high-impact polystyrene, HIPS, GPPS, yogurt cup materials

Introduction to polystyrene, high-impact polystyrene, HIPS, GPPS, yogurt cup materials and PS food-grade cup lid materials:

Polystyrene (PS)

Classification: Mainly includes ordinary polystyrene (GPPS), high-impact polystyrene (HIPS), expanded polystyrene (EPS) and syndiotactic polystyrene (SPS).

- top leader plastic

- China

- 19 business days

- 1500 tons/month

- Information

Introduction to polystyrene, high-impact polystyrene, HIPS, GPPS, yogurt cup materials and PS food-grade cup lid materials:

Polystyrene (PS)

Classification: Mainly includes ordinary polystyrene (GPPS), high-impact polystyrene (HIPS), expanded polystyrene (EPS) and syndiotactic polystyrene (SPS).

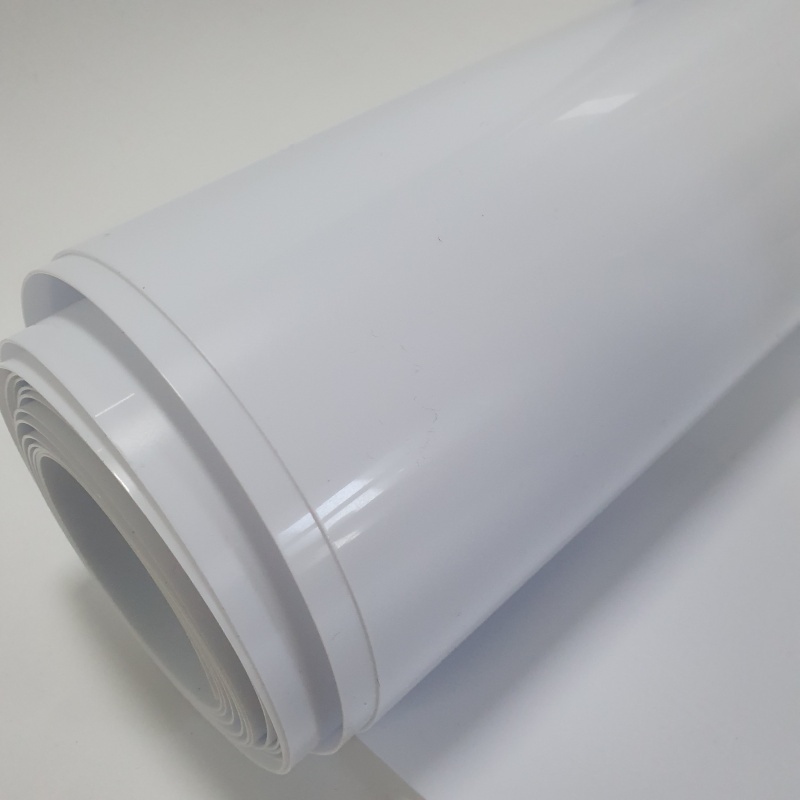

Features: It has excellent optical properties, can transmit visible light of all wavelengths, and has a glass transition temperature higher than 100°. It has good thermal insulation and high resistivity. It is an excellent insulating material, easy to process and shape, and low price.

Uses: It can be used to make disposable tableware, packaging materials, building materials, powder cakes in the cosmetics field, etc. It is a good insulating material and thermal insulation material in terms of electricity.

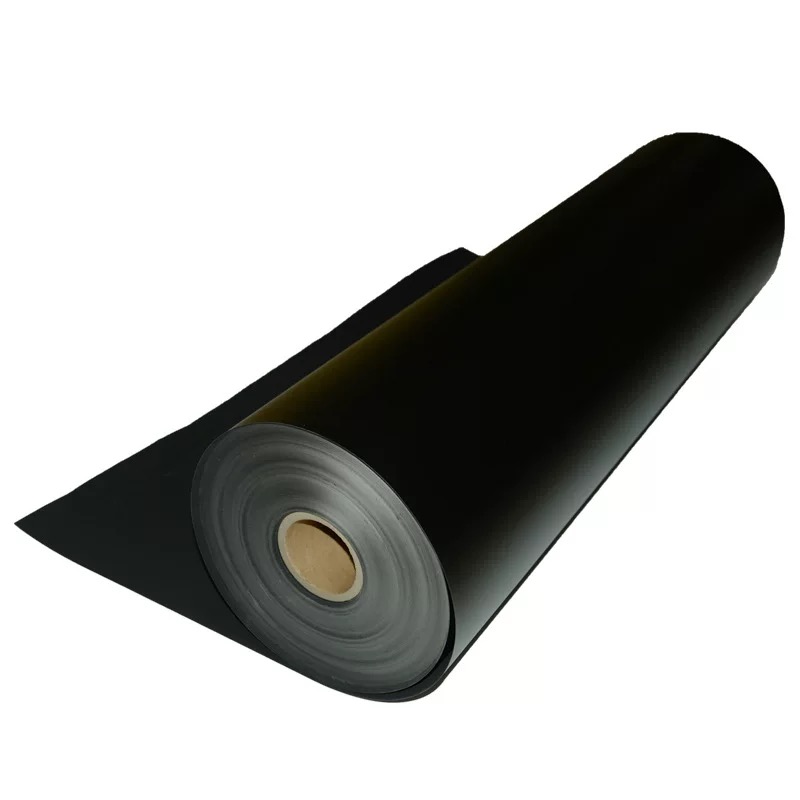

Features: It has good low temperature resistance and can adapt to the refrigerated storage conditions of yogurt; it has good hygienic properties and meets the relevant standards of food contact materials to ensure that it will not have adverse effects on the quality of yogurt; it has good surface gloss and strong printing adaptability, and can be beautifully packaged and printed to enhance the attractiveness of the product.

PS food grade cup lid material

Ingredients: Generally, it is a polystyrene material that has been specially treated and tested, which may be GPPS or HIPS, and must comply with relevant food hygiene and safety standards.

Features: In addition to some of the characteristics of polystyrene itself, it also has good sealing properties, which can effectively prevent the liquid in the cup from overflowing; it has good chemical corrosion resistance and will not react chemically with the ingredients in food; during the processing, it can adapt to various molding processes, such as injection molding, thermoforming, etc., to make cup lids of different shapes and sizes.

Within 15-20 days after received payment...more