Characteristic and Application of EVA/PE Composite Film in Different Fields of Packing

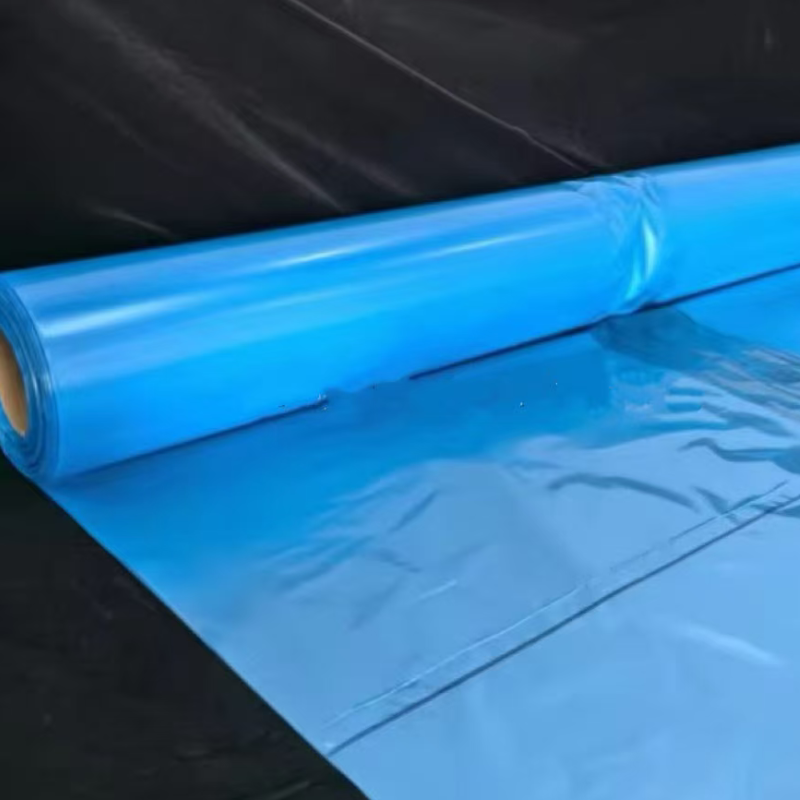

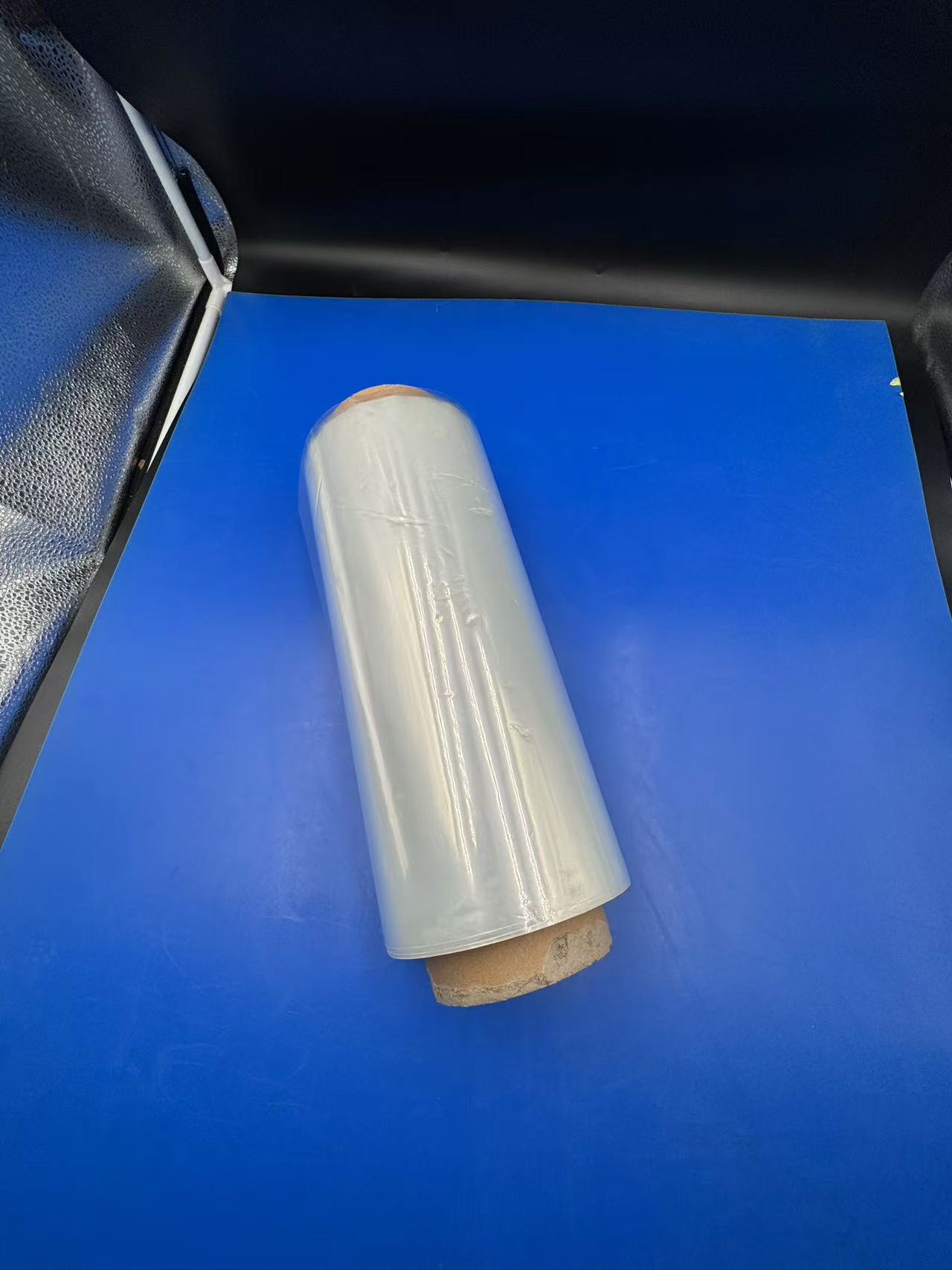

Material: EVA/ PE COMPOSIETE FILM ROLL

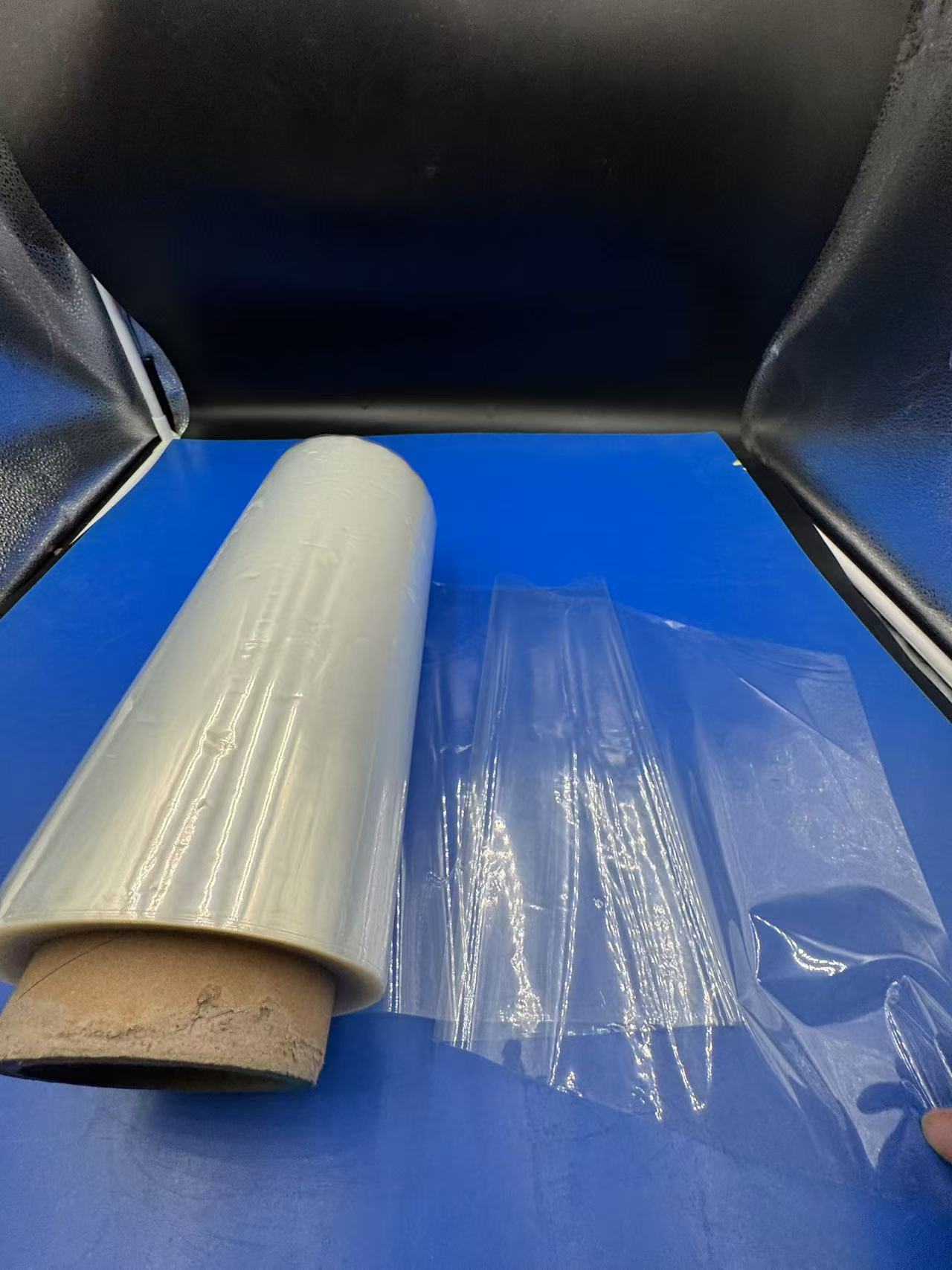

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/pearl white/ customization

location: china

usage :for food packing,cigarette ,gift packing ,candy packing

Material: Flexible PVC ROLL

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

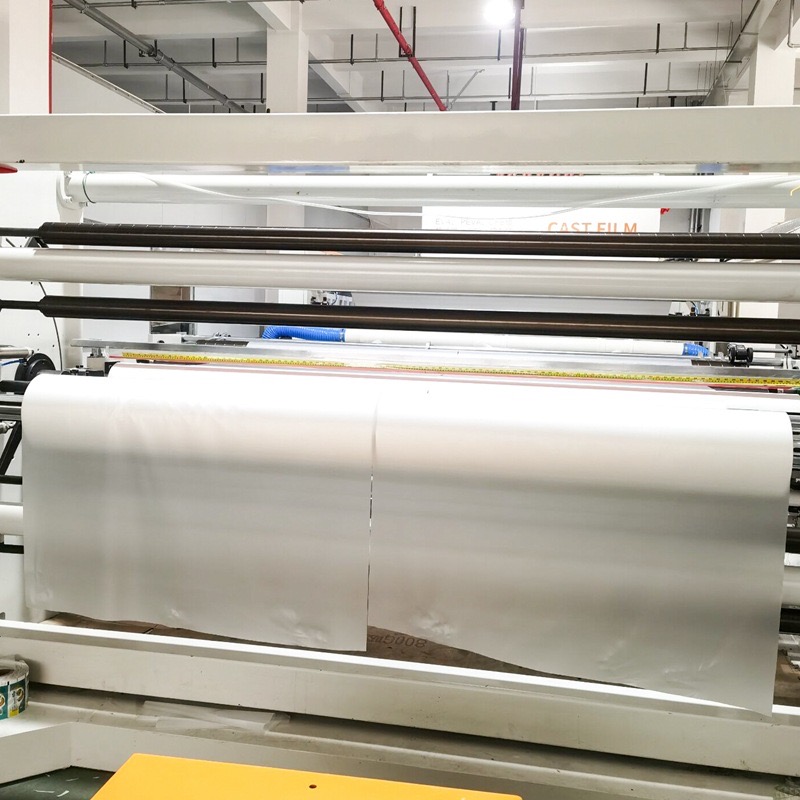

Ethylene-vinyl acetate/polyethylene composite films have gained significance as one of the vital packaging materials due to their unique property combination that fits the requirements for a wide variety of applications. The present article describes the characteristics of EVA/PE composite films and their huge applications in various sectors of packaging, showing the advantages and versatility of such films. Characteristics of EVA/PE Composite Films Barrier Properties

EVA/PE composite films show selective barrier properties. While pure EVA exhibits poorer gas and moisture barriers compared to pure PE, the combination enhances some characteristics:

Permeability to Oxygen and Gas: EVA, when blended with PE, changes the permeability characteristics. The increased vinyl acetate content in EVA reduces crystallinity, hence increasing the permeability of gases like oxygen, which may be desired in certain applications such as modified atmosphere packaging, where controlled gas exchange is required to extend the shelf life.

Water Vapor Resistance: EVA, as such, is not a good moisture barrier; however, the composite with PE can be tuned to offer adequate resistance while providing flexibility that will address the requirement for moisture protection in packaging.

Flexibility and Toughness

Low Temperature Flexibility: One of the most characteristic advantages of the EVA/PE films is their excellent properties at low temperatures. The vinyl acetate addition in EVA reduces the crystallinity of PE, making this film more flexible and less susceptible to brittleness, a critical factor for packaging solutions intended for cold storage or freezer applications.

Impact Resistance: EVA adds toughness to the film, providing excellent resistance to impact. This property is very important in packaging that may be subjected to physical stress in shipment or handling.

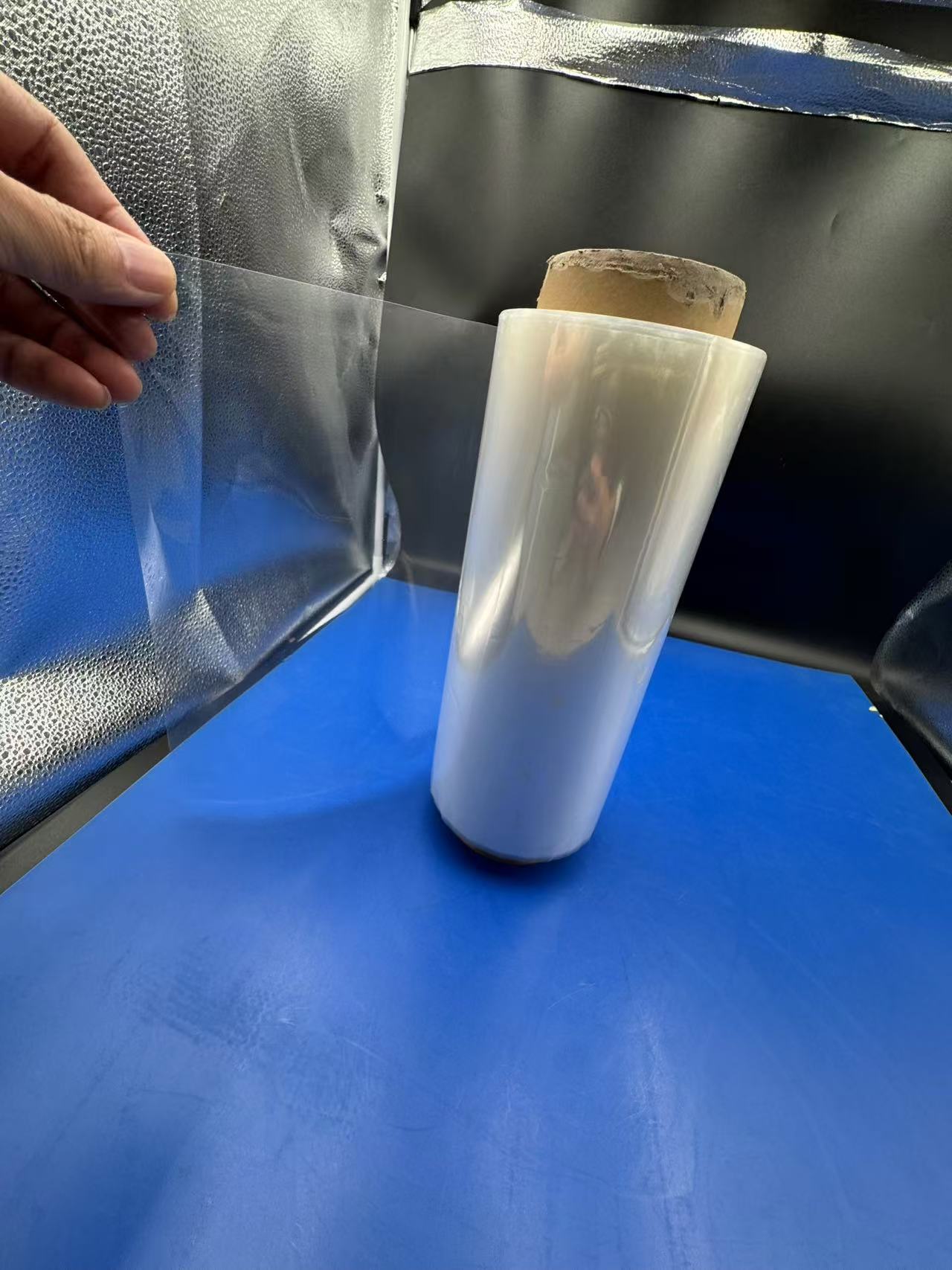

Optical Clarity

Transparency: EVA/PE films can be formulated for high clarity, which is especially useful in packaging where product visibility is required, such as in food packaging or medical applications where visual inspection is necessary.

Sealability

Heat Sealability: The blend significantly lowers the seal initiation temperature compared to PE alone. Due to this property, sealing processes in packaging lines can be easier and more energy-efficient, thereby enhancing productivity coupled with energy conservation.

Applications in Packaging

Food Packaging

Fresh Produce: Controlled permeability of the films allows MAP, a process in which the atmosphere inside the package is changed to extend the freshness of fruits, vegetables, and meats. The flexibility and puncture resistance also contribute to maintaining package integrity during transportation.

Dairy and Frozen Foods: EVA/PE films find applications in packing ice cream, frozen vegetables, or cheese because of the nature of this low-temperature application, which requires maintaining the product's appearance and integrity at low temperatures.

Pharmaceuticals

Blister Packs: The clarity coupled with good sealing properties makes these films suitable in pharmaceutical blister packs for visibility of the product and protection against environmental factors.

Medical Devices: These films are toxic free and safe, hence RF sealing equipment can process them and applied for packing medical devices for keeping them sterile.

Industrial Packaging

Protective Films: The usage of these films might be in many forms in industrial uses as surface protector for appliances or goods being manufactured or delivered due to protection and the efficiency of adhesion in placing or removing them. Solar Panels

Encapsulation: EVA in higher percentages, such as 33%, can serve in applications related to the encapsulation of solar cells within solar panels. The ability of the film here to bond with other materials, along with offering UV stability and clarity, holds the key for long-term maintenance of panel efficiency.

Cosmetics and Personal Care

Cosmetic Tubes and Bottles: It is used for the production of laminated tubes or for coating bottles, which require cosmetic appeal yet still provide high functionality due to elasticity and sealing characteristics.

Future Trends and Innovations

Sustainability: In today's day-to-day push toward sustainable packaging, biodegradable or recyclable versions of the EVA/PE films are under extensive research. This presents the challenge of the production of such film variants without compromising the properties desired.

Advanced Barrier Films: Further improvement of the barrier properties, probably by nanotechnology or new polymer blends, will be directed at meeting the increasingly sophisticated demands made by advanced packaging.

Smart Packaging: Integration of smart technologies, such as sensors, in EVA/PE films for the development of intelligent packaging capable of monitoring freshness or responding to environmental changes is further extending the functionality beyond mere containment.

Conclusion

EVA/PE composite films exhibit a combination of flexibility, toughness, clarity, and sealability that makes them suitable for a wide range of packaging applications, from food product protection to encapsulation for solar cells. The films illustrate the ways in which polymer science can be applied to solve sophisticated packaging problems. Such materials will continue to play an increasingly important role in packaging applications as the industry moves forward to meet emerging demands for sustainability, efficiency, and sophisticated functionality.

The wide discussion brings into perspective not only the utility but also the further inventive possibilities in EVA/PE composite films, so that these are at the front line of packaging technology.

Within 15-20 days after received payment...more