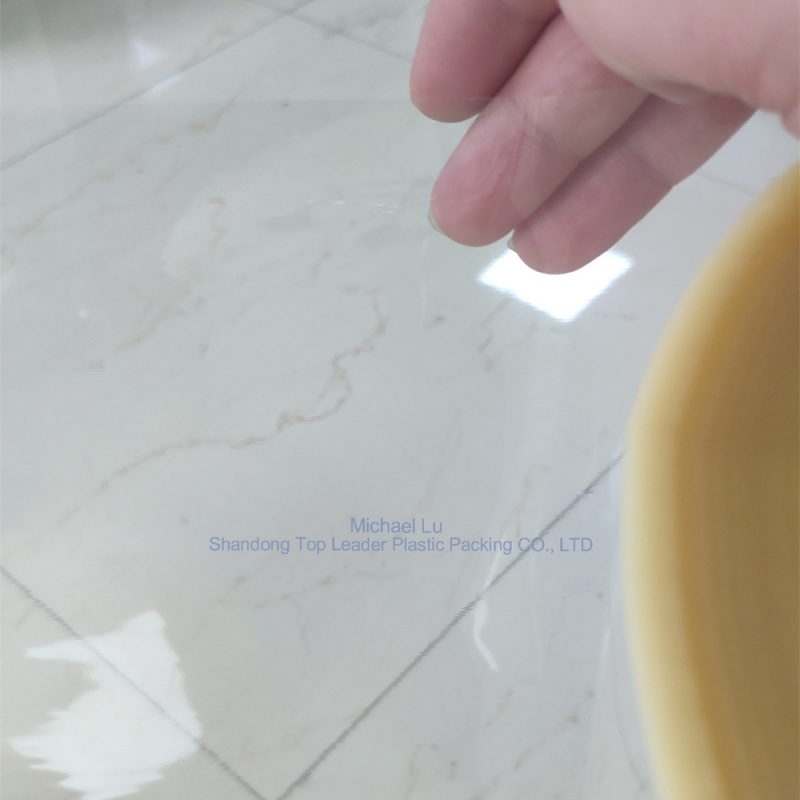

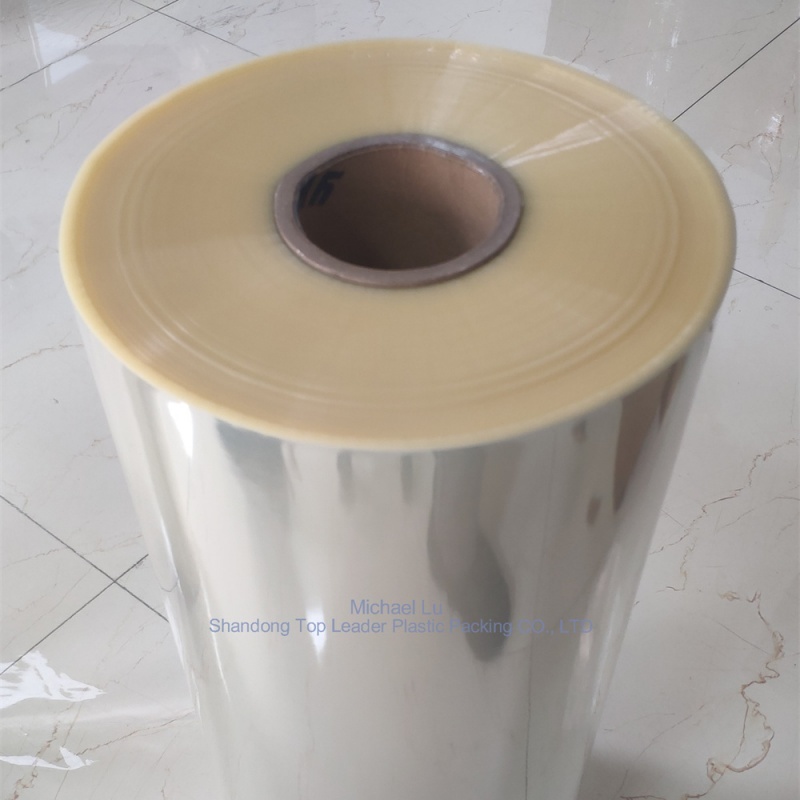

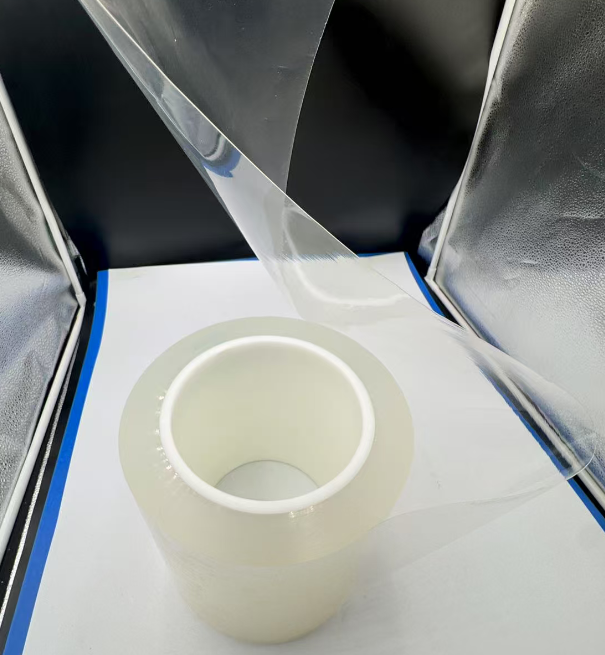

40 microns transparent PVC shrink film

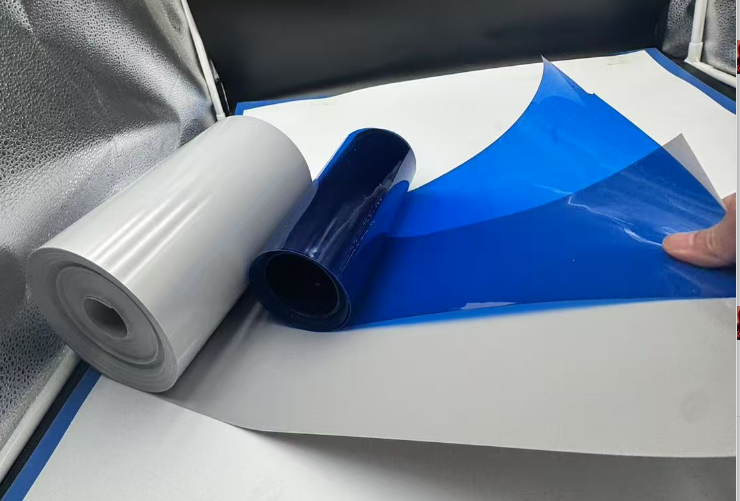

PVC Printable heat shrink film,

blown film, cast film, calendar film

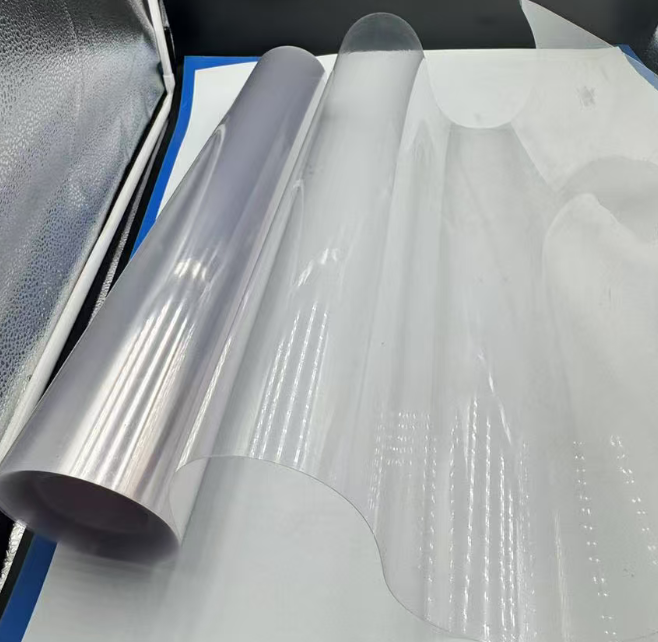

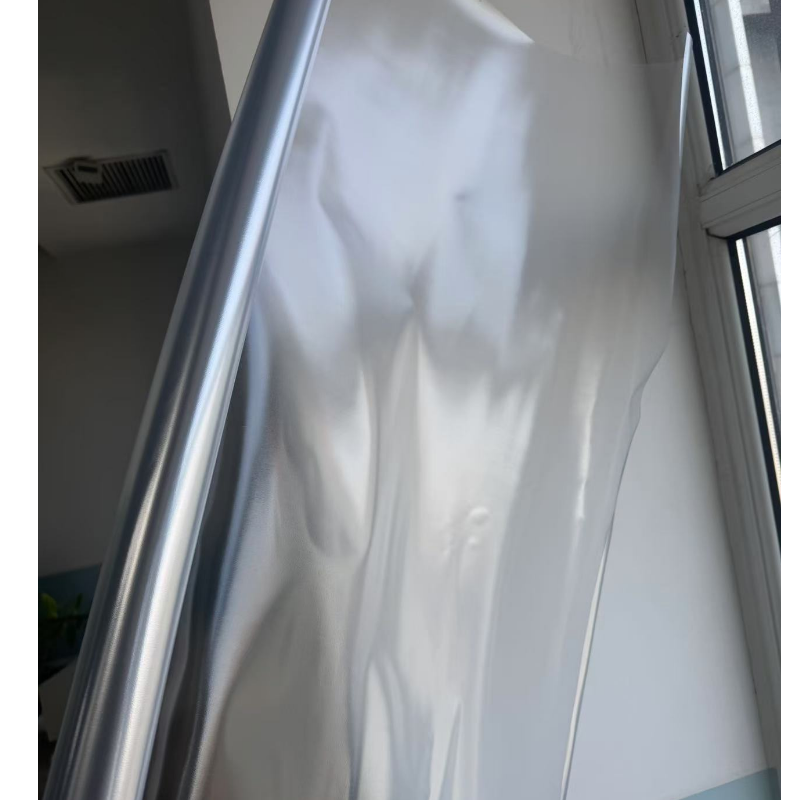

Cast PVC is produced by first dissolving the PVC, plasticizer, and colorant using a solvent. Consequently, a thin film of the liquid mixture will then be poured onto a casting sheet. After that, it will be dried and cured in a series of ovens at a high temperature, producing a flexible film with a smooth finish. The casting sheet determines the texture of the surface of the film.

- top leader plastic

- China

- 15 business days

- 150 tons/month

- Information

Production process

• PVC blown shrink film: produced by the blow molding process, the melted PVC resin is extruded through a circular die to form a tube, and then it is inflated and stretched into a film by air pressure. This process allows the film to have a certain stretch in both the transverse and longitudinal directions, and the molecular chains are oriented.

• PVC cast shrink film: The PVC resin solution or melt is cast onto a smooth surface such as a cooling roller or steel belt using the cast process, and then cooled and solidified to form a film. The film produced by the cast process has good flatness and uniformity4.

Performance characteristics

• PVC blown shrink film

o High transparency: has good optical properties and can clearly display the product in the package.

o Good shrinkage performance: can shrink quickly and evenly when heated, tightly wrap the product, and provide good packaging appearance and protection.

o High strength: has a certain tensile strength and tear resistance, and can withstand a certain external force and friction.

o Good flexibility: soft and elastic, suitable for packaging products of various shapes, especially irregular shaped items.

• PVC cast shrink film

o High transparency: The film surface is smooth and highly transparent, making the contents of the package clear at a glance, which can effectively enhance the visual appeal of the product.

o Uniform shrinkage: The lateral shrinkage rate can be as high as 58% or even higher, and the shrinkage force is uniform, which can make the label and other products fit flat and firmly on the package without wrinkles or bubbles.

o Good printing adaptability: It has strong adhesion to ink and can be printed with high quality. It can clearly and accurately present various patterns, texts and colors to meet the design requirements of brand packaging4.

o Good dimensional stability: During storage and use, it is not easy to change significantly due to changes in ambient temperature and humidity, which ensures the accuracy and consistency of the packaging.

Application areas

• PVC blown shrink film

o Food and beverage packaging: Such as the outer packaging of bottled beverages, canned foods, cakes, etc., which can play a role in moisture-proof, dust-proof, and deterioration-proof, while showing the appearance of the product.

o Daily necessities packaging: used for packaging of daily necessities such as shampoo, shower gel, cosmetics, etc., to protect the products from damage during transportation and storage, and can attract consumers by printing exquisite patterns.

o Electronic product packaging: packaging of electronic products such as mobile phones, tablets, headphones, etc. to prevent scratches and dust pollution, while the transparency of the shrink film allows consumers to see the product directly.

• PVC cast shrink film

o Beverage bottle labels: It is a common material for beverage bottle labels, such as mineral water bottles, carbonated beverage bottles, etc. It can perfectly fit the bottle body, display brand information and product content, and has good water resistance and friction resistance.

o Medical packaging: used for packaging of medicine bottles, medicine boxes, etc., the film is required to have good barrier properties and stability to protect the quality and safety of the medicine.

o Wine packaging: on the packaging of wine bottles, it can not only display the appearance design of the wine bottle, but also play an anti-counterfeiting and protection role, and enhance the grade and added value of wine products.

Within 15-20 days after received payment...more