Exploring Printable PVC Film and PVC Wear Layer Film in Wall Panel and Wallpaper Manufacturing

NamePVC soft film roll

SizeTk:0.01-3mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageSoft PVC film, corrosion resistance, fireproofing, waterproofing, anti-static, wall paper making

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- 中国

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

In the realm of interior design and architectural finishes, the choice of materials significantly impacts both aesthetics and functionality. Printable PVC film and PVC wear layer film have become cornerstone materialsbud materials in the production of wall panels and wallpapers, offering a unique blend of versatility, durability, and visual appeal.  These PVC-based films are prized for their ability to transform surfaces, providing customizable designs and robust protection. Printable PVC film allows for high-quality, vibrant graphics, while PVC wear layer film adds a protective, durable surface to withstand wear and tear. This article delves into the characteristics of these two materials, their applications in wall panel and wallpaper manufacturing, and their contributions to modern interior design. Through a detailed exploration, we aim to provide a comprehensive understanding of how printable PVC film and PVC wear layer film elevate both residential and commercial spaces.

These PVC-based films are prized for their ability to transform surfaces, providing customizable designs and robust protection. Printable PVC film allows for high-quality, vibrant graphics, while PVC wear layer film adds a protective, durable surface to withstand wear and tear. This article delves into the characteristics of these two materials, their applications in wall panel and wallpaper manufacturing, and their contributions to modern interior design. Through a detailed exploration, we aim to provide a comprehensive understanding of how printable PVC film and PVC wear layer film elevate both residential and commercial spaces.

Characteristics of Printable PVC Film

Printable PVC film is a polyvinyl chloride-based material designed specifically for digital or screen printing, enabling the creation of intricate patterns, textures, and images. Its properties make it an ideal choice for decorative applications in wall panels and wallpapers. Below are the key characteristics that define printable PVC film:

Printability and Color Vibrancy

Printable PVC film is engineered to accept a wide range of inks, including UV, solvent, and eco-solvent inks, ensuring sharp, high-resolution prints with vivid colors. The smooth, non-porous surface of the film prevents ink bleeding, resulting in crisp designs that maintain their clarity over time. This property is particularly valuable for wallpapers, where intricate patterns or photorealistic images are often desired. The film’s compatibility with modern printing technologies allows manufacturers to produce bespoke designs, catering to diverse aesthetic preferences.

Flexibility and Conformability

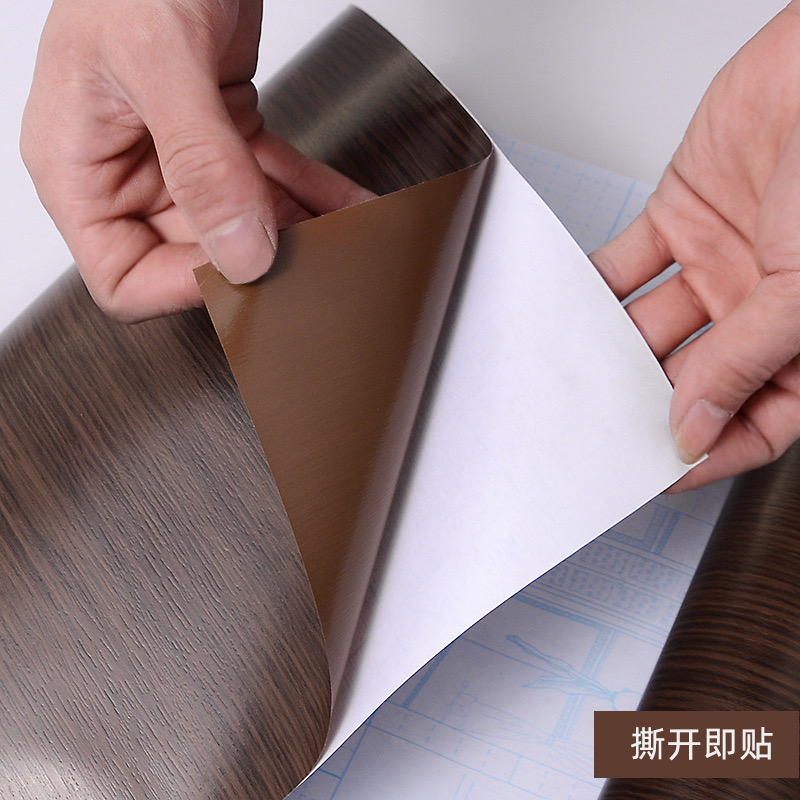

The inherent flexibility of PVC makes printable PVC film highly conformable, allowing it to adhere seamlessly to various substrates, including flat, curved, or textured surfaces. In wall panel manufacturing, this flexibility enables the film to wrap around edges or conform to embossed textures, creating a cohesive and polished appearance. For wallpapers, the film’s ability to stretch slightly during application ensures easy installation, even on uneven walls, reducing the risk of air bubbles or wrinkles.

Durability and Stability

Printable PVC film is resistant to fading, moisture, and mild chemicals, ensuring that printed designs remain vibrant and intact in various environmental conditions. Its UV resistance is particularly beneficial for wallpapers and wall panels in sunlit areas, as it prevents color degradation over time. Additionally, the film’s dimensional stability prevents shrinking or stretching, maintaining the integrity of the printed design during and after application.

Customizability and Texture Options

Available in a range of thicknesses (typically 0.08 mm to 0.3 mm) and finishes (matte, gloss, or textured), printable PVC film offers extensive customization options. Manufacturers can emboss the film to mimic materials like wood, stone, or fabric, enhancing the tactile and visual appeal of wall panels and wallpapers. This versatility allows designers to create products that align with specific themes, from minimalist modern to rustic traditional.

Cost-Effectiveness

Compared to traditional materials like wood veneer or fabric, printable PVC film is a cost-effective alternative that delivers high-end aesthetics at a lower price point. Its efficient production process and compatibility with high-speed printing technologies enable manufacturers to produce large volumes quickly, making it an attractive option for both small-scale and industrial applications.

Characteristics of PVC Wear Layer Film

PVC wear layer film is a transparent or semi-transparent PVC-based material applied as a protective topcoat over wall panels, wallpapers, or other surfaces. Its primary function is to enhance durability and resistance to wear, making it an essential component in high-traffic or demanding environments. The key characteristics of PVC wear layer film include:

Abrasion and Scratch Resistance

PVC wear layer film is engineered to withstand surface abrasion, scratches, and scuffs, making it ideal for wall panels and wallpapers in commercial settings like offices, hotels, or retail spaces. The film’s high tensile strength and hardness protect underlying designs from damage caused by furniture, foot traffic, or cleaning processes, extending the lifespan of the product.

Chemical and Stain Resistance

The non-porous nature of PVC wear layer film makes it resistant to stains, spills, and common cleaning agents, such as detergents or disinfectants. This property is particularly valuable for wallpapers in kitchens, bathrooms, or healthcare facilities, where hygiene is paramount. The film’s ability to repel liquids also prevents mold or mildew growth, ensuring a clean and safe environment.

Impact Resistance

PVC wear layer film adds a layer of toughness to wall panels, enabling them to withstand minor impacts without denting or cracking. This is especially important in high-traffic areas or spaces with heavy furniture, where accidental bumps are common. The film’s elasticity allows it to absorb and distribute impact energy, preserving the structural integrity of the underlying substrate.

UV Protection and Fade Resistance

Similar to printable PVC film, PVC wear layer film offers excellent UV resistance, protecting printed designs or colored substrates from fading due to sunlight exposure. This property ensures that wall panels and wallpapers retain their original appearance, even in brightly lit spaces like atriums or sunrooms.

Customizable Clarity and Finish

PVC wear layer film is available in various levels of clarity (clear, frosted, or tinted) and finishes (glossy, matte, or anti-slip). Manufacturers can select a finish that complements the underlying design, such as a glossy wear layer to enhance vibrant wallpapers or a matte finish for a subdued, elegant wall panel. The film can also be formulated with anti-slip properties for safety in wet or high-traffic areas.

Applications in Wall Panel Manufacturing

Within 15-20 days after received payment...more