Characteristics and Applications of White PS Film in Packaging and Beyond

2025-08-28 17:13PS film, white packaging, food packaging, industrial applications, thermoforming

White Polystyrene (PS) film, a versatile and widely used material, is celebrated for its lightweight nature, rigidity, and aesthetic appeal. Derived from polystyrene, a thermoplastic polymer, this film is typically processed into thin, flexible sheets or rigid forms, often with a white coloration that enhances its visual and functional properties. Its cost-effectiveness, ease of processing, and adaptability make it a popular choice across industries, particularly in food packaging, industrial applications, and specialty uses. This article explores the defining characteristics of white PS film and its practical applications, supported by evidence and vivid examples to illustrate its significance in modern packaging and beyond.Characteristics of White PS FilmRigidity and Structural Integrity

White PS film is known for its excellent rigidity, particularly in its high-impact polystyrene (HIPS) form, which offers a tensile strength of approximately 20–30 MPa. This structural integrity makes it ideal for applications requiring dimensional stability, such as trays or containers. The film’s stiffness ensures it maintains its shape under moderate stress, providing reliable protection for packaged goods during handling and transport. Its ability to be thermoformed into precise shapes further enhances its utility in creating custom packaging solutions.

Opacity and Aesthetic Appeal

The white coloration of PS film provides a clean, professional appearance, making it a favorite for branding and labeling. The opacity protects light-sensitive products from UV degradation, extending shelf life for items like dairy or pharmaceuticals. The smooth surface of PS film supports high-quality printing, enabling vibrant graphics and clear text for product information or marketing. This aesthetic versatility makes it a go-to choice for applications where visual appeal is as important as functionality.

Lightweight and Cost-Effective

PS film is notably lightweight, reducing material costs and transportation expenses compared to heavier alternatives like glass or metal. Its low density (approximately 1.05 g/cm³) makes it an economical choice for high-volume packaging. The film’s affordability, combined with its ease of processing through extrusion or thermoforming, allows manufacturers to produce large quantities of packaging at a lower cost, making it particularly attractive for budget-conscious industries.

Thermal Formability and Versatility

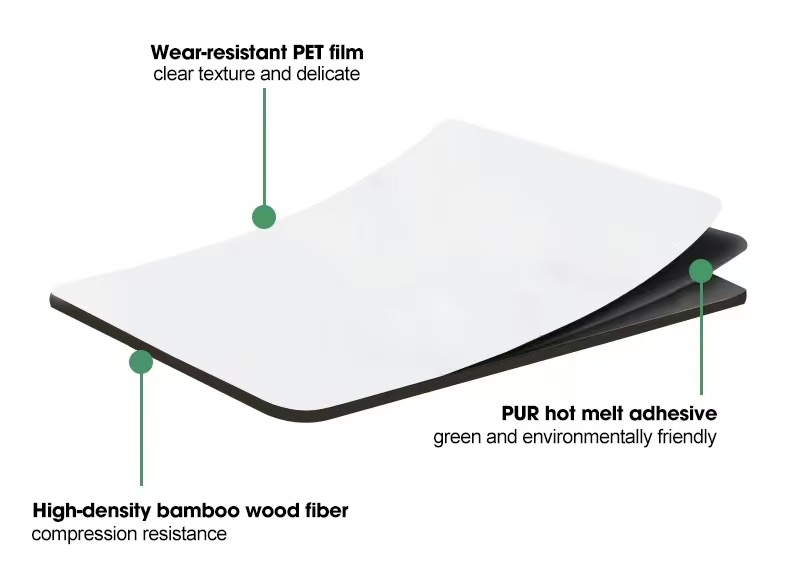

White PS film excels in thermoforming, a process where it is heated and shaped into trays, lids, or containers. Its low melting point (around 240°C) and ability to retain fine details during forming make it ideal for creating intricate packaging designs. This property is especially valuable in food packaging, where PS film is molded into trays for baked goods or clamshell containers for produce. Its versatility also extends to lamination with other materials to enhance barrier properties or strength.

Chemical and Impact Resistance

While PS film is not as chemically resistant as materials like PVC/PVDC, it offers adequate resistance to water, mild acids, and oils, making it suitable for packaging non-aggressive food products. High-impact PS variants improve toughness, reducing the risk of cracking or shattering during handling. For example, HIPS films can withstand drops or impacts better than standard PS, ensuring product safety in retail or industrial settings.

Recyclability and Environmental Considerations

PS film is recyclable, aligning with growing demand for sustainable packaging. However, its recycling rate remains lower than other plastics like PET due to challenges in sorting and processing. Advances in chemical recycling are improving its environmental profile, and its lightweight nature reduces material usage, lowering the overall carbon footprint. Still, concerns about polystyrene’s environmental persistence have prompted research into bio-based alternatives, though PS film remains a staple due to its performance and cost advantages.

Applications of White PS Film1. Food PackagingWhite PS film is a cornerstone in food packaging, particularly for dairy, bakery, and fresh produce, where its rigidity, opacity, and aesthetic properties shine.Dairy Products: Yogurt cups, cream cheese containers, and butter tubs often use white PS film due to its ability to form rigid, lightweight containers. The film’s opacity protects light-sensitive dairy fats from UV degradation, extending shelf life. For instance, a typical yogurt cup made from PS film maintains structural integrity while showcasing vibrant branding through printed labels. Industry data suggests that PS-based yogurt packaging can reduce spoilage rates by up to 20% compared to less protective materials.

Bakery Goods: PS film is thermoformed into trays or clamshells for cakes, pastries, and cookies. Its rigidity ensures baked goods remain intact during transport, while the white color provides a clean backdrop for colorful products. For example, a bakery tray made from PS film can securely hold delicate macarons without crushing them, enhancing presentation on store shelves.

Fresh Produce: Clamshell containers for berries, tomatoes, or salads often utilize white PS film for its formability and lightweight nature. The film’s moderate moisture resistance protects produce from condensation in refrigerated displays, while its opacity shields light-sensitive items like leafy greens.

Takeout and Ready Meals: PS film is used for disposable trays and lids in takeout packaging. Its heat-formability allows for compartmentalized trays that keep food separated, while its affordability makes it ideal for high-volume restaurant use. For instance, fast-food chains like KFC use PS film trays for meal combos, balancing cost and functionality.