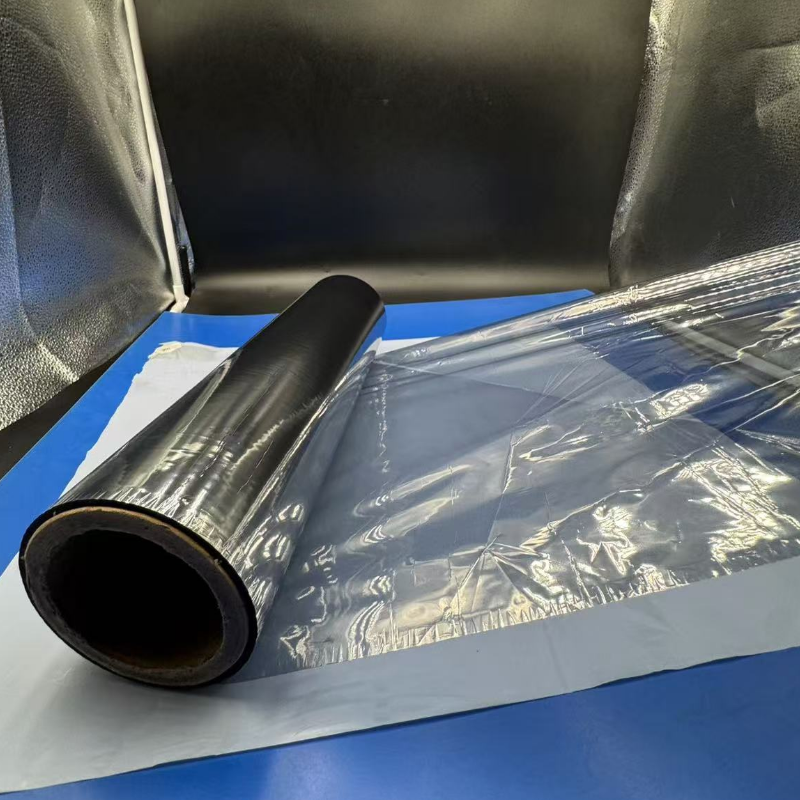

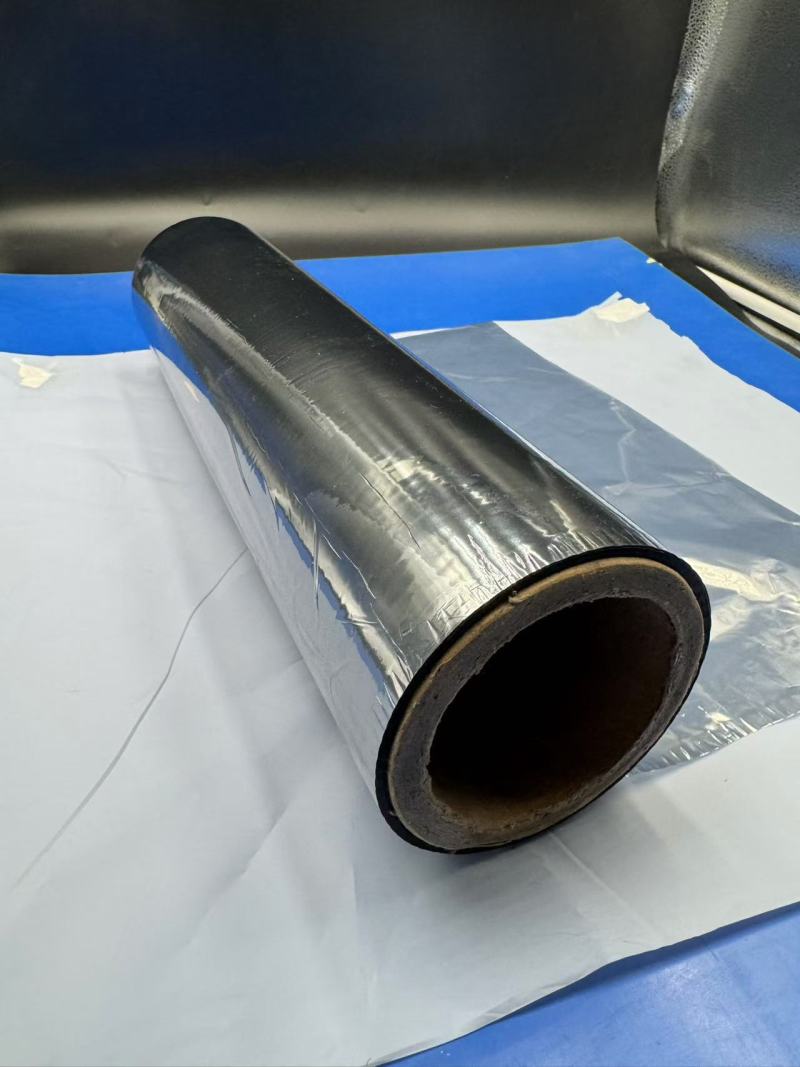

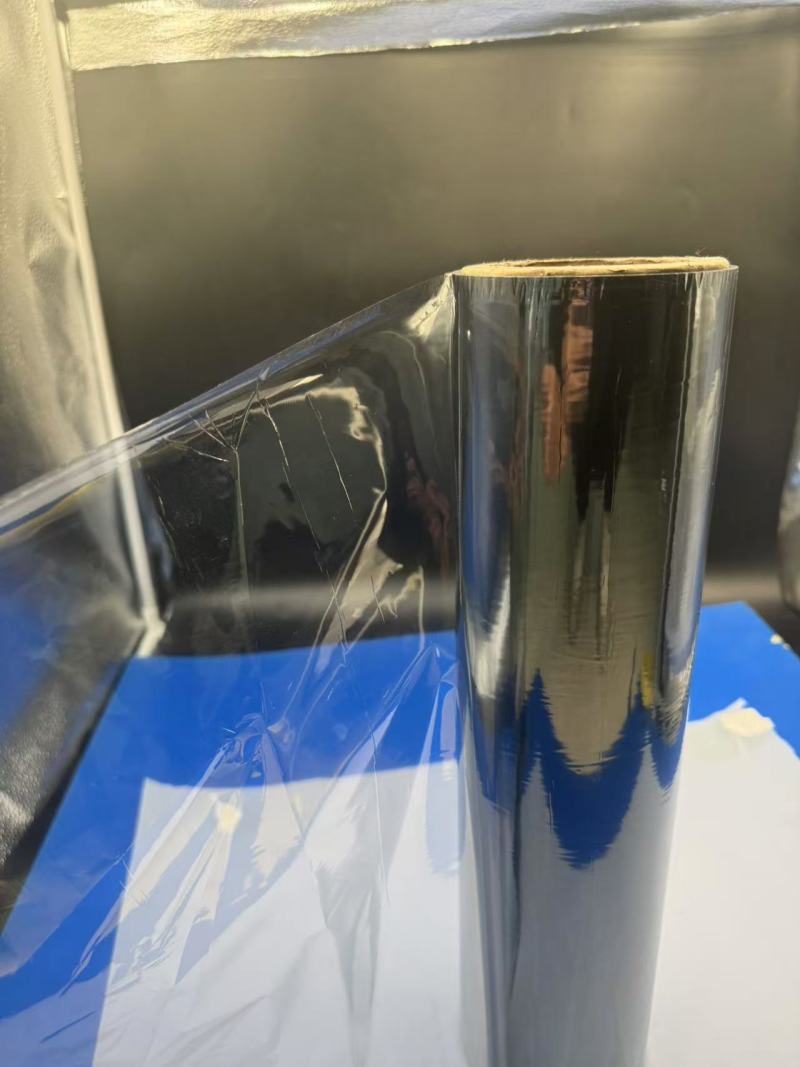

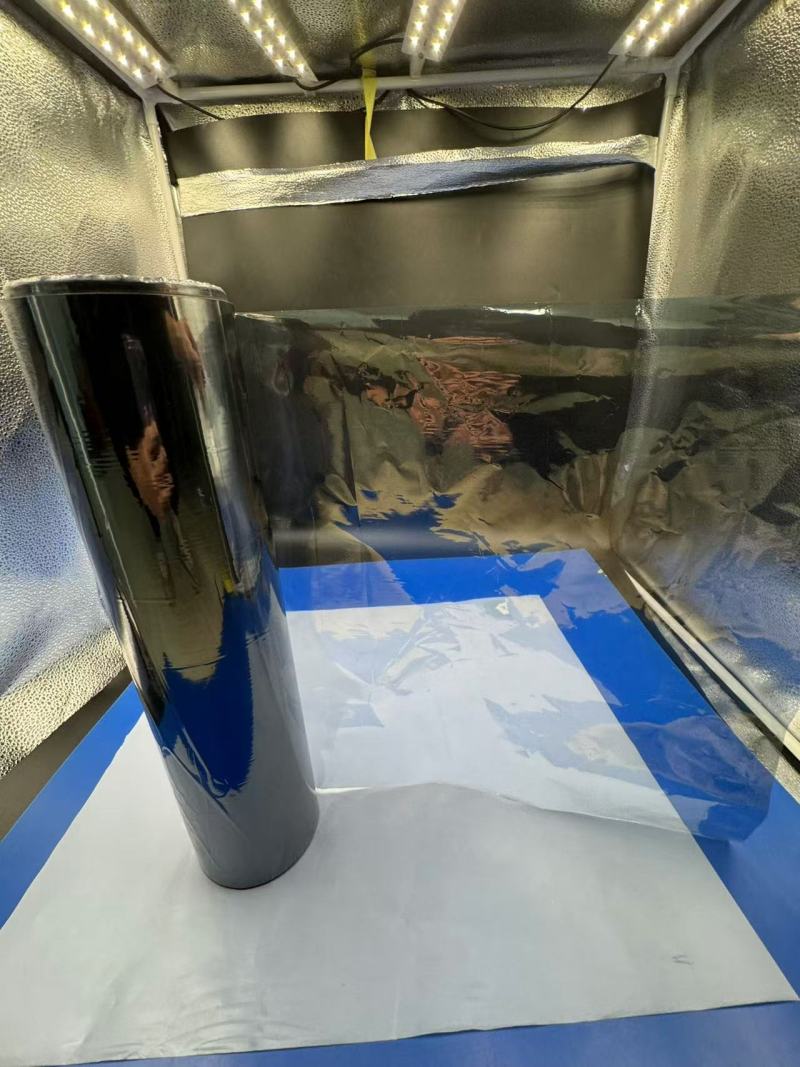

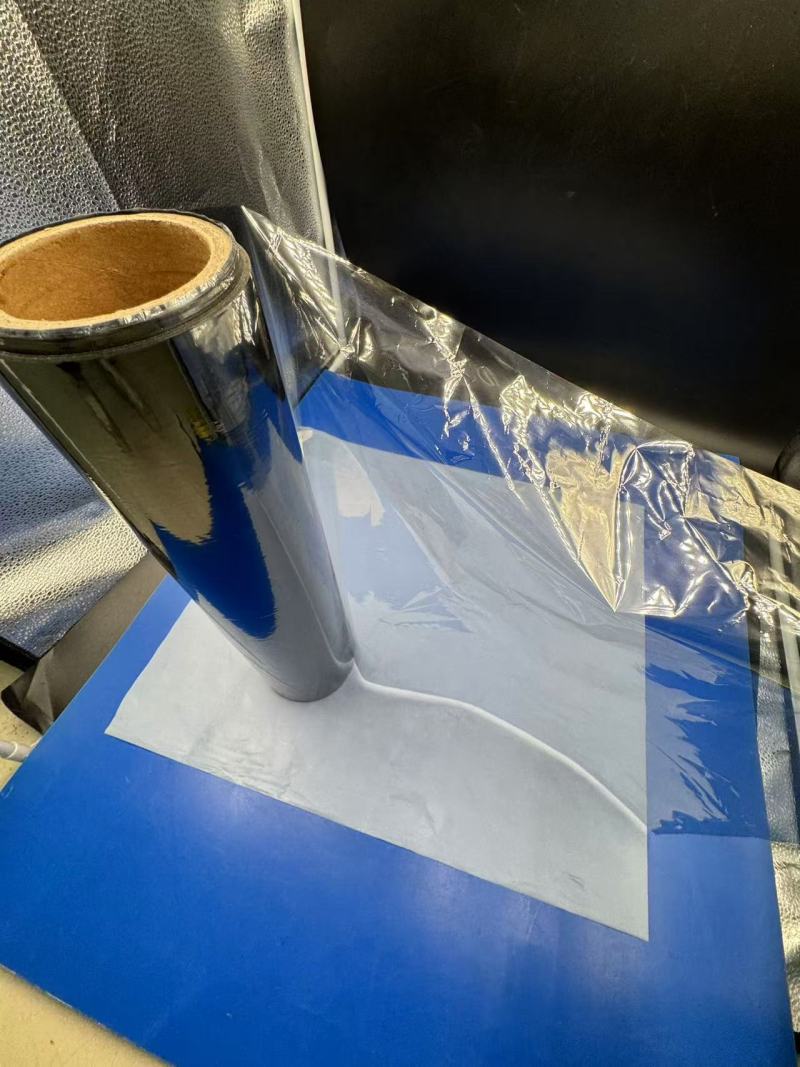

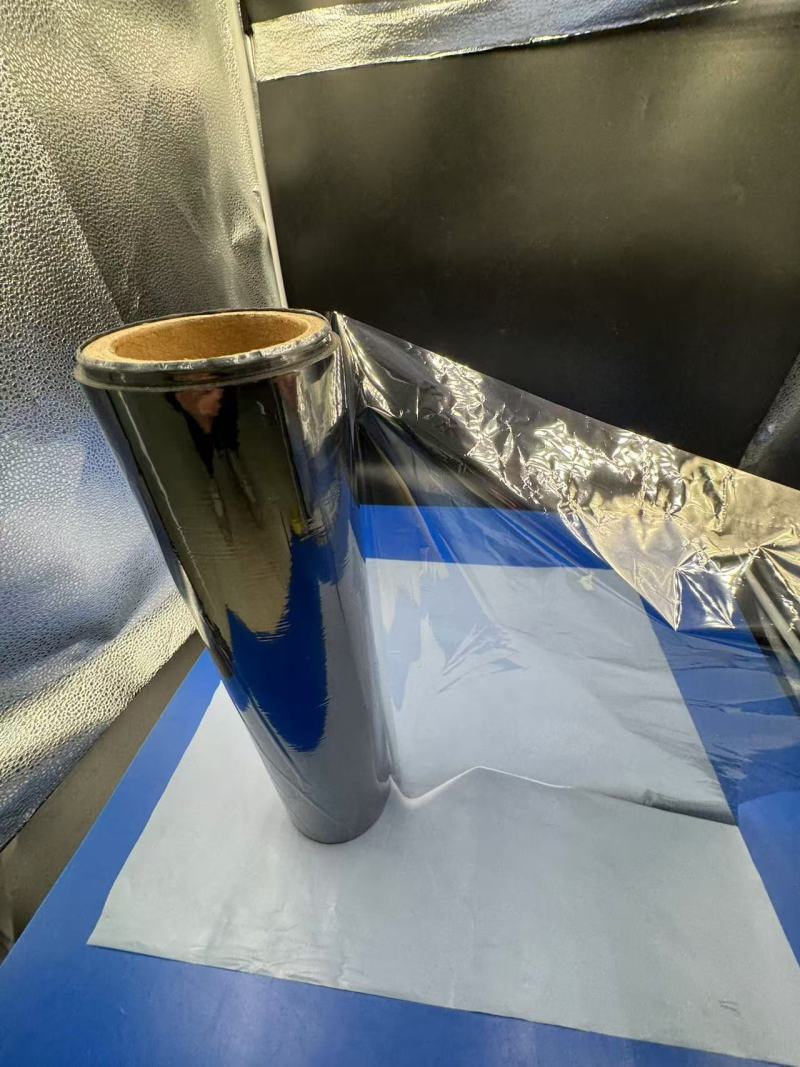

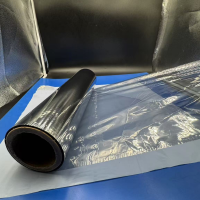

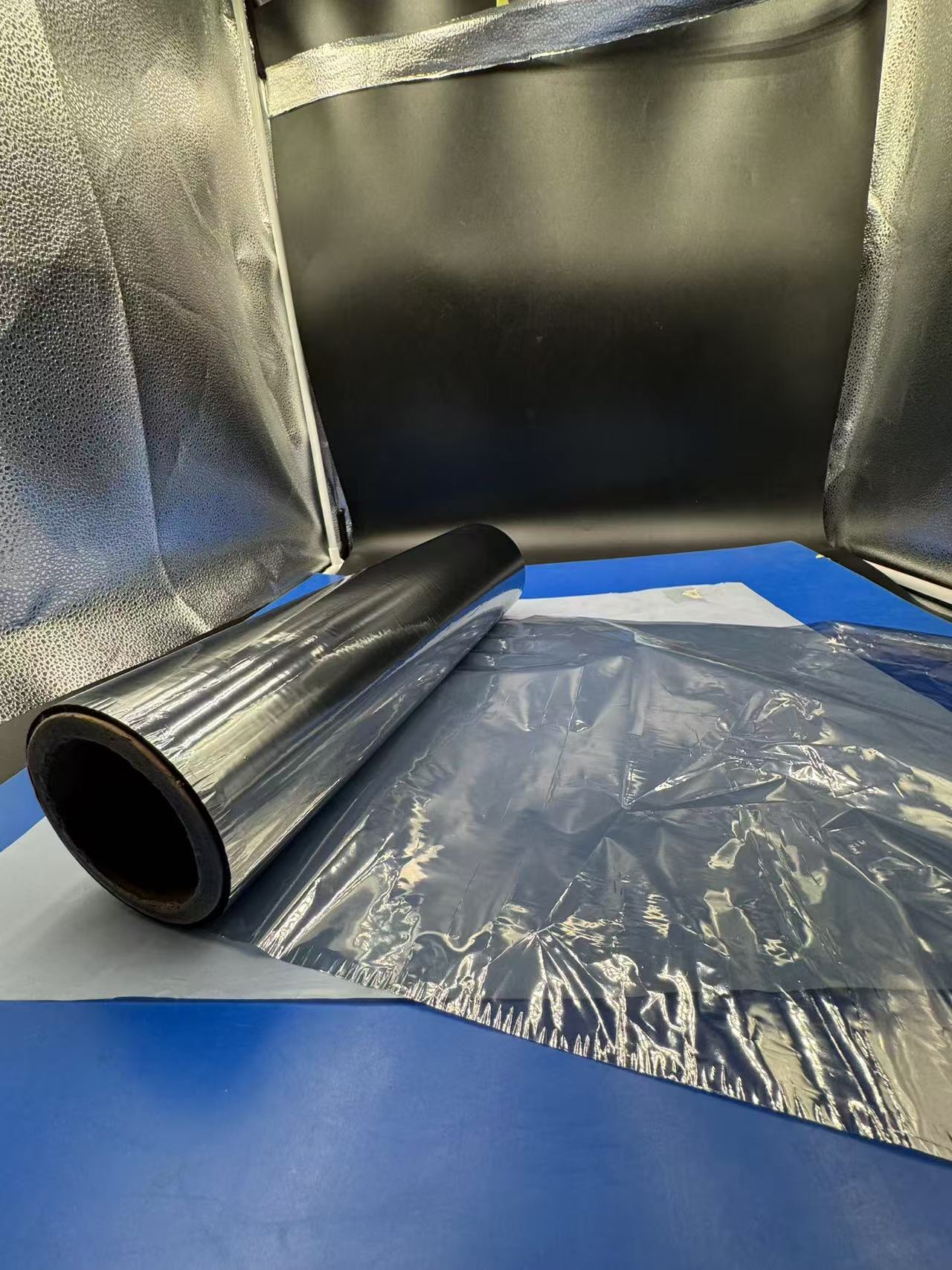

PET Antistatic Film: Characteristics and Applications in Capacitor Manufacturing and Electronic Packaging

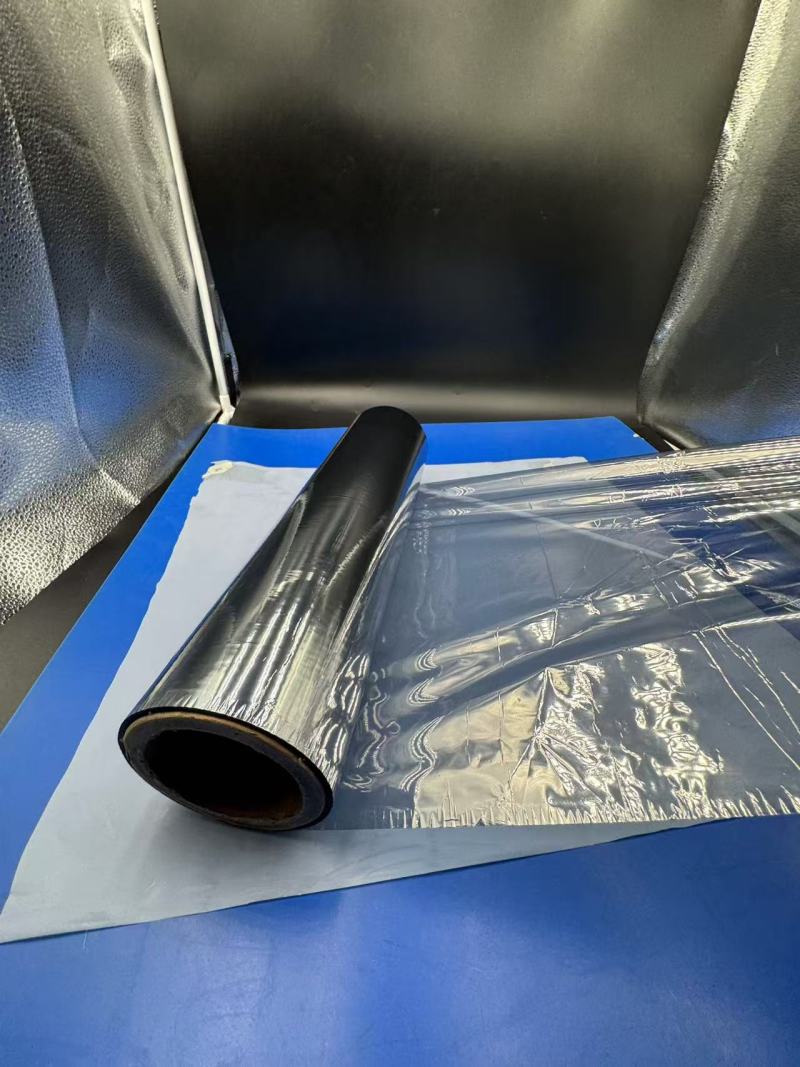

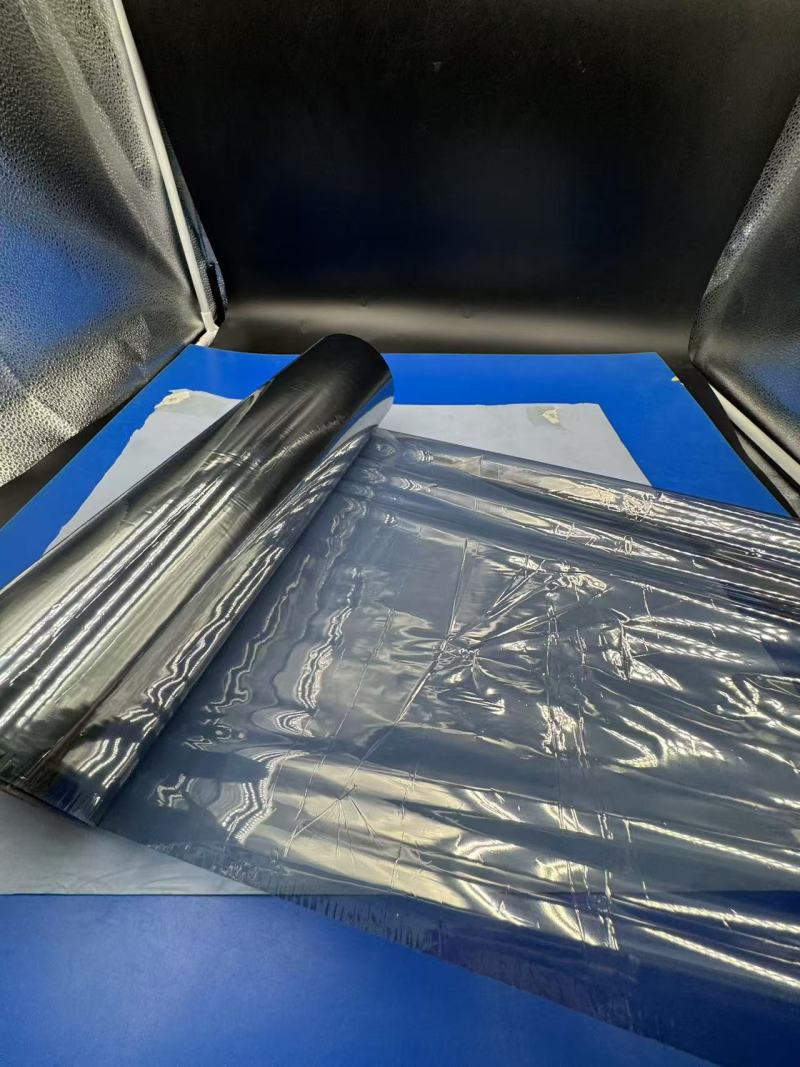

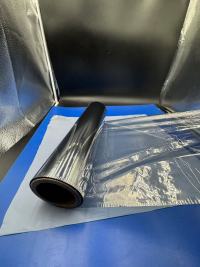

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: TOP grade film

color: transparent/white/ customization

location: china

usage :for CAPACITY, ELECTRONIC PACKING

- TOPLEADER

- CHINA

- 15 WORKING DAYS

- 50000000T/M

- Information

- Video

- Download

Introduction

Polyethylene terephthalate (PET) antistatic film has become a cornerstone in both the electronics manufacturing sector and electronic packaging due to its unique properties. This article delves into the characteristics of PET antistatic film, its role in capacitor production, and its applications in safeguarding electronic components from electrostatic discharge (ESD).

Characteristics of PET Antistatic Film

Chemical Composition and Structure: PET is a thermoplastic polymer resin of the polyester family, renowned for its toughness and versatility. When modified to be antistatic, PET films incorporate specific additives or coatings to control static electricity. These can include:

Antistatic Agents: These are compounds that reduce surface resistivity, allowing static charges to dissipate safely. Common agents include quaternary ammonium salts or glycerol esters.

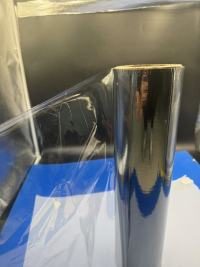

Conductive Layers: Some PET films have thin metallic or carbon-based layers that enhance conductivity, further aiding in static dissipation.

Physical Properties:

Durability: PET films are known for their resistance to impact, abrasion, and chemicals. This makes them suitable for harsh manufacturing environments or during the handling of electronic components.

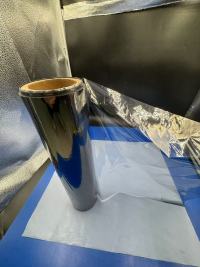

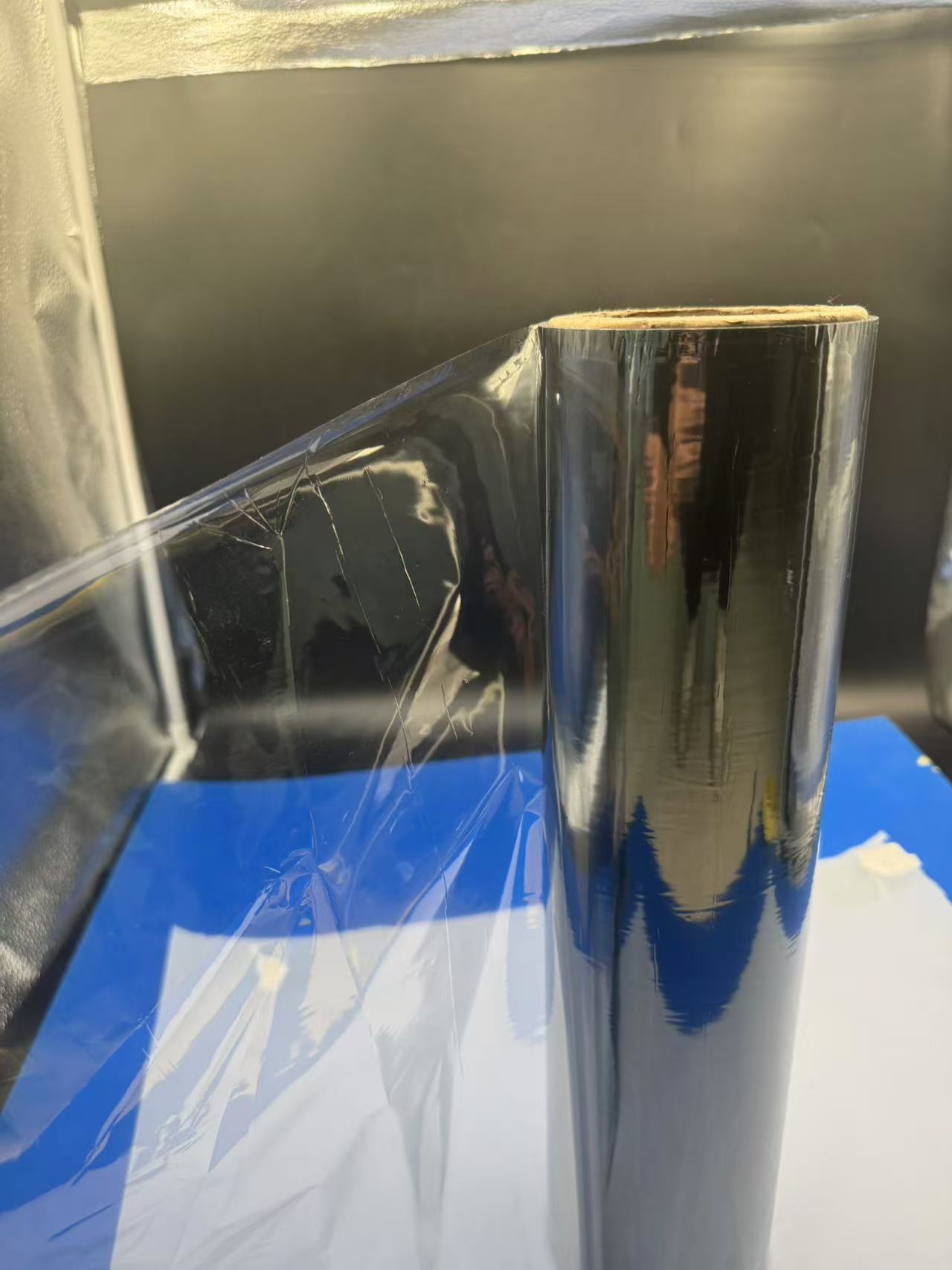

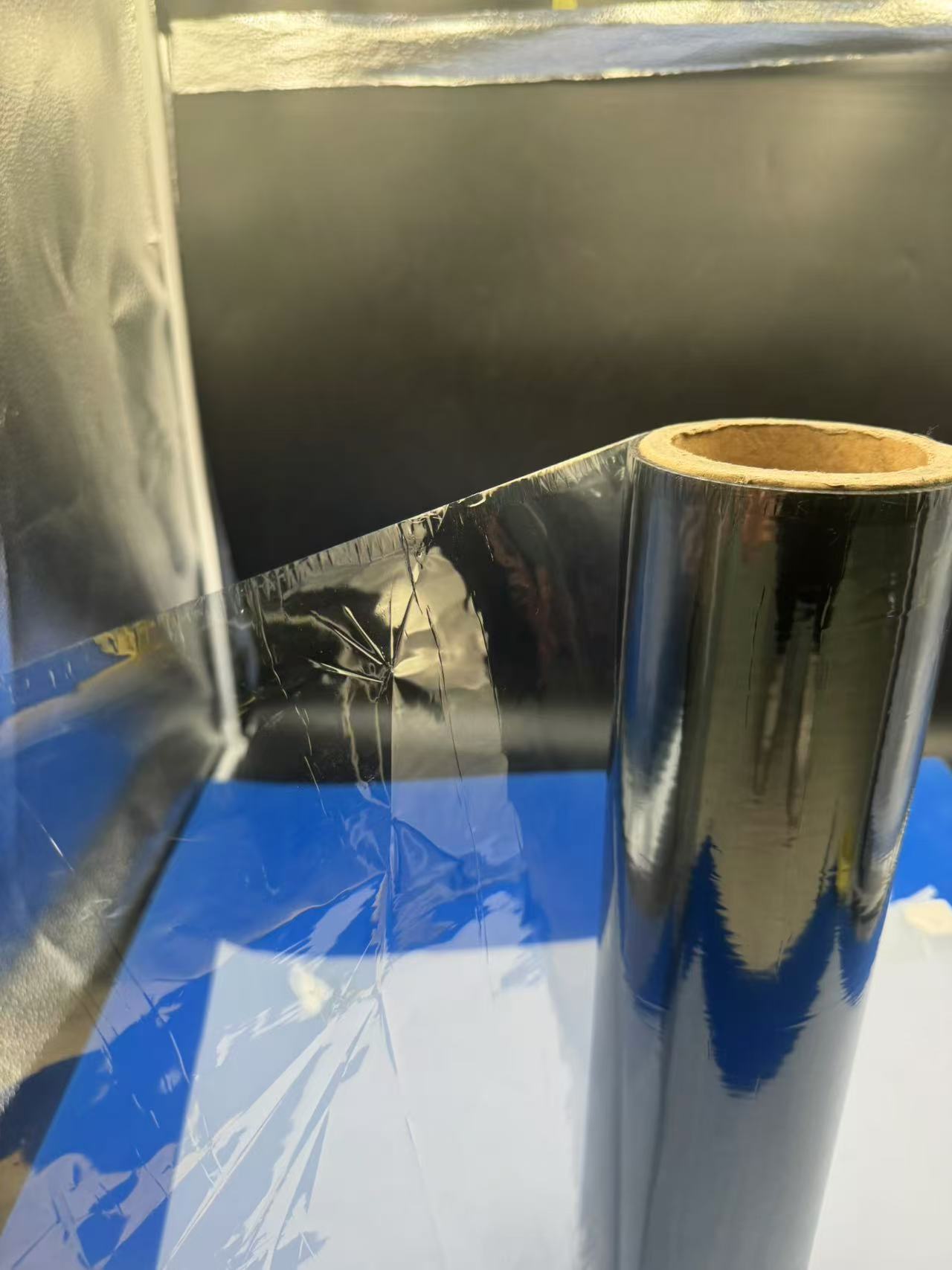

Transparency: Despite the addition of antistatic properties, PET films typically maintain high clarity, which is crucial for visual inspections in electronic assembly.

Flexibility: The film can be easily cut, folded, or heat-sealed, which is beneficial for packaging applications where customization is required.

Thermal Stability: PET has a relatively high melting point, ensuring it can withstand elevated temperatures in manufacturing processes without degrading.

Electrical Properties:

Surface Resistivity: Antistatic PET films have controlled surface resistivity, usually between 10^6 - 10^9 ohms per square, which prevents static build-up while not allowing enough conductivity to short-circuit sensitive electronics.

Dissipation Factor: Low, ensuring minimal energy loss when used in capacitors.

Application in Capacitor Manufacturing

Dielectric Material:

Stability: PET films provide excellent dielectric stability with a relative permittivity (εr) of approximately 3.2, making them ideal for film capacitors where consistency in capacitance over time is crucial.

Thinness: Modern manufacturing techniques can produce PET films down to 0.7 μm, enabling the creation of compact capacitors with high capacitance values.

Self-Healing: Antistatic films used in metallized capacitors have self-healing properties where minor dielectric breakdowns can repair themselves, enhancing capacitor longevity.

Manufacturing Process:

Metallization: PET films are often metallized with aluminum or zinc to form one of the capacitor's electrodes. The antistatic property ensures that any static during the process does not damage the delicate metal layers.

Winding: These films are used in both wound and stacked capacitor configurations, where their antistatic nature reduces the risk of ESD during winding.

Use in Electronic Packaging

Protective Packaging:

ESD Prevention: The primary use of PET antistatic film in packaging is to prevent damage from static electricity. Sensitive components like ICs, LCDs, and microprocessors are often packaged in antistatic bags or pouches made from these films.

Barrier Properties: Beyond static protection, PET films offer good moisture and oxygen barrier properties, crucial for long-term storage of electronics.

Versatile Packaging: These films can be used in various forms like tapes, wraps, liners, and clamshells, providing flexibility in how electronic products are packaged.

Packaging for Transport:

Durability: The physical durability of PET ensures that electronic goods remain protected from physical damage during transit.

Customization: The film's properties allow for printing, enabling branding or instructional graphics on packaging, which can be vital for consumer electronics.

Case Studies and Applications

Smartphone Manufacturing: In the assembly lines of smartphones, where numerous components are sensitive to static, PET antistatic film is used in trays and tapes for component placement.

Automotive Electronics: High-value automotive sensors and control units are often shipped in antistatic PET packaging to ensure they arrive undamaged by static or environmental factors.

Medical Devices: Due to the precision required in medical electronics, antistatic packaging ensures that devices like pacemakers or portable diagnostic tools are not compromised.

Future Trends

The demand for PET antistatic film is expected to grow with the expansion of the electronics market:

Sustainability: There's an increasing trend towards biodegradable additives in PET to make the films eco-friendlier.

Enhanced Functionality: Research continues into films with improved antistatic properties at thinner profiles, which could revolutionize miniaturization in electronics.

Multi-functional Films: Combining antistatic with other properties like UV protection or increased tensile strength might become standard to meet diverse industry needs.

Conclusion

PET antistatic film plays a pivotal role in both capacitor manufacturing and electronic packaging. Its unique blend of mechanical, thermal, and electrical properties makes it indispensable in environments where static electricity could spell disaster for sensitive electronics. As technology evolves, so too will the applications and enhancements of PET antistatic films, continuing to support the ever-growing, ever-demanding world of electronics.

Within 15-20 days after received payment...more