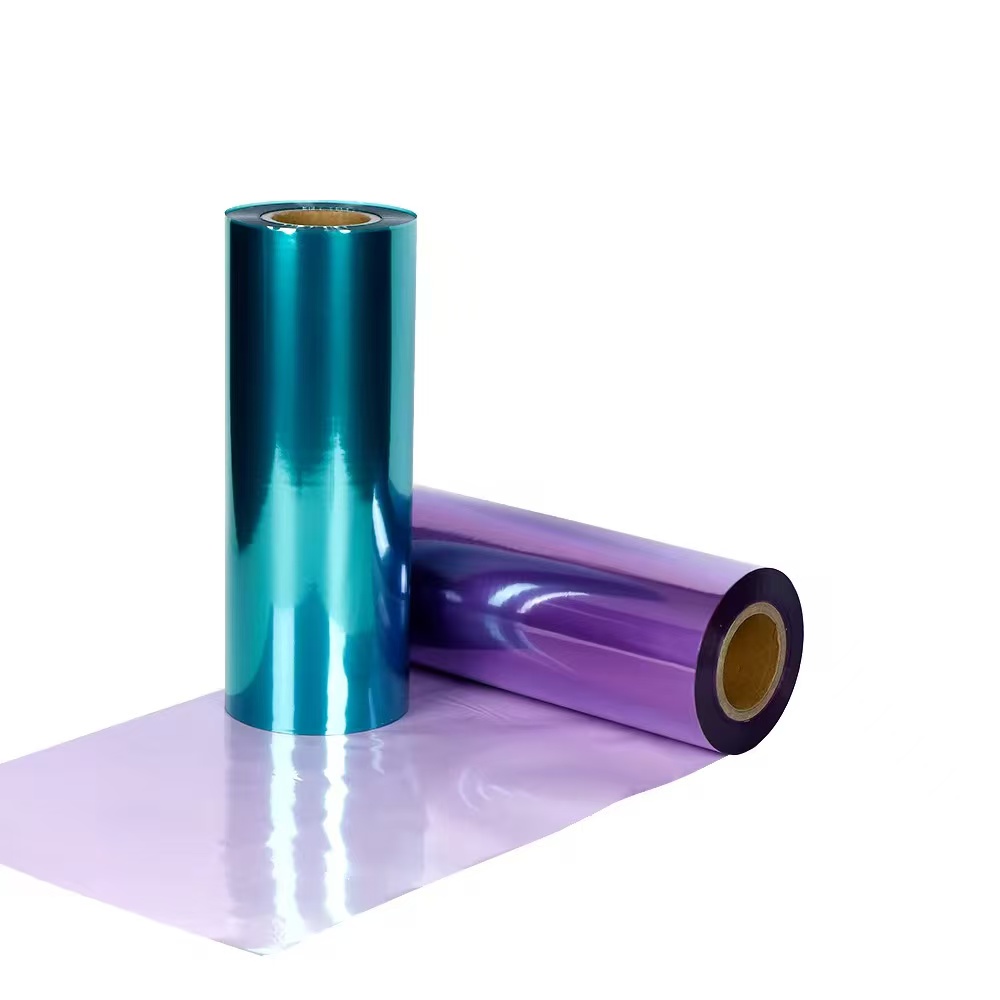

Customizable Thickness and Surface Treatments:

Available in thicknesses ranging from 12 to 350 microns, high-temperature PET film can be tailored to specific needs. Surface treatments, such as corona treatment or coatings, enhance adhesion for printing, lamination, or metallization, expanding its versatility.

Sustainability and Recyclability:

PET film is recyclable, supporting circular economy initiatives and reducing environmental impact. Its lightweight nature also minimizes transportation emissions, making it an eco-friendly choice for manufacturers aiming to meet sustainability goals.

Applications of Transparent High-Temperature PET Film The unique properties of transparent high-temperature PET film make it a preferred material across multiple industries, including food packaging, medical sterilization, electrical insulation, and industrial applications. Below, we explore its key uses in detail, illustrating how PET film enhances product performance, safety, and appeal.

1. Food Packaging for High-Temperature Processes Transparent high-temperature PET film is widely used in food packaging applications that require exposure to elevated temperatures, such as ovenable trays, microwaveable containers, and boil-in-bag packaging. Its ability to withstand temperatures up to 220°C makes it ideal for ready-to-eat meals,  frozen foods, and baked goods that undergo cooking or reheating processes.For example, consider a pre-packaged lasagna sold in a supermarket. Packaged in a transparent high-temperature PET film tray, the meal can go directly from the freezer to the oven without compromising the packaging’s integrity. The film’s clarity allows consumers to see the vibrant layers of pasta, cheese, and sauce, enhancing the product’s appeal. Its excellent barrier properties prevent moisture loss, ensuring the food remains fresh and flavorful during storage and cooking.The film’s chemical inertness ensures that no harmful substances leach into the food, meeting stringent food safety standards such as those set by the FDA and EU regulations. Additionally, its recyclability aligns with consumer demand for sustainable packaging, making it a preferred choice for eco-conscious brands. According to industry reports, the global market for ovenable packaging is expected to grow at a CAGR of 5.2% from 2023 to 2030, with high-temperature PET film playing a pivotal role.

frozen foods, and baked goods that undergo cooking or reheating processes.For example, consider a pre-packaged lasagna sold in a supermarket. Packaged in a transparent high-temperature PET film tray, the meal can go directly from the freezer to the oven without compromising the packaging’s integrity. The film’s clarity allows consumers to see the vibrant layers of pasta, cheese, and sauce, enhancing the product’s appeal. Its excellent barrier properties prevent moisture loss, ensuring the food remains fresh and flavorful during storage and cooking.The film’s chemical inertness ensures that no harmful substances leach into the food, meeting stringent food safety standards such as those set by the FDA and EU regulations. Additionally, its recyclability aligns with consumer demand for sustainable packaging, making it a preferred choice for eco-conscious brands. According to industry reports, the global market for ovenable packaging is expected to grow at a CAGR of 5.2% from 2023 to 2030, with high-temperature PET film playing a pivotal role.