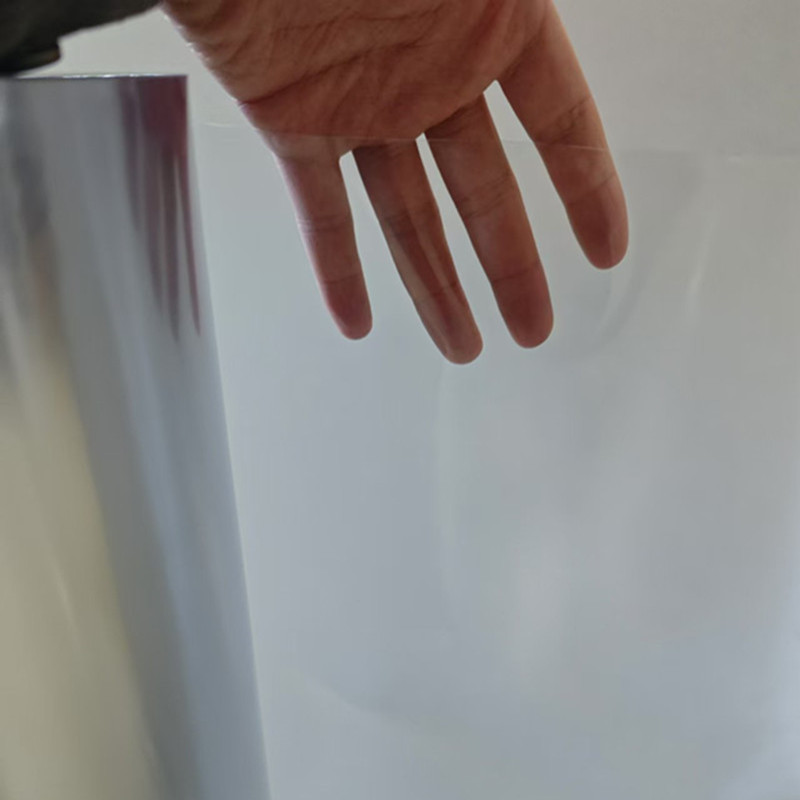

high barrier Alu cold lamination film for Pharmaceutical blister packaging

Excellent processing properties with thickness 60 -100 mic.

This pvc layer dry bond lamination with Cold Formable Alu-Alu and OPA.

Totally against the visible light and UV rays, and nearly 100% resistant to moisture,

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

0.06mm transparent film layer pvc for high barrier Alu cold lamination film for Pharmaceutical blister packaging

for laminating with Alu Alu to produce blister Coldform Laminates.

For high barrier demands on water vapour, oxygen and aroma permeability

This pvc layer dry bond lamination with Cold Formable Alu-Alu and OPA.

Totally against the visible light and UV rays, and nearly 100% resistant to moisture,

oxygen, a perfect primary packaging barrier for high sensitive medicines.

For heat sealing with hard alu foil to pack capsules,pills or tablets.

Blister Foil Cold-Formed Alu Alu Foil/Pvc Feature

Polyamide layer colored or printed

High barrier performance to resist moisture, oxygen, and light.

Improved tensile property, minimum the bubble crack rate, refuse delamination.

Applications:

oxygen and moisture-proof cold aluminum foil

Cold forming aluminum foil, the scientific name is cold stamping forming the solid medicinal composite rigid sheet (commonly known as cold forming aluminum, alu alu foil, cold form alu alu foil). Aluminum foil has a series of good properties, it is mainly used in three major fields such as medical packaging, electrical, and construction. Among them, the demand for packaging is the largest, and the packaging takes medicinal blister packaging as an example. Medicinal blister packaging is generally made of medicinal cold-formed composite alu household foil.