Food-grade, high-temperature resistant polypropylene sheet

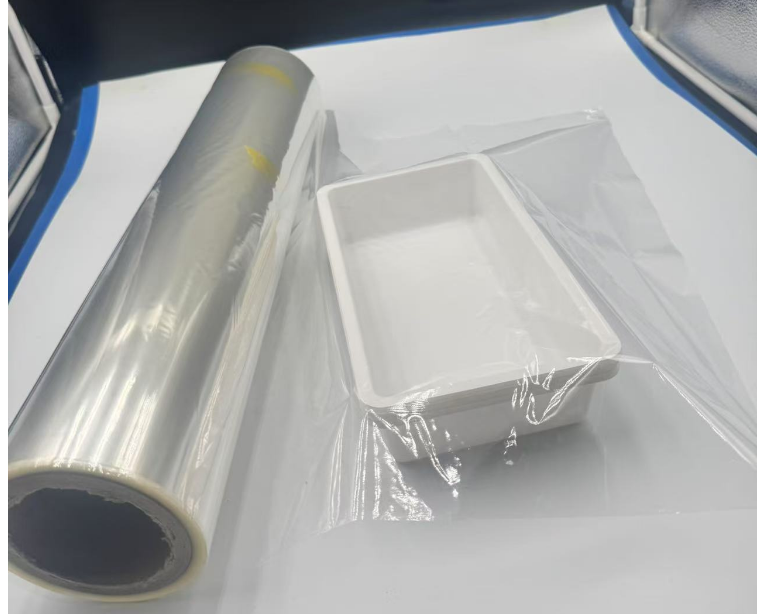

Translucent PP thermoforming roll,

Food-grade, high-temperature resistant polypropylene sheet

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

Translucent PP thermoforming rolls are a type of polypropylene material with excellent thermoforming properties. Typically supplied in roll form, they exhibit a degree of translucency and can be used in a variety of thermoforming processes to create plastic products in a variety of shapes. Food-grade, high-temperature-resistant polypropylene sheets meet food contact safety standards and can withstand higher temperatures, making them safe for use in food packaging and other applications. Below is a detailed introduction to these materials:

Features

Translucency: A degree of transparency allows for partial visibility of the package contents, facilitating product inspection while also providing a degree of obscurity, enhancing the product's appeal and aura.

Thermoformability: Upon heating, they become pliable, allowing them to be easily molded into various shapes, such as food boxes, trays, and containers, to meet diverse product packaging needs.

Food-grade safety: They comply with relevant food contact safety standards, such as those of the FDA (U.S. Food and Drug Administration) and EU 10/2011. They do not contain toxic or hazardous substances, such as bisphenol A (BPA), making them safe for food packaging and protecting consumer health. High Temperature Resistance: It has excellent heat resistance and can withstand high temperatures without deformation. It can be used in microwave heating and hot filling applications, generally withstanding temperatures of around 120°C.

Other Characteristics: It is lightweight, chemically resistant, impact-resistant, and mechanically strong. PP material is also recyclable, meeting environmental requirements.

Production Process

Raw Material Selection: Food-grade polypropylene resin pellets are selected, with melt flow rate, density, and other parameters considered based on product performance requirements.

Ingredients: Additives such as antioxidants, UV absorbers, and lubricants may be added to enhance the sheet's performance and processing characteristics.

Melt Extrusion: Raw materials and additives are added to an extruder, heated to melt, and then extruded into a sheet by the screw.

Calendering: The extruded sheet passes through the rollers of a calender, where high temperature and pressure create a uniform thickness, a smooth surface, and further orientation, improving the sheet's mechanical properties. Cooling and Shaping: The calendered sheet passes through a cooling system, rapidly cooling and solidifying it to maintain the desired shape and size.

Rewinding: The cooled and shaped sheet is rewound to form a translucent PP thermoformed roll.

Applications

Food Packaging: Widely used in the production of food packaging boxes, trays, bowls, lids, and more, such as fast food boxes, fruit trays, and cake boxes, protecting and showcasing the food.

Pharmaceutical Packaging: Suitable for pharmaceutical blister packaging and trays, requiring excellent sealing and hygienic properties to ensure drug quality and safety.

Other Applications: It can also be used in cosmetics packaging and electronic component packaging, leveraging its excellent thermoformability and physical properties to provide product protection and aesthetically pleasing packaging.

Within 15-20 days after received payment...more