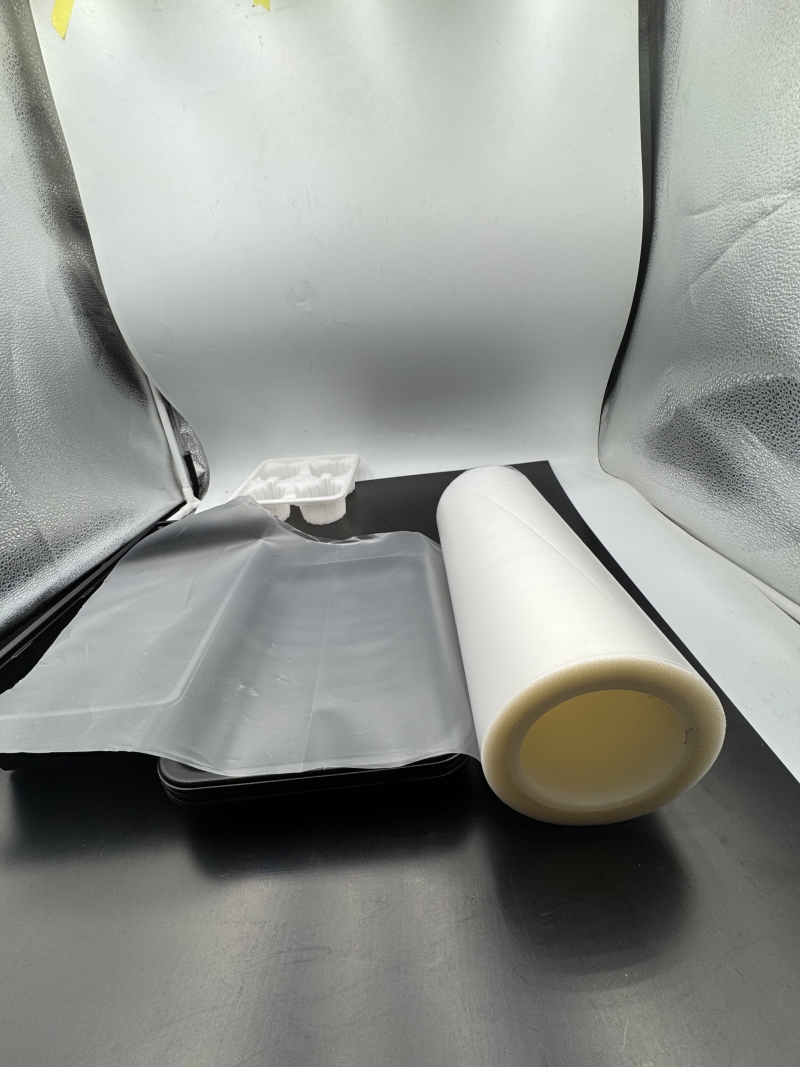

CPP film Pouches Made from Matte CPP Film: Characteristics and Applications

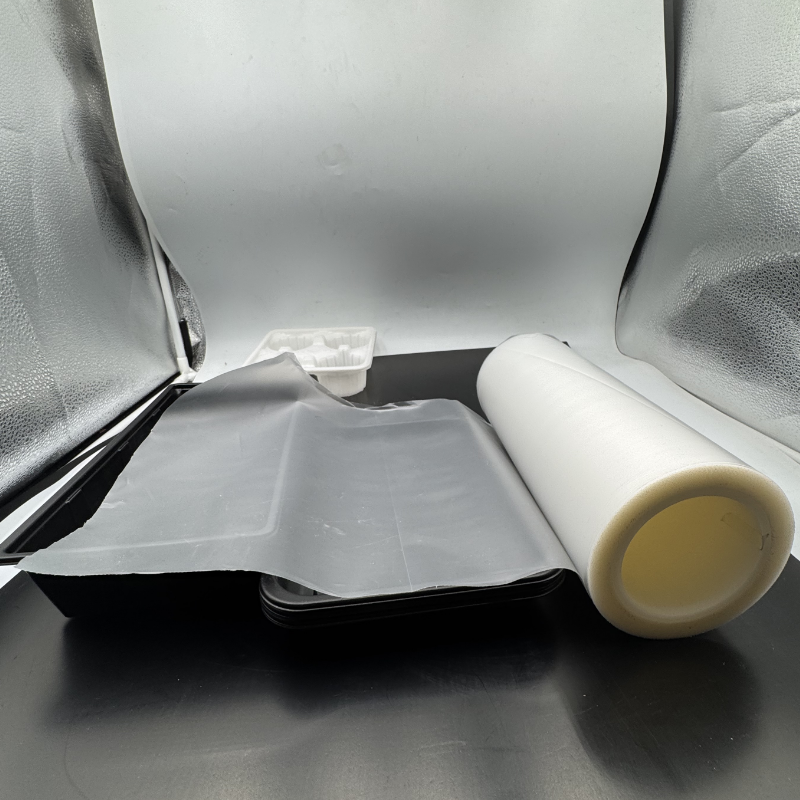

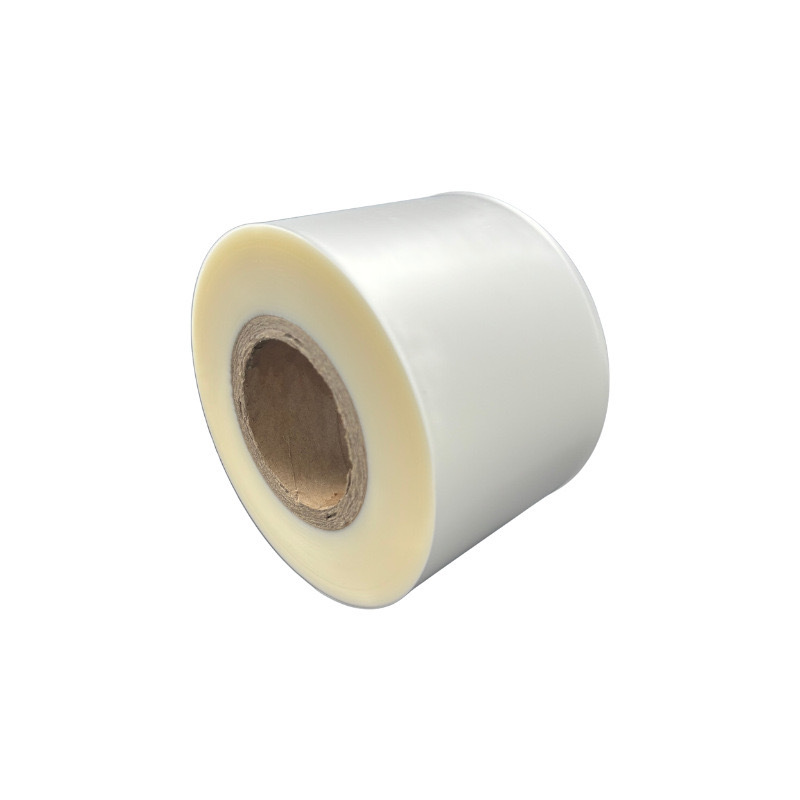

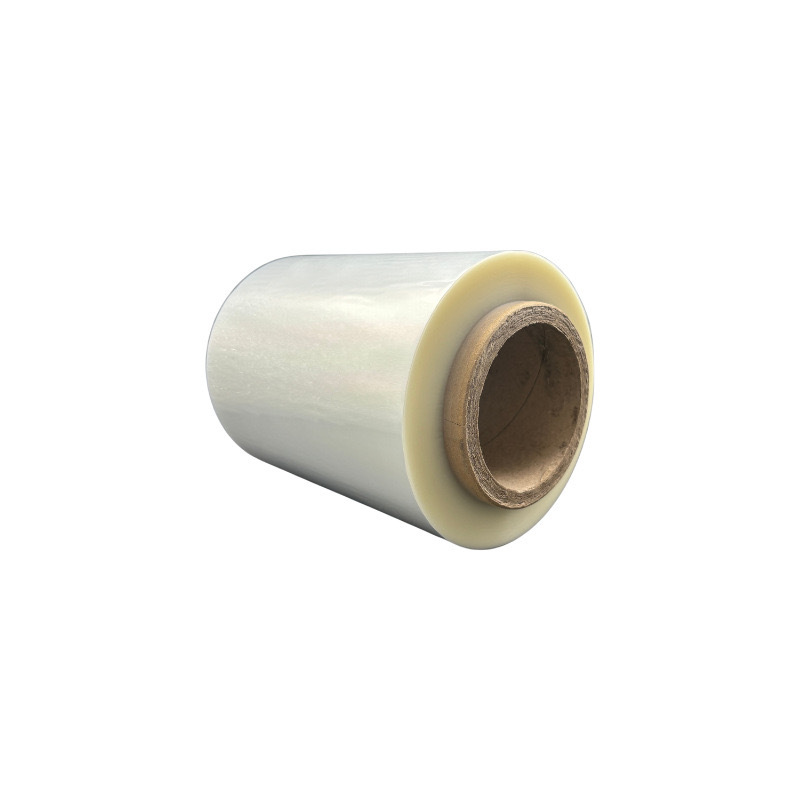

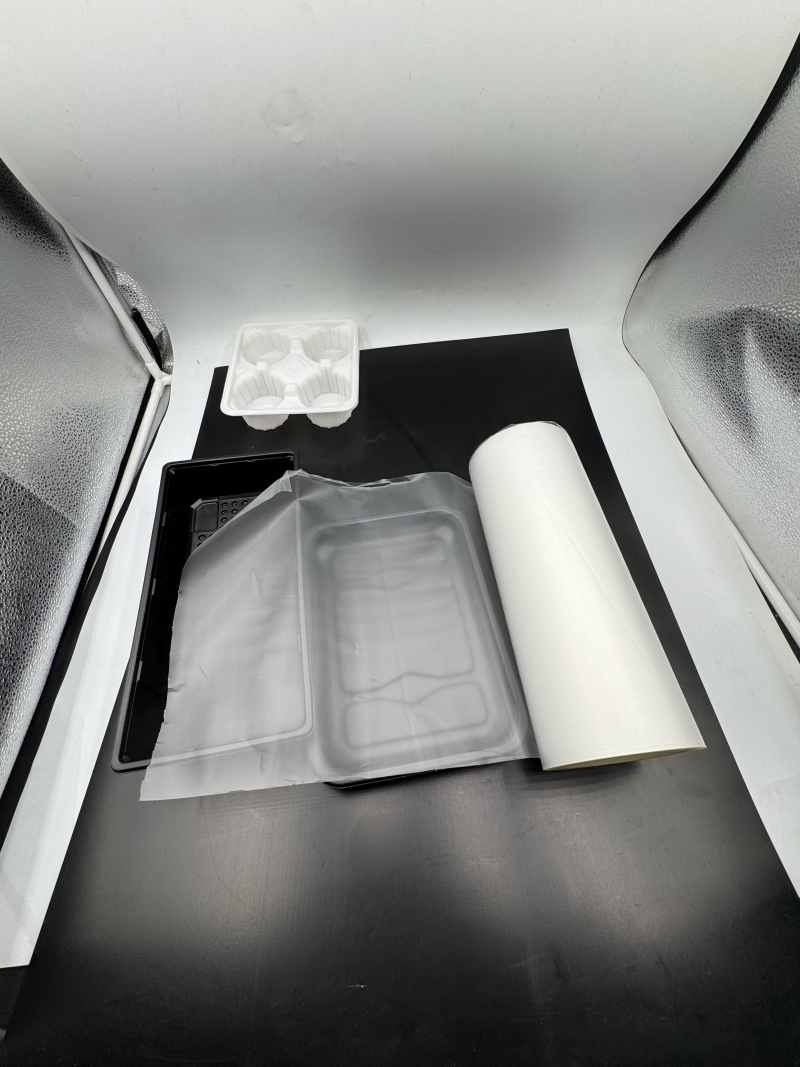

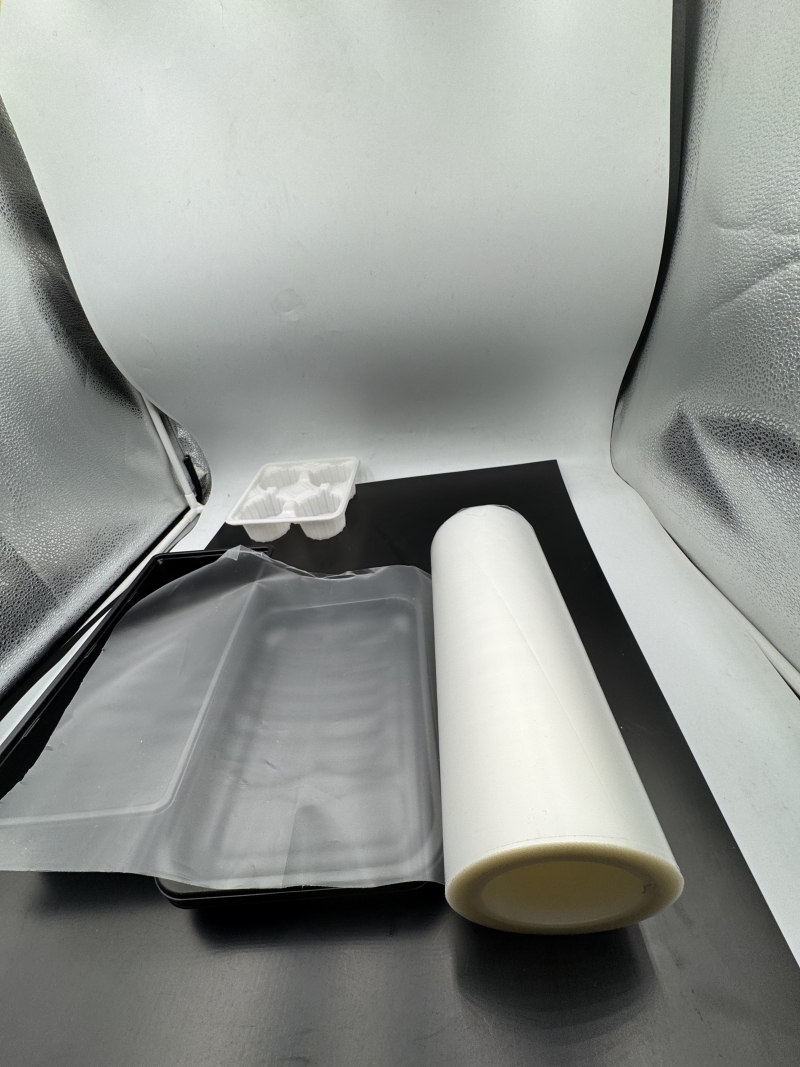

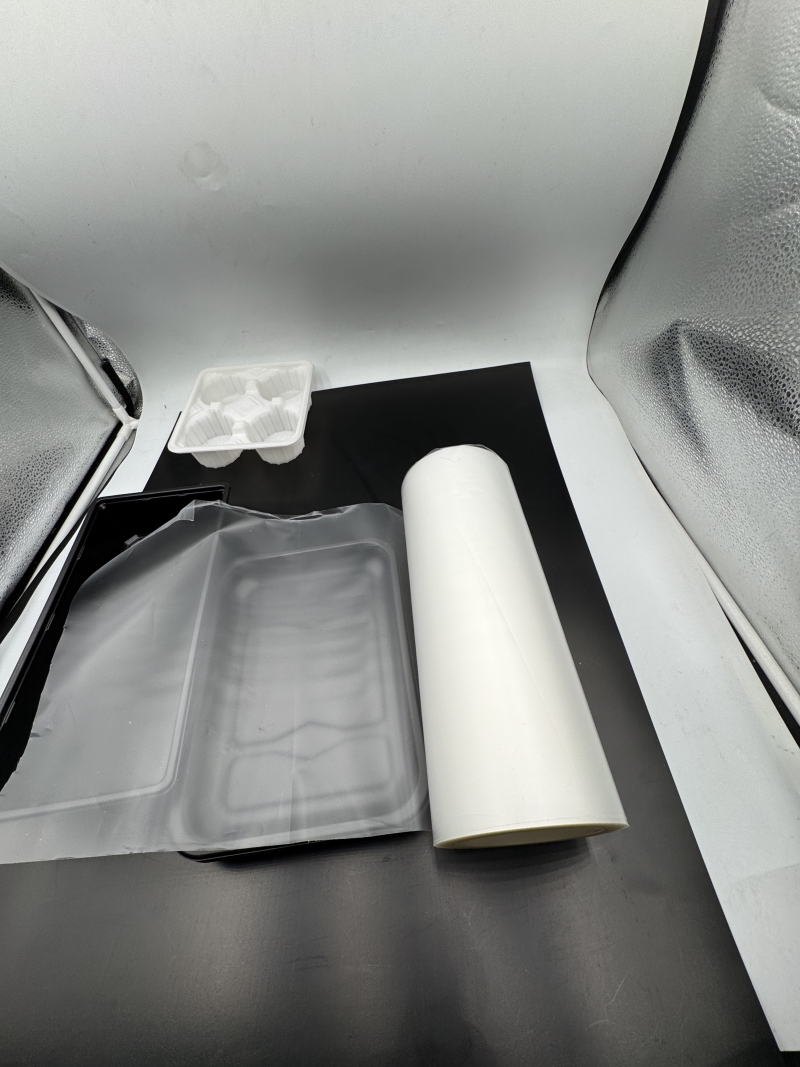

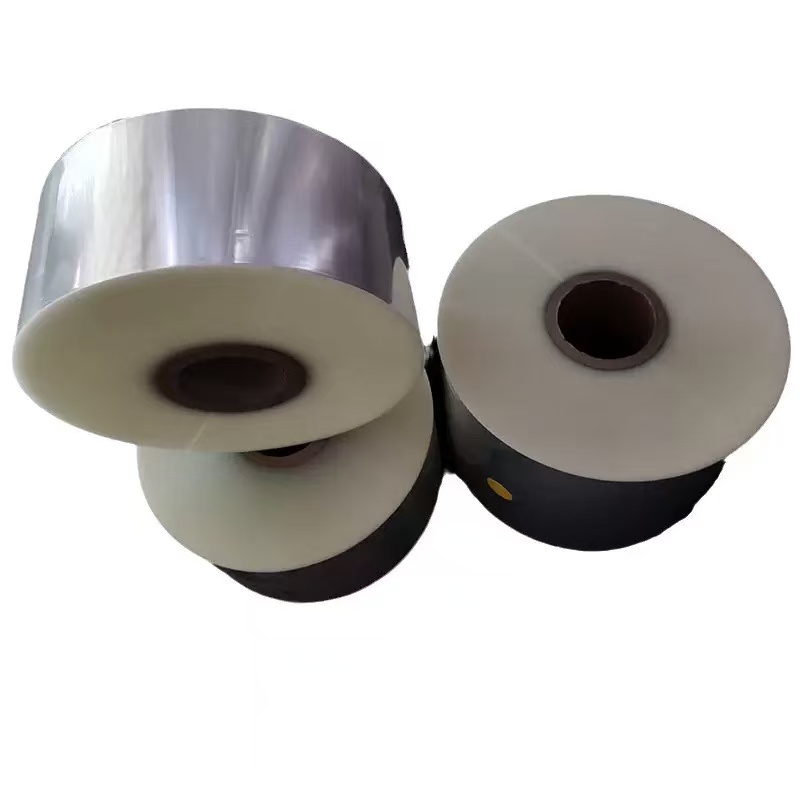

Material: cpp film roll

Thickness 0.012mm/customization

Size: A4/Customization

GRADE: Food grade film

color: white/fog/matt/ clear customization

location: china

usage: for food protection, food heat-sealing box,lamination

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Application of Transparent Matt CPP Film in Packaging: Unraveling its Potential

Introduction

Materials play a very vital role in determining the functionality, aesthetics, and overall quality of the final product in this dynamic and ever-evolving world of packaging. Among the myriad of options available, transparent matt CPP (cast polypropylene) film has emerged as a remarkable choice, finding extensive utility in diverse packaging applications. With its unique combination of properties, which includes transparency, a matte finish, flexibility, and durability, it is highly in demand for the manufacture of composite films, packaging solutions in various industries, and at the same time, bags that are stylish and serviceable. This article focuses on the characteristics of transparent matt CPP film, their manufacturing process, wide range of applications, advantages conferred, and challenges overcome, thereby presenting a vivid picture of its standing in modern packaging design.

Material Properties of Transparent Matt CPP Film

Chemical Composition and Structure

Transparent matt CPP film is made from polypropylene, which is a kind of thermoplastic polymer produced by the polymerization of propylene monomers. The molecular structure of polypropylene is made up of long chains of carbon atoms with methyl groups attached at regular intervals. It is this linear but somewhat flexible arrangement that gives the material inherent strength and chemical stability. For the matt variant, specific additives and processing techniques are used during manufacturing to achieve the desired matte finish without compromising the film's transparency. These additives act subtly to disrupt the surface smoothness, scattering light in a way that reduces glare and imparts a soft, non-reflective appearance, while maintaining the clarity necessary for product visibility.

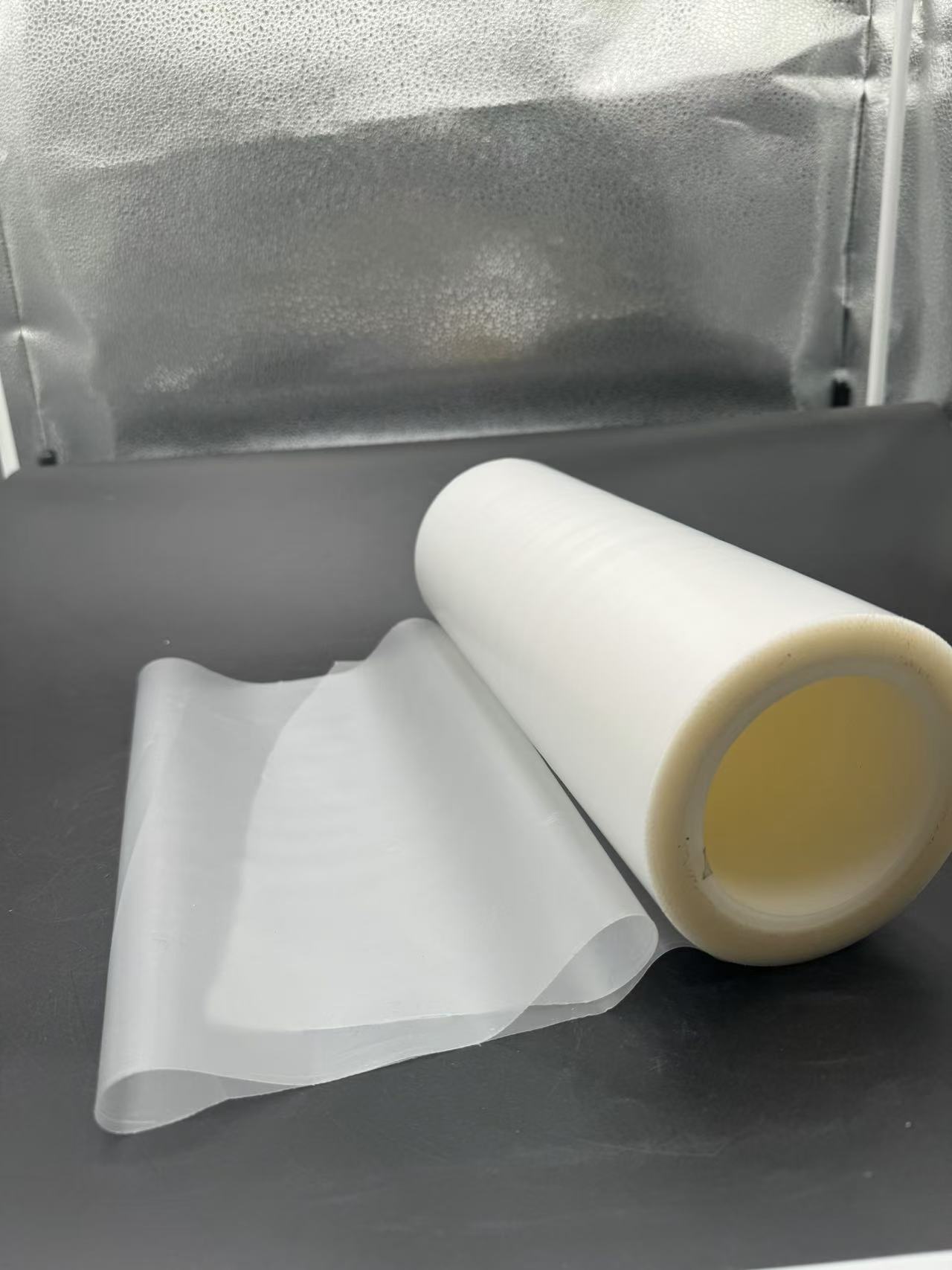

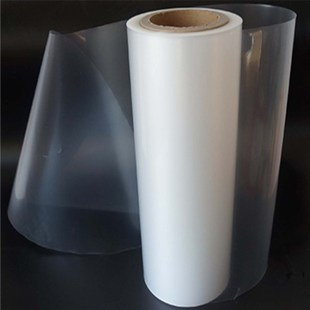

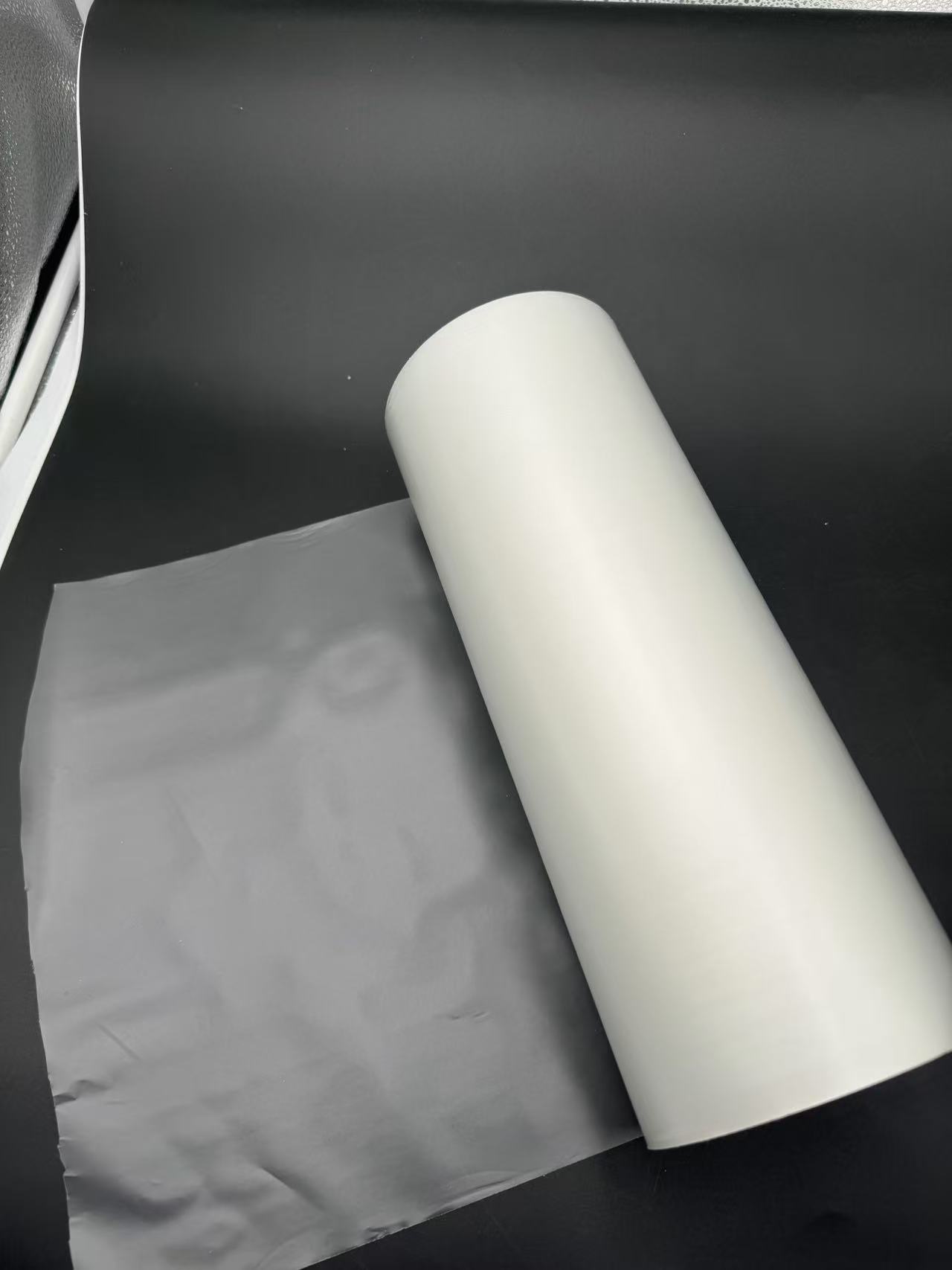

Transparency and Matte Finish

One of the most striking things about this film is how it manages to incorporate transparency along with a matte texture. The transparency allows for clarity of the contents it encapsulates, which is extremely useful in packaging applications where the customer needs to make judgments about the quality and appearance of the product. For example, in food packaging, whether it be a tray of fresh pastries or a bag of colorful candies, the film allows customers to see the items in all their glory and entices them to make a purchase. The matte finish, on the other hand, exudes elegance and sophistication. It reduces fingerprints and smudges, maintaining a clean and professional look even after handling. This cosmetic industry matte finish gives a feeling of luxury for delicate products such as lipsticks or eyeshadow palettes, adding perceived value to the product on store shelves. Mechanical Properties The film is very mechanically strong and flexible. It bears a good tensile strength, which can withstand stretching and pulling forces during packaging operations, such as when the film is being formed into bags or wrapped around products. The strength will ensure that the film does not tear easily and protects the contents against any form of damage during handling, transportation, and storage. Its flexibility allows it to fit snugly over irregular shapes, making it suitable for a wide variety of items ranging from oddly shaped toys to food products with curved surfaces. Besides that, it has fair puncture resistance, which can prevent accidental punctures from sharp edges inside the packed goods or even from harsh handling.

Barrier Properties

Regarding the barrier protection of packaged products, transparent matt CPP film possesses a medium to good barrier level. First of all, it has a good barrier against moisture, which is important for keeping a lot of products fresh. In food packaging, it prevents baked goods from drying out and keeps dry snacks, such as chips or crackers, from getting moist. Against gases like oxygen and carbon dioxide, it restricts permeation to a certain extent, slowing down the oxidation process and preserving the integrity of oxygen-sensitive products. In the case of fresh produce, it can assist in regulating the internal gas environment, prolonging shelf life, and reducing waste.

Heat Resistance: The film shows a good level of heat resistance, making it suitable for different packaging processes and end-use applications. It can stand up to the temperatures involved in heat-sealing operations to ensure that packages are securely closed and airtight. This is important in industries like food and pharmaceuticals, where sterility and integrity of the product are of utmost importance. Moreover, it can tolerate a range of temperatures during storage and transportation, without significant deformation or loss of its properties, making it viable for items that may be exposed to mild heat, such as in the case of some processed food products that undergo pasteurization or sterilization at relatively low temperatures.

Chemical Resistance

Transparent matt CPP film exhibits strong chemical resistance to a host of substances. It is resistant to many acids, alkalis, and solvents; it does not react with the products it packs. In applications related to food, it resists the contact of food acids, oils, and detergents used in cleaning. It maintains its structural and functional properties in such conditions. The pharmaceutical and cosmetic industries use such formulation that can comprise many varieties of chemical ingredients, wherein the film remains chemically inert and helps in preventing the entry of external contaminants that may adulterate the product and thus keeps the purity of the packed items intact.

Manufacturing Process of Transparent Matt CPP Film

Raw Material Preparation

Transparent matt CPP film manufacturing starts with selecting high-quality polypropylene resin. The resin is supplied by trustworthy companies since its purity and regularity are important, and any kind of impurities will have disastrous effects on the properties of the film. Additives like antioxidants are added to protect the resin from deterioration during processing as well as during storage later on, and this extends the life of the film. To produce the matte effect, additions like silica or talcum powder in specific quantities are made. These additives are mixed with the resin in a mixer to a uniform distribution within the material, preparing it for the extrusion process.

Extrusion Process

The properly mixed raw materials are fed into an extruder, which is a cylindrical device fitted with a rotating screw. As the material advances along the extruder's heated barrel, it is melted progressively under controlled temperature and pressure conditions. The temperature profile within the extruder is carefully calibrated for uniform melting and proper flow of the molten polypropylene. After reaching a molten state, the material is forced through a flat die at the end of the extruder. The die determines the width and initial thickness of the emerging film, and the extrusion speed is adjusted to achieve the desired film dimensions, with precision being of utmost importance at this stage.

Casting and Cooling

Following extrusion, the molten film is taken to the stage of casting. It is cast onto a chilled roller or a conveyor belt, which rapidly cools the film, thereby solidifying it into its final flexible form. The cooling rate is precisely controlled to manage the crystallinity of the film and, hence, the mechanical and optical properties. In the case of a matt finish, the cooling process further helps in setting the texture created by the added matte-forming additives so that a consistent and smooth matte appearance is attained over the film surface.

Annealing and Conditioning

In order to remove internal stresses developed during the fabrication process and improve the mechanical properties of the film, an annealing process can be performed. Annealing consists of heating the film up to a temperature below its melting point and then letting it cool down very slowly. This step is important in the stabilization of the molecular structure of the film, making it less liable to warping or cracking in later handling and usage. In addition, depending on the purpose, the film may go through additional conditioning processes where its surface energy is optimized for improving printability or adhesion in composite film applications. The manufacturing process involves close quality control at every step. High-precision instrumentation is used to measure thickness as specified by standards and even small variations in such can lead to a decline in the performance of the film. Besides these processes, there is a variety of lab tests conducted in the areas of transparency, matte finish quality, mechanical strength, barrier properties, heat and chemical resistance, etc. Any film, not confirming to the narrow range specifications, gets rejected. Then comes winding in large, small, and Jumbo sizes for its onward dispatch in rolls to packaging manufacturers, converters across various industries.

Application of Transparent Matt CPP Film in Composite Films

Composite films are applied to Food Packaging

The CPP film that is transparent and matt usually finds application in food packaging as a composite film to improve properties. It could be laminated with aluminum foil to give a good barrier against light, oxygen, and moisture, thus keeping products sensitive to these agents, like coffee or snacks containing much fat. Paired with polyethylene, it achieves better heat-sealing properties and flexibility for frozen or microwaveable food packaging. The CPP layer in the composite film imparts transparency, a matte finish for aesthetic appeal, and mechanical strength, while the other layers work in concert to protect the food and meet specific packaging requirements. In a composite film used for packaging cheese slices, for example, the top layer of matt CPP provides clarity to view the product while the aluminum foil layer in the middle keeps it fresh and protected from spoilage.

Industrial and Technical Composite Films

Apart from the food industry, transparent matt CPP film is also utilized in industrial and technical composite films. It may be used in the electronics industry as a part of some composite film for the protection of sensitive components against ESD and moisture. Chemical resistance and flexibility of the film make it suitable for such an application, while its ability to be combined with conductive materials is of assistance in dissipating static electricity. In the building industry, it can be used in building wraps or insulation materials where its resistance to moisture and durability will contribute a great deal in protecting the structures from elements of weather. For example, a building wrap that is made for preventing the infiltration of water, the matt CPP film adds another layer of protection while giving a neat and professional look.

Applications of Transparent Matt CPP Film in Packaging

Food Packaging

Food packaging widely uses transparent matt CPP because it can protect and also showcase products attractively. It wraps around the loaves of bread, pastries, and cakes in bakery packaging to keep them fresh through prevention of moisture loss while showing the delicious appearance of these items due to its transparency. The matte gives it an added touch of elegance to make the baked items more appealing on store shelves. The film is used in the packaging of fresh produce, such as cucumbers, tomatoes, or berries, to maintain humidity levels, prevent damage during transportation and handling, and also to allow consumers to immediately assess the quality of the fruits and vegetables.

Cosmetic Packaging

The film is applied in the cosmetic industry for packaging different products. It adds translucency to the films for makeup items such as lipsticks, mascaras, and eyeshadow palettes, allowing them to be seen in their true colors and textures. Adding a matte finish gives these items an upscale and quality appearance. Within perfume packaging, film can serve as a sleeve or a wrap, thus safeguarding a bottle against scratch or fingerprint damage, while amplifying visual appeal. The film has a strong chemical resistance which makes sure that it doesn't interact with the chemical elements in cosmetics and that retains their originality.

Pharmaceutical Packaging

When packaging pharmaceuticals, it is required to make sure of product safety, integrity, and well-communicated information. For packaging medicine, there are usages of transparent matt CPP film as both blister web for primary and secondary packagings. The film can be used for blister packs, covering cavities holding the tablets or capsules, thus protecting it against moisture, light, and physical damage. This will allow patients to have better visibility of the drug due to the transparency and gives it a professional and clean look with a matte finish. It may be combined in secondary packaging, like boxes or pouches, to give additional protection and a very appealing appearance with the printed information standing out clearly against the matte background.

Applications of Transparent Matt CPP Film in Packaging Bags

Retail Packaging Bags

Transparent matt CPP film is very much in demand for creating retail packaging bags, whether for clothing, accessories, or small consumer goods. This film's translucency allows contents inside to be visible; such a package is more alluring to consumers, especially because they can view the product they are purchasing. The matte finish lends sophistication and style to these bags, elevating them from bland shiny ones. Its durability and strength ensure the strength needed so that the bags bear those tugs and jerks of carrying and handling and secure the contents inside. These bags can also be used to package upscale garments in any boutique cloth store, allowing the store to enhance customers' shopping experiences and impressions of a brand.

Food and Snack Packaging Bags

Packaging bags in food and snacks made from transparent matt CPP film are functional, as well as eye-catching, for sales displays. Its barrier properties keep the food fresh, while with transparency and matte finish, the packages look appetizing on every store shelf. A bag of potato chips or pretzels packaged in this kind of film stays crispy but also in an invitingly appealing appearance, with matte dispelling glare and fingerprints. The heat-sealing feature of the film ensures the bags are tightly closed against air and moisture ingress, retaining the quality of snacks.

Advantages of Using Transparent Matt CPP Film in Packaging

Aesthetic Appeal

The combination of transparency and matte finish gives products a unique and sophisticated look. It stands out on store shelves, attracting consumers with its understated elegance. Whether it's food, cosmetics, or retail items, the film enhances the visual presentation, making the products more desirable and potentially increasing sales.

Product Protection

The mechanical strength, barrier properties, heat resistance, and chemical resistance of the film all work in harmony to protect packaged items. It protects food against spoilage, cosmetics against degradation, and industrial components against damage during handling, storage, and transportation. It acts like a shield for keeping moisture, gases, odors, and physical impacts away and maintains the integrity and quality of packaged items.

Versatility in Packaging Design

Transparence Matt CPP Film comes with very good formability into a wide variety of shapes and sizes according to different requirements. Wrap, bags, pouches, as single wraps or components in composite films, all types of applications are also able to provide hybrid packages for various values added functions and appearance when combined together. It will allow several packaging creativities, bespoke packages per different needs and brands in response to products' specific characteristics.

Printability

Although it features a matte surface, it has good printability. It can be printed into various colors and clearly delivered text and design for better conveyance of branding information to the target group. This is because inks well accept the film surface; hence, any printed information is clear, long-lasting, and durable even after various exposures with environmental conditions. Therefore, it may become your best choice if your labeling requires clear attractiveness on its packaging.

Recyclability

The key advantage of CPP is its recyclability, as the material can be processed into new products after the end of its life by gathering, recycling, and then reprocessing. This tends to minimize waste and helps to preserve resources. Transparency of matt CPP film on account of this recyclability will be an attractive alternative for consumers and all those manufacturers committed to sustainable packaging.

Case Studies of Transparent Matt CPP Film in Packaging Applications

Case Study 1: Bakery's Packaging Transformation

A local bakery had problems with the freshness and appearance of the packaging of their bakeries. They started using transparent matt CPP film for wrapping their loaves of bread, pastry, and cakes. Barrier properties of the film helped in maintaining the freshness of the products for a longer time, hence reducing spoilage by more than 30%. This gave the baked goods a more appetizing look on store shelves, and their sales increased by 20% in the first few months following implementation. The bakery also indicated that the film was easy to handle during packaging and therefore enhanced their production efficiency.

Case Study 2: Packaging Upgrade for Cosmetic Brand

A cosmetic brand wanted to give its makeup products an increased feel of luxury and protection. They used transparent matt CPP film for packaging their lipsticks and eyeshadow palettes. The transparency of the film made the colors show really well, while the matte finish gave it an added touch of high-class quality, increasing the perceived value of the products. The chemical resistance of the film kept the makeup whole and intact, without letting any external factors affect it. It saw a 15% increase in pre-orders and sales, with consumers praising the sophisticated packaging.

Case Study 3: Innovation in Retailer's Packaging

A retailer of clothing was facing problems regarding the quality and appearance of their shopping bags. The retailer switched to using transparent matt CPP film for their bags. The strength and durability of the film let the bags carry heavier loads without tearing, while the transparency and matte finish made them look stylish and professional. The retailer felt there was a 25% increase in customer satisfaction with the new bags and a 10% increase in repeat customers, partly due to improved packaging.

Challenges and Solutions in the Use of Transparent Matt CPP Film in Packaging

Improvement in Barrier Property

While transparent matt CPP film has moderate barrier properties, some applications require an even higher level of protection against moisture, gases, or odors. Multilayer films are an option in which the CPP film is combined with other materials having superior barrier capabilities, such as ethylene - vinyl alcohol (EVOH) or aluminum foil. Extra coating of the film with additional barrier layers or the use of nanocomposites increases its barrier performance.

Printing and Labeling Difficulties

Printing on the matte surface of the film can sometimes be difficult because it has less surface energy than glossy films. Surface treatment methods like corona treatment or plasma treatment can be done to enhance the surface energy of the film and hence improve the adhesion of ink on it. Using special inks and printing techniques specifically for plastic films can also ensure high-quality and durable printing.

Environmental Concerns

While the CPP is recyclable, the general trend in recycling rates for plastic films is relatively low. In improving this, efforts should be made to increase consumer awareness of the recyclability of CPP film and improvement in collection and recycling infrastructure. Manufacturers may also explore developing biodegradable or compostable versions of CPP film for further environmental impact reduction.

Heat Sealability and Compatibility with Filling Processes

The problem, in many instances, is to obtain consistent, reliable heat sealability on transparent matt CPP film where this is used in association with specific filling processes. Voluminous testing by manufacturers in determining optimum heat-seal parameters in various applications and working with equipment suppliers to ensure compatibility of the packaging machinery with the film's heat seal requirements are other ways of ensuring such issues. Besides, if necessary, additives or an adjustment in the composition may be used to enhance further the heat sealability properties of the film.

Conclusion

The transparent matt CPP film has turned out to be a great asset in this industry due to its great application in food, cosmetic, pharmaceutical, and retail industries. This material is a combination of various properties like transparency, matte finish, excellent mechanical strength, barrier, heat resistance, and also recyclable. Although barrier enhancement, printing difficulties, environmental concerns, and issues related to heat sealability are some of the problems, solutions to these can be found. The outlook for transparent matt CPP film in the future is more promising, considering the continuous evolution in the packaging industry for sustainability, product protection, and aesthetics, with ongoing research and development to improve its performance and environmental friendliness.

Within 15-20 days after received payment...more