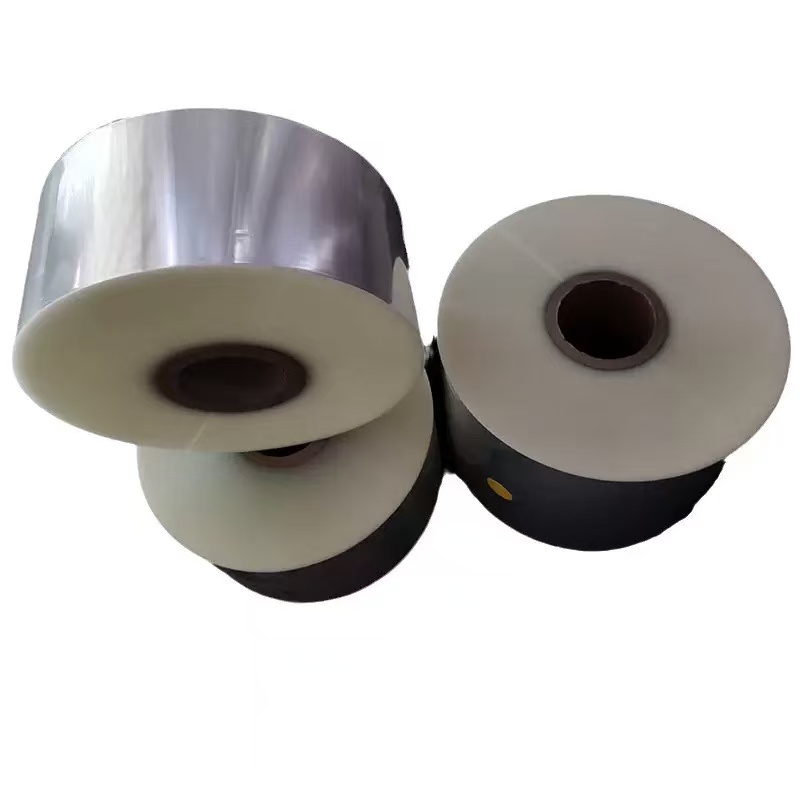

TL-PP-322 THE PP FILMS FOR DRINKING CUPS

In the world of packaging materials, polypropylene (PP) films have emerged as a reliable and versatile solution. With their unique properties and wide range of applications, PP films play a crucial role in various industries, particularly in the production of blister cups. This article explores the diverse uses of PP films in blister cups and other areas, highlighting their advantages and contributions to modern packaging.

- TOPLEADER

- CHINA

- 15WORKING DAYS

- 25000000PC/D

- Information

- Video

- Download

Title: The Versatile Use of PP Films in Blister Cups and Beyond

Introduction

In the world of packaging materials, polypropylene (PP) films have emerged as a reliable and versatile solution. With their unique properties and wide range of applications, PP films play a crucial role in various industries, particularly in the production of blister cups. This article explores the diverse uses of PP films in blister cups and other areas, highlighting their advantages and contributions to modern packaging.

I. Properties of PP Films

PP films are known for their excellent mechanical properties. They are highly durable, with good tensile strength and tear resistance. This makes them suitable for packaging applications that require robustness and protection. Additionally, PP films have a low moisture permeability, which helps to keep the contents of the package dry and free from moisture damage.

Another important property of PP films is their chemical resistance. They can withstand exposure to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for packaging products that may come into contact with harsh substances during storage or transportation.

PP films also offer good clarity and transparency, allowing the contents of the package to be easily visible. This is particularly important for products that need to be showcased or inspected. Moreover, PP films can be easily printed on, enabling manufacturers to add branding, product information, and decorative elements to the packaging.

II. Use of PP Films in Blister Cups

A. Protection and Presentation

Blister cups are widely used in the packaging of various products, such as pharmaceuticals, cosmetics, electronics, and small consumer goods. PP films play a crucial role in blister packaging by providing protection and an attractive presentation.

The rigid structure of blister cups, combined with the flexibility of PP films, ensures that the contents are securely held in place. The films act as a barrier against dust, moisture, and other contaminants, safeguarding the product's quality and integrity. At the same time, the transparency of PP films allows consumers to see the product clearly, enhancing its visual appeal and increasing the likelihood of purchase.

B. Customization and Branding

PP films offer great flexibility in terms of customization. Manufacturers can choose from a variety of colors, thicknesses, and finishes to create unique blister packaging that stands out on the shelves. Additionally, PP films can be printed with high-quality graphics and logos, enabling effective branding and product promotion.

For example, pharmaceutical companies can use PP films with specific colors and printing to distinguish different types of medications. Cosmetic brands can create eye-catching blister packs with decorative elements to attract consumers. Electronics manufacturers can use PP films with anti-static properties to protect sensitive components during packaging and transportation.

C. Easy Opening and Closure

Many blister cups are designed with easy-opening features, and PP films contribute to this convenience. The films can be easily peeled off or punctured, allowing for quick and hassle-free access to the product. Some blister cups also have reclosable features, where the PP film can be resealed to keep the product fresh and protected.

This ease of opening and closure is not only convenient for consumers but also helps to reduce waste. Instead of having to discard the entire packaging, consumers can reuse the blister cup or reseal it for future use.

III. Other Applications of PP Films

A. Food Packaging

PP films are widely used in food packaging due to their excellent barrier properties and food safety compliance. They are suitable for packaging a variety of food products, including snacks, fruits, vegetables, and frozen foods.

For snacks, PP films can be used to create individual portion packs or multipacks. The films keep the snacks fresh and prevent them from getting crushed or stale. In the case of fruits and vegetables, PP films with perforations can be used to create breathable packaging that helps to extend the shelf life of the produce.

For frozen foods, PP films with low-temperature resistance are essential. These films can withstand the extreme cold temperatures of freezers without cracking or losing their integrity. They also provide a good barrier against moisture and oxygen, preventing freezer burn and maintaining the quality of the frozen food.

B. Medical Packaging

In the medical field, PP films are used for packaging sterile medical devices, pharmaceuticals, and laboratory supplies. The films must meet strict regulatory requirements for cleanliness and sterility.

PP films for medical packaging are often treated with anti-static agents to prevent the build-up of static electricity, which can damage sensitive medical devices. They may also be coated with a special layer to provide additional barrier properties against moisture, oxygen, and microorganisms.

Medical blister packs made of PP films are widely used for packaging single-use medical devices such as syringes, needles, and catheters. The blister packs provide a sterile environment for the devices and ensure their safety and efficacy until they are used.

C. Industrial Packaging

PP films are also used in industrial packaging applications, such as packaging of automotive parts, electronics components, and construction materials. The films offer protection against dust, moisture, and mechanical damage during transportation and storage.

For automotive parts, PP films can be used to create custom-sized packaging that fits the shape of the part. This helps to reduce waste and improve packaging efficiency. In the electronics industry, PP films with anti-static properties are used to protect sensitive components from electrostatic discharge.

Construction materials such as pipes, fittings, and insulation materials can be packaged in PP films to protect them from dirt, moisture, and damage during transportation and storage. The films can also be printed with product information and handling instructions for easy identification and use.

IV. Environmental Impact

As concerns about the environment continue to grow, the use of sustainable packaging materials is becoming increasingly important. PP films offer several environmental benefits compared to other packaging materials.

Firstly, PP films are recyclable. They can be collected, sorted, and processed into new products, reducing waste and conserving resources. Additionally, PP films can be made from recycled materials, further reducing the environmental impact.

Secondly, PP films are lightweight, which helps to reduce transportation costs and carbon emissions. The lower weight also means that less energy is required to produce and transport the packaging materials.

Finally, PP films have a long lifespan and can be reused multiple times. This reduces the demand for new packaging materials and helps to minimize waste.

Conclusion

PP films have proven to be a highly versatile and reliable packaging material, with extensive applications in blister cups and other areas. Their excellent mechanical properties, chemical resistance, clarity, and printability make them ideal for a wide range of products. Whether it's protecting pharmaceuticals, enhancing the presentation of cosmetics, or packaging food and industrial products, PP films offer a combination of functionality and aesthetics.

Moreover, PP films also have a positive environmental impact, being recyclable, lightweight, and reusable. As the demand for sustainable packaging continues to grow, PP films are likely to play an even more important role in the future. With ongoing research and development, we can expect to see further improvements in the properties and applications of PP films, making them an even more valuable packaging solution.

Within 15-20 days after received payment...more