The Art of Food Preservation: Harnessing PVC Film in Thermoforming for Culinary Delights

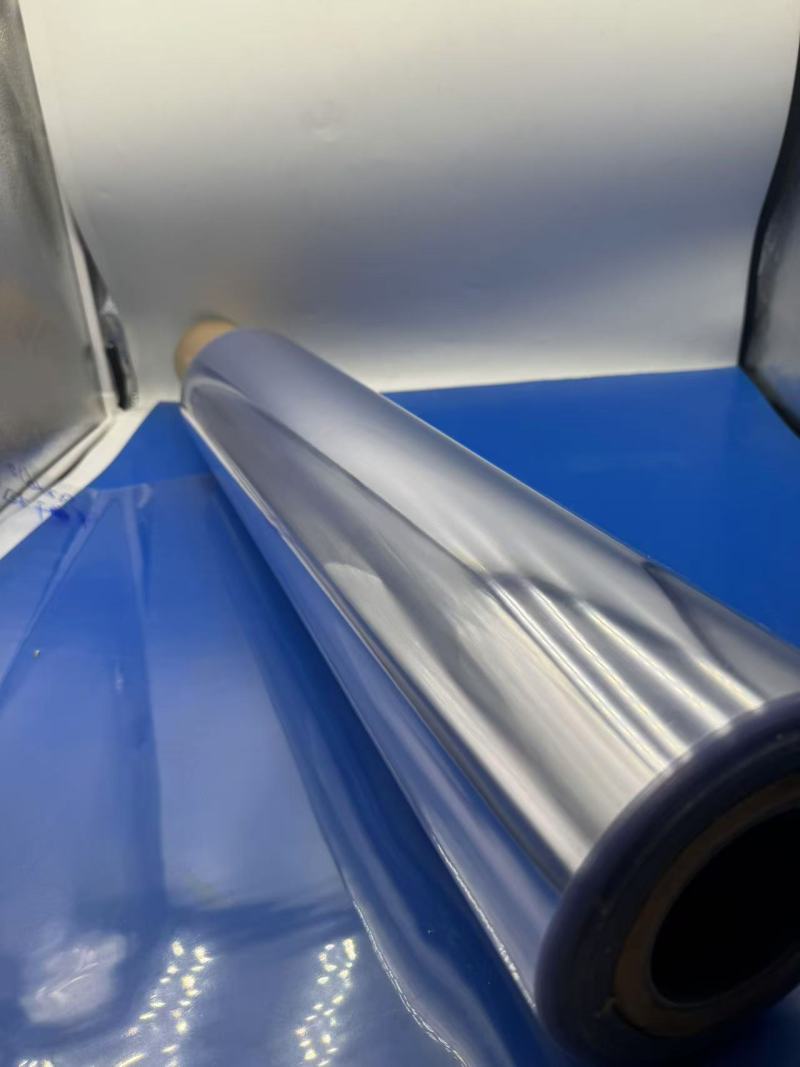

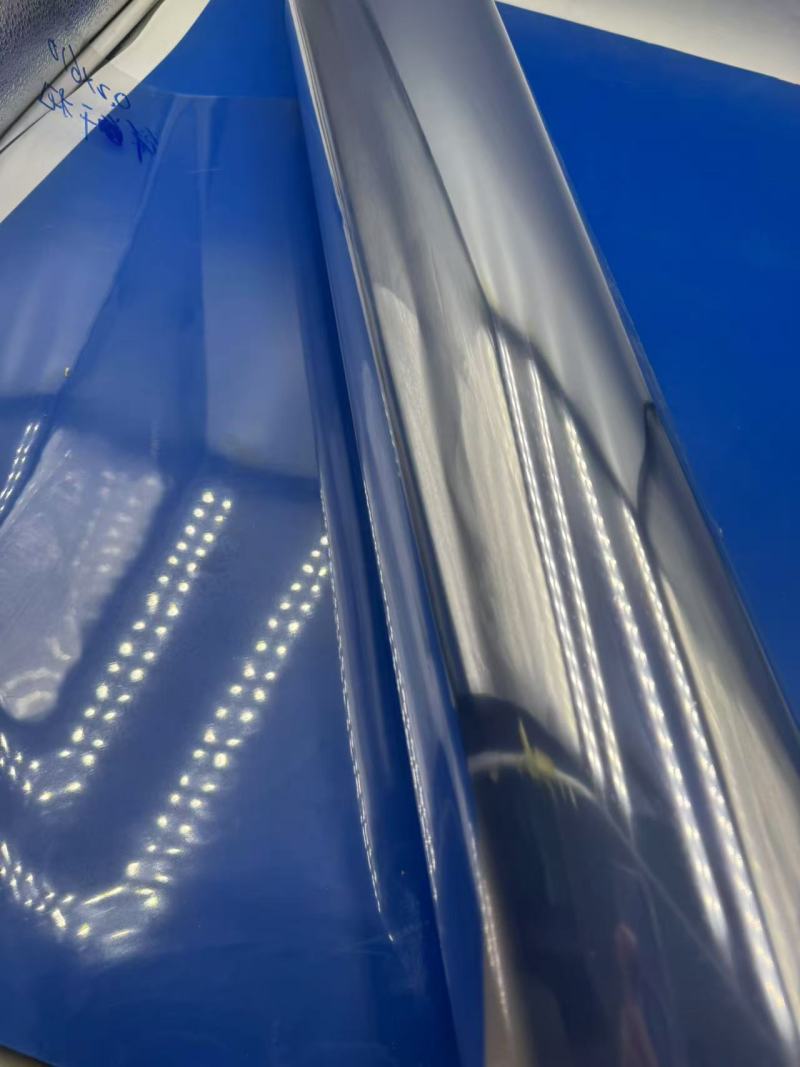

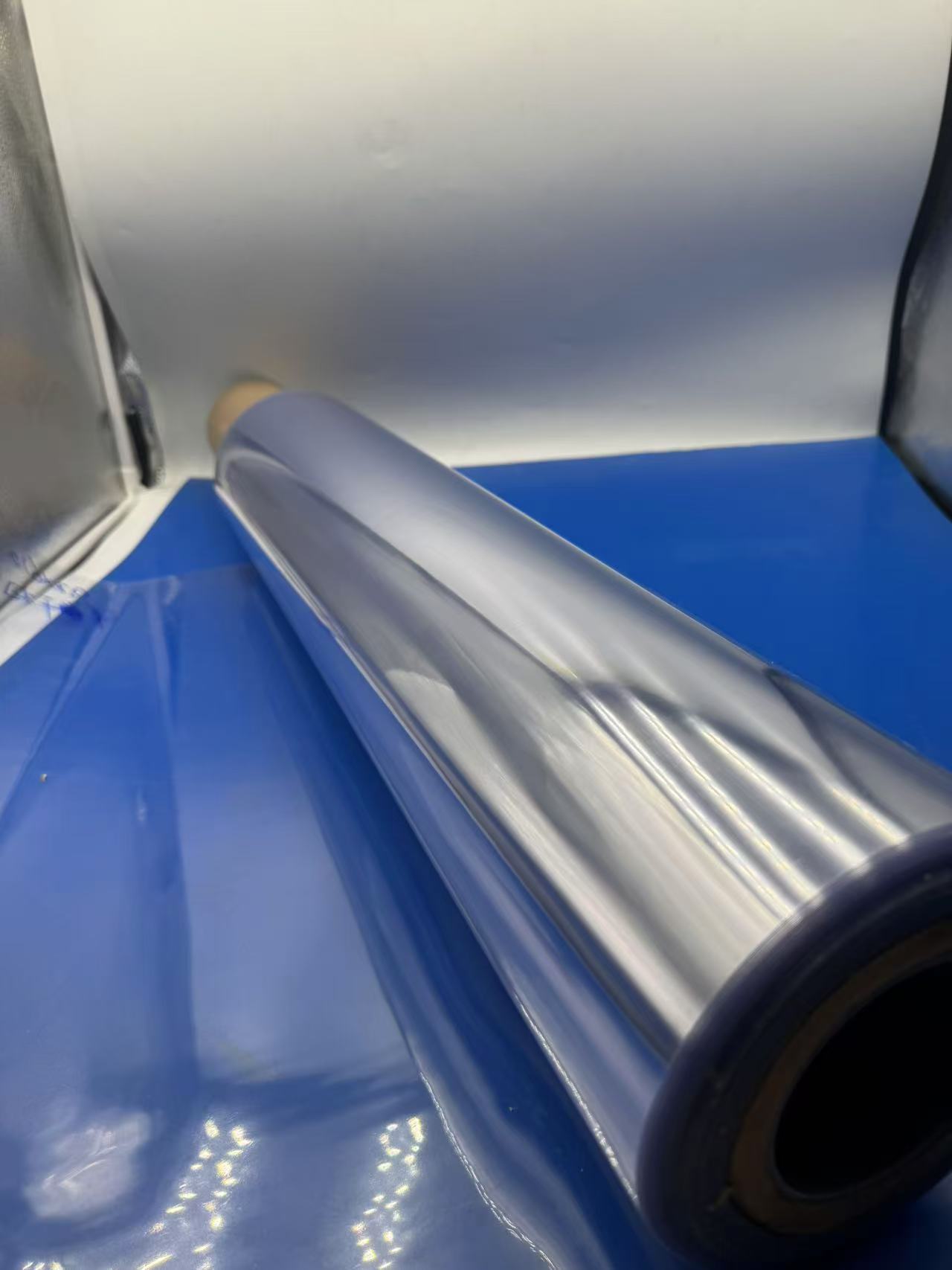

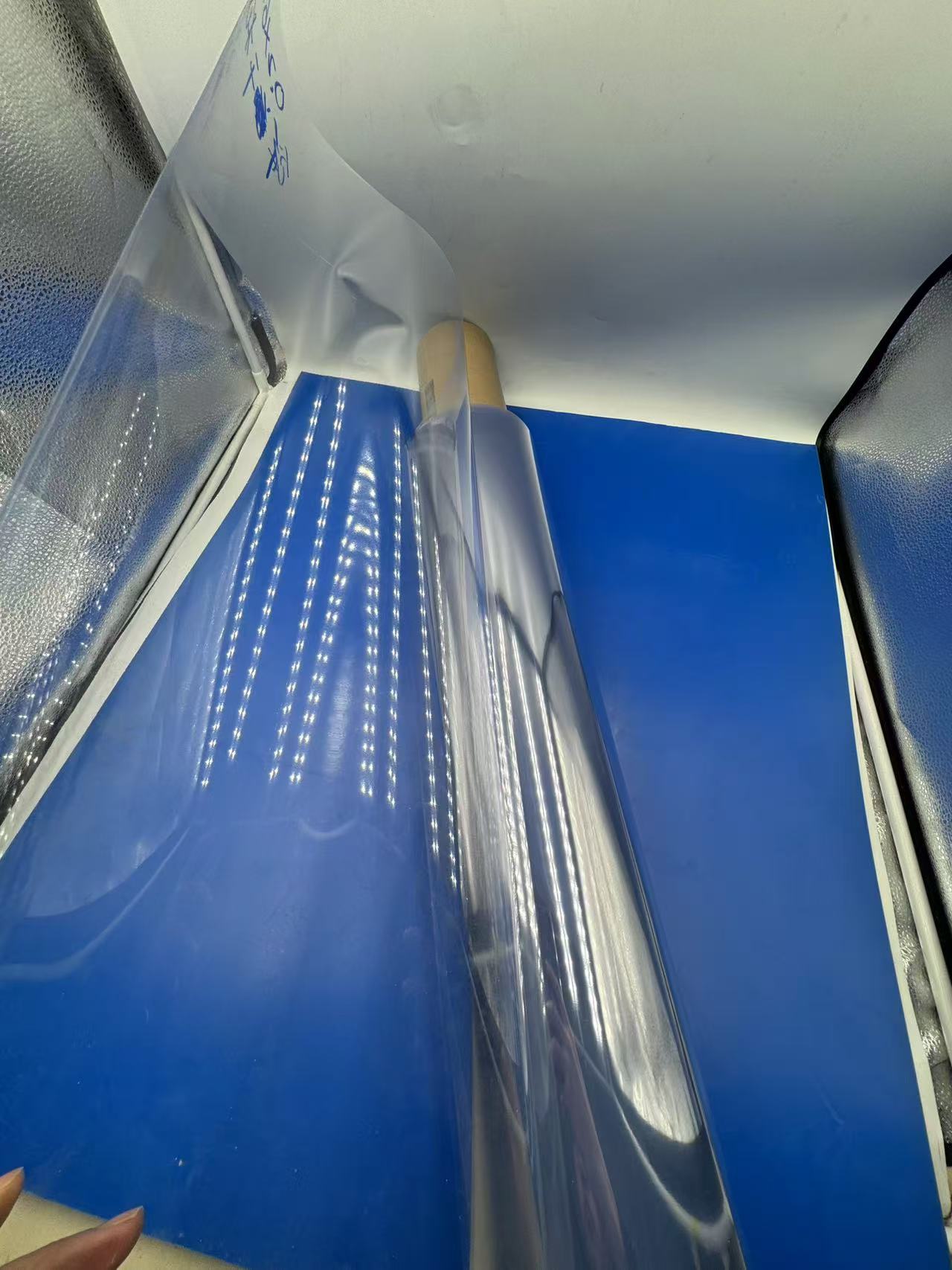

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

PVC Film in Food Thermoforming Applications: An In-Depth Exploration Introduction

In food packaging, which greatly stresses innovation and efficiency, PVC film has carved out a niche for itself mainly in the field of thermoforming-for instance, cookie trays, meat trays, and other rigid food containers. This article discusses the many uses of PVC films in food thermoforming and gives a descriptive and factual account of how this material has become indispensable in the food industry.

PVC Film Fundamentals

Polyvinyl Chloride, popularly known as PVC, is a versatile thermoplastic polymer liked for its strength combined with flexibility and clarity. When produced as film for application in foods, PVC is favored for some reasons, including the following:

• Transparency: The clarity of PVC allows for the effective presentation of the packed food, an important aspect concerning consumer appeal at the point of sale.

• Barrier Properties: PVC film offers good barriers to oxygen and moisture, which are important for maintaining food freshness. While not as impermeable as some other materials, such as EVOH, it is sufficiently impermeable for many applications in the short to medium term.

• Cost-Effectiveness: The material PVC is economically viable. The manufacturing process of PVC is less complicated and consumes less energy than other polymers, hence being a favorite of cost-conscious manufacturers.

• Ease of Processing: Excellent thermoformability allows for intricate, complex shapes to be made, such as those required for cookie or biscuit trays.

Thermoforming with PVC Film

Thermoforming is the process by which a plastic sheet is heated until pliable and then shaped over or into a mold. PVC film is especially popular for this process because:

• Flexibility: It can be made into everything from shallow trays for cookies to deeper containers for deli meats in a very accurate way.

• Strength and Durability: Once formed, PVC maintains its rigid construction to protect whatever food product is inside through transportation and visual display.

• Sealability: PVC can be sealed by heating or RF (radio frequency), thus allowing safe closure in packages that have contents like a tray of cookies; these should be tamper-proof and fresh. Applications in Specific Food Packaging

• Cookie Trays: Probably the most visually pleasing applications, PVC films are used in the creation of clear, rigid trays to pack cookies and biscuits. Transparency is great to view the product itself, and the form can be designed so as to hold the cookies in place during transportation. Barrier properties help extend the shelf life through protection from humidity and oxygen.

Example: Just picture coming into a supermarket and finding an array of colorful cookies arranged in neat rows inside clear, transparent trays. Every tray became a showcase rather than a container, owing its clarity and formability to PVC. The trays not only protect the cookies from damage but also allow the consumer to see exactly what they are buying, thereby enhancing the buying experience.

• Meat and Deli Trays: PVC is the common packaging material for fresh and processed meats because it does a pretty good job in maintaining product integrity under refrigeration. Its toughness ensures that the weight of the product is retained by the tray, while sealability ensures freshness of the contents.

o Example: a butcher uses PVC trays to wrap its famous varieties of sausages. It is formed and folded in ways that juices never spill over, while due to clarity, film the good quality of the meat is ensured before being bought.

Fresh Produce Trays: Fruits and vegetables, being perishable items, require a breathing environment that also protects them via PVC trays. They can be designed to have perforations or can be combined with films that allow the right amount of gas exchange to keep the produce fresh.

• Cheese Packaging: Hard cheeses, which require a balance between air exposure and protection from contaminants, are ideally served by the properties of PVC. Trays can be designed to cradle various cheese shapes, enhancing presentation while ensuring safety.

Advantages in Thermoforming

• Design Flexibility: Manufacturers can create bespoke packaging that aligns with branding or product-specific needs, from simple shapes to more complex, multi-compartment designs for meal kits.

• Production Speed: Thermoforming PVC is fast, hence allowing for high-volume production, something very important in peak seasons or at large scales.

• Material Efficiency: The fact that PVC can be formed with minimal waste contributes to cost savings and aligns with sustainability goals by reducing material use.

Safety and Regulatory Compliance

• Food Safety: Food-grade PVC must conform to high regulatory levels in all parts of the world. In the United States, compliance with FDA dictates ensures there isn't any case of migration that would be injurious to foods. Organoleptic properties on films are most commonly tested on the premise they must not impinge on tastes or smells within foods.

• Recycling and Environmental Impact: While PVC has its critics due to environmental concerns, modern PVC films are engineered for recycling. Advances in recycling technology are addressing historical issues, with some companies now offering PVC recycling programs specifically for food packaging.

Challenges and Considerations

• Plasticizer Use: Traditional PVC might include phthalate plasticizers, which have become a point of controversy based on health concerns. However, modern food-grade PVC uses non-phthalate plasticizers to improve safety profiles.

• Environmental Footprint: With some recycling in place, the disposal of PVC remains a valid concern. Innovations in biodegradable additives or alternative material blends are currently being pursued.

• Rigidity vs. Flexibility: While PVC imparts rigidity in such applications, these may not be suitable for all flexible packaging applications where PE or PP is preferred.

Future Directions

• Sustainable Alternatives: A drive to develop PVC films with improved environmental credentials is in process, including the addition of bio-based additives and more efficient recycling processes.

• Improved Barrier Properties: Investigation on enhancing PVC barrier properties by co-extrusion with other polymers or addition of nano-particles that improve oxygen and moisture resistance continues.

• Smart Packaging: Integrating sensors or indicators into PVC films to monitor freshness in real time can be a 'game-changer' by providing an additional layer of safety and quality assurance to consumers.

Conclusion

It finds value in the right balance of functionality, cost, and aesthetic appeal in food thermoforming applications like cookie trays. Environmental and health concerns, though there and challenging, have seen the continuous evolution of the industry in order to respond to such demands. The future of PVC in food packaging is towards sustainability and higher performance, possibly integrating technology in efforts to keep pace with ever-demanding consumers seeking safety, quality, and environmental responsibility. As we forge on with innovation, the role that PVC plays may evolve and change; its basic elements of clarity, durability, and cost efficiency are sure to hold it on the packaging charts for many years to come.

Within 15-20 days after received payment...more