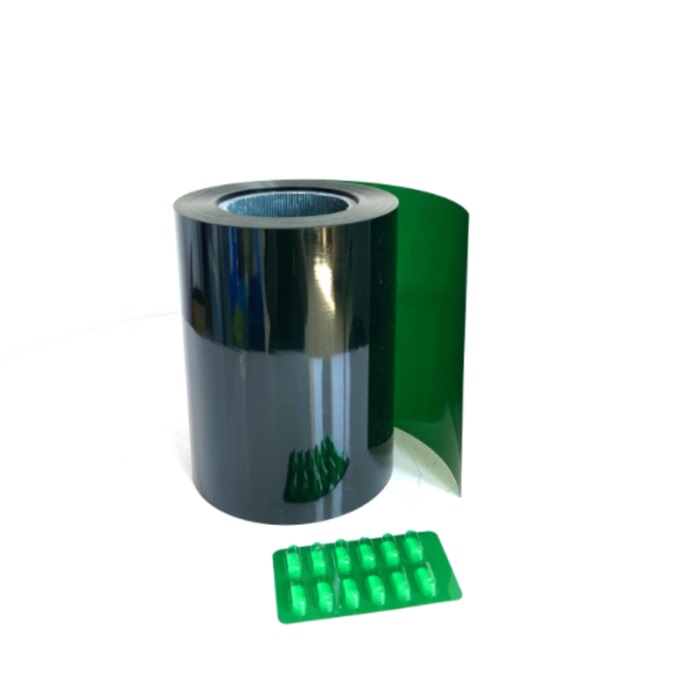

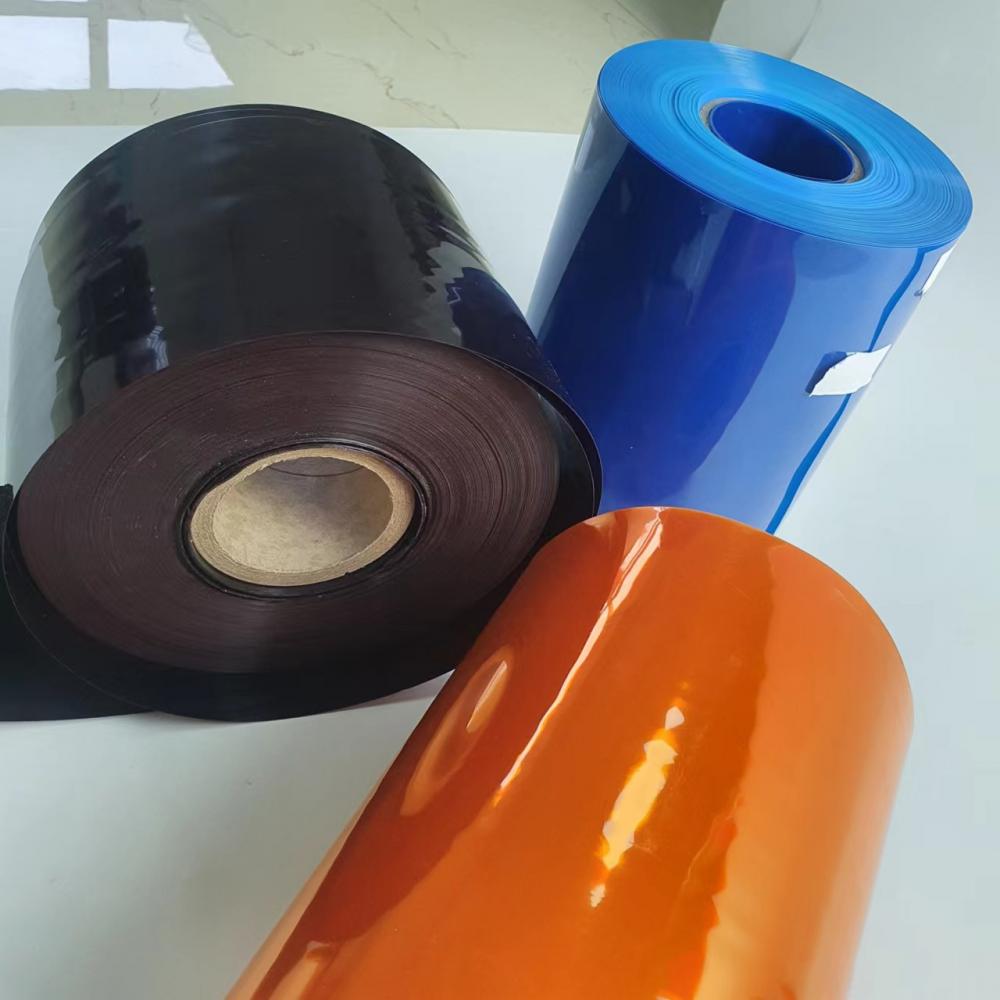

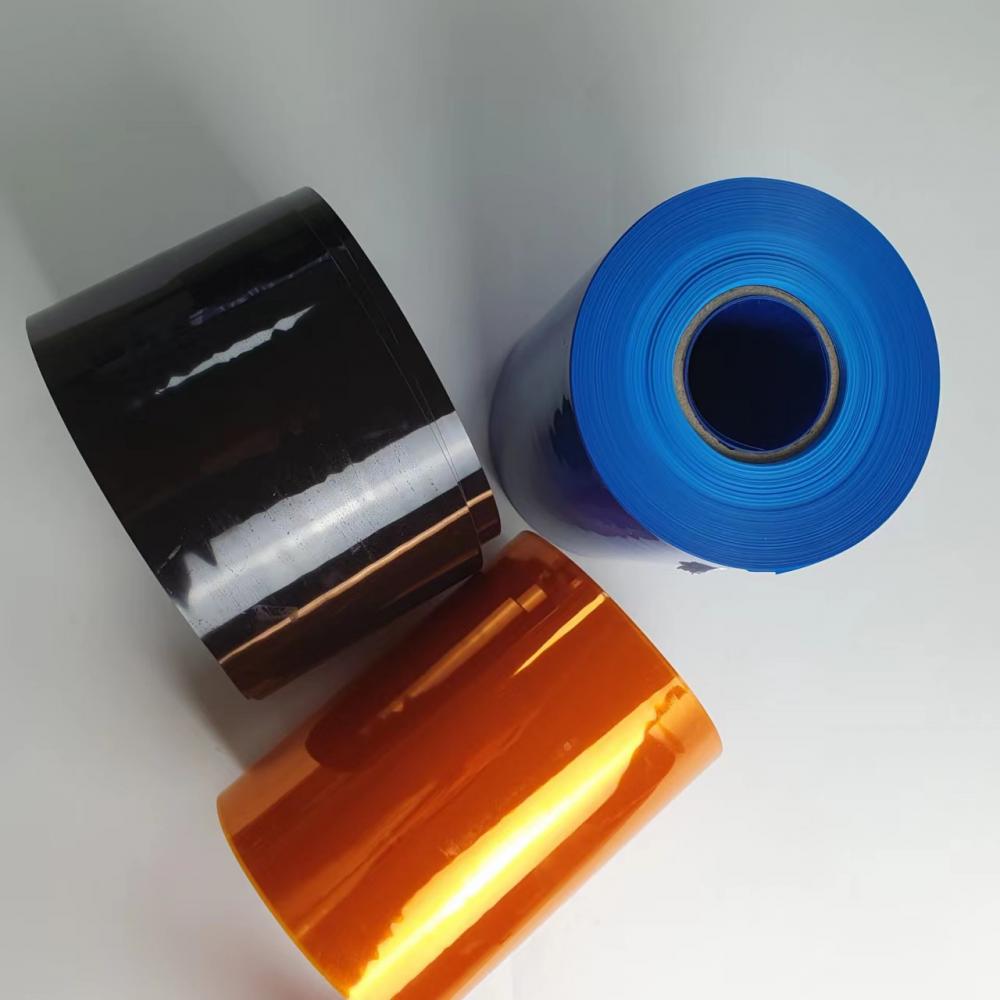

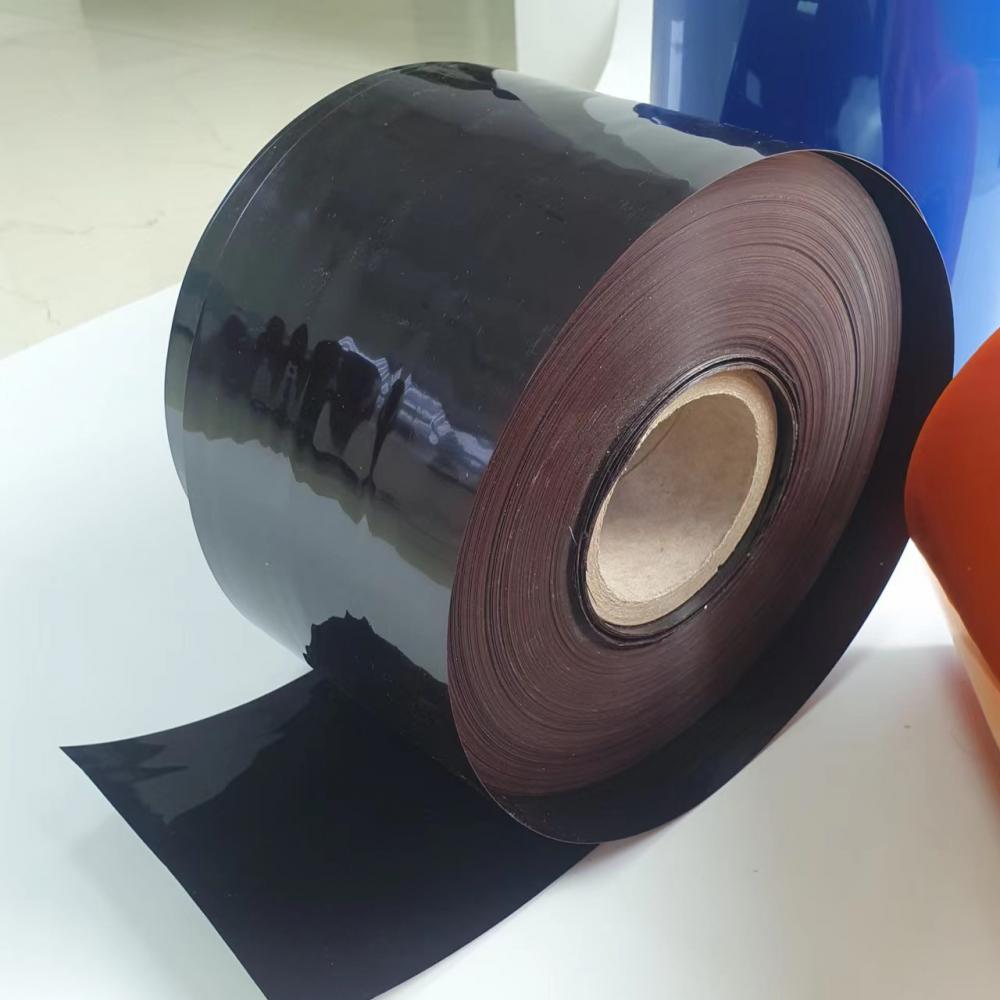

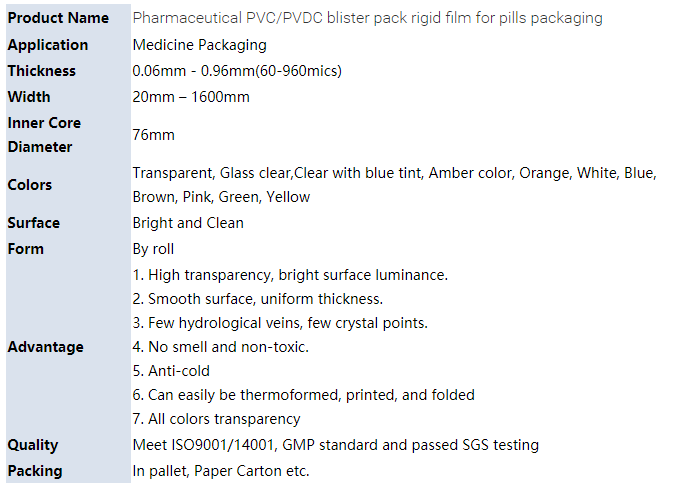

Color PVC pharmaceutical packaging sheet

The products are easily processed. The processing methods for PVC Plates are very similar to that for acrylics. All processing equipment for acrylics can be used directly to process PVC Sheet.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Product introduction

PVC (Polyvinyl Chloride) blister thermoforming pharmaceutical film sheets are widely used in the pharmaceutical industry for packaging tablets, capsules, and other solid dosage forms. Here are some of the key advantages of using PVC blister thermoforming film sheets:

1. Cost-Effective:

- PVC is relatively inexpensive compared to other materials like PET (Polyethylene Terephthalate) or Aclar. This makes it a cost-effective option for pharmaceutical packaging.

2. Versatility:

- PVC can be easily formed into various shapes and sizes, making it suitable for a wide range of pharmaceutical products. It can accommodate different types and sizes of tablets and capsules.

3. Transparency:

- PVC is transparent, allowing for easy visual inspection of the contents. This is important for quality control and for consumers to see the product before opening the package.

4. Barrier Properties:

- While not as effective as some other materials, PVC still provides a good barrier against moisture and gases, which helps to protect the medication from environmental factors that could affect its stability and efficacy.

5. Sealability:

- PVC can be easily sealed with a variety of lidding materials, such as aluminum foil, paper, or other plastic films. This ensures a secure and tamper-evident seal, which is crucial for maintaining the integrity of the medication.