PLA Biodegradable Film: Revolutionizing Food Sealing and Preservation

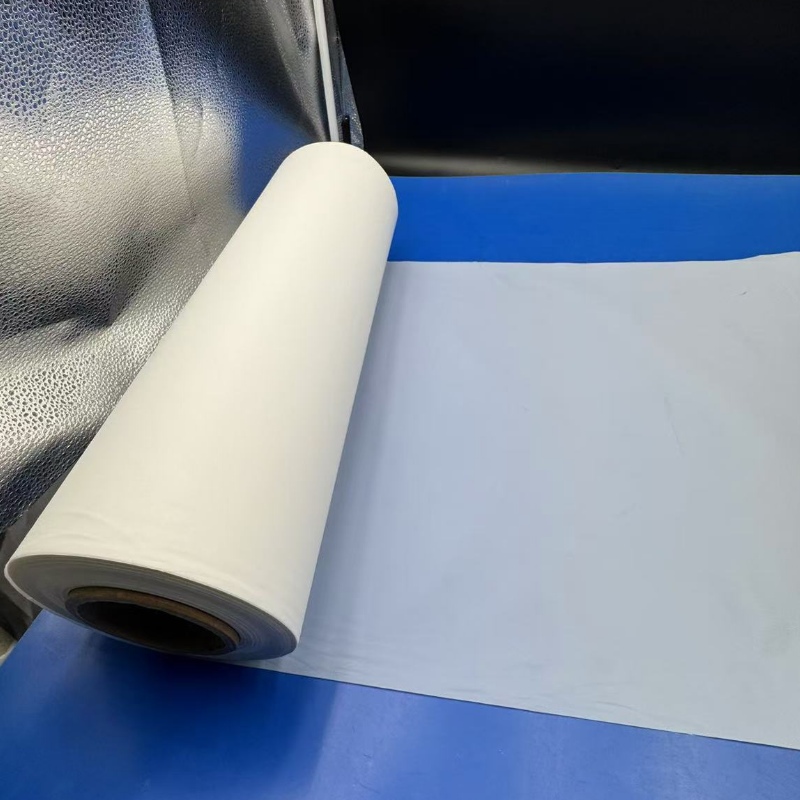

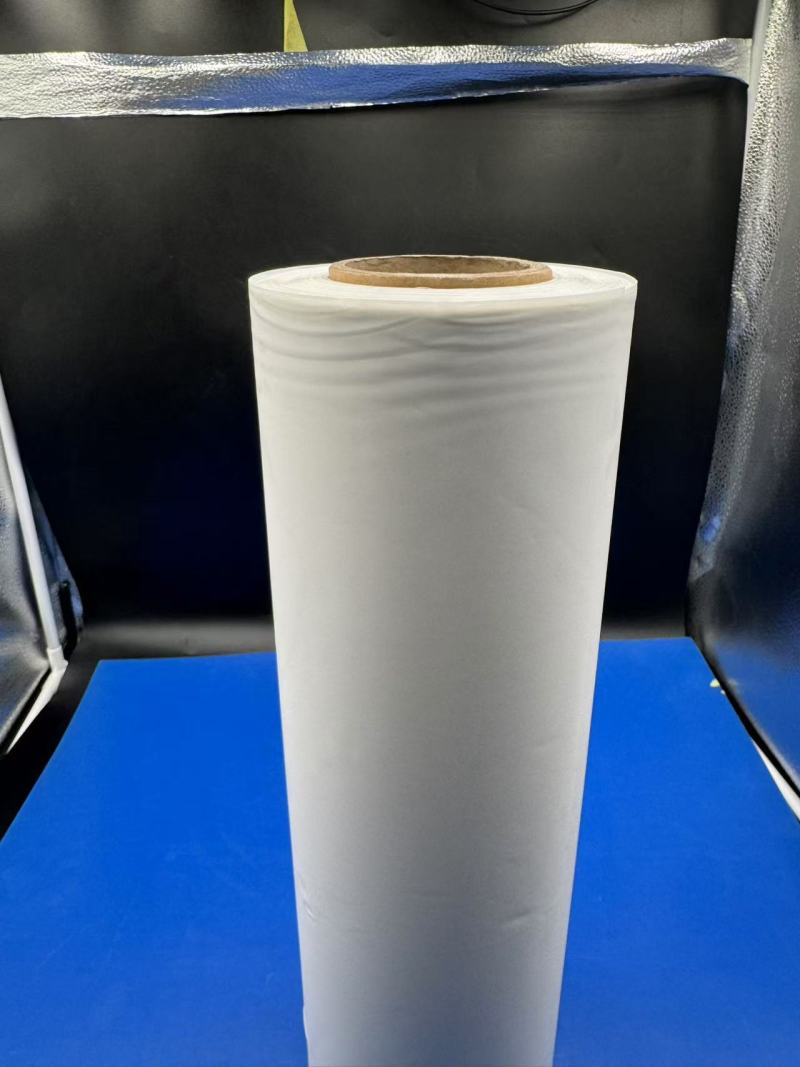

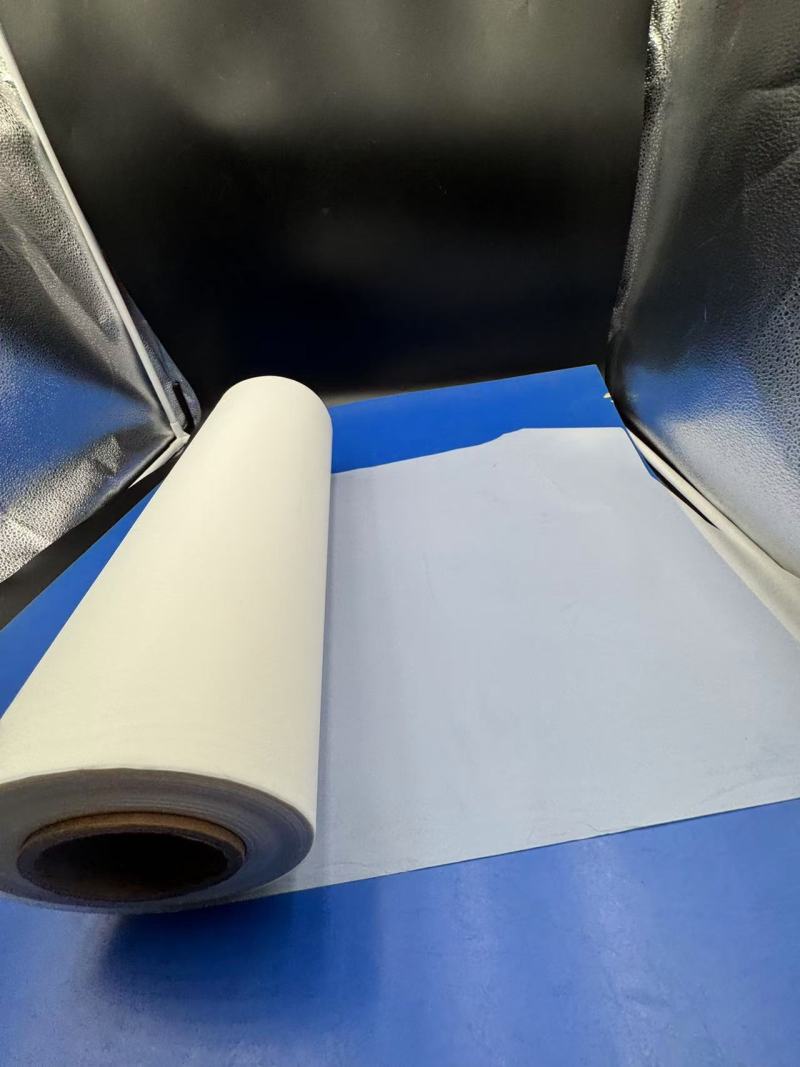

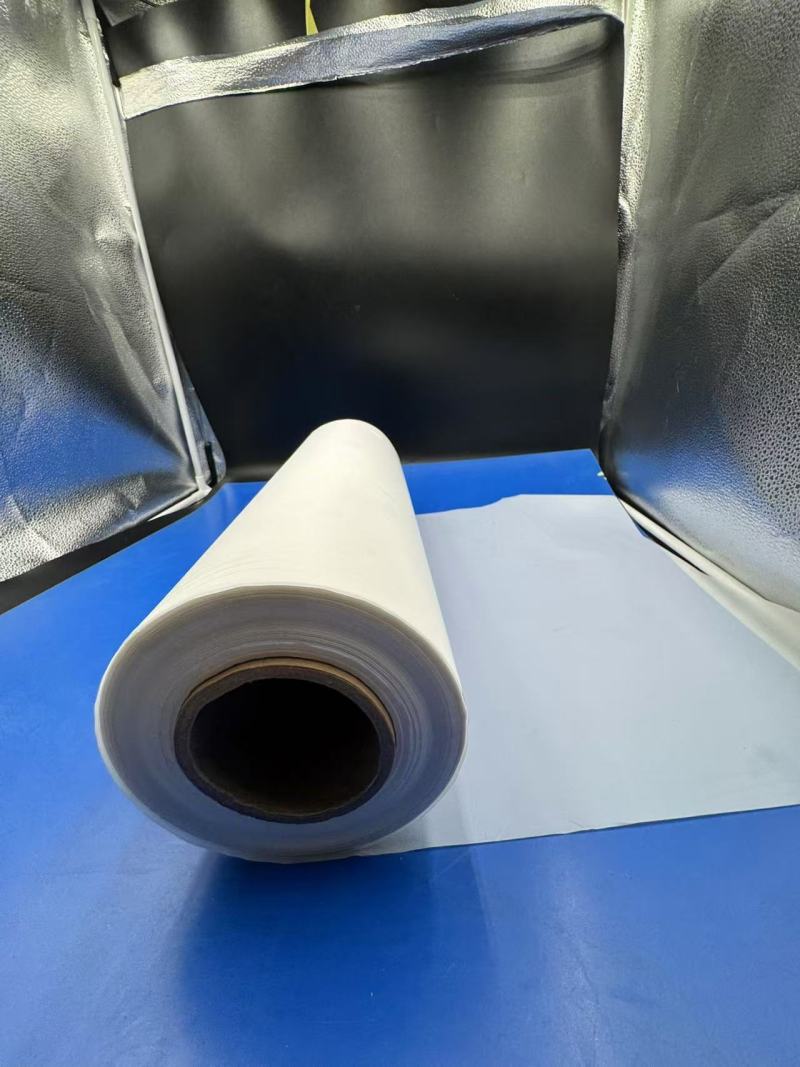

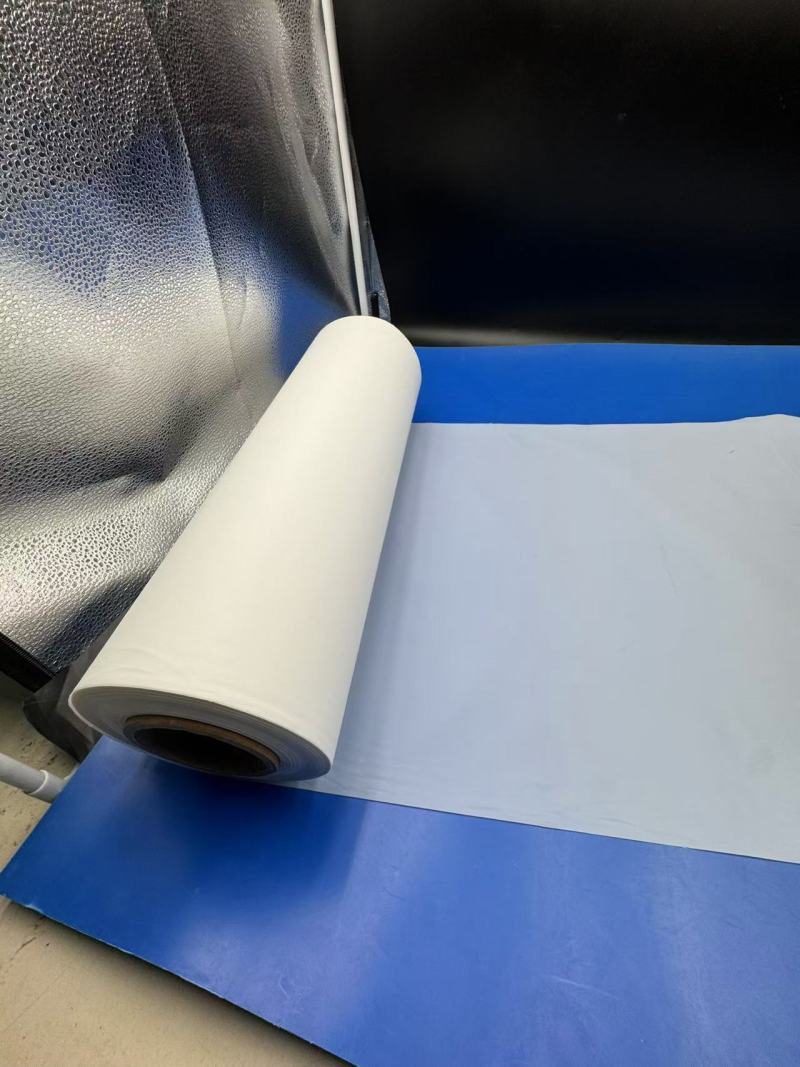

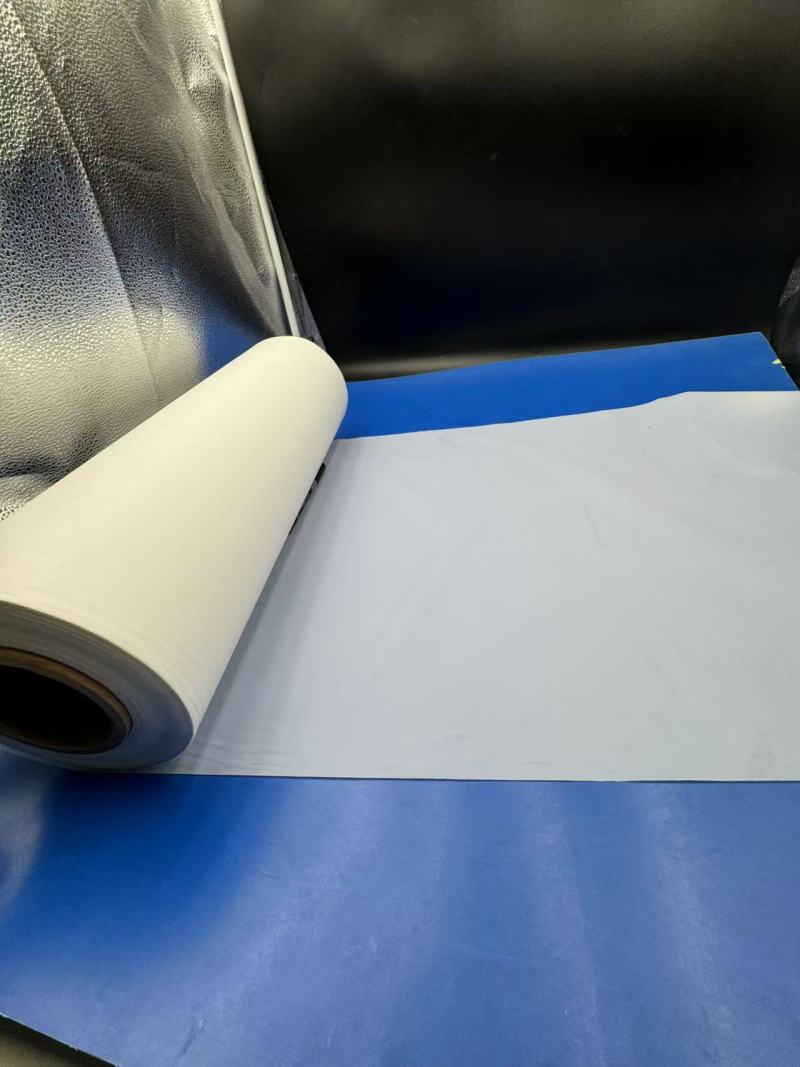

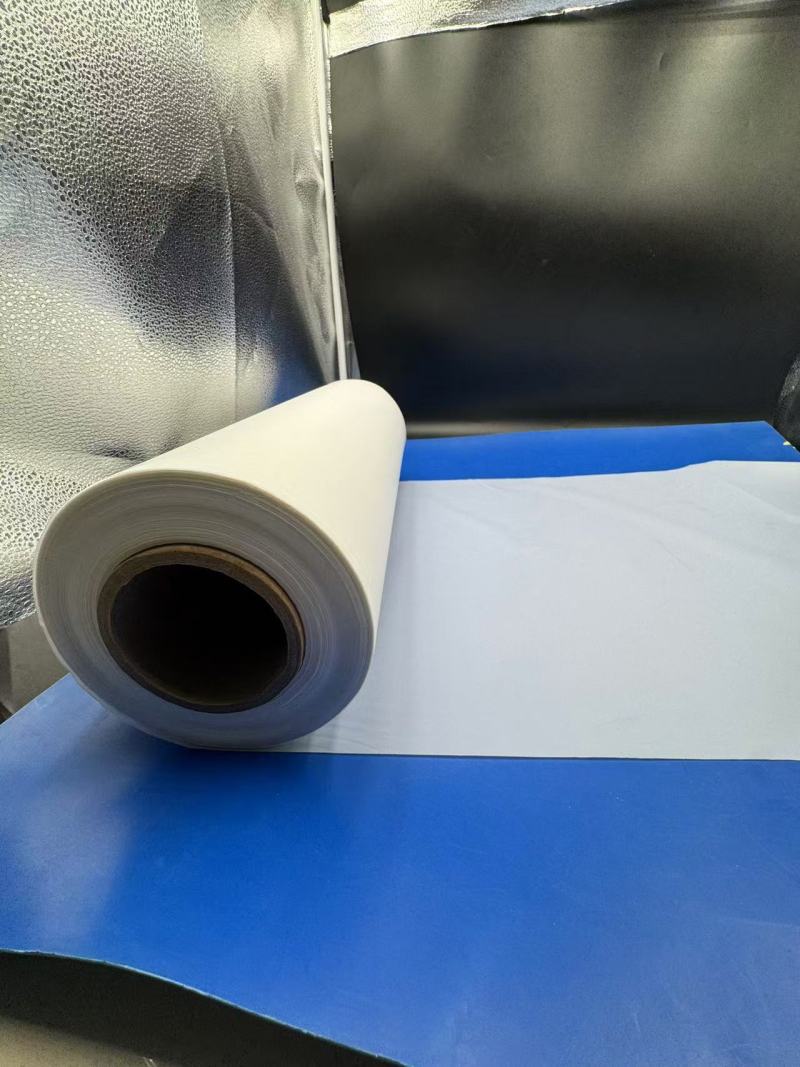

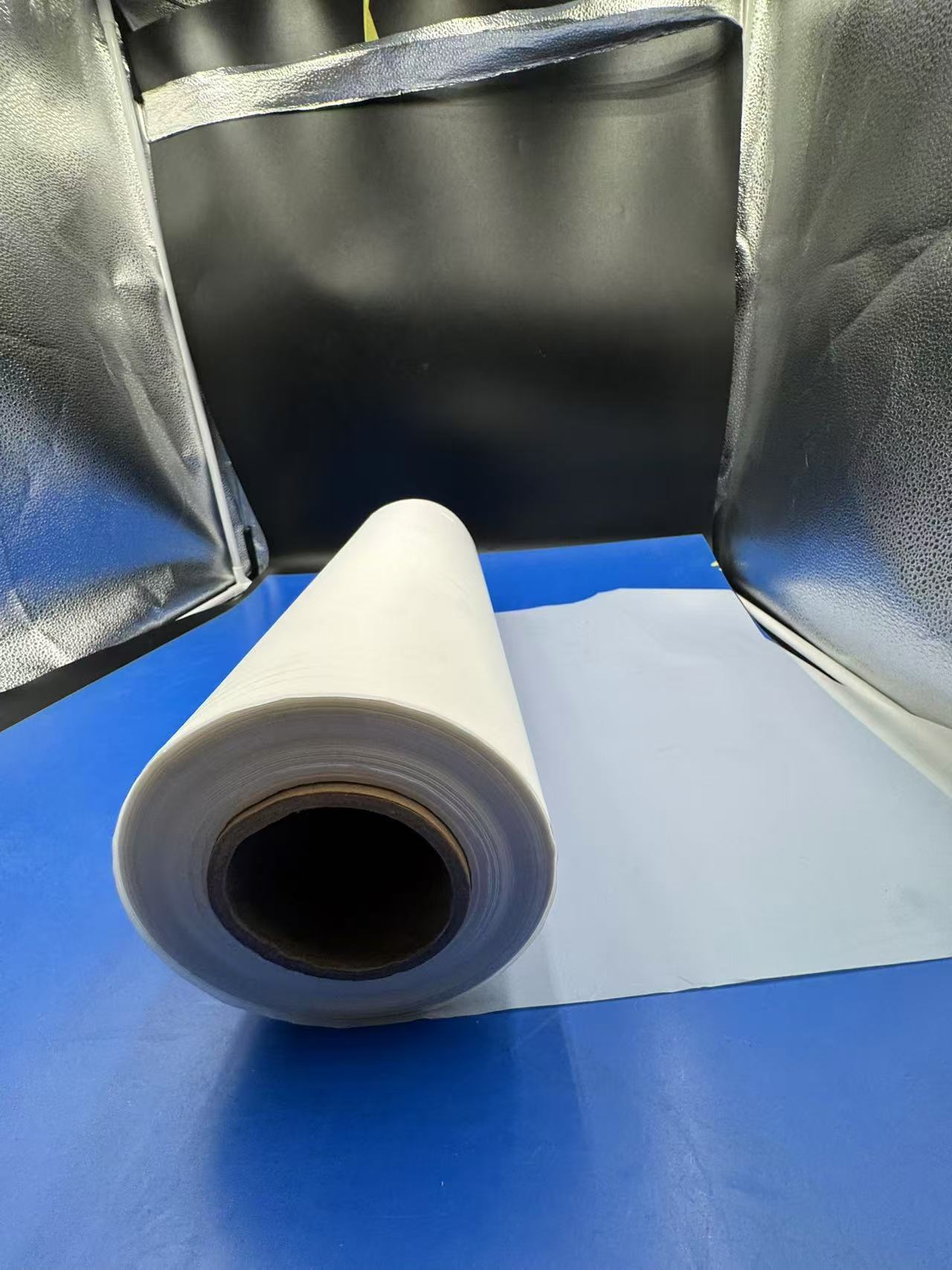

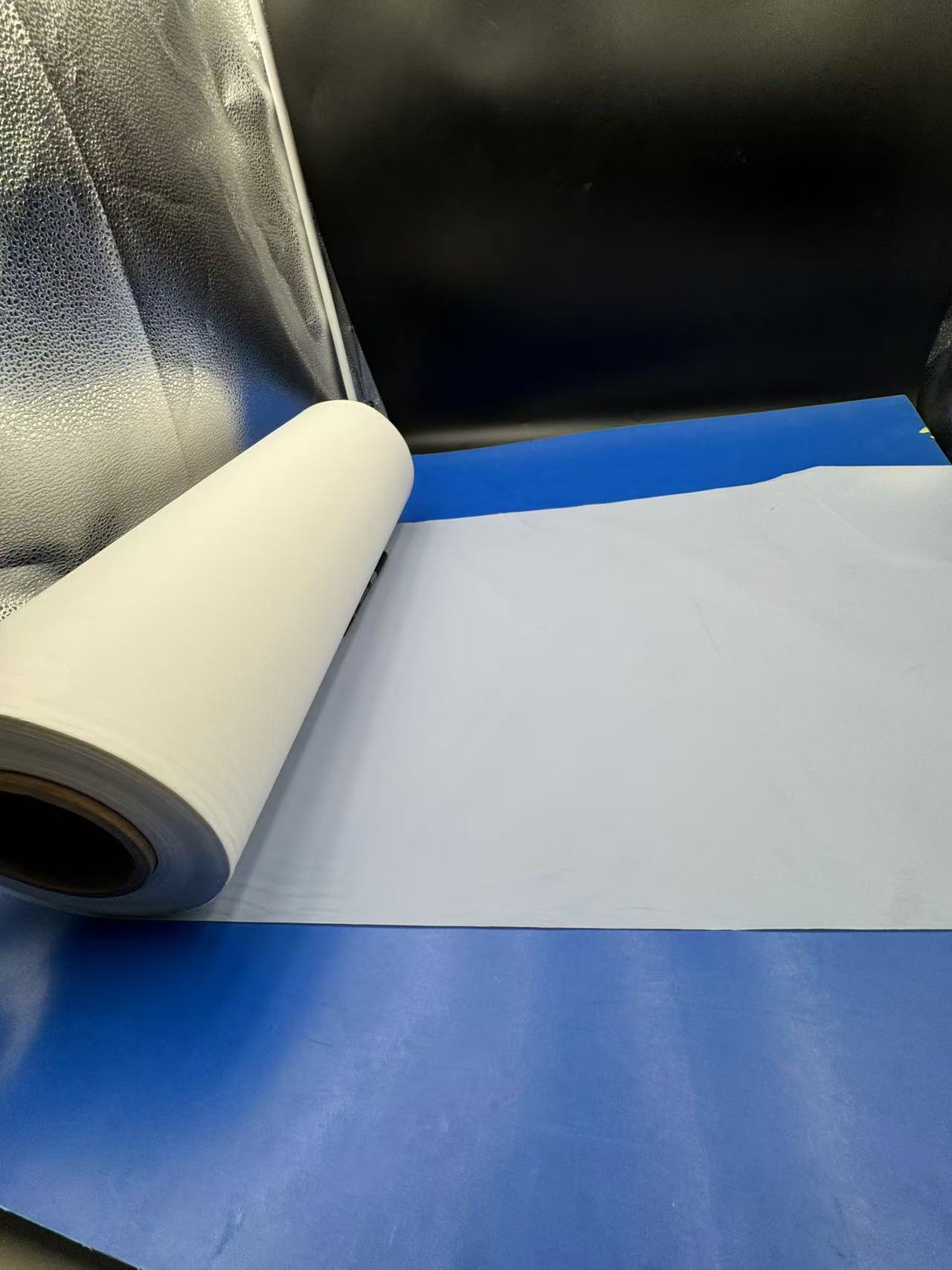

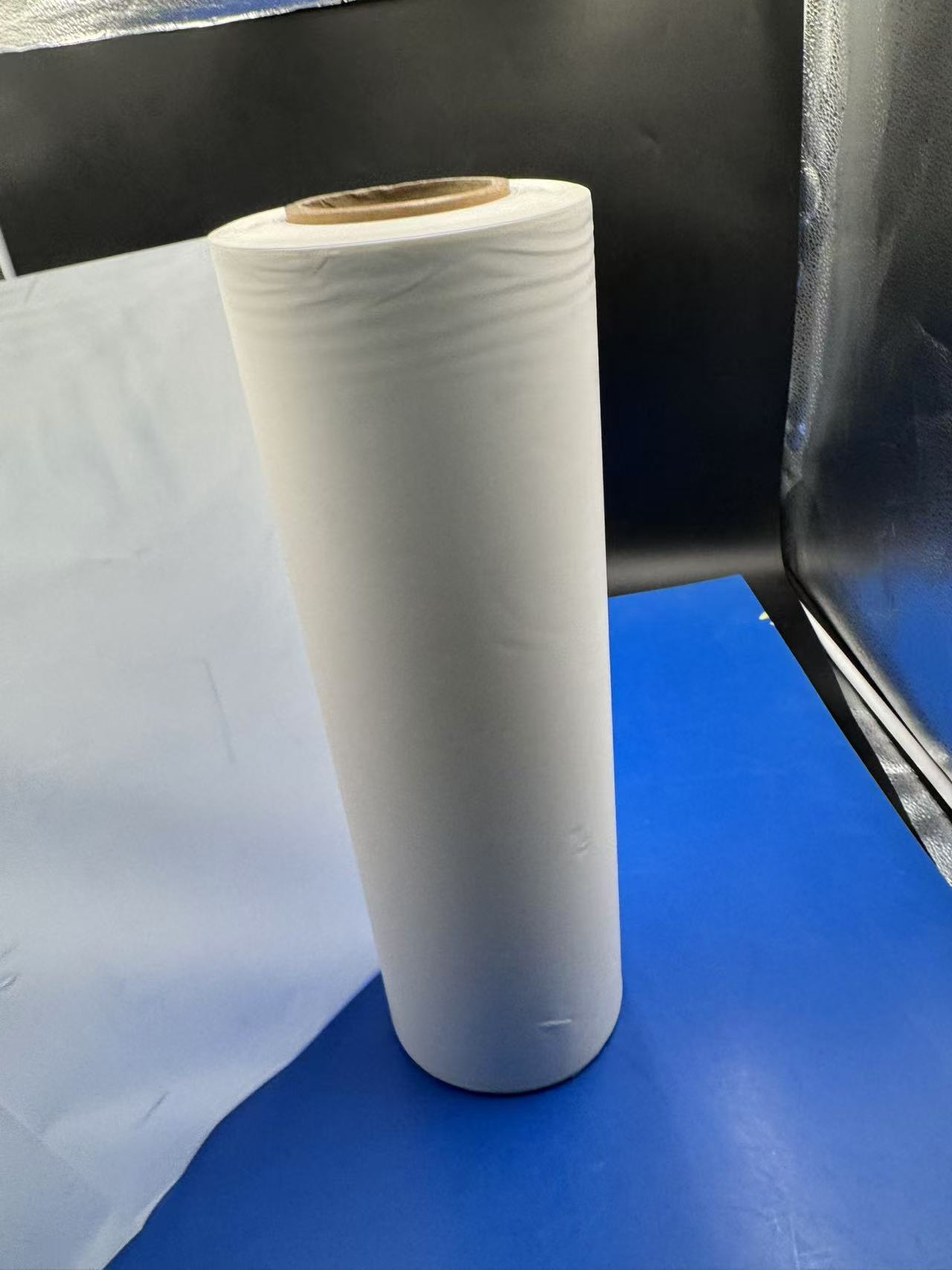

Material: PLA FILM ROLL

Thickness 0.012mm/1.0 customization

Size: 100mm/Customization

GRADE: Food grade film

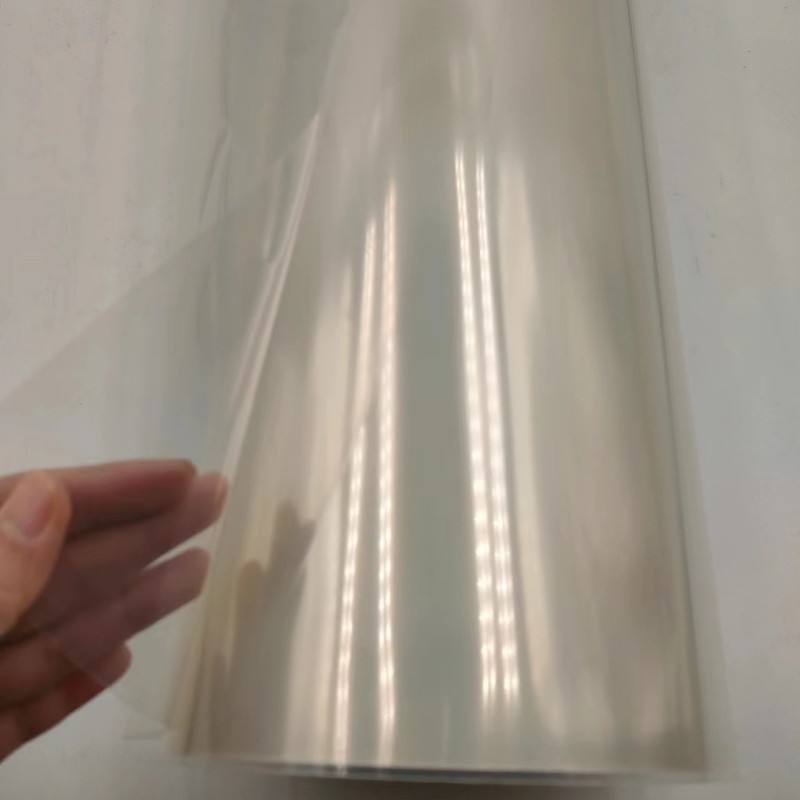

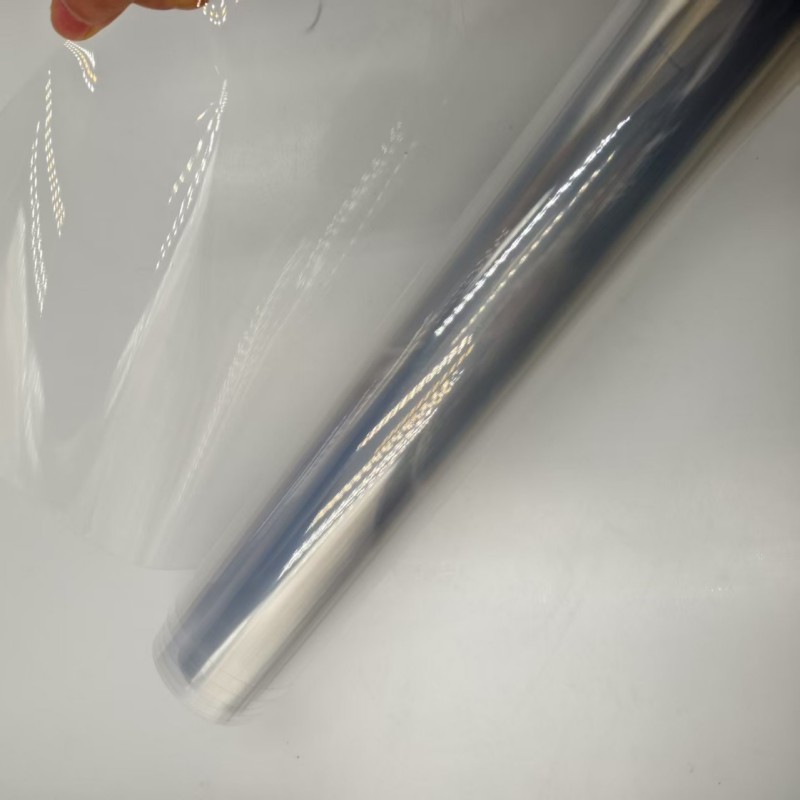

color: transparent/pearl white/ customization

location: china

usage :for food packing, gift packing ,candy packing

food heat sealing, and its role in enhancing food protection through sustainable packaging solutions.

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

Polylactic Acid (PLA) biodegradable film has emerged as a promising alternative to traditional petroleum-based plastics in the food packaging industry. This article explores the distinctive properties of PLA film, its application in food heat sealing, and its role in enhancing food protection through sustainable packaging solutions.

Characteristics of PLA Biodegradable Film

Chemical Composition:

Source Material: PLA is derived from renewable resources, primarily corn starch, sugarcane, or other biomass. This organic origin underpins its environmental credentials.

Polymer Structure: PLA is a linear aliphatic polyester that can be processed into films through various methods like blown film extrusion or casting.

Physical Properties:

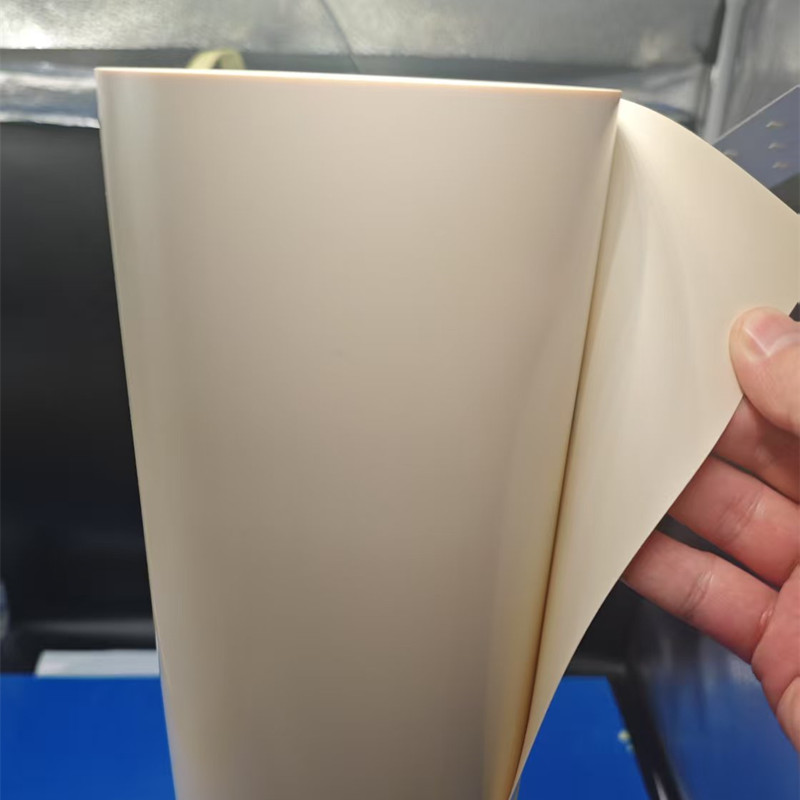

Clarity: PLA films provide excellent optical clarity, which is crucial for consumers to view the product inside without unwrapping, enhancing the visual appeal of packaged goods.

Flexibility: Despite being biodegradable, PLA films can be formulated to be flexible, yet they maintain sufficient strength for packaging demands.

Thermal Properties: PLA has a melting point around 150-160°C, suitable for most food packaging applications, although it requires careful control during heat sealing to avoid degradation.

Barrier Properties: While naturally PLA's barrier properties are moderate compared to traditional plastics, advancements have led to modified PLA films with enhanced oxygen and moisture barriers.

Biodegradability:

Degradation Process: PLA degrades into lactic acid, which is then metabolized by microorganisms into CO2, water, and biomass under composting conditions. This process can take several months to a couple of years, depending on environmental conditions.

Compostability: Certified PLA films meet standards like EN 13432 or ASTM D6400, ensuring they can be industrially composted, reducing landfill waste.

Applications in Food Heat Sealing

Heat Sealing Techniques:

Seal Strength: PLA films can achieve good seal strength when the sealing temperature and pressure are optimized. This is vital for maintaining product integrity and preventing leakage.

Seal Integrity: The polymer's ability to form strong, uniform seals is fundamental for applications like pouches, bags, and trays used in supermarkets.

Machinability: PLA films can be processed on standard packaging machinery with minor adjustments to account for its lower heat tolerance compared to polyethylene.

Practical Applications:

Fresh Produce: PLA films are used for packaging fruits, vegetables, and salads, where oxygen and moisture management are critical for freshness.

Meat and Dairy: For these products, modified PLA films with better gas barrier properties extend shelf life by reducing spoilage from oxidation or dehydration.

Ready Meals: In the case of ready-to-eat meals, PLA films ensure that the food remains sealed and protected from contamination while preserving flavor and texture.

Use in Food Protection Packaging

Preservation:

Moisture Control: PLA can be tailored to control humidity, which is essential for products that are sensitive to moisture, like baked goods or certain cheeses.

Oxygen Scavenging: Some PLA films are combined with oxygen scavengers to significantly prolong the shelf life of oxygen-sensitive foods.

Flavor Retention: The film's structure can help retain volatile compounds responsible for the food's flavor, which is particularly beneficial for packaged spices or coffee.

Safety and Compliance:

Food Contact: PLA is FDA-approved for food contact, ensuring safety for consumers. It does not leach harmful substances, making it a clean choice for direct food contact.

Regulatory Compliance: PLA films adhere to various international standards for biodegradable and compostable packaging, promoting responsible consumer disposal.

Case Studies and Practical Examples

Supermarket Chains: Many have adopted PLA for packaging fresh produce, reducing their environmental footprint while meeting consumer demand for sustainability.

Catering and Takeaway: PLA has been popular for disposable food service items like cups, cutlery, and containers, which are now commonly seen in eco-conscious eateries.

Innovative Packaging: Companies are exploring new designs like PLA-based trays with built-in compartments for different food items, all sealed with PLA film to ensure each component stays fresh.

Future Trends and Challenges

Recycling and Composting Infrastructure: As PLA usage grows, there's a need for expanded composting facilities to handle the increased volume of biodegradable waste.

Improvements in Barrier Technology: Continued research aims at enhancing PLA's natural barriers without compromising its biodegradability, possibly through multi-layer films or coatings.

Cost Efficiency: While PLA is more expensive than conventional plastics, economies of scale and technological advancements are expected to narrow this gap.

Consumer Education: Educating consumers on proper disposal methods for PLA packaging to maximize its environmental benefits remains a challenge.

Conclusion

PLA biodegradable film stands at the forefront of sustainable packaging, particularly in food applications where heat sealing and preservation are crucial. Its ability to merge functionality with environmental responsibility makes it an increasingly popular choice among manufacturers, retailers, and environmentally aware consumers. As technology and infrastructure evolve, PLA film is poised to play an even more significant role in our journey towards a more sustainable future in food packaging.

Within 15-20 days after received payment...more