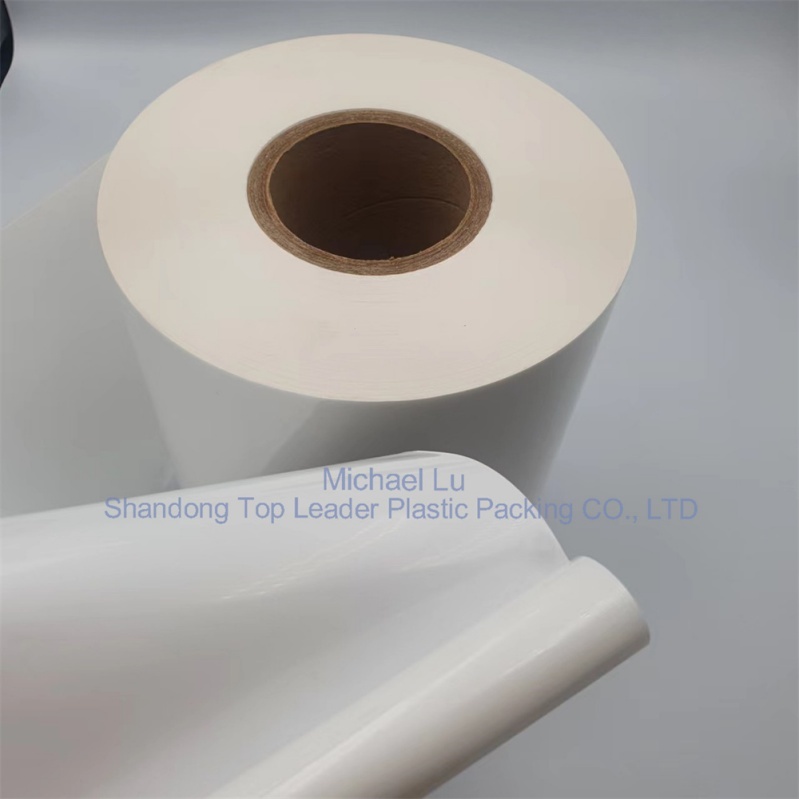

printable PET film, heat-sealable white PET film

White opaque PET top film, printable PET film,

heat-sealable white PET film,

WHITE OPAQUE PET TOP FILM White opaque PET (Polyethylene Terephthalate) films are commonly used in food packaging due to their excellent barrier properties, durability, and aesthetic appeal.

- top leader plastic

- China

- 19 business days

- 1500 tons/month

- Information

ADVANTAGES OF WHITE OPAQUE PET FILM * Barrier Properties: Provides excellent resistance to moisture and gases, which helps preserve the quality and shelf life of packaged goods. * Strength and Durability: Offers superior strength and resistance to tearing and puncturing, ensuring packaging remains intact during handling and transport. * Printability: The surface of white opaque PET film allows for exceptional print quality, making it ideal for detailed and vibrant packaging designs. * Versatility: Its ability to be heat-sealed and printed on makes it suitable for a wide range of packaging applications. White opaque PET films serve as a valuable component in the packaging industry, combining functionality with attractive design possibilities for effective product marketing.

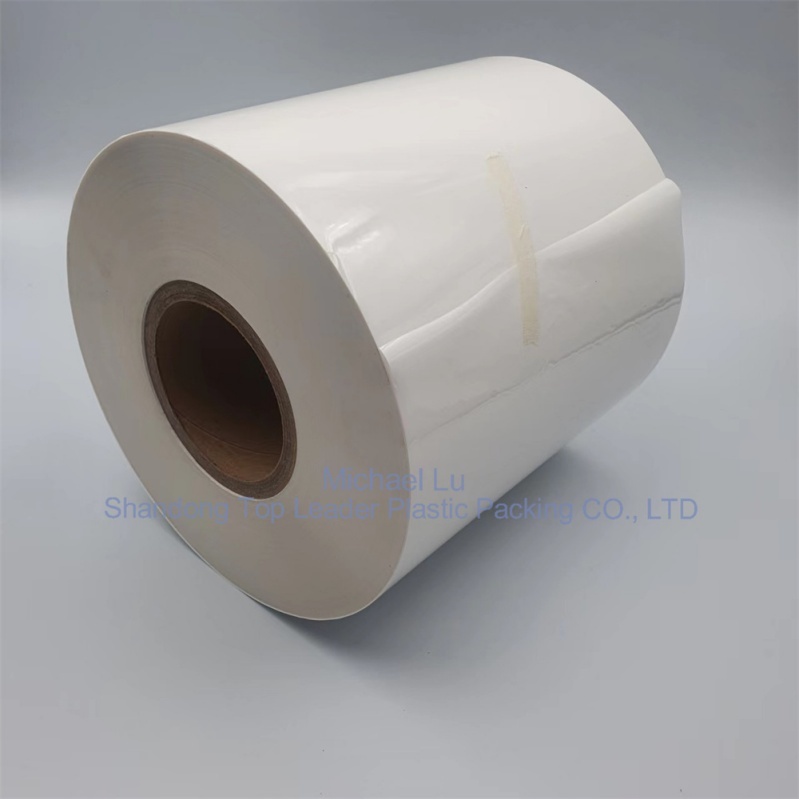

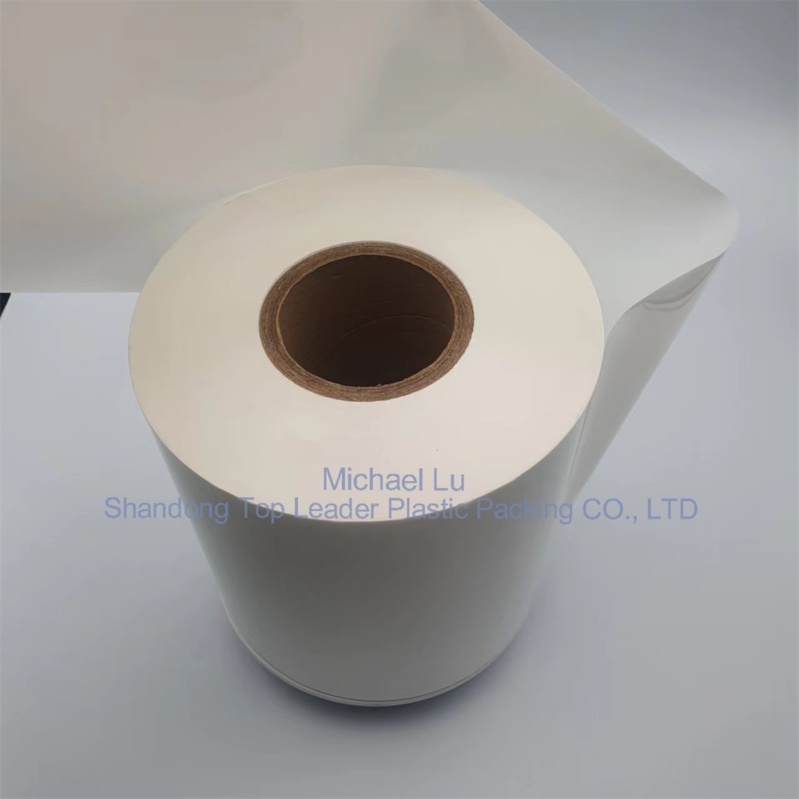

White Opaque PET Top Film, Printable PET Film, Heat-Sealable White PET Film

White Opaque PET Top Film

Features

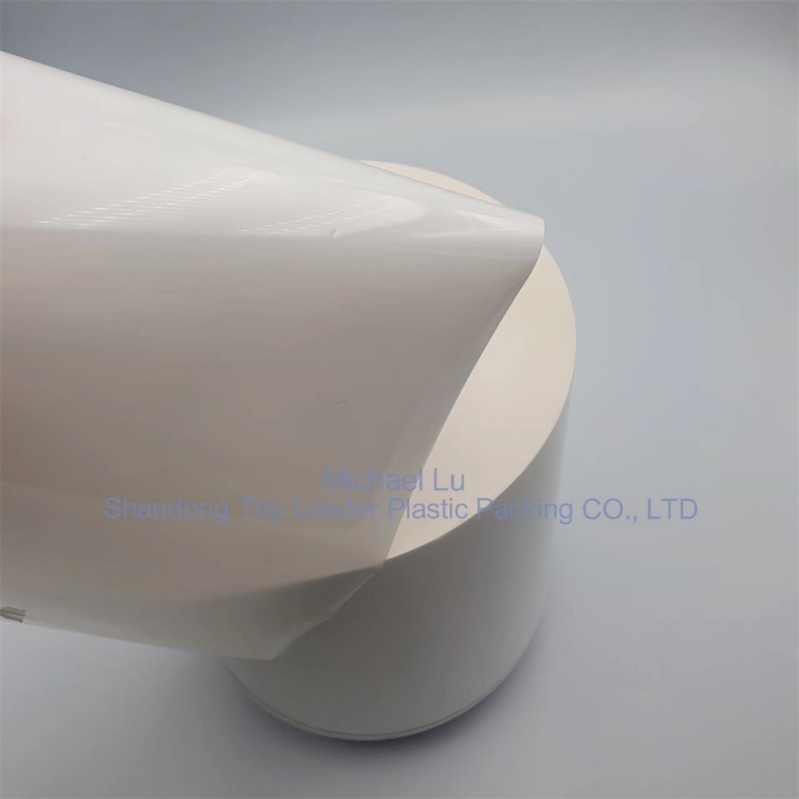

Excellent Light-Blocking Properties: Effectively blocks light, preventing contents from being affected by sunlight. Suitable for packaging light-sensitive products, such as certain pharmaceuticals and cosmetics.

Clean White Appearance: Pure, uniform color and a smooth, flat surface create a visually appealing effect, enhancing the overall aesthetics and quality of the product. Commonly used for packaging high-end products.

Excellent Physical Properties: Inheriting the high strength and toughness of PET film, it offers high tensile and impact strength, excellent support, and dimensional stability, effectively protecting contents from damage during transportation and storage.

Applications

Packaging: Widely used in packaging for food, pharmaceuticals, cosmetics, and electronic products, such as pharmaceutical blister packs and cosmetics boxes, protecting the products while enhancing their display.

Solar Energy: As the backing material for solar panels, it provides light-blocking, insulation, and protection for the cells, improving the performance and service life of solar panels. Printable PET Film

Features

Excellent Printability: Special surface treatments, such as corona treatment and coating, impart high surface tension to the film, enabling excellent bonding with various printing inks and coatings, ensuring clarity, color vividness, and adhesion of printed designs.

High Transparency: Transparent printable PET film boasts over 90% transparency, clearly displaying the product inside. Printed designs also stand out, enhancing the product's visual appeal.

Excellent Chemical Resistance: Highly resistant to various chemicals, printed designs are less susceptible to chemical corrosion and contamination, ensuring consistent print quality.

Applications: Label Printing: Suitable for producing labels for various products, such as food, beverage, and daily necessities. A variety of exquisite designs and text can be designed to meet specific needs.

Packaging Printing: Printing on packaging materials such as boxes and bags creates attractive designs that capture consumers' attention, such as electronic product boxes and cosmetics packaging. Heat-sealable PET White Film

Features

Excellent heat-sealability: Through modified PET resin or multi-layer co-extrusion technology, the film possesses excellent heat-seal properties. Under certain temperature, pressure, and time conditions, it can securely seal to itself or other materials to form a sealed packaging container.

Excellent barrier properties: It exhibits excellent barrier properties, effectively blocking the transmission of oxygen, moisture, and odors, extending the shelf life of products and maintaining their quality.

Hygiene and safety: Non-toxic and odorless, it meets food hygiene and pharmaceutical packaging requirements and can be used directly for packaging food, pharmaceuticals, and other products.

Applications

Food packaging: Widely used in packaging a variety of foods, such as biscuits, candies, meat, and seafood, effectively preventing moisture and spoilage, and extending the shelf life of foods.

Within 15-20 days after received payment...more