Black and white polystyrene sheets, thermoforming PS film

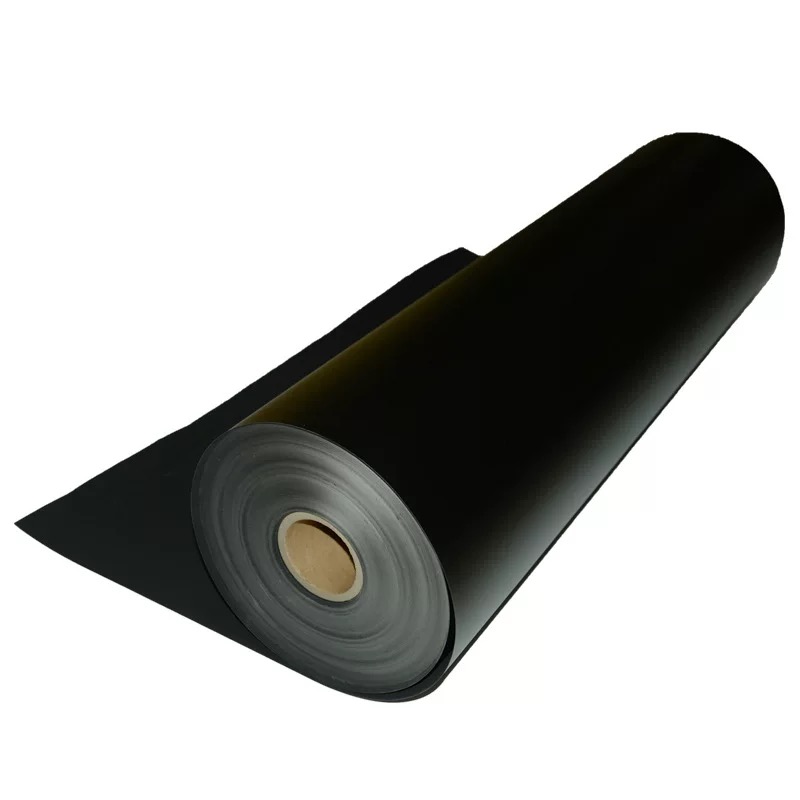

Black and white polystyrene sheets, thermoforming PS rolls

Material Nature: Rigid plastic sheets made from polystyrene (PS) resin with the addition of black/white masterbatch. They are divided into two categories: general purpose (GPPS) and high impact (HIPS).

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

Black/White Polystyrene (PS) Sheets

Material Nature: Rigid plastic sheets made from polystyrene (PS) resin with the addition of black/white masterbatch. They are divided into two categories: general purpose (GPPS) and high impact (HIPS).

Core Characteristics:

Physical Properties: Density 1.04-1.05 g/cm³, thickness range 0.15-6 mm, width customizable to 300-1600 mm;

Processing Advantages: No obvious melting point (melting range 120-180℃), good thermal stability (decomposition temperature > 300℃), excellent flowability during thermoforming, and fast cooling speed;

Color Characteristics: Black version has a light-blocking rate of 99.9%, suitable for light-proof packaging; white version has strong light-blocking properties and good printability, with a smooth, particle-free surface.

2. Thermoforming PS Rolls

Product Positioning: Continuous roll PS material designed specifically for thermoforming/vacuum forming processes, compatible with vacuum forming, pressure forming, and other processing methods. Key Advantages:

* **Molding Efficiency:** Quickly conforms to the mold contour after heating, achieving high fidelity in complex shapes and a short production cycle;

* **Process Adaptability:** Extrusion molding temperature 150-200℃, thermoforming temperature 180-215℃, no pre-drying required (except for special high-transparency requirements);

* **Flexible Specifications:** Thickness 0.3-2.0mm, core diameter 3 inches or 6 inches, custom width and length supported.

3. Food-Grade HIPS Blister Sheets

* **Material Upgrade:** A specialized blister material with high impact resistance and food contact safety, based on PS with added rubber modifiers.

* **Performance Enhancement:** Impact strength up to 35MPa, tensile strength 29MPa, heat distortion temperature 85℃, withstands environments from -20℃ to 80℃;

* **Processing Characteristics:** Easy to print and coat, anti-fog, moisture-proof, leaves no residue after blistering, suitable for direct food contact.

Key Quality Control Points: Appearance: Surface free of particles, bubbles, and scratches; uniform color (black without translucency, white without yellowing); Performance: Thickness tolerance meets standards; no cracking or deformation after thermoforming; Environmental Protection: Prioritize products made from 100% virgin materials and support recycling.

Within 15-20 days after received payment...more