Glass-clear PETG film

Glass-clear PETG film

Heat-sealable PETG blister sheet

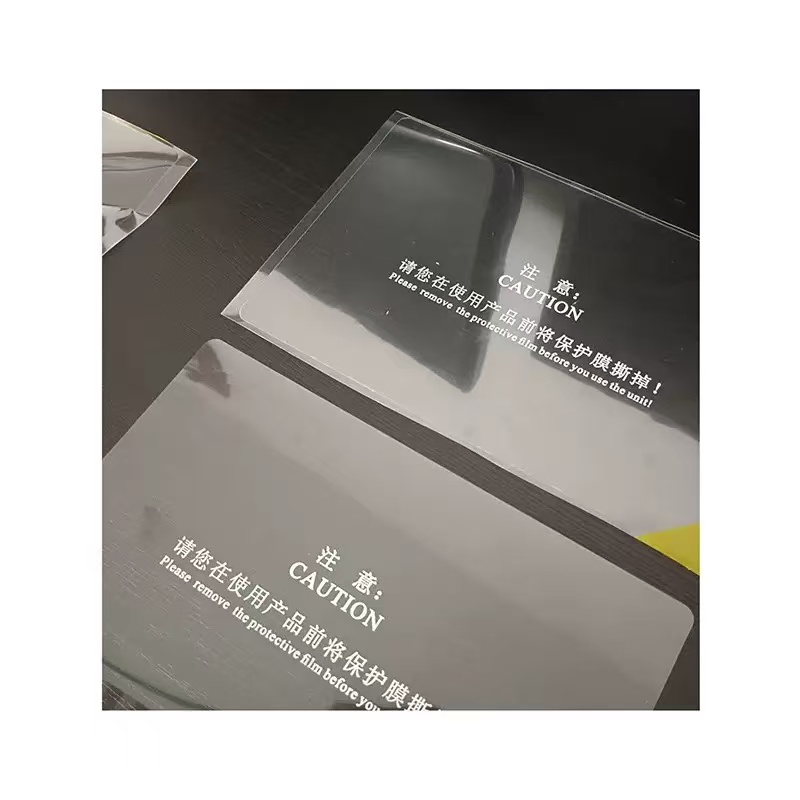

Optional surface protective film

- top leader plastic

- China

- 16 business days

- 1800 tons/month

- Information

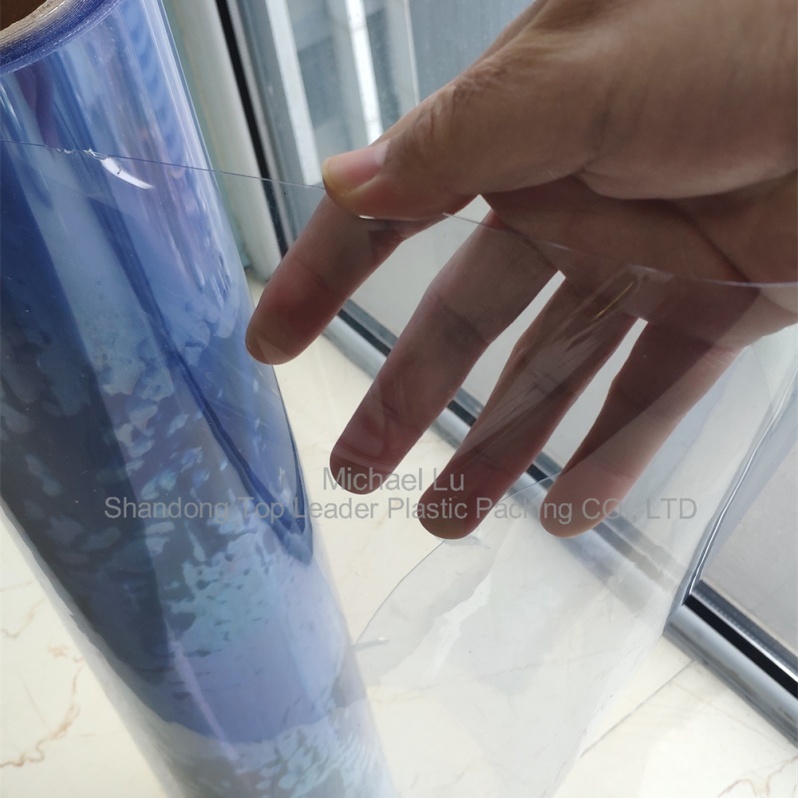

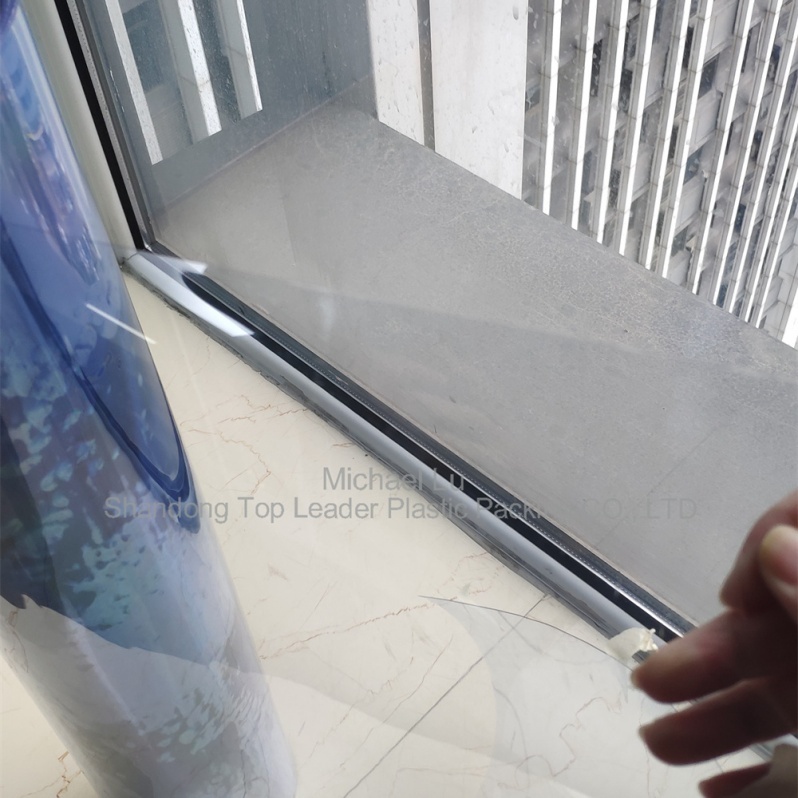

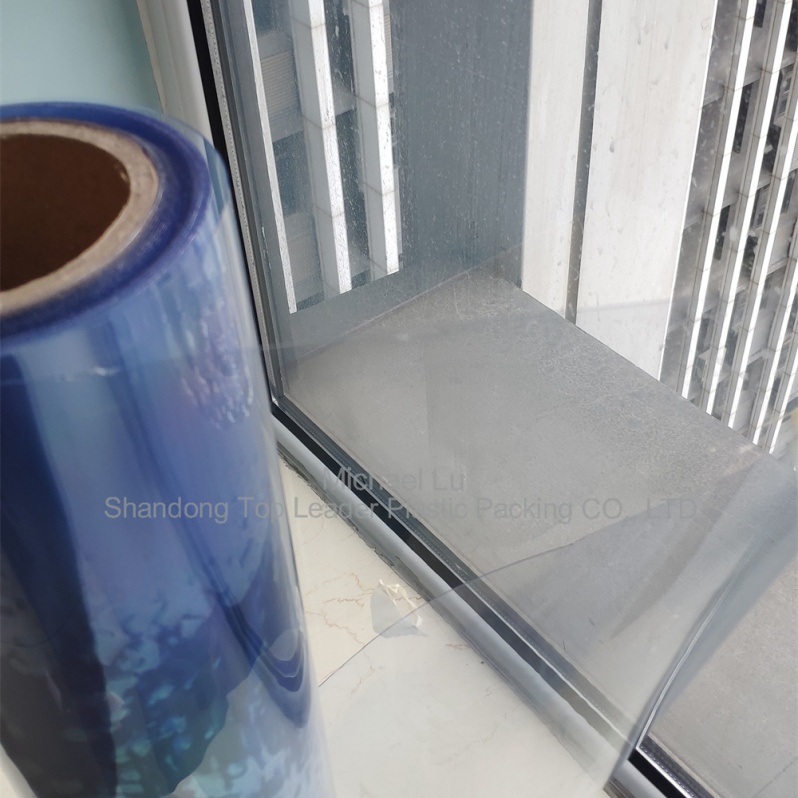

Glass-transparent PETG film is typically available in rolls as a flexible material (typically 0.2-1mm thick). Its key features include "high transparency and easy heat sealing." It's commonly used in packaging applications requiring both visibility and sealing, and is particularly suitable for products with high aesthetic requirements. 1. Core Advantages: Beyond Transparency, It Also Offers These Practical Skills

Extremely Transparent, Enhancing Product Beauty: With a light transmittance of over 90% and a haze of less than 1%, the film is virtually invisible—when wrapping cakes, the gloss of the cream and the freshness of the fruit can be clearly seen; when wrapping electronic accessories, it allows for intuitive display of the precise details of the components, enhancing the product's premium feel even more than ordinary transparent films.

Excellent Heat Sealability, No Leakage: Unlike PET film, which requires a PE heat-sealing layer, PETG film can be directly heat-sealed, offering high seal strength (peel strength >30N/15mm). This prevents leakage even when packaging oily foods (such as chocolate and nuts) or liquid cosmetic samples. The wide heat-sealing temperature range allows it to be used with equipment ranging from small heat-sealing machines to large assembly lines, ensuring a low barrier to entry.

Stable Weather Resistance, No Deformation Over Time: In - The film remains brittle or softens within a temperature range of 40°C to 60°C, making it suitable for packaging refrigerated foods (such as mousse cakes) and can withstand the high temperatures of summer transportation. It also resists yellowing (as common PET film does) even under prolonged exposure to sunlight, ensuring the packaging maintains its pristine appearance.

2. Typical Applications: These Applications Use It:

Food Packaging: It features "high transparency + airtightness," such as individual packaging for baked goods (cakes and cookies), outer wrapping for chocolate, and top film for refrigerated yogurt—it showcases the food's appearance while locking in freshness.

Beauty and Daily Use: It's used for outer packaging of lipstick and eyeshadow (enhancing gloss), sealing bags for serum samples (alcohol-resistant and leak-proof), and the inner layer of aluminum-plastic composite bags for facial masks (highly transparent, allowing for easy inspection of the mask's appearance).

Electronic Products: It's used for transparent packaging of headphones and chargers (showcasing product details) and as scratch-resistant protective film for electronic components (balancing transparency and impact resistance). Core Form 2: Heat-Sealable PETG Blister Sheet: "Shaping Freedom" + "Reliable Sealing"

Heat-sealable PETG blister sheet comes in the form of a rigid sheet or roll (typically 0.1-1.0mm thick). Its key features include "high transparency, easy blistering, and heat-sealability." It's ideal for rigid packaging such as blister trays and boxes, and is particularly suitable for products requiring a fixed shape and sealed protection. 1. Core Advantages: In addition to blister packaging, heat sealing is a key advantage.

Easy blister packaging, stress-free molding: PETG has a moderate heat deformation temperature (approximately 70-90°C) and excellent stretchability after heating, making it easy to form complex shapes through the blister packaging process. Examples include cosmetic trays with grooves to hold lipstick and eye shadow, food blister boxes with ridges to separate cake slices, and shaped electronic product liners to protect earphones. The formed shape is stable, and it does not shrink or deform after cooling, with high dimensional accuracy (tolerance <0.1mm).

Heat-sealable for easier sealing: Compared to PVC or PET sheets used for conventional blister packaging, PETG sheets do not require additional heat-sealing film and can be directly heat-sealed to themselves or PETG film, creating a leak-proof and dust-proof enclosure. For example, heat-sealing blister packaging for cookies preserves the crisp texture; heat-sealing blister packaging for electronic components prevents dust intrusion.

High transparency and drop resistance: With a light transmittance of over 90%, blister packaging clearly displays the product inside (e.g., macarons in a baking blister packaging, blush in a beauty blister packaging). High impact resistance means it's not susceptible to cracking even if dropped (common PET blister packaging is prone to brittle cracking), making it ideal for protecting items during transportation.

Chemical resistance: Suitable for a wide range of products: It can withstand the oils and sugars in food and the alcohol and fragrances in cosmetics without dissolving or discoloring. For example, a PETG blister packaging for chocolate won't become sticky due to oil penetration, and a blister tray for toner samples won't be corroded by alcohol.