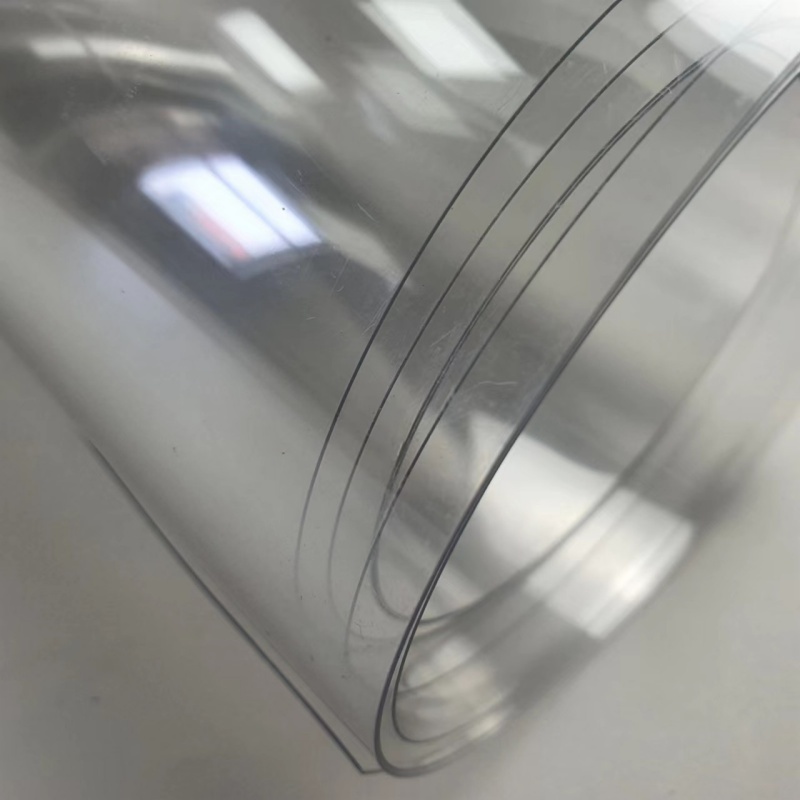

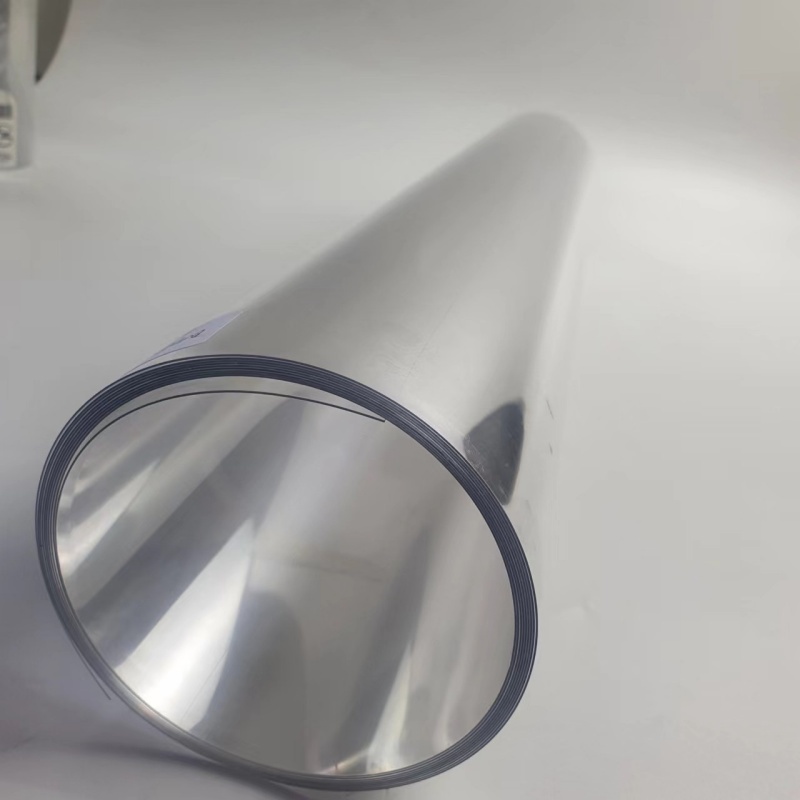

Built-in silicone oil APET coil

Features of APET coils, blister sheets and 0.6mm RPET transparent sheets with built-in silicone oil

Good demoulding performance: The built-in silicone oil reduces the friction between the coil and the mold during the blister processing, making demoulding easier, effectively improving production efficiency and reducing product damage or deformation caused by demoulding difficulties.

- top leader plastic

- China

- 10-15 working days

- 1900 tons/month

- Information

Features of APET coils, blister sheets and 0.6mm RPET transparent sheets with built-in silicone oil

Built-in silicone oil APET coil.

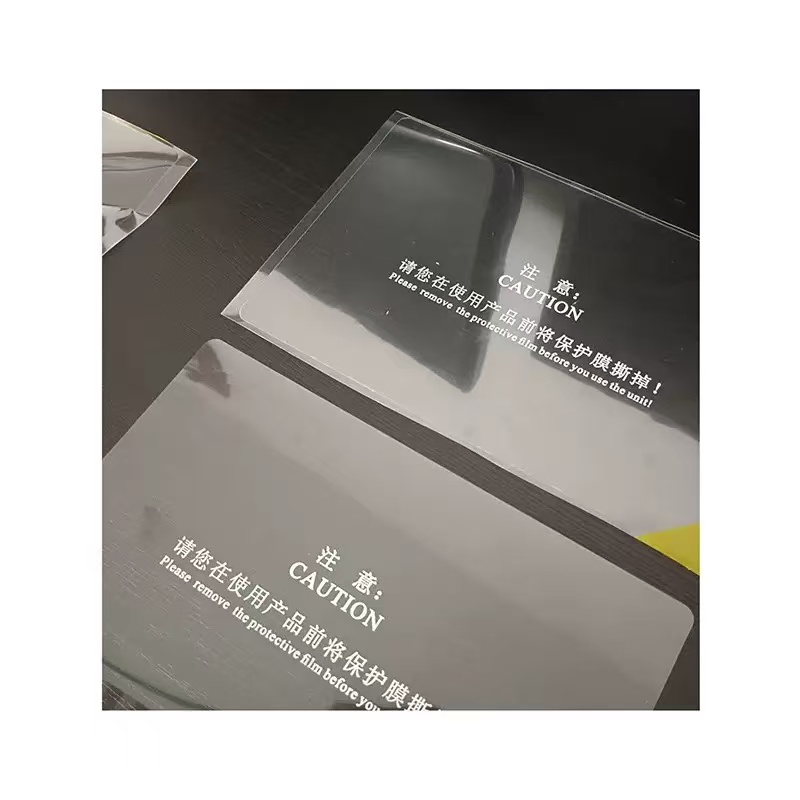

0.6mm RPET FILM can be recycled, easy to release the mold, the finished product is not sticky

High transparency: APET itself has high transparency, which can clearly display the products in the package and enhance the display effect of the products. It is suitable for product packaging with high requirements for appearance display, such as cosmetics, electronic products, etc.

Excellent mechanical properties: It has high strength and toughness, good impact resistance, and can better protect the product during transportation and storage, and is not prone to cracking or damage.

Strong chemical stability: It has strong resistance to oil and grease and chemicals, is not easily corroded by chemicals, and can be used to package products containing oil or chemicals.

Environmental protection: APET materials can be recycled, meet environmental protection requirements, and reduce pollution to the environment.

Application areas: It is widely used in packaging in food, cosmetics, medicine, electronics and other industries. Such as chocolate, candy, biscuits and other packaging in food packaging; lipstick, eye shadow, cream and other packaging in cosmetic packaging; drug blister packaging in medical packaging; tray packaging of electronic products in the electronics industry, etc.

Blister sheet

Definition and production process: Blister sheet is a plastic sheet that is softened by heating, and then adhered to the mold surface by vacuum adsorption or pressure molding, and then cooled to form various shapes of plastic products. Common blister sheets include APET, PETG, PVC and other materials.

Features

Strong plasticity: Various complex shapes and sizes can be made according to different mold shapes to meet the packaging needs of different products, such as special-shaped packaging, three-dimensional packaging, etc.

High transparency: Most blister sheets have good transparency, which allows consumers to see the product intuitively and enhances the attractiveness of the product.

Good protection performance: It can fix the product in a specific position to prevent the product from being damaged by collision, extrusion, etc. during transportation and storage, and play a good protective role.

Easy to process: The blister molding process is relatively simple, with high production efficiency, and a large number of blister products can be produced quickly.

Application fields: Mainly used in the packaging field, such as trays and blisters in food packaging; toothbrush and toothpaste packaging in daily necessities packaging; toy packaging; stationery packaging, etc. In addition, it can also be used for lining packaging of electronic and electrical products, as well as the production of some display items.

Within 15-20 days after received payment...more