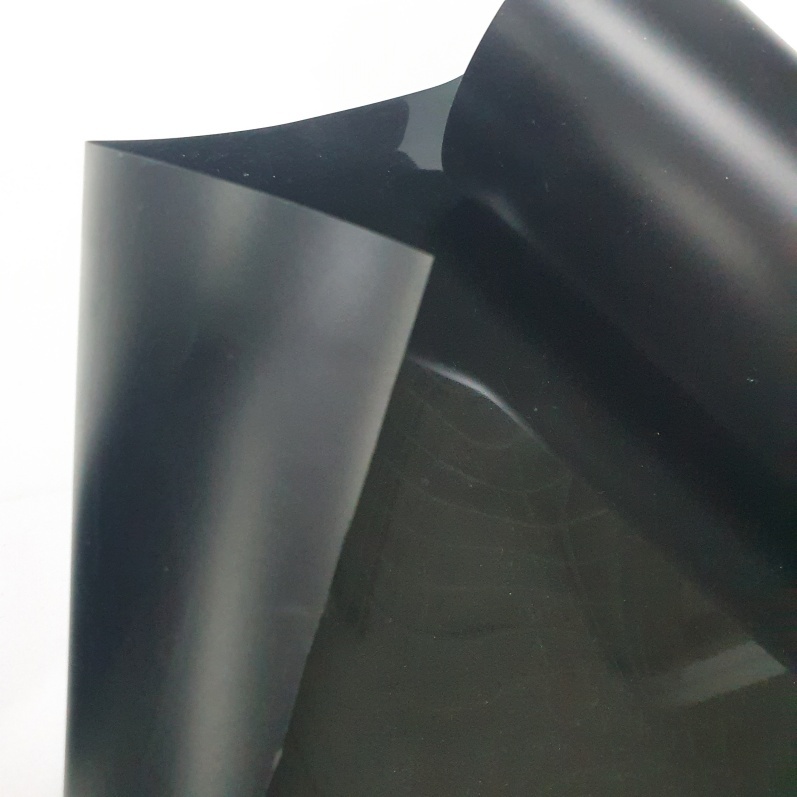

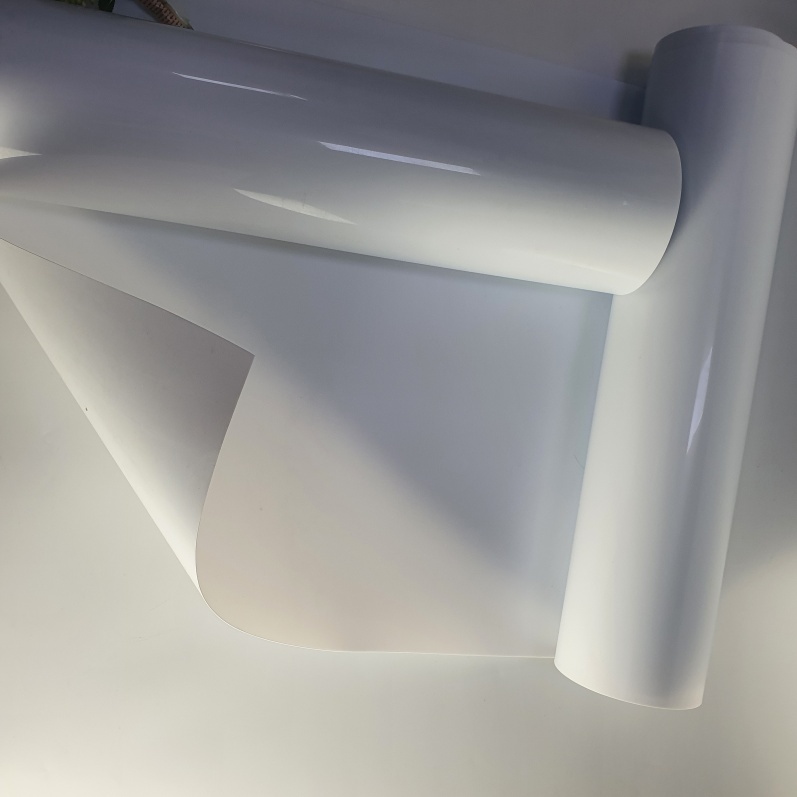

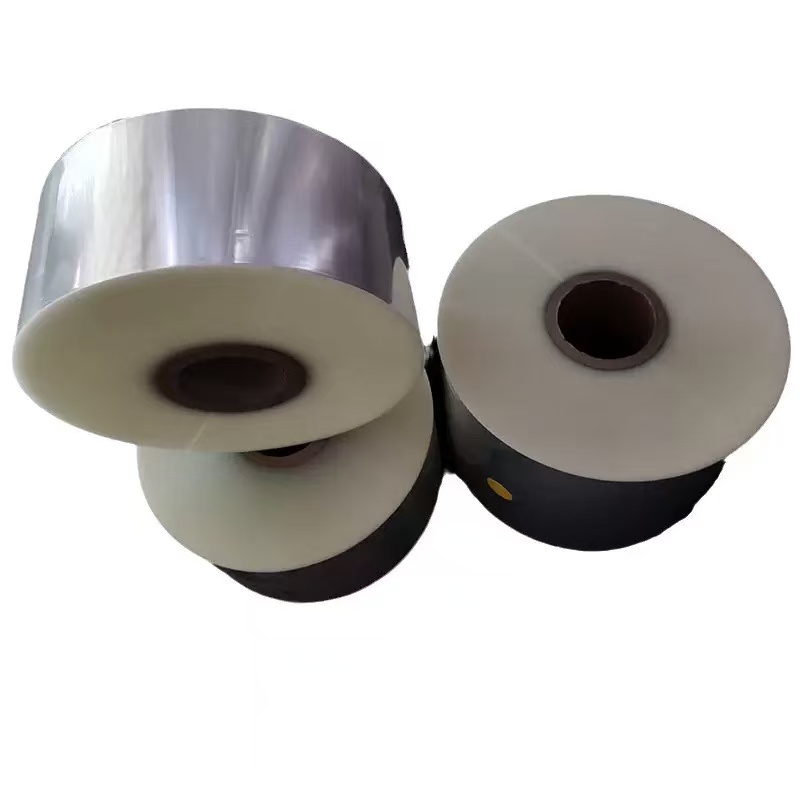

black white opaque pp film polypropylene sheet

black white opaque pp film polypropylene sheet

Excellent light-blocking properties, effectively blocking ultraviolet and visible light to prevent oxidation and spoilage of food due to light exposure, extending shelf life.

- top leader plastic

- China

- 16 business days

- 2000 tons/month

- Information

Food-grade black and white opaque PP film (polypropylene sheet) is a high-performance packaging material widely used in food packaging and other fields. Here is a detailed introduction:

Characteristics:

* **Opacity:** Excellent light-blocking properties, effectively blocking ultraviolet and visible light to prevent oxidation and spoilage of food due to light exposure, extending shelf life.

**Food-grade Safety:** Meets relevant food contact material safety standards and ISO (International Organization for Standardization) standards. The material is non-toxic and odorless, ensuring food safety by preventing contamination.

**Good Physical Properties:** High strength and toughness, good tensile and impact resistance, protecting food from damage during transportation and storage. It is also easy to process and can be made into various packaging forms through heat sealing and folding.

**Chemical Stability:** Good resistance to acids, alkalis, and salts, and does not easily react chemically with food components, maintaining the integrity and stability of the packaging.

**Moisture Resistance:** Provides some moisture resistance, preventing external moisture from entering the packaging and preventing food spoilage due to moisture, maintaining the taste and quality of the food. Application Areas

Food Packaging: Can be used to package various foods, such as meat, dried goods, snacks, and baked goods. For example, it can effectively prevent dried goods like beef jerky and nuts from getting damp and oxidizing; and it can maintain the freshness and taste of baked goods like bread and cakes.

Food Containers: Can be thermoformed into food trays, cups, and other containers, such as fruit trays and fast food boxes commonly found in supermarkets, providing safe and hygienic containers for food.

Production Process: Typically uses extrusion molding. Polypropylene granules are heated and melted, then extruded into films or sheets using an extruder. Subsequent processing, such as cooling, drawing, and cutting, is then performed as needed. During production, different additives can be added to improve the performance of the PP film, such as adding opaque agents to achieve a black and white opaque effect, and adding antistatic agents to prevent dust adsorption.

Refrigerated/Frozen Scenarios (e.g., low-temperature meat products, frozen snacks):

Requires the selection of "low-temperature resistant PP film" to ensure it does not crack in environments ranging from -20℃ to 0℃ (ordinary PP film is prone to hardening and cracking at low temperatures). You can request the supplier to provide a "low-temperature impact test report," or take a sample and freeze it for 24 hours; if it doesn't break when manually bent, it's considered合格 (qualified).

For microwave heating scenarios (such as microwaveable pre-prepared food packaging):

Use "high-temperature resistant PP film" (temperature resistance ≥120℃) and label it "microwaveable" to avoid film softening and the release of harmful substances during heating. Pay special attention to verifying the "heat distortion temperature."

Within 15-20 days after received payment...more