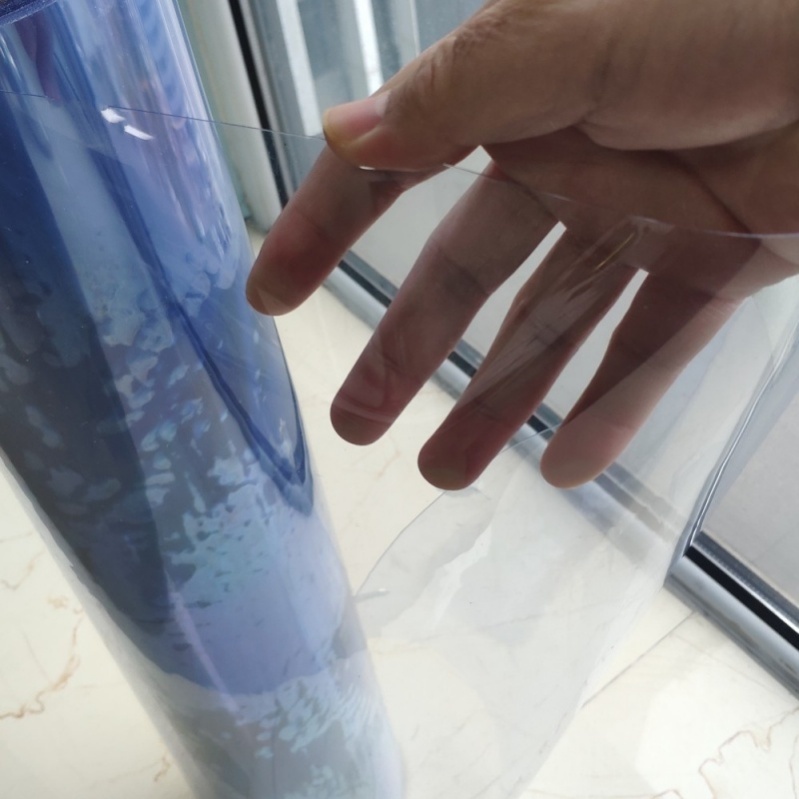

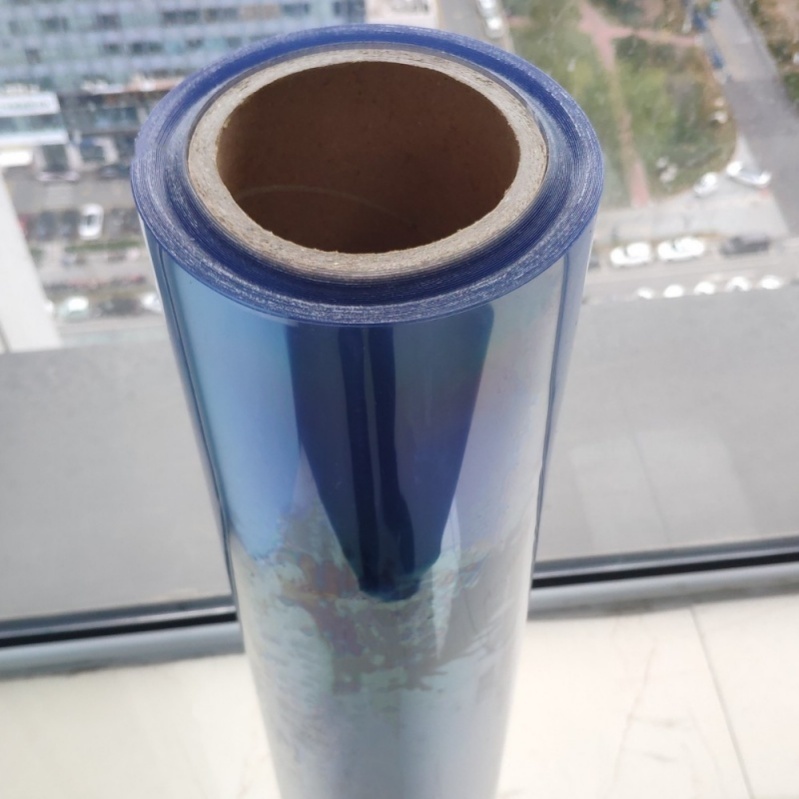

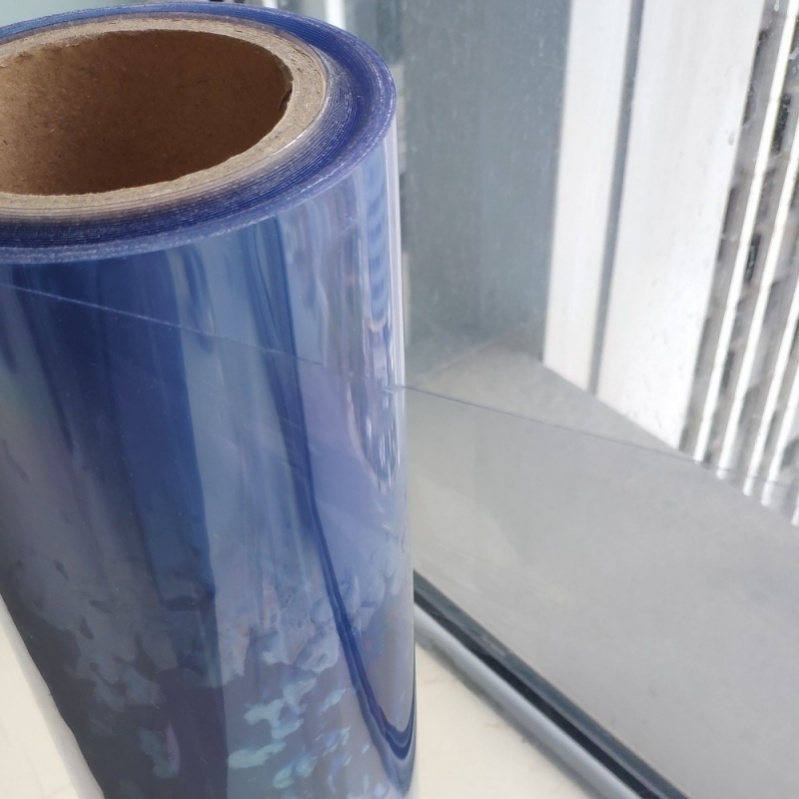

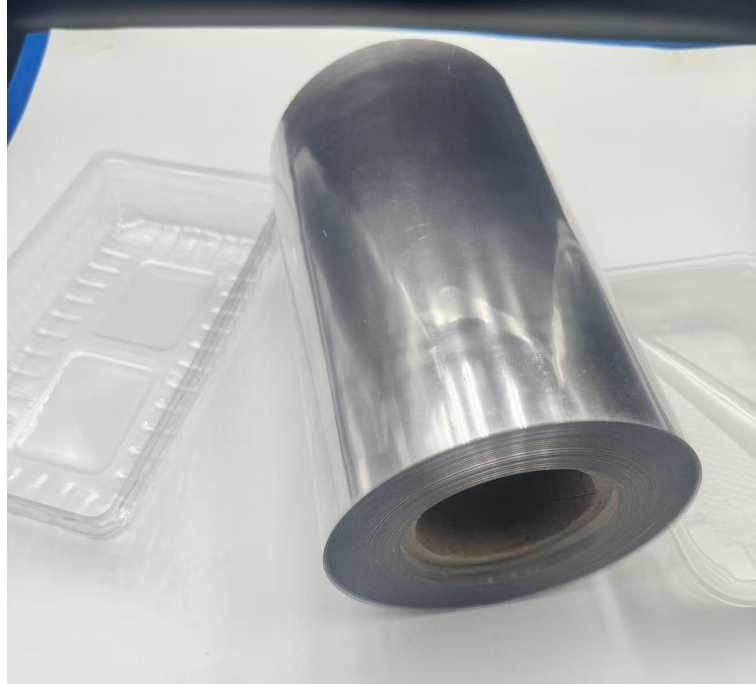

Transparent light blue PETG roll for medical trays

Heat sealable PETG rigid sheet

Good heat-sealing performance: PETG rigid sheets have excellent heat-sealing performance, easy operation and reliable sealing effect, which can ensure the sealing of the package, which is crucial for medical product packaging that requires a sterile environment.

- top leader plastic

- China

- 16 business days

- 1900 tons/month

- Information

Heat-sealable PETG rigid sheets and transparent light blue PETG coils for medical trays

Characteristics

Good heat-sealing performance: PETG rigid sheets have excellent heat-sealing performance, easy operation and reliable sealing effect, which can ensure the sealing of the package, which is crucial for medical product packaging that requires a sterile environment.

High transparency: Its transparency can reach more than 92%, with good texture, which can make the items in the package clearly visible, making it convenient for medical staff to check the medical equipment or medicines in the tray.

High impact resistance: The material is hard and durable, and its physical properties are good even at a low temperature of -40℃. It can withstand a certain impact force during processing, transportation and use, which helps prevent rupture and protect the internal items.

Excellent processing performance: It can be processed by sawing, die cutting, drilling and laser cutting, and can also be processed by cold bending and hot bending, bonding, welding and polishing, printing and coating. Secondary processing, such as printing, coating, etc., is also possible, and the cold bending does not whiten and has a bright appearance.

Good chemical resistance: It can withstand a variety of chemicals and commonly used cleaning agents, and is suitable for contact with various medical supplies and disinfectants.

Environmental protection and hygiene: It meets environmental protection requirements, is non-toxic and harmless to the human body and the natural environment, and can be used in food and medical products.

Application areas

Medical packaging: It is commonly used for the packaging of medical devices, medicines, etc., such as blister packaging of syringes, infusion sets, blood collection needles, etc., and tray packaging of large and heavy medical devices such as orthopedic implants and pacemakers.

Food packaging: It can be used for food container packaging, such as yogurt cups, fast food boxes, etc., which can provide good sealing and transparency and extend the shelf life of food.

Electronic device packaging: Due to its good impact resistance and transparency, it can also be used for the packaging of electronic devices, such as mobile phone screens, electronic components, etc., to play a role in protection and display.

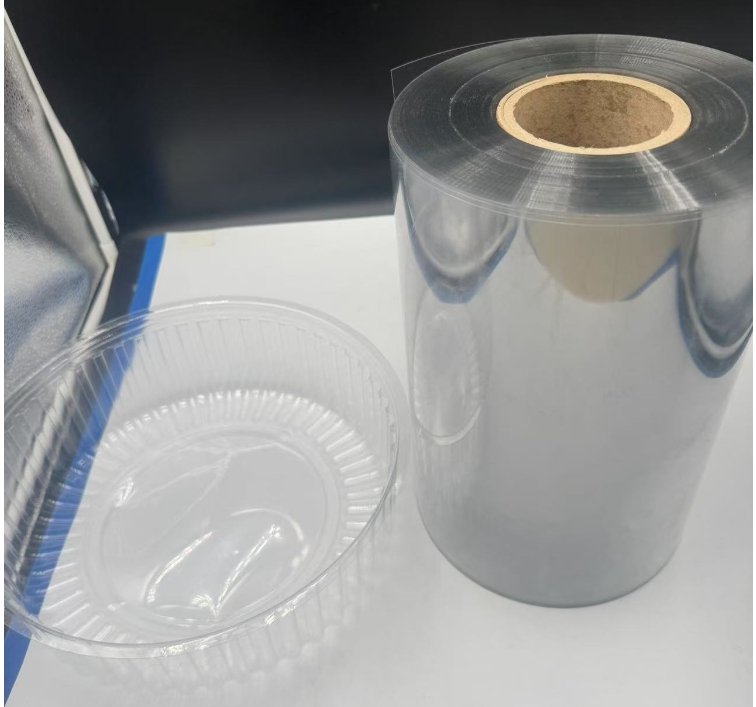

Transparent light blue PETG coil for medical trays

Advantages

Color identification: The light blue PETG coil gives the medical tray a certain color identification function, which is convenient for medical staff to quickly identify and distinguish trays of different types or uses during use, which helps to improve work efficiency.

The coil form is convenient for processing: PETG materials in coil form can be continuously cut, thermoformed and processed according to actual needs, which is suitable for large-scale production of medical trays, can improve production efficiency and reduce production costs.

Meet the requirements of medical environment: Transparent light blue PETG coil has many advantages of PETG materials, such as high transparency, impact resistance, good chemical resistance, heat sealability, etc., which can meet the requirements of medical trays in terms of sterility, cleanliness, protection, etc.

Production requirements

Raw material quality: Select PETG resin particles that meet medical grade standards to ensure the purity and stable performance of raw materials, and provide a physical property composition table of raw materials.

Production environment: The production process should be carried out in a clean workshop or other environment that meets the requirements of medical production to prevent dust, microorganisms, etc. from contaminating the product, and a corresponding clean workshop report is required.

Processing technology: Use advanced extrusion, thermoforming and other processing technologies to ensure uniform thickness and transparency of the coil, as well as the dimensional accuracy and appearance quality of the tray. At the same time, parameters such as heat sealing temperature, time and pressure should be strictly controlled to ensure the heat sealing effect.

Quality inspection: The transparent light blue PETG coils and medical trays produced are strictly inspected for quality, including appearance inspection, dimension measurement, heat seal strength test, impact resistance test, microbial test, etc., to ensure that the products meet the relevant standards and requirements.

Within 15-20 days after received payment...more