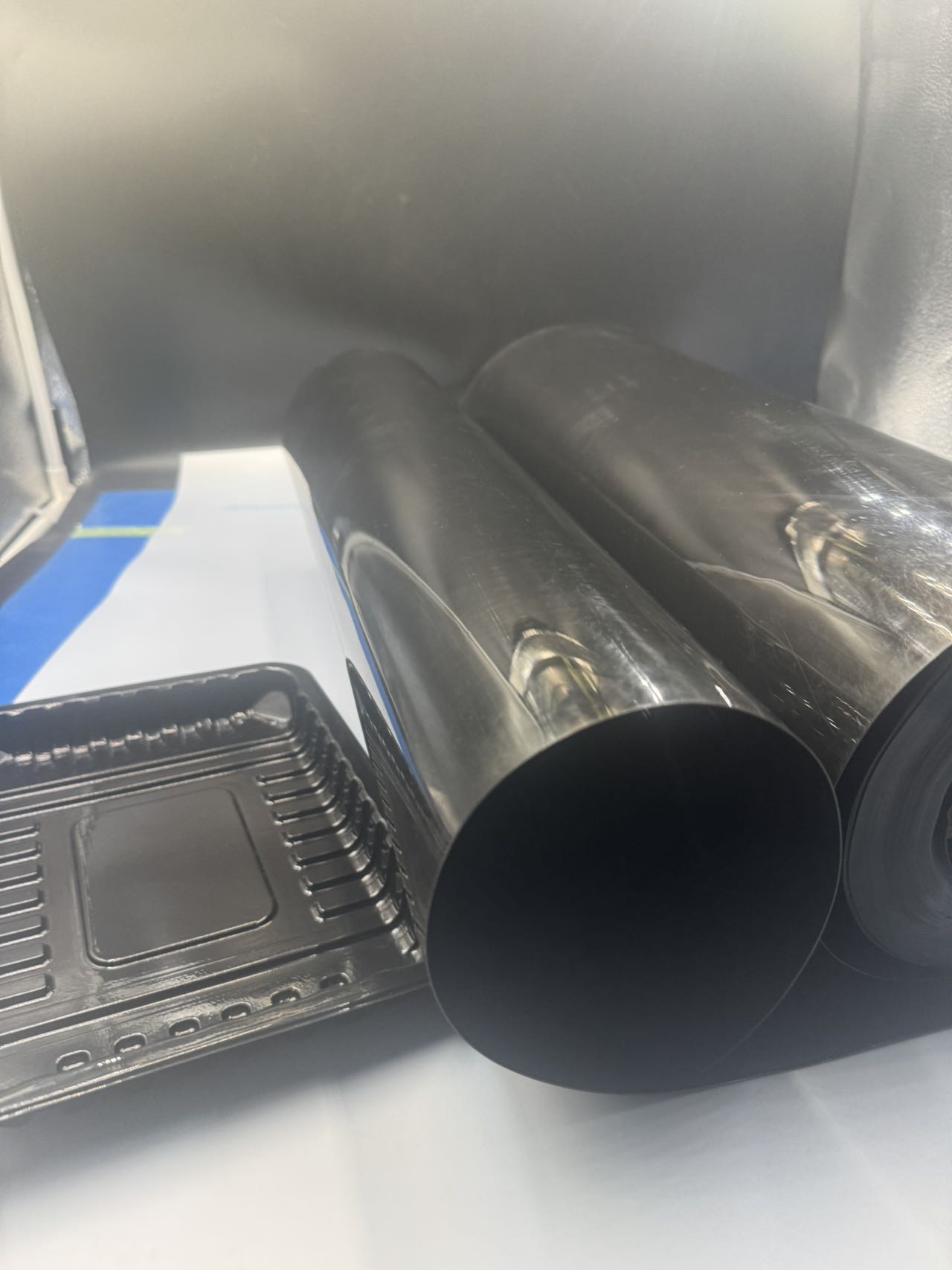

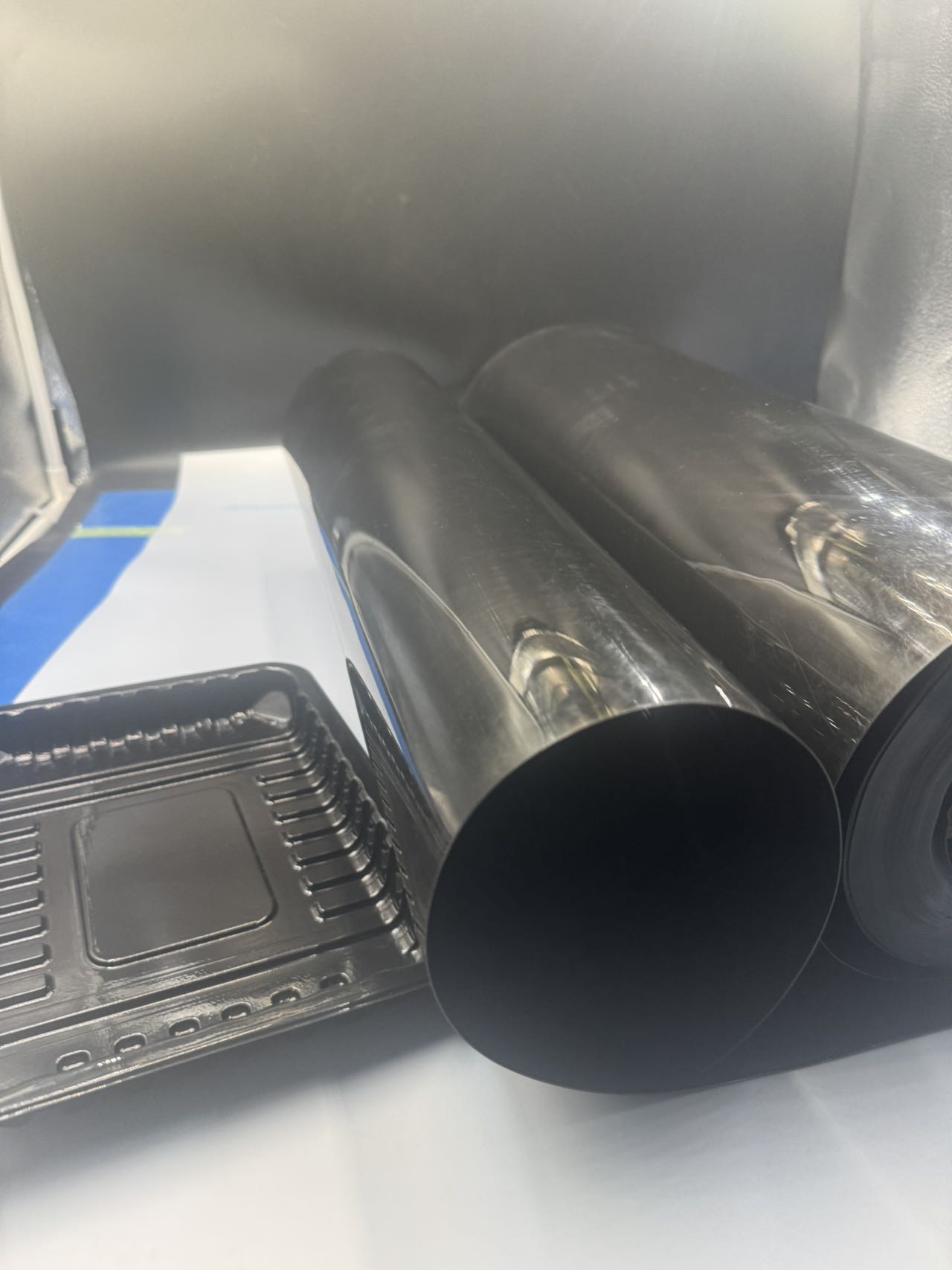

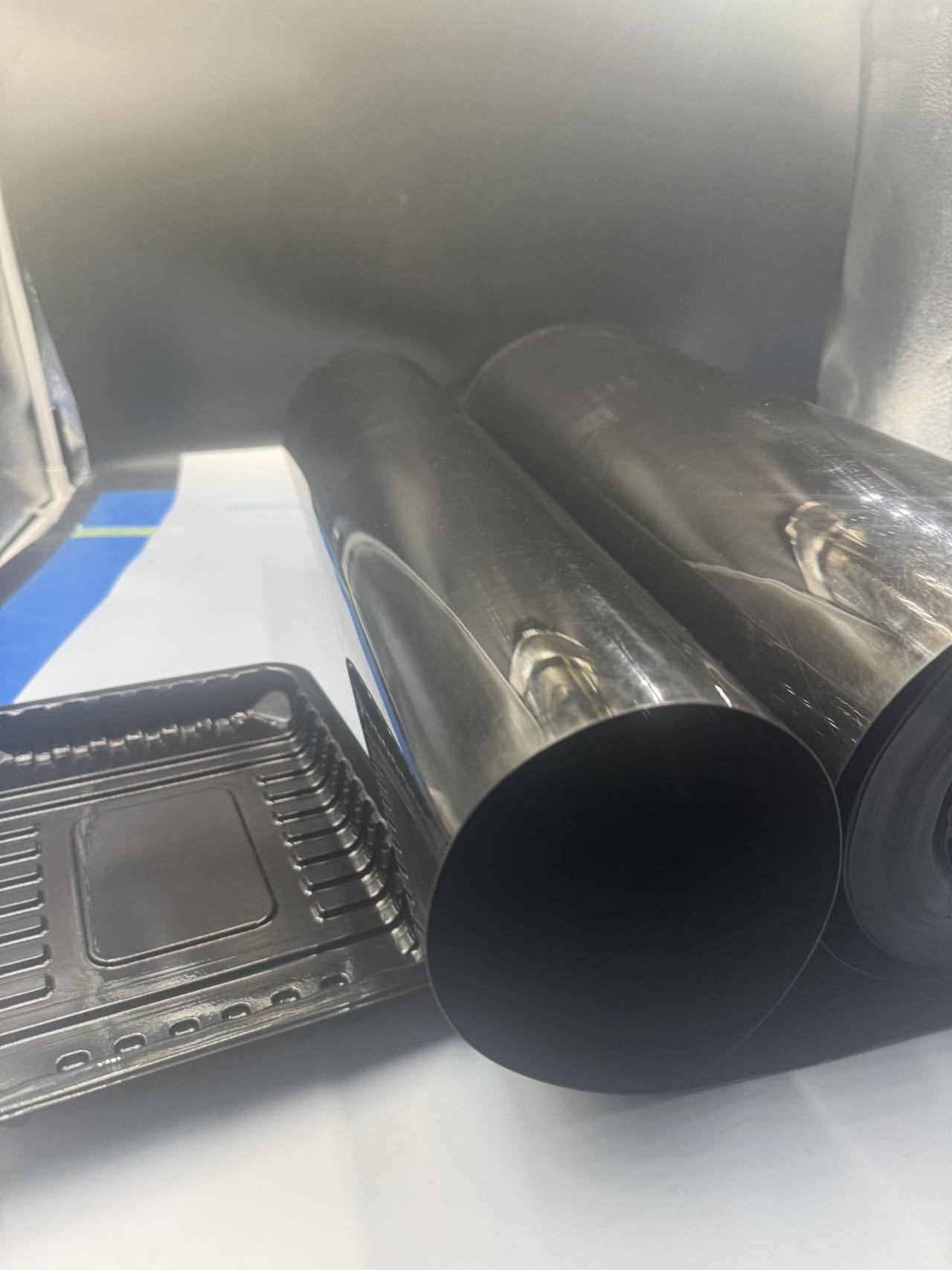

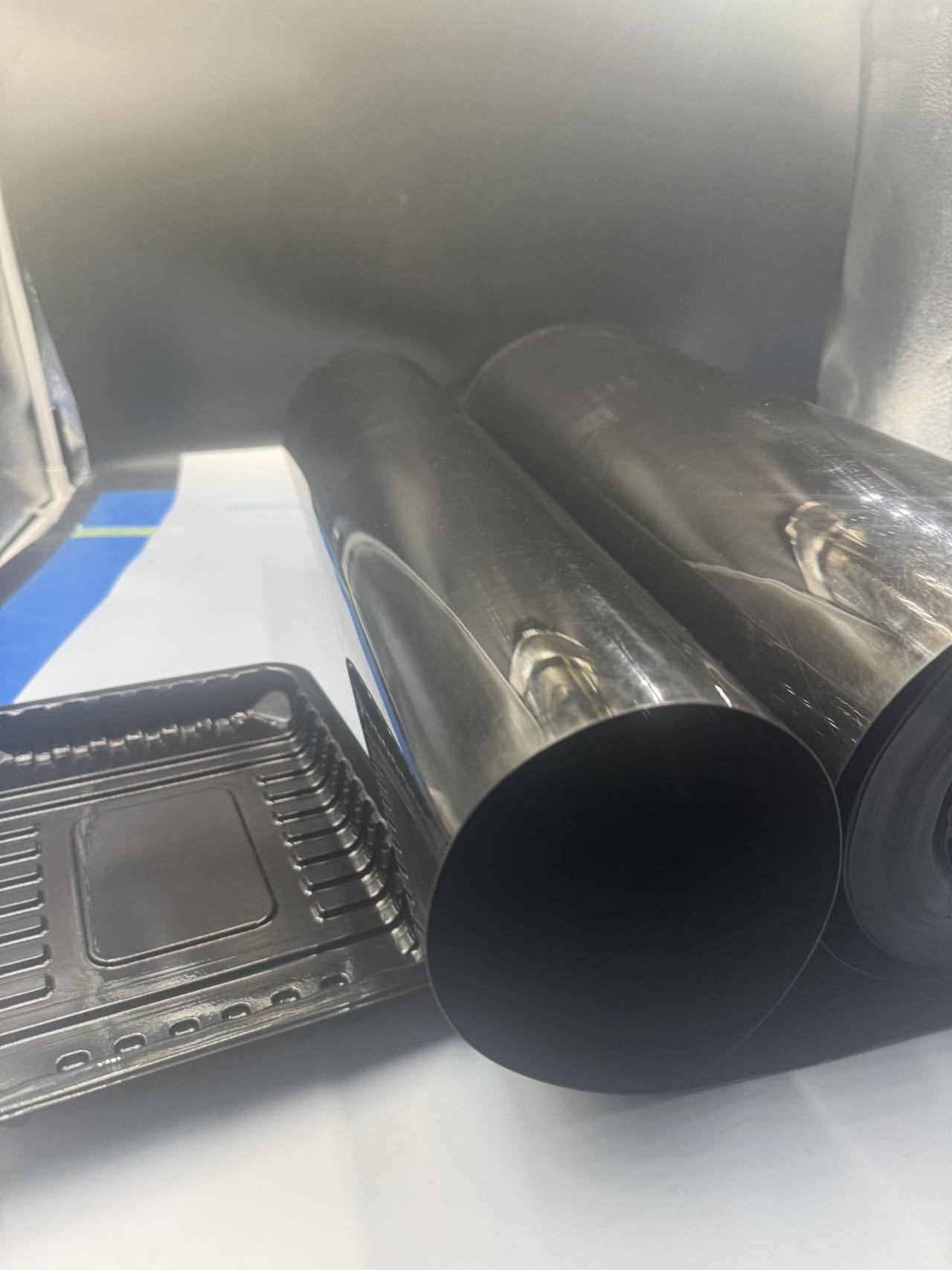

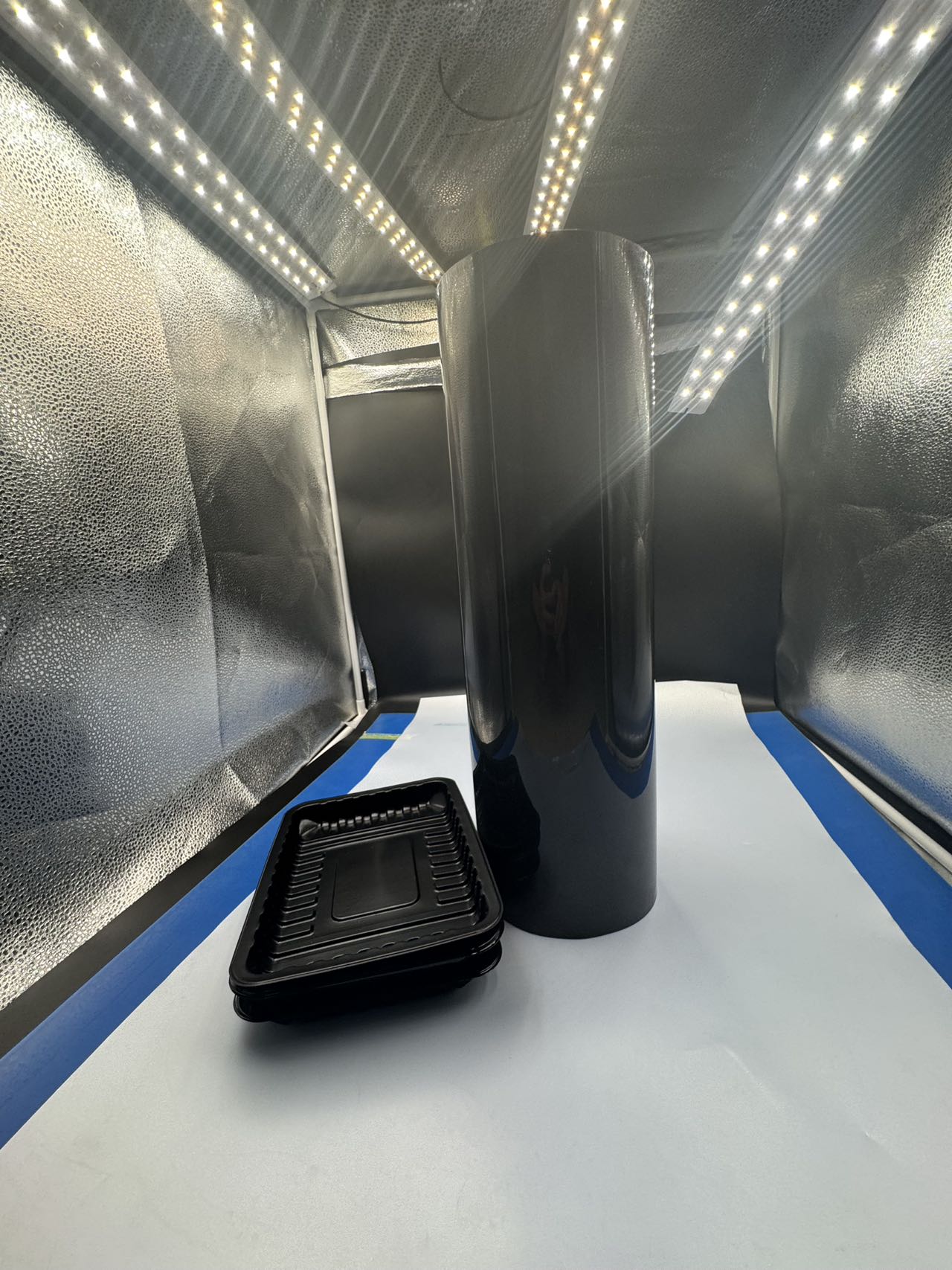

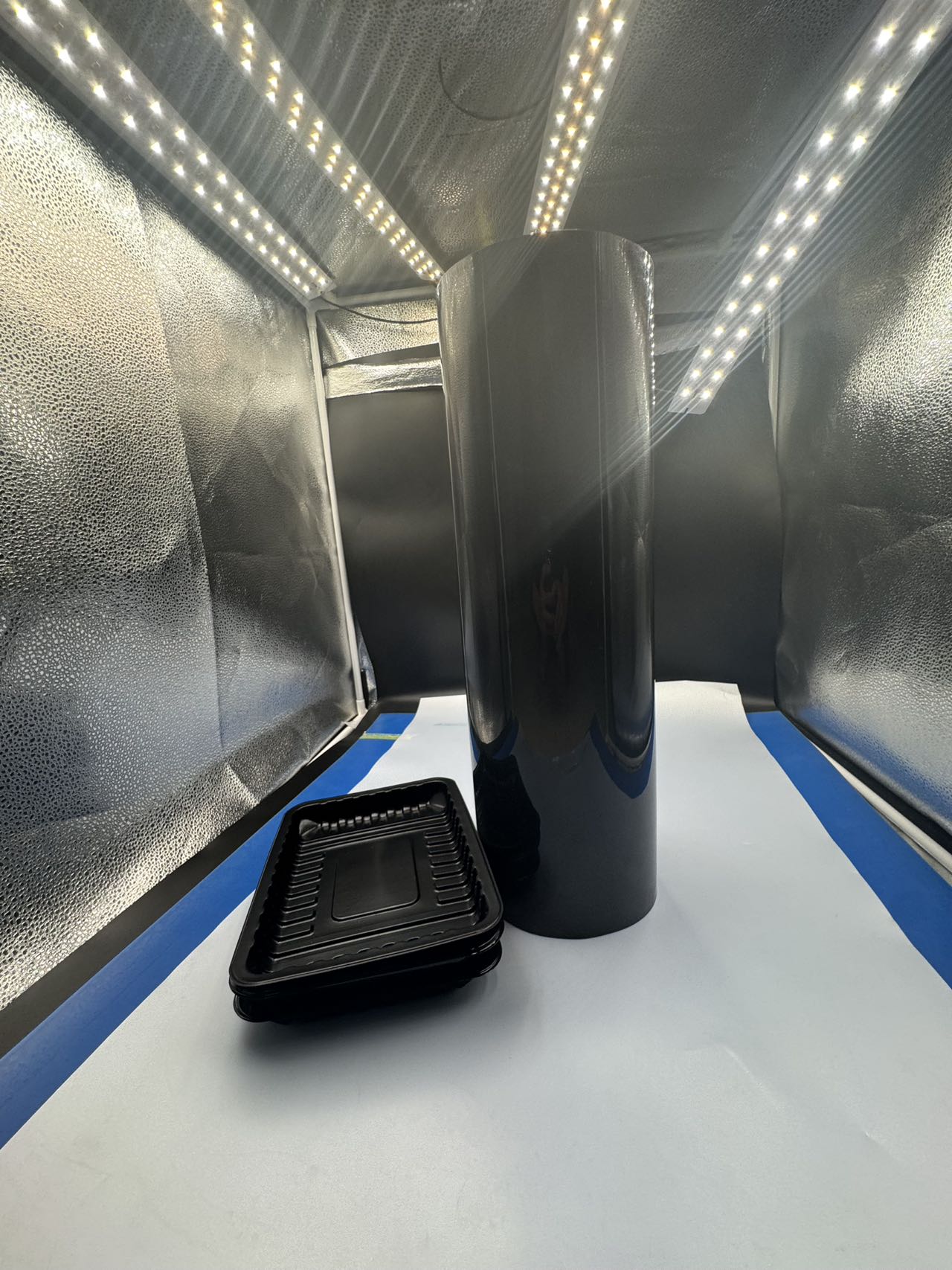

Unveiling the Power of Black PP Film for Food Preservation and Presentation

Material: PP Thermal formed sheet

Thickness 0.25-0.9mm/customization

Size: 300mm/Customization

GRADE: Food grade film

color: black/white/ customization

location: china

usage :for food tray ,mircronwave food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

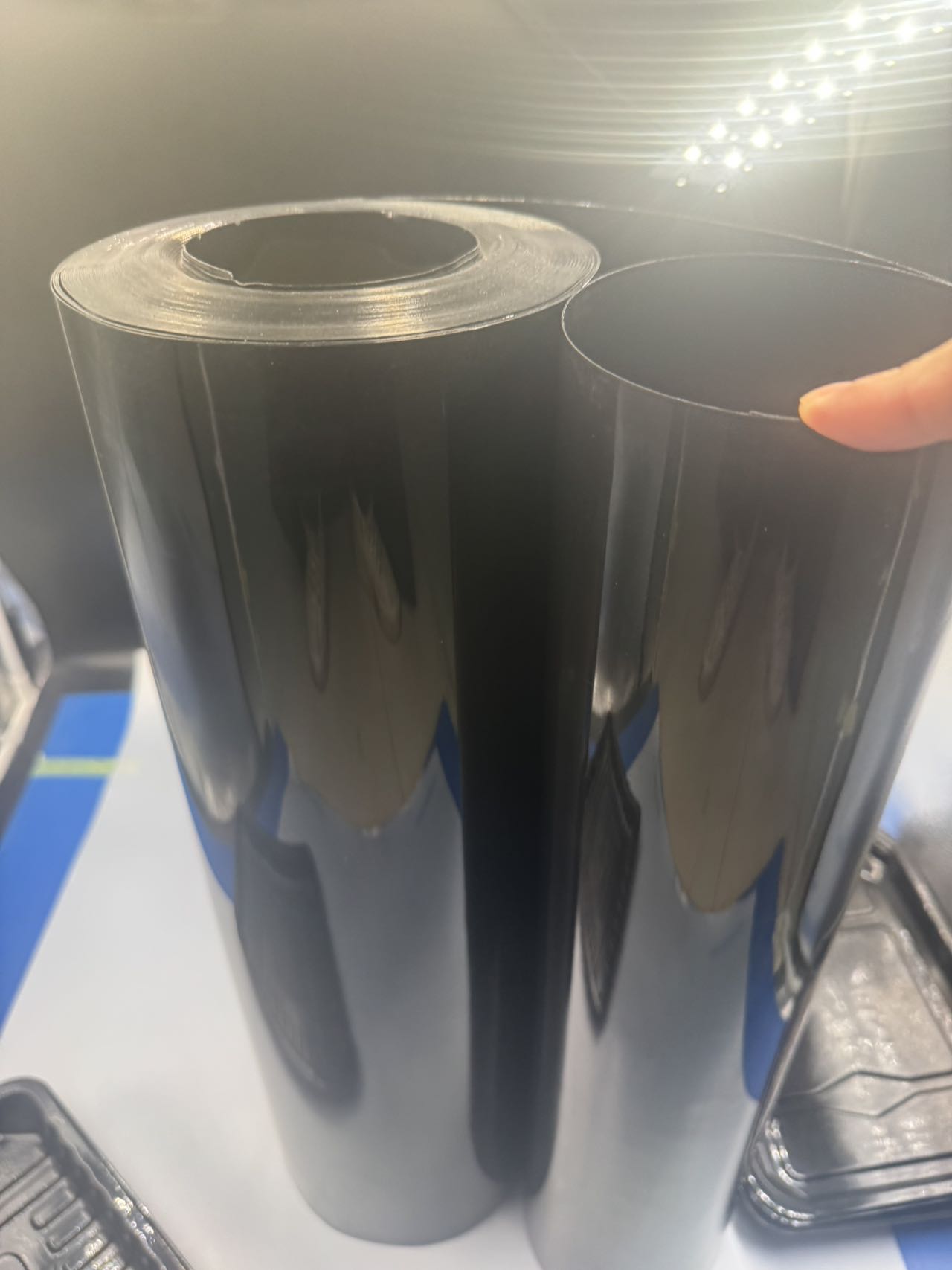

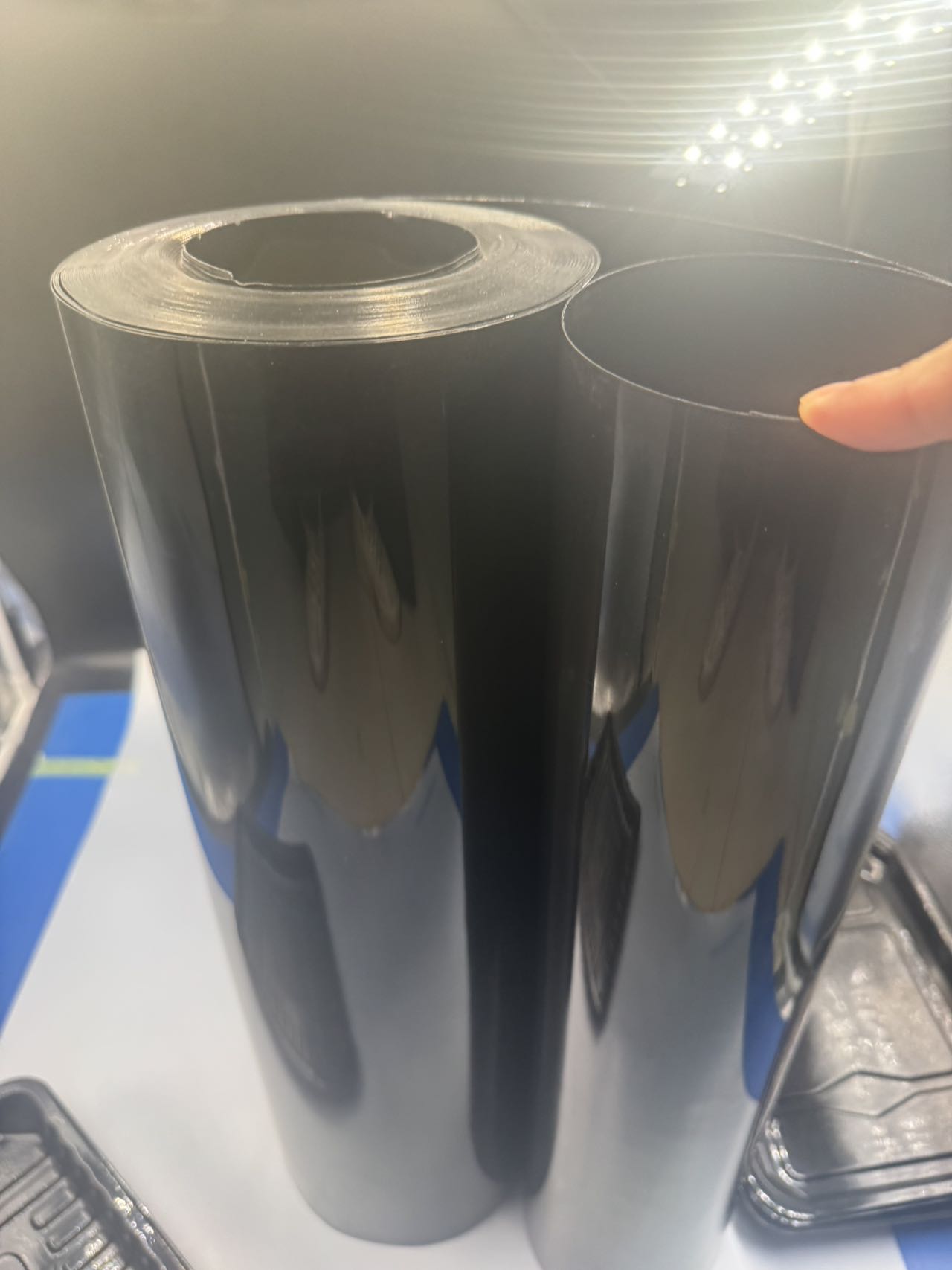

In the dynamic realm of food packaging, black PP film has emerged as a remarkable solution. Made from polypropylene (PP), a widely trusted thermoplastic, this dark-hued film has carved a significant niche in food thermoforming packaging. It safeguards a diverse range of food products, from piping hot ready meals to delicate fresh produce. Its unique combination of strength, flexibility, and aesthetic appeal makes it an essential element in ensuring food reaches consumers in optimal condition.

The Core Characteristics of Black PP Film

Black PP film is far more than an ordinary packaging material. It is a meticulously engineered tool designed to meet the stringent requirements of food preservation and presentation. Its dark color, achieved using food-grade carbon black, serves both functional and aesthetic purposes. Here are its key characteristics:

Heat Resistance and Stability

Black PP film is known for its high heat resistance, with a melting point between 160–170°C (320–338°F). This property enables it to endure processes such as hot-filling, sterilization, and microwave reheating without warping or releasing harmful substances. In food thermoforming, it allows trays to hold hot food items, like a steaming chicken Alfredo, maintaining the integrity of both the food and the package.

Mechanical Strength and Durability

This film exhibits impressive tensile strength and puncture resistance. During thermoforming, when it is heated and stretched into various shapes, it resists tearing and cracking under stress. This durability is crucial for protecting fragile or sharp-edged food products, such as a tray of bone-in pork ribs. Even during rough handling in transit, black PP film keeps the trays and their contents intact.

Chemical Inertness and Food Safety

Safety is of utmost importance in food packaging, and black PP film excels in this aspect. Polypropylene's natural chemical inertness means it does not react with acidic, oily, or salty foods, such as a tangy tomato sauce or buttery seafood. The black pigment used in the film complies with FDA or EU food-contact standards, ensuring no toxins migrate into the food. For example, a black PP tray can safely hold a spicy curry, preserving its flavor and safety.

Barrier Properties for Freshness

While standard PP offers some protection against moisture and gases, black PP film can be enhanced with co-extruded layers like EVOH (ethylene vinyl alcohol) to improve its barrier capabilities. This helps extend the shelf life of perishable foods by blocking oxygen and retaining moisture. For instance, a black PP tray of sliced turkey in a supermarket cooler stays fresh and juicy for longer due to the enhanced film's ability to keep out spoilage-causing air.

Aesthetic Appeal and Versatility

The sleek, matte black finish of the film not only serves practical purposes but also adds a touch of elegance. It gives packaged foods a premium and modern look, making it ideal for gourmet or high-end products such as sushi platters or artisanal cheeses. The film's surface can be printed with vivid logos and nutritional information, enhancing brand visibility. On a crowded store shelf, a black PP tray of chocolate truffles stands out, attracting discerning consumers.

The Role of Black PP Film in Food Thermoforming Packaging

Thermoforming involves heating a plastic sheet until it becomes pliable, shaping it in a mold, and then cooling it to form rigid containers like trays or clamshells. Black PP film is perfectly suited for this process, offering the flexibility and resilience required for food packaging.

Versatility Across Food Types

Black PP film can be used for a wide variety of food products. In the ready-meal industry, it is used for microwaveable trays that can hold dishes like shepherd's pie or stir-fried noodles. Its heat resistance allows it to withstand hot-filling, where food is packed at high temperatures to kill bacteria. For fresh meats and seafood, its puncture resistance protects against sharp edges, and its dark color enhances the visual appeal. For example, a tray of glistening salmon fillets looks more appealing in a black PP tray.

Extending Shelf Life and Ensuring Safety

Preserving freshness is a top priority, and black PP film excels in this area. It is compatible with advanced sealing methods such as vacuum packaging and modified atmosphere packaging (MAP). In vacuum packaging, it tightly conforms to the food, removing air that could cause spoilage. In MAP, where gases like nitrogen replace oxygen, the enhanced black PP film maintains the internal environment, extending the shelf life of products like deli meats and leafy greens. Additionally, its food-safe nature ensures no chemical leaching, keeping food products pure and safe.

Efficiency in Production and Use

Manufacturers appreciate black PP film for its processability. Its low forming temperature and excellent flow properties allow it to be molded into complex shapes, such as deep wells for soups or shallow compartments for snacks, with minimal energy consumption. This efficiency speeds up production lines and reduces costs. For consumers, the film's microwave compatibility enables easy reheating of meals directly in the tray, and its rigidity allows for convenient stacking.

Enhancing Branding and Consumer Appeal

Packaging serves as a brand's visual representation, and black PP film makes a strong impression. Its dark and elegant finish conveys quality, making it suitable for premium products like organic meals or specialty desserts. The film's printability allows for eye-catching designs, which can attract consumers. For example, a soup brand can add a sleek logo and a vivid image of vegetables to a black PP tray, enticing shoppers to choose their product.

Practical and Sustainable Benefits

Black PP film offers practical advantages such as its lightweight nature (with a density of around 0.9 g/cm³), which reduces shipping costs. It is also recyclable, aligning with sustainability goals. Although the black pigment can pose challenges in traditional recycling, new technologies like NIR-detectable pigments are improving its recyclability. A company using black PP trays for plant-based burgers can market them as eco-friendly, appealing to environmentally conscious consumers.

Real-World Examples and Insights

In the meal kit industry, black PP film is used in multi-compartment trays to hold pre-portioned ingredients, such as marinated tofu and rice, which are sealed for freshness and shipped across the country. The dark color of the trays not only enhances their appearance but also withstands the rigors of transit. In the fast-food sector, black PP trays for burgers or fries offer durability and a modern look, meeting the needs of on-the-go consumers.

Data supports the effectiveness of black PP film. A 0.1 mm black PP film with EVOH layering can extend the shelf life of meat by up to 30 days under MAP conditions, which is highly beneficial for retail. In the case of microwaveable meals, its heat resistance allows for reheating at 100°C without deformation, as demonstrated in many home kitchens.

Challenges and Considerations

Black PP film does face some challenges. Excessive heat (above 170°C) can cause it to soften during processing, potentially resulting in shape distortion, so precise temperature control is essential. The black pigment can also pose difficulties in recycling, although emerging technologies are working to address this issue. Users need to carefully consider these factors and choose enhanced formulations, such as thicker films for heavy-duty applications, to optimize performance.

In terms of sustainability, while PP is not as eco-friendly as some bioplastics, its lightweight design and recyclability make it a competitive option. A company that values environmental credentials can combine the use of black PP film with recycling initiatives to balance practicality and environmental goals.

Conclusion

Black PP film is a powerful force in food thermoforming packaging. It combines heat resistance, durability, and food safety with an attractive aesthetic. Whether it's protecting hot meals or keeping perishables fresh, it meets the industry's highest standards. For producers, it streamlines operations, and for consumers, it provides convenience and quality. As the food packaging industry continues to evolve, black PP film is well-positioned to drive innovation, ensuring that every food product is presented safely, freshly, and attractively.

What's your delivery time?

Within 15-20 days after received payment...more

Within 15-20 days after received payment...more

Get the latest price? We'll respond as soon as possible(within 12 hours)