News

Transparent Pet film, with its unique properties and versatility, has found extensive applications in various industries. In this article, we will explore the uses of transparent Pet film in different fields at room temperature, including blister jewelry packaging, blister tool packaging, blister pharmaceutical packaging, and insulation boards. Through vivid descriptions and real-life examples, we will showcase the importance and advantages of this remarkable material.

Blister Pharmaceutical Packaging The pharmaceutical industry also relies heavily on transparent PET film for packaging. Similar to food packaging, the transparency of PET film allows for easy inspection of the contents, ensuring the integrity and quality of the medications. PET film provides a barrier against moisture, light, and oxygen, which can degrade the potency of drugs. This is especially important for sensitive medications such as tablets, capsules, and powders.

PLA packaging for cosmetics and skincare products is also in line with the growing trend towards sustainable beauty. Consumers are increasingly looking for products that are packaged in environmentally friendly materials, and PLA film meets this demand. Additionally, PLA can be customized with different colors, prints, and finishes to create unique and eye-catching packaging designs.

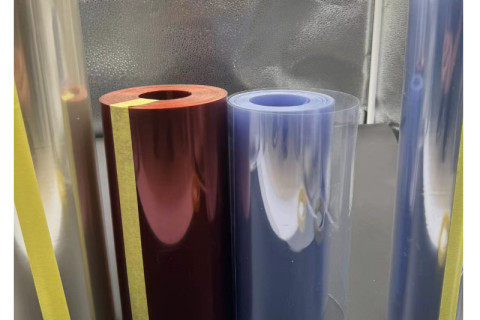

Furniture can also be given a new lease on life with colored PVC film. Old pieces can be refurbished to match the latest decor trends, saving money and reducing waste. PVC film is available in a variety of finishes, including glossy, matte, and textured, adding depth and character to any piece of furniture.

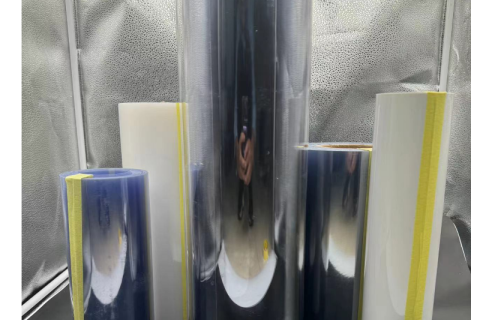

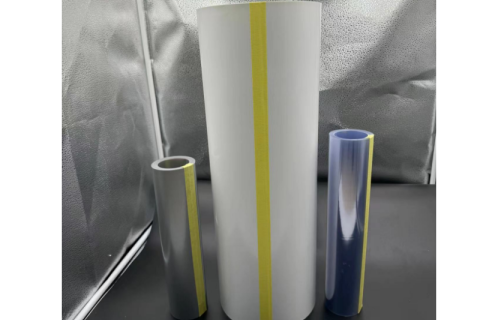

Material Protection Film A. Protecting Surfaces during Transportation and Installation Transparent PVC film is widely used as a material protection film to protect surfaces from scratches, abrasions, and dirt during transportation and installation. Whether it's protecting metal sheets, glass panels, or plastic parts, PVC film provides a temporary yet effective solution. For example, when shipping metal sheets or coils, they are often covered with transparent PVC film to prevent scratches and dents. The film acts as a cushion, absorbing impacts and protecting the surface from damage. Similarly, when installing glass panels or mirrors, PVC film is used to protect the surface from scratches and fingerprints until the installation is complete.

Branding and Marketing High-transparency PETG film can be printed with logos, brand names, and product information, providing an effective way to promote the brand and market the product. For example, a toy manufacturer can use PETG blisters with colorful printing to create an eye-catching packaging that stands out on store shelves. This not only enhances the brand image but also helps to attract the attention of potential customers.

In the medical field, red PVC film also has its applications. It can be used for packaging medical supplies and devices. The material is sterile and can be easily sterilized again if needed. The red color can be used to indicate special instructions or warnings, making it easier for healthcare professionals to identify and handle the packages.

Secondly, white PVC film provides a good barrier against moisture, oxygen, and other contaminants. This helps to extend the shelf life of food products by preventing spoilage and degradation. It keeps the food fresh and flavorful for a longer period, reducing food waste and ensuring consumer satisfaction.

In conclusion, white HIPS film's unique combination of properties, including impact resistance and high internal pressure resistance, has led to its widespread use in a diverse range of fields. From health packaging to electronic insulation, decoration to protection, and construction to manufacturing, this versatile film continues to prove its worth. As technology and innovation progress, it is likely that new and exciting applications for white HIPS film will emerge, further expanding its role in our daily lives.

Transparent PET film is a versatile material with a wide range of applications in different fields. Its unique properties, such as transparency, durability, and barrier properties, make it an ideal choice for many applications. Whether it is used for insulation, packaging, decoration, or healthcare, PET film plays an important role in our lives.